1

/

su

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1653-2020 English PDF (YYT1653-2020)

YY/T 1653-2020 English PDF (YYT1653-2020)

Prezzo di listino

$205.00 USD

Prezzo di listino

Prezzo scontato

$205.00 USD

Prezzo unitario

/

per

Spese di spedizione calcolate al check-out.

Impossibile caricare la disponibilità di ritiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY/T 1653-2020

Historical versions: YY/T 1653-2020

Preview True-PDF (Reload/Scroll if blank)

YY/T 1653-2020: Administration set use with infusion pump

YY/T 1653-2020

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.30

C 35

Administration set use with infusion pump

ISSUED ON: FEBRUARY 21, 2020

IMPLEMENTED ON: JANUARY 01, 2021

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Robustness identification marking ... 6

5 Requirements ... 6

6 Test method ... 9

Appendix A (Normative) Test unit ... 15

Administration set use with infusion pump

1 Scope

This Standard specifies the terms and definitions, requirements, test methods,

marking and manual for administration set use with infusion pump.

This Standard applies to administration set use with infusion pump.

This Standard does not apply to administration set use with the following special

infusion pumps:

-- Infusion pump for ambulatory use;

-- Volumetric infusion pump whose maximum speed is less than 20 mL/h,

and drip-rate infusion pump whose maximum speed is less than 20

drops/min;

-- Infusion pump that is specially used for diagnostics or similar purposes;

-- Internal infusion pump;

-- Extracorporeal circulation infusion pump for blood;

-- Implantable device or single-use infusion pump;

-- Emergency pump;

-- Nutrition pump, flushing pump, etc.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB 8368-2005, Infusion sets for single use, gravity feed (ISO 8536-4:2004,

MOD)

GB 9706.27-2005, Medical electrical equipment - Part 2: Particular

requirements for the safety of infusion pumps and controllers (IEC 60601-2-

24:1998, IDT)

3.9 SVclass administration set

The administration set use with infusion pump that uses the test unit that is

specified in Appendix A for the robustness verification.

3.10 MVclass administration set

The administration set use with infusion pump that uses the infusion pump that

is specified by the manufacturer for the robustness verification.

3.11 Administration set change interval

The service time of the administration set that is specified by the manufacturer.

4 Robustness identification marking

The marking of UVclass administration set is as follows:

Administration set for UVclass pump

The marking of SVclass administration set is as follows:

Administration set for SVclass pump

The marking of MVclass administration set is as follows:

Administration set for MVclass pump - configurable infusion pump information

- administration set change interval (see 6.5.2)

Note 1: UVclass administration set may not be marked [see 5.8.1g)].

Note 2: The configurable infusion pump information shall usually include the

manufacturer and model information. If it is marked as a series model,

all models in the entire series shall pass verification or evaluation.

5 Requirements

5.1 Transparency

The liquid path of the administration set shall be transparent, with visible gas-

water interface.

5.2 Particulate pollution

The surface of the liquid channel shall be smooth and clean, and shall not

exceed the pollution index.

a) Text description of the contents, such as “Administration set for disposable

pumps”;

b) Use the graphic symbols that are given in YY 0466.1-2016 to indicate that

the fluid path is aseptic;

c) The administration set has no heat source, or the administration set has

no bacterial endotoxin (if the administration set is provided as part of the

infusion set, it can be expressed as that the infusion set has no heat

source, or the administration set has no bacterial endotoxin);

d) The liquid path is for one-time use only, or equivalent text, or graphical

symbols that comply with YY 0466.1-2016;

e) Instructions for use, including warnings;

f) Lot number, start with the word “LOT”, or use graphic symbols of YY

0466.1-2016;

g) Robustness identification marking (see Chapter 4); if there is no marking,

the administration set is considered to be a UVclass administration set;

h) Manufacturer, supplier name or logo and address;

i) Year and month of expiration and the corresponding text or graphical

symbols in accordance with YY 0466.1-2016.

If the area is too small to give all the information and/or symbols, it shall at least

be marked with the markings/requirements that are specified in f) and i). In this

case, the information that is required by this article needs to be given on the

larger shelf or multi-unit container.

5.8.2 Shelf or multi-unit container

The shelf or multi-unit container shall be marked with at least the following

information:

a) Text description of the contents, such as “Administration set for disposable

pumps”;

b) Year and month of expiration and the corresponding text or graphical

symbols in accordance with YY 0466.1-2016;

c) Robustness identification mark (see Chapter 4); if there is no mark, the

administration set is considered to be a UVclass administration set (the

ISVclass shall be at least marked with an ISVclass set; the rest of the

information is stated in the manual);

Fill de-bubbled distilled water into the liquid path; connect it to a vacuum device;

make it withstand a pressure of -20 kPa at (23±1) °C and (40±1) °C for 15 s;

check whether air enters the liquid path.

Note: Use the atmospheric pressure as the reference pressure. According to

ISO 31-3, the pressure can be assumed to be positive or negative.

6.5 Robustness test

6.5.1 SVclass administration set robustness

6.5.1.1 4 h test

The 4 h test operation is as follows:

1) Unless otherwise specified by the manufacturer, the test temperature shall

be in the range of 23 °C ± 2 °C; the test humidity shall be in the range of

60% ± 15%; the atmospheric pressure shall be in the range of 860 hPa ~

1 060 hPa;

2) Take an unused administration set and install it on the test unit (see

Appendix A);

3) Build the test platform as shown in Figure 1; use the grade-3 water for

analysis laboratory;

4) Adjust and record the motor speed of the test unit, so that the actual flow

rate reaches the range of 25 (1 ± 10%) mL/h; start the test after it stabilizes;

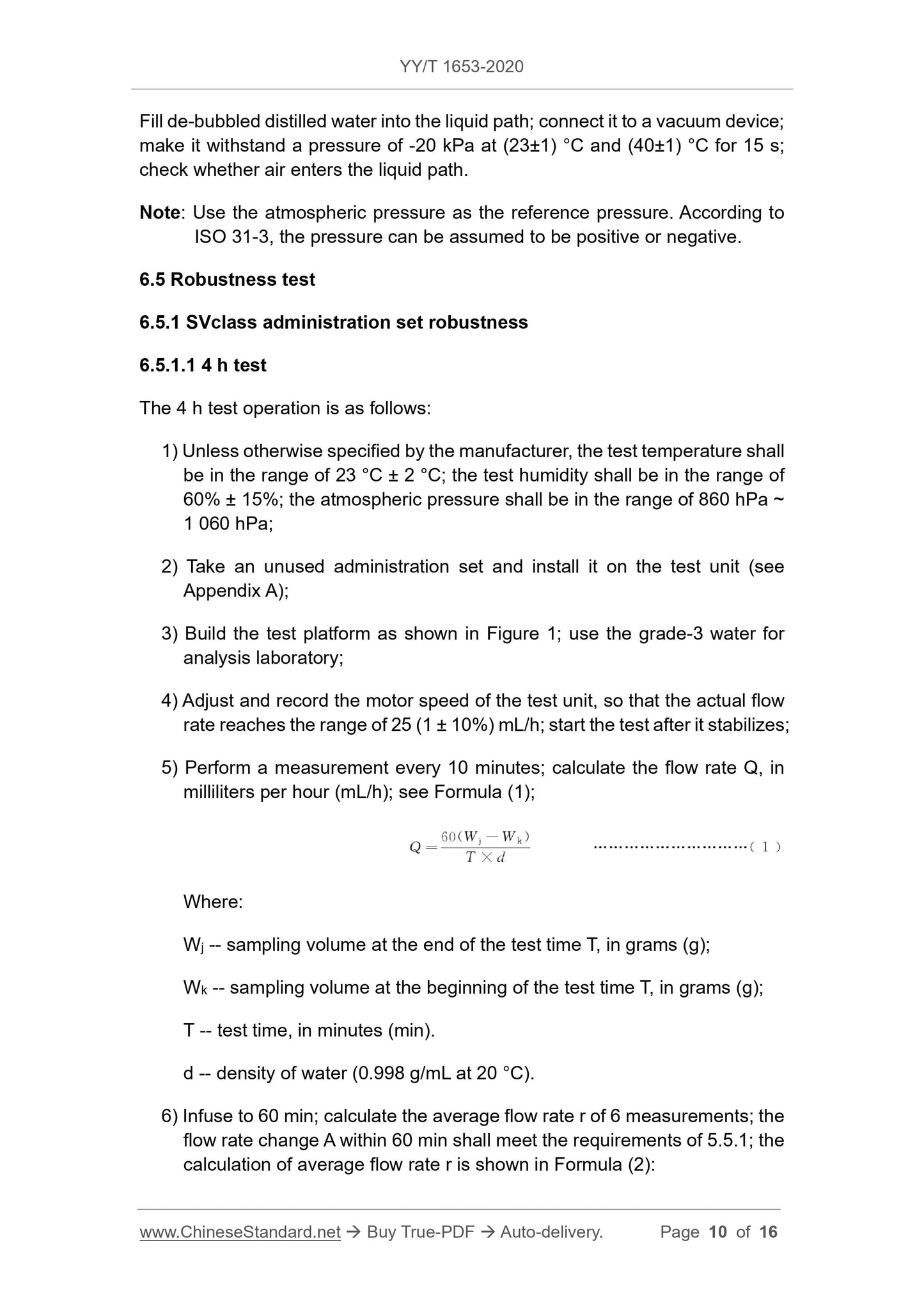

5) Perform a measurement every 10 minutes; calculate the flow rate Q, in

milliliters per hour (mL/h); see Formula (1);

Where:

Wj -- sampling volume at the end of the test time T, in grams (g);

Wk -- sampling volume at the beginning of the test time T, in grams (g);

T -- test time, in minutes (min).

d -- density of water (0.998 g/mL at 20 °C).

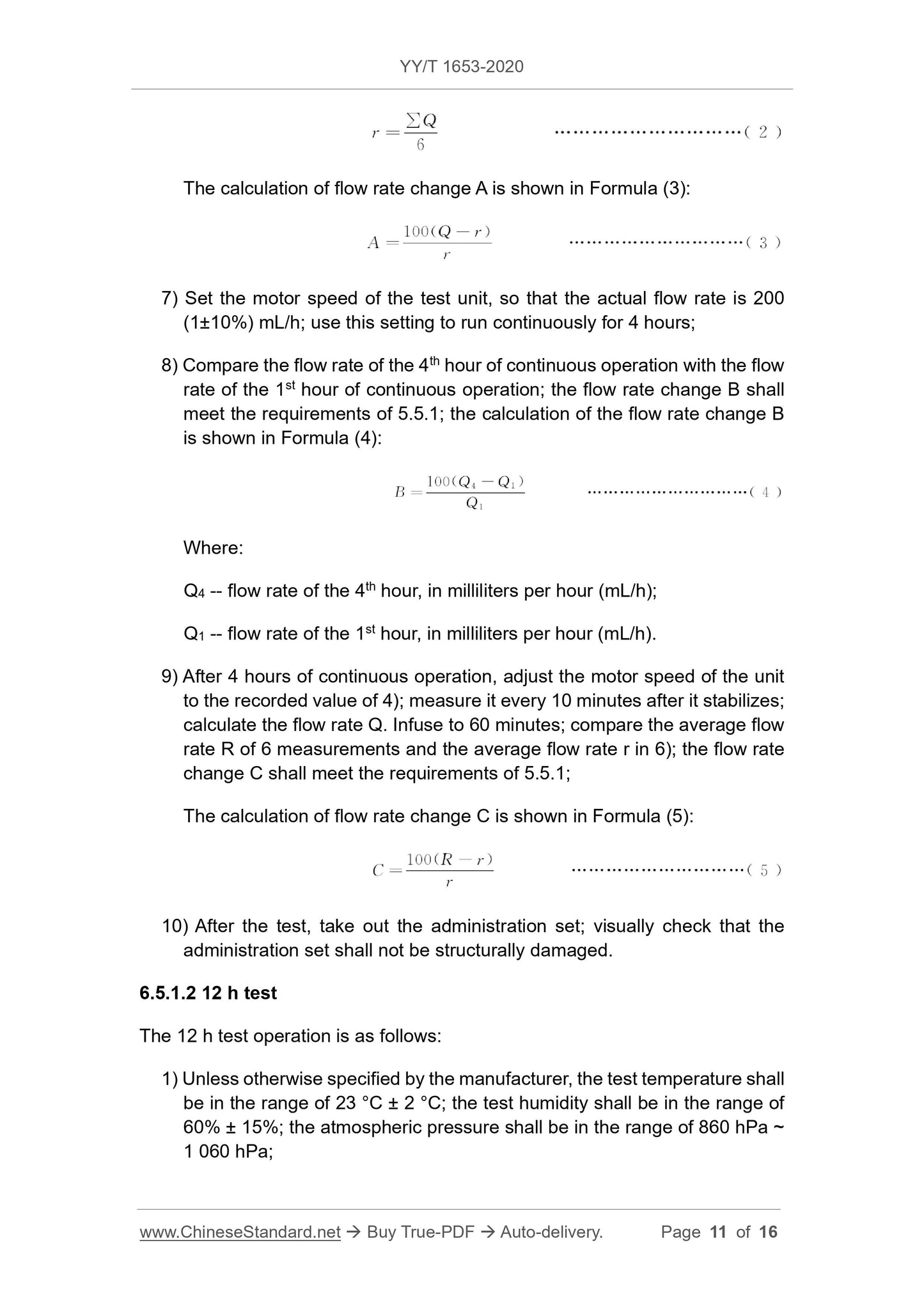

6) Infuse to 60 min; calculate the average flow rate r of 6 measurements; the

flow rate change A within 60 min shall meet the requirements of 5.5.1; the

calculation of average flow rate r is shown in Formula (2):

2) Take an unused administration set and install it on the test unit (see

Appendix A);

3) Build the test platform as shown in Figure 1; use the grade-3 water for

analysis laboratory;

4) Adjust and record the motor speed of the test unit, so that the actual flow

rate reaches the range of 25 (1 ± 10%) mL/h; start the test after it stabilizes;

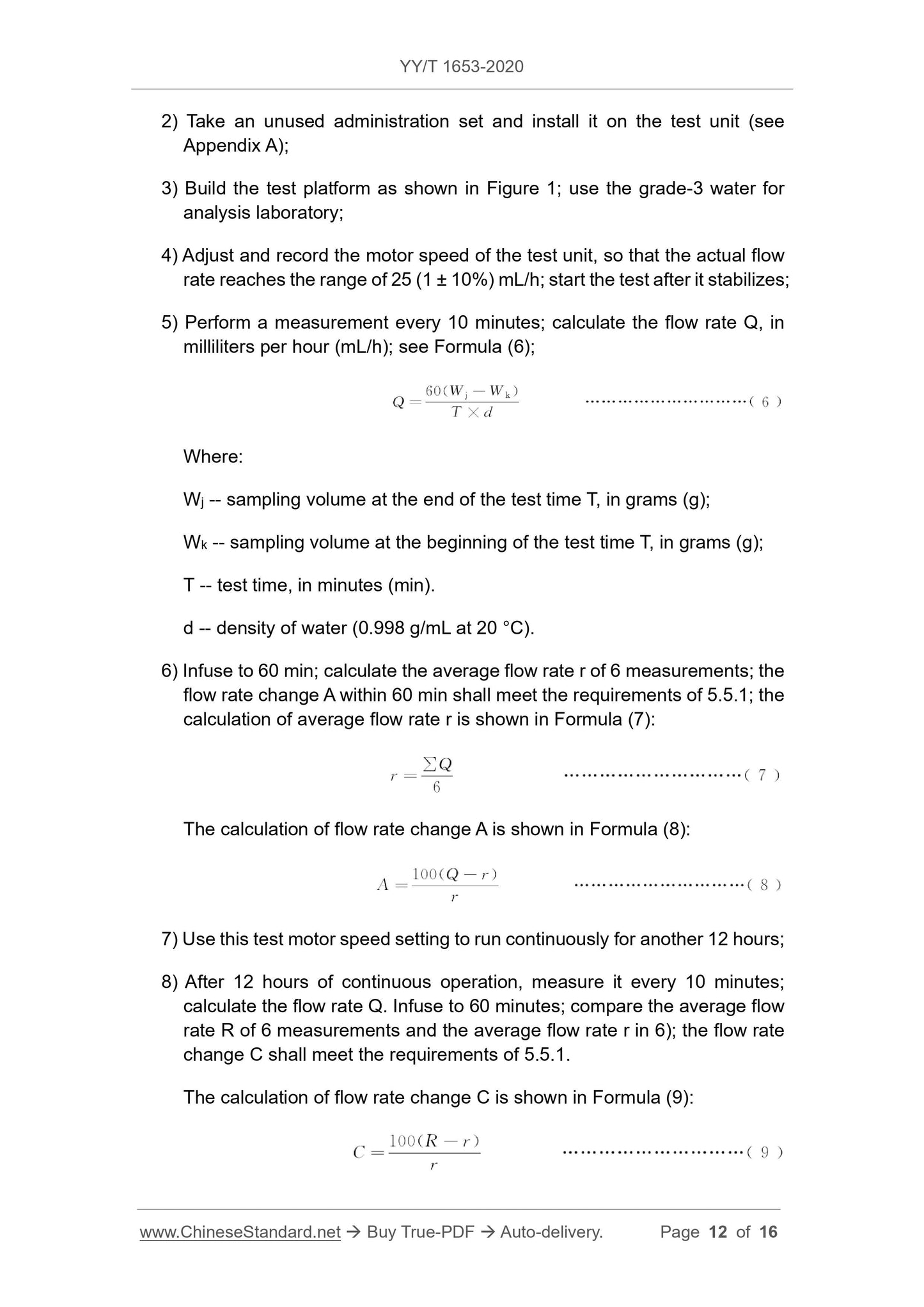

5) Perform a measurement every 10 minutes; calculate the flow rate Q, in

milliliters per hour (mL/h); see Formula (6);

Where:

Wj -- sampling volume at the end of the test time T, in g...

Get QUOTATION in 1-minute: Click YY/T 1653-2020

Historical versions: YY/T 1653-2020

Preview True-PDF (Reload/Scroll if blank)

YY/T 1653-2020: Administration set use with infusion pump

YY/T 1653-2020

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.30

C 35

Administration set use with infusion pump

ISSUED ON: FEBRUARY 21, 2020

IMPLEMENTED ON: JANUARY 01, 2021

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Robustness identification marking ... 6

5 Requirements ... 6

6 Test method ... 9

Appendix A (Normative) Test unit ... 15

Administration set use with infusion pump

1 Scope

This Standard specifies the terms and definitions, requirements, test methods,

marking and manual for administration set use with infusion pump.

This Standard applies to administration set use with infusion pump.

This Standard does not apply to administration set use with the following special

infusion pumps:

-- Infusion pump for ambulatory use;

-- Volumetric infusion pump whose maximum speed is less than 20 mL/h,

and drip-rate infusion pump whose maximum speed is less than 20

drops/min;

-- Infusion pump that is specially used for diagnostics or similar purposes;

-- Internal infusion pump;

-- Extracorporeal circulation infusion pump for blood;

-- Implantable device or single-use infusion pump;

-- Emergency pump;

-- Nutrition pump, flushing pump, etc.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB 8368-2005, Infusion sets for single use, gravity feed (ISO 8536-4:2004,

MOD)

GB 9706.27-2005, Medical electrical equipment - Part 2: Particular

requirements for the safety of infusion pumps and controllers (IEC 60601-2-

24:1998, IDT)

3.9 SVclass administration set

The administration set use with infusion pump that uses the test unit that is

specified in Appendix A for the robustness verification.

3.10 MVclass administration set

The administration set use with infusion pump that uses the infusion pump that

is specified by the manufacturer for the robustness verification.

3.11 Administration set change interval

The service time of the administration set that is specified by the manufacturer.

4 Robustness identification marking

The marking of UVclass administration set is as follows:

Administration set for UVclass pump

The marking of SVclass administration set is as follows:

Administration set for SVclass pump

The marking of MVclass administration set is as follows:

Administration set for MVclass pump - configurable infusion pump information

- administration set change interval (see 6.5.2)

Note 1: UVclass administration set may not be marked [see 5.8.1g)].

Note 2: The configurable infusion pump information shall usually include the

manufacturer and model information. If it is marked as a series model,

all models in the entire series shall pass verification or evaluation.

5 Requirements

5.1 Transparency

The liquid path of the administration set shall be transparent, with visible gas-

water interface.

5.2 Particulate pollution

The surface of the liquid channel shall be smooth and clean, and shall not

exceed the pollution index.

a) Text description of the contents, such as “Administration set for disposable

pumps”;

b) Use the graphic symbols that are given in YY 0466.1-2016 to indicate that

the fluid path is aseptic;

c) The administration set has no heat source, or the administration set has

no bacterial endotoxin (if the administration set is provided as part of the

infusion set, it can be expressed as that the infusion set has no heat

source, or the administration set has no bacterial endotoxin);

d) The liquid path is for one-time use only, or equivalent text, or graphical

symbols that comply with YY 0466.1-2016;

e) Instructions for use, including warnings;

f) Lot number, start with the word “LOT”, or use graphic symbols of YY

0466.1-2016;

g) Robustness identification marking (see Chapter 4); if there is no marking,

the administration set is considered to be a UVclass administration set;

h) Manufacturer, supplier name or logo and address;

i) Year and month of expiration and the corresponding text or graphical

symbols in accordance with YY 0466.1-2016.

If the area is too small to give all the information and/or symbols, it shall at least

be marked with the markings/requirements that are specified in f) and i). In this

case, the information that is required by this article needs to be given on the

larger shelf or multi-unit container.

5.8.2 Shelf or multi-unit container

The shelf or multi-unit container shall be marked with at least the following

information:

a) Text description of the contents, such as “Administration set for disposable

pumps”;

b) Year and month of expiration and the corresponding text or graphical

symbols in accordance with YY 0466.1-2016;

c) Robustness identification mark (see Chapter 4); if there is no mark, the

administration set is considered to be a UVclass administration set (the

ISVclass shall be at least marked with an ISVclass set; the rest of the

information is stated in the manual);

Fill de-bubbled distilled water into the liquid path; connect it to a vacuum device;

make it withstand a pressure of -20 kPa at (23±1) °C and (40±1) °C for 15 s;

check whether air enters the liquid path.

Note: Use the atmospheric pressure as the reference pressure. According to

ISO 31-3, the pressure can be assumed to be positive or negative.

6.5 Robustness test

6.5.1 SVclass administration set robustness

6.5.1.1 4 h test

The 4 h test operation is as follows:

1) Unless otherwise specified by the manufacturer, the test temperature shall

be in the range of 23 °C ± 2 °C; the test humidity shall be in the range of

60% ± 15%; the atmospheric pressure shall be in the range of 860 hPa ~

1 060 hPa;

2) Take an unused administration set and install it on the test unit (see

Appendix A);

3) Build the test platform as shown in Figure 1; use the grade-3 water for

analysis laboratory;

4) Adjust and record the motor speed of the test unit, so that the actual flow

rate reaches the range of 25 (1 ± 10%) mL/h; start the test after it stabilizes;

5) Perform a measurement every 10 minutes; calculate the flow rate Q, in

milliliters per hour (mL/h); see Formula (1);

Where:

Wj -- sampling volume at the end of the test time T, in grams (g);

Wk -- sampling volume at the beginning of the test time T, in grams (g);

T -- test time, in minutes (min).

d -- density of water (0.998 g/mL at 20 °C).

6) Infuse to 60 min; calculate the average flow rate r of 6 measurements; the

flow rate change A within 60 min shall meet the requirements of 5.5.1; the

calculation of average flow rate r is shown in Formula (2):

2) Take an unused administration set and install it on the test unit (see

Appendix A);

3) Build the test platform as shown in Figure 1; use the grade-3 water for

analysis laboratory;

4) Adjust and record the motor speed of the test unit, so that the actual flow

rate reaches the range of 25 (1 ± 10%) mL/h; start the test after it stabilizes;

5) Perform a measurement every 10 minutes; calculate the flow rate Q, in

milliliters per hour (mL/h); see Formula (6);

Where:

Wj -- sampling volume at the end of the test time T, in g...

Share