1

/

su

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1302.1-2015 English PDF (YYT1302.1-2015)

YY/T 1302.1-2015 English PDF (YYT1302.1-2015)

Prezzo di listino

$150.00 USD

Prezzo di listino

Prezzo scontato

$150.00 USD

Prezzo unitario

/

per

Spese di spedizione calcolate al check-out.

Impossibile caricare la disponibilità di ritiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY/T 1302.1-2015

Historical versions: YY/T 1302.1-2015

Preview True-PDF (Reload/Scroll if blank)

YY/T 1302.1-2015: Physical requirements and microbiological performance of ethylene oxide sterilization - Part 1: Physical aspects

YY/T 1302.1-2015

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.080.01

C 47

Physical requirements and microbiological

performance of ethylene oxide sterilization -

Part 1: Physical aspects

ISSUED ON: MARCH 02, 2015

IMPLEMENTED ON: JANUARY 01, 2016

Issued by: China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Equipment for ethylene oxide sterilization process ... 5

5 Determine the minimum temperature of product before preconditioning ... 12

6 Calculate humidity ... 14

7 Calculation of ethylene oxide concentration ... 17

8 Calculation by the use of flammability curves ... 19

9 Guide to statistical contrast methods for determining process equivalence 20

Appendix A (Informative) An example of a method for determining the

concentration of ethylene oxide gas based on the physical formula of an ideal

gas ... 26

Appendix B (Informative) Calculation example using a flammability curve ... 29

Physical requirements and microbiological

performance of ethylene oxide sterilization -

Part 1: Physical aspects

1 Scope

This part of YY/T 1302 specifies the physical requirements for the sterilization

of ethylene oxide.

This part is intended to provide guidance for sterilization equipment,

preconditioning, calculation of relative humidity, concentration of ethylene oxide,

flammability, statistical applications in process equivalents.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB 3836.1-2010 Explosive atmospheres - Part 1: Equipment - General

requirements

GB 3836.14-2014 Explosive atmospheres - Part 14: Classification of areas

- Explosive gas atmosphere

GB 50169-2006 Code for construction and acceptance of grounding

connection electric equipment installation engineering

GBZ 2.1-2007 Occupational exposure limits for hazardous agents in the

workplace Part 1: Chemical hazardous agents

ISO 11135-1:2007 Sterilization of health care products - Ethylene oxide -

Part 1: Requirements for development, validation and routine control of a

sterilization process of medical devices

3 Terms and definitions

The terms and definitions as defined in ISO 11135-1:2007 as well as the

following terms and definitions apply to this document.

GB 3836.14-2014;

b) The interior of the sterilizing cabinet shall also comply with the

requirements or equivalent requirements of the category T2 electrical

equipment in the zone IIB0 in GB 3836.1-2010 and GB 3836.14-2014;

c) Equipment and piping shall comply with the grounding requirements of GB

50169-2006 or other equivalent requirements;

d) The storage, disposal, use of ethylene oxide shall comply with relevant

national regulations;

e) When designing the sterilization cycle, the environment inside the

sterilizing cabinet shall be kept non-flammable.

4.1.2 Under abnormal conditions (such as equipment failure, power interruption,

test cycle, etc.), when the product is exposed to an ethylene oxide sealed

environment and lack proper ventilation (failure of air exhaust or ventilation

equipment, etc.), it shall pay attention to the hazard as caused by the

accumulation of the flammable and explosive ethylene oxide. The possibility of

this hazard is independent of the mixture used.

4.1.3 Fume hoods or ventilation areas (buildings, rooms) shall be equipped with

equipment that removes sterilized gases and restores them to a safe level (see

GBZ 2.1-2007).

4.1.4 For electromagnetic interference as caused by the equipment or

environment or both inside the workshop (such as a mobile phone) or outside

the workshop, it shall evaluate the impact on the sterilization process. When

designing the plant, it shall comprehensively consider the infrastructure

(appropriate grounding, shielded cables, circuit isolation, protective building

materials, etc.), to avoid interference with the sterilization process.

Note: For guidance on electromagnetic interference, see GB/T 17799.

4.2 Preconditioning area (outside sterilizing cabinet)

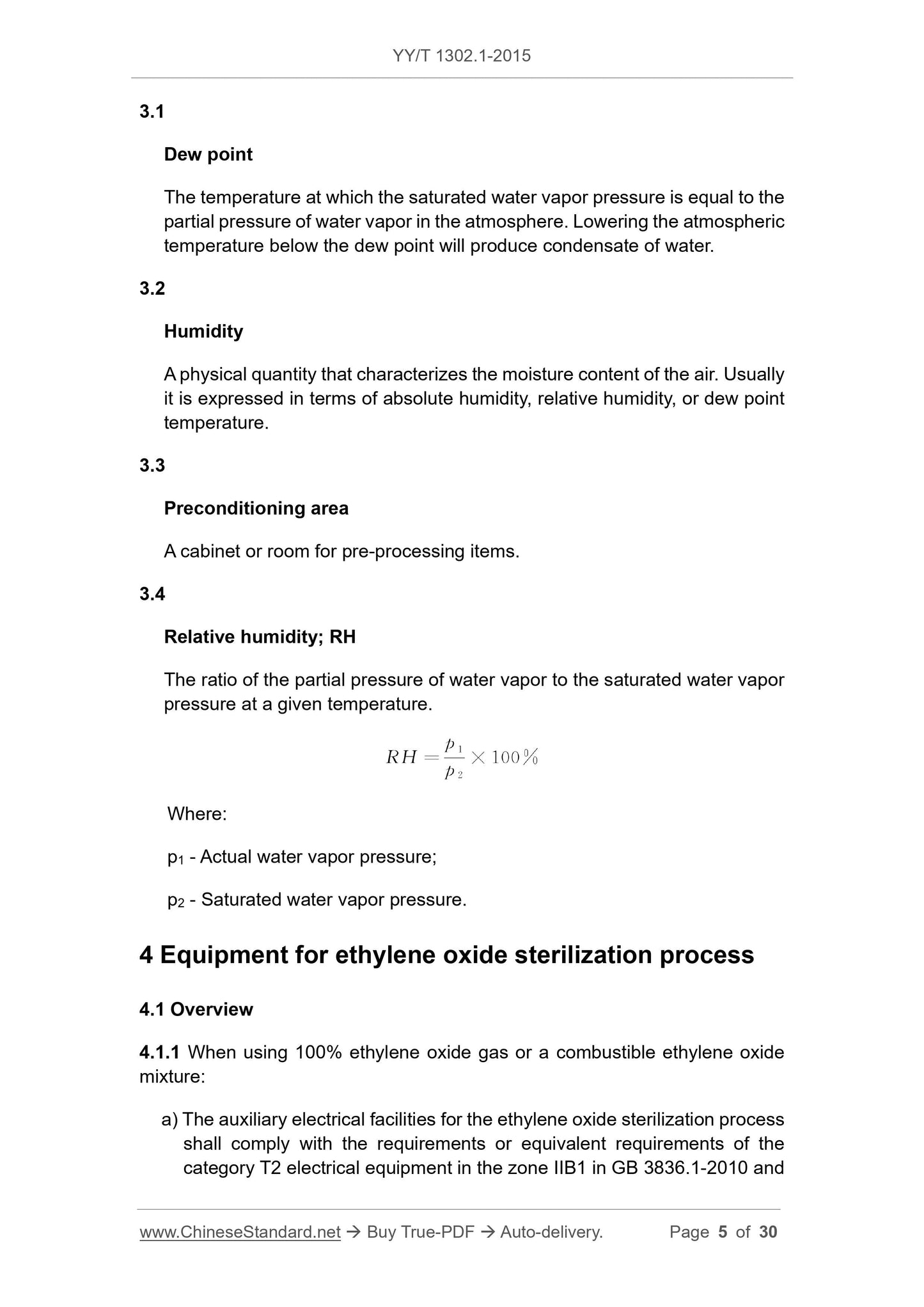

4.2.1 If the product is heated and humidified in the workshop, there shall be

equipment to adequately control and record the room temperature and humidity.

In ISO 11135-1:2007, humidity is only expressed in terms of relative humidity.

Humidity may also be recorded in other engineering units, such as dew point,

absolute humidity, water vapor pressure.

4.2.2 It shall use supporting air circulation to meet the requirements for the

temperature and humidity control and its distribution as specified in the

available rooms (areas).

4.2.3 During identification of equipment, it shall establish and record the air

4.3.4 It shall select the sensors which are suitable for the ethylene oxide

sterilization process (such as pressure, temperature, gas concentration, relative

humidity sensors, etc.).

4.3.5 If there is a deviation in the sterilization process, it shall use audible and/or

visual alarm to alarm the operator.

4.3.6 Sterilizing cabinets shall be mechanically (interlocked) designed to

prevent inadvertent contact loading prior to the completion of the sterilization

cycle. If the sterilization cycle fails, it shall be limited only to understanding the

fault condition and the employee contact loading which may has risk.

4.3.7 When the sterilizing cabinet is used to condition the product loading

(regardless of static or dynamic), it shall be able to adequately control and

record the sterilizing cabinet’s temperature, pressure, other parameters to

achieve the desired process conditions.

4.3.8 Since the process conditions within the sterilizing cabinet may reach the

dew point of the water, it shall evaluate the condensate on products and

equipment. In particular, the condensate at cold point will reduce the partial

pressure of water vapor in the sterilizing cabinet, resulting in additional steam

injection to maintain a constant pressure under static processing conditions.

Excessive condensate in the sterilizing cabinet or on the product/package will

impede the killing effect of ethylene oxide gas on the microorganism of the

product; meanwhile it will adsorb ethylene oxide gas and ethylene oxide

derivative. The adsorbed ethylene oxide gas will diffuse when the product

loading is ventilated or stored, endangering the health of the staff. In addition,

the condensate in the sterilizing cabinet or on the product load will re-evaporate

and make the humidity level in the headspace of the sterilizing cabinet exceed

the confirmed level.

4.3.9 For equipment designed to heat and humidify, the sterilizing cabinet shall

avoid direct humidification of the product loading (such as the use of manifolds

or partitions). Generally, it uses steam valves, traps and/or coalescing filters to

control the quality of the steam which enters the sterilizing cabinet. Steam water

shall not contain contaminants that affect the sterilization process or damage

the sterilizing cabinet or sterilized load.

4.3.10 It shall select the equipment that has sufficient control over the

parameters as provided and as selected by the monitoring, such as:

a) Pressure control;

b) Rate control (such as exhaus...

Get QUOTATION in 1-minute: Click YY/T 1302.1-2015

Historical versions: YY/T 1302.1-2015

Preview True-PDF (Reload/Scroll if blank)

YY/T 1302.1-2015: Physical requirements and microbiological performance of ethylene oxide sterilization - Part 1: Physical aspects

YY/T 1302.1-2015

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.080.01

C 47

Physical requirements and microbiological

performance of ethylene oxide sterilization -

Part 1: Physical aspects

ISSUED ON: MARCH 02, 2015

IMPLEMENTED ON: JANUARY 01, 2016

Issued by: China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Equipment for ethylene oxide sterilization process ... 5

5 Determine the minimum temperature of product before preconditioning ... 12

6 Calculate humidity ... 14

7 Calculation of ethylene oxide concentration ... 17

8 Calculation by the use of flammability curves ... 19

9 Guide to statistical contrast methods for determining process equivalence 20

Appendix A (Informative) An example of a method for determining the

concentration of ethylene oxide gas based on the physical formula of an ideal

gas ... 26

Appendix B (Informative) Calculation example using a flammability curve ... 29

Physical requirements and microbiological

performance of ethylene oxide sterilization -

Part 1: Physical aspects

1 Scope

This part of YY/T 1302 specifies the physical requirements for the sterilization

of ethylene oxide.

This part is intended to provide guidance for sterilization equipment,

preconditioning, calculation of relative humidity, concentration of ethylene oxide,

flammability, statistical applications in process equivalents.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB 3836.1-2010 Explosive atmospheres - Part 1: Equipment - General

requirements

GB 3836.14-2014 Explosive atmospheres - Part 14: Classification of areas

- Explosive gas atmosphere

GB 50169-2006 Code for construction and acceptance of grounding

connection electric equipment installation engineering

GBZ 2.1-2007 Occupational exposure limits for hazardous agents in the

workplace Part 1: Chemical hazardous agents

ISO 11135-1:2007 Sterilization of health care products - Ethylene oxide -

Part 1: Requirements for development, validation and routine control of a

sterilization process of medical devices

3 Terms and definitions

The terms and definitions as defined in ISO 11135-1:2007 as well as the

following terms and definitions apply to this document.

GB 3836.14-2014;

b) The interior of the sterilizing cabinet shall also comply with the

requirements or equivalent requirements of the category T2 electrical

equipment in the zone IIB0 in GB 3836.1-2010 and GB 3836.14-2014;

c) Equipment and piping shall comply with the grounding requirements of GB

50169-2006 or other equivalent requirements;

d) The storage, disposal, use of ethylene oxide shall comply with relevant

national regulations;

e) When designing the sterilization cycle, the environment inside the

sterilizing cabinet shall be kept non-flammable.

4.1.2 Under abnormal conditions (such as equipment failure, power interruption,

test cycle, etc.), when the product is exposed to an ethylene oxide sealed

environment and lack proper ventilation (failure of air exhaust or ventilation

equipment, etc.), it shall pay attention to the hazard as caused by the

accumulation of the flammable and explosive ethylene oxide. The possibility of

this hazard is independent of the mixture used.

4.1.3 Fume hoods or ventilation areas (buildings, rooms) shall be equipped with

equipment that removes sterilized gases and restores them to a safe level (see

GBZ 2.1-2007).

4.1.4 For electromagnetic interference as caused by the equipment or

environment or both inside the workshop (such as a mobile phone) or outside

the workshop, it shall evaluate the impact on the sterilization process. When

designing the plant, it shall comprehensively consider the infrastructure

(appropriate grounding, shielded cables, circuit isolation, protective building

materials, etc.), to avoid interference with the sterilization process.

Note: For guidance on electromagnetic interference, see GB/T 17799.

4.2 Preconditioning area (outside sterilizing cabinet)

4.2.1 If the product is heated and humidified in the workshop, there shall be

equipment to adequately control and record the room temperature and humidity.

In ISO 11135-1:2007, humidity is only expressed in terms of relative humidity.

Humidity may also be recorded in other engineering units, such as dew point,

absolute humidity, water vapor pressure.

4.2.2 It shall use supporting air circulation to meet the requirements for the

temperature and humidity control and its distribution as specified in the

available rooms (areas).

4.2.3 During identification of equipment, it shall establish and record the air

4.3.4 It shall select the sensors which are suitable for the ethylene oxide

sterilization process (such as pressure, temperature, gas concentration, relative

humidity sensors, etc.).

4.3.5 If there is a deviation in the sterilization process, it shall use audible and/or

visual alarm to alarm the operator.

4.3.6 Sterilizing cabinets shall be mechanically (interlocked) designed to

prevent inadvertent contact loading prior to the completion of the sterilization

cycle. If the sterilization cycle fails, it shall be limited only to understanding the

fault condition and the employee contact loading which may has risk.

4.3.7 When the sterilizing cabinet is used to condition the product loading

(regardless of static or dynamic), it shall be able to adequately control and

record the sterilizing cabinet’s temperature, pressure, other parameters to

achieve the desired process conditions.

4.3.8 Since the process conditions within the sterilizing cabinet may reach the

dew point of the water, it shall evaluate the condensate on products and

equipment. In particular, the condensate at cold point will reduce the partial

pressure of water vapor in the sterilizing cabinet, resulting in additional steam

injection to maintain a constant pressure under static processing conditions.

Excessive condensate in the sterilizing cabinet or on the product/package will

impede the killing effect of ethylene oxide gas on the microorganism of the

product; meanwhile it will adsorb ethylene oxide gas and ethylene oxide

derivative. The adsorbed ethylene oxide gas will diffuse when the product

loading is ventilated or stored, endangering the health of the staff. In addition,

the condensate in the sterilizing cabinet or on the product load will re-evaporate

and make the humidity level in the headspace of the sterilizing cabinet exceed

the confirmed level.

4.3.9 For equipment designed to heat and humidify, the sterilizing cabinet shall

avoid direct humidification of the product loading (such as the use of manifolds

or partitions). Generally, it uses steam valves, traps and/or coalescing filters to

control the quality of the steam which enters the sterilizing cabinet. Steam water

shall not contain contaminants that affect the sterilization process or damage

the sterilizing cabinet or sterilized load.

4.3.10 It shall select the equipment that has sufficient control over the

parameters as provided and as selected by the monitoring, such as:

a) Pressure control;

b) Rate control (such as exhaus...

Share