1

/

の

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

DL/T 259-2012 English PDF (DLT259-2012)

DL/T 259-2012 English PDF (DLT259-2012)

通常価格

$145.00 USD

通常価格

セール価格

$145.00 USD

単価

/

あたり

配送料はチェックアウト時に計算されます。

受取状況を読み込めませんでした

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click DL/T 259-2012

Historical versions: DL/T 259-2012

Preview True-PDF (Reload/Scroll if blank)

DL/T 259-2012: Calibration regulation for SF6 gas density monitor

DL/T 259-2012

DL

ELECTRIC POWER INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 29.120.70

K 33

Filing No.. 36413-2012

Calibration regulation for SF6 gas density relay

ISSUED ON. APRIL 6, 2012

IMPLEMENTED ON. JULY 1, 2012

Issued by. National Energy Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 General technical requirements ... 6

5 Metrological property requirements ... 10

6 Calibration conditions ... 11

7 Calibration method ... 13

8 Calibration standard, cycle and items ... 16

Annex A (Normative) Test process ... 18

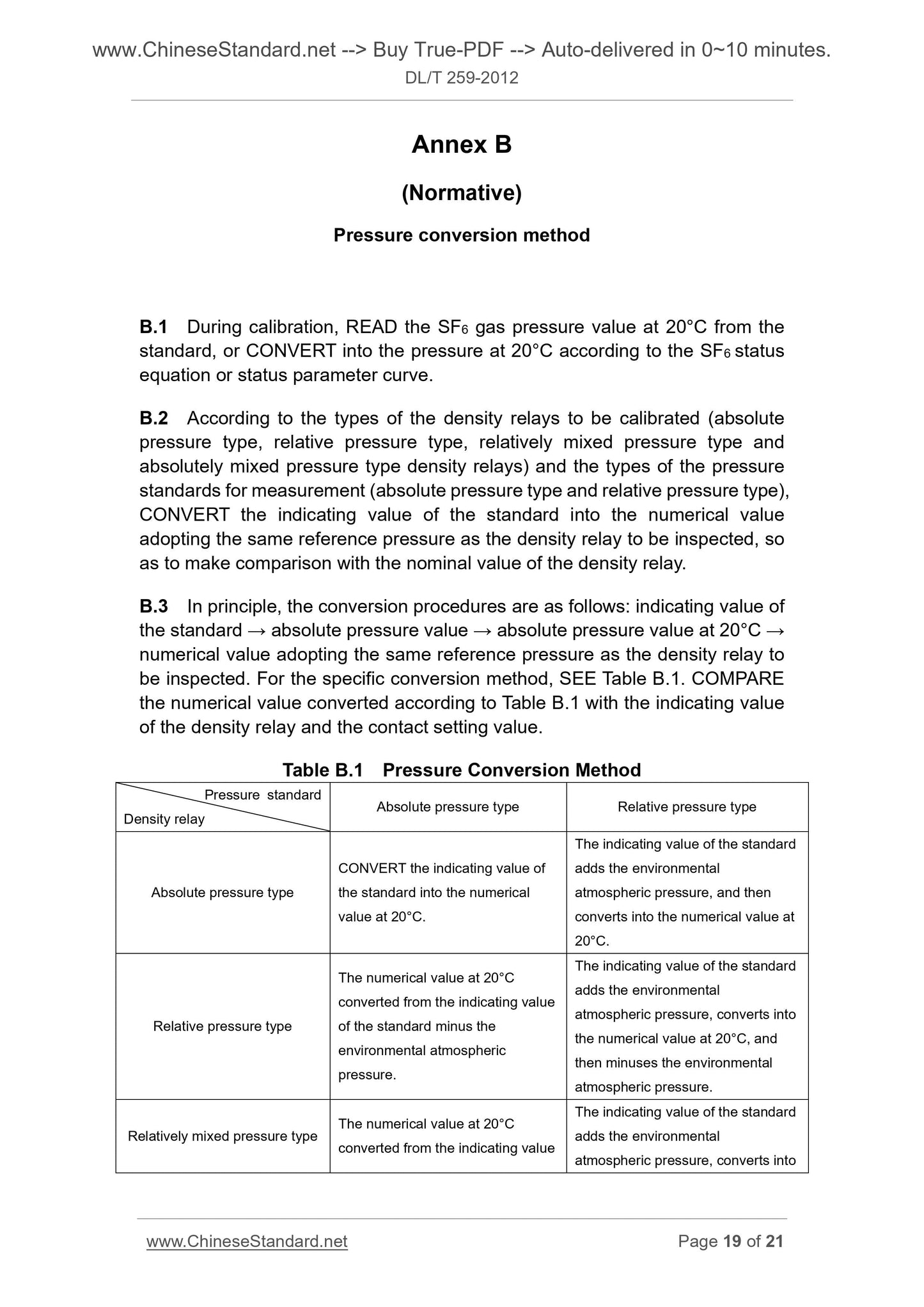

Annex B (Normative) Pressure conversion method ... 19

Annex C (Informative) SF6 gas status equation ... 21

Calibration regulation for SF6 gas density relay

1 Scope

This Standard specifies the general technical requirements, metrological

property requirements, calibration items and calibration methods of the spring

tube type SF6 gas density relays (hereinafter referred to as “density relays”).

This Standard is applicable to the on-site calibration and laboratory calibration

of the spring tube type SF6 gas density relays newly produced, in use and after

repair. Other types of SF6 gas density relays can be calibrated by reference to

this Standard.

2 Normative references

The following documents are essential to the application of this Standard. For

dated references, only the editions with the dates indicated are applicable to

this Standard. For undated references, only the latest editions (including all the

amendments) are applicable to this Standard.

GB/T 2423.10 Environmental testing for electric and electronic products -

Part 2. Test methods - Test Fc. Vibration (sinusoidal) (GB/T 2423.10-2008,

IEC 60068-2-6. 1995, IDT)

GB/T 11287 Electrical relays - Part 21. Vibration, shock, bump and seismic

tests on measuring relays and protection equipment - Section one. Vibration

tests (sinusoidal) (GB/T 11287-2000, IEC 255-21-1.1988, IDT)

GB/T 22065-2008 Pressure type SF6 gas density monitor

DL/T 393 Regulations of condition-based maintenance and test for electric

equipment

3 Terms and definitions

The terms and definitions defined in DL/T 393-2010 and the following ones are

applicable to this Standard.

3.1 Rating pressure

It refers to the pressure of filling the equipment air chamber with the required

SF6 gas under standard atmospheric conditions, before the equipment is put

into operation or during air injection.

3.2 Alarm pressure

It refers to the pressure of giving alarm signals, when the SF6 gas pressure in

the equipment air chamber drops to a certain set value.

3.3 Lock pressure

It refers to the pressure of giving lock signals, when the SF6 gas pressure in the

equipment air chamber drops to a certain set value.

3.4 Overpressure alarm pressure

It refers to the pressure of giving overpressure alarm signals, when the SF6 gas

pressure in the equipment air chamber rises to a certain set value exceeding

the rating pressure.

3.5 Absolute pressure type density relay

It refers to the gas density relay indicated with absolute pressure and using

absolute vacuum as reference pressure.

3.6 Relative pressure type density relay

It refers to the gas density relay indicated with relative pressure and using

environmental atmospheric pressure as reference pressure.

3.7 Relatively mixed pressure type density relay

It refers to the gas density relay indicated with relative pressure and using

standard atmospheric pressure as reference pressure.

3.8 Absolutely mixed pressure type density relay

It refers to the gas density relay indicated with absolute pressure and using

environmental atmospheric pressure as reference pressure.

3.9 Condition-based maintenance

It refers to a kind of maintenance strategy used for arranging the maintenance

reasonably, based on the equipment status and taking the security, reliability,

environment, cost and other factors into overall consideration.

[Definition 3.1.1 in DL/T 393-2010]

4.2.1 As for the density relay equipped with a stop pin, whose scale starts

from a certain positive pressure value, when the ambient temperature is 20°C

and the atmospheric pressure is standard atmospheric pressure, the pointer

shall rest against the limit nail under non-pressure working condition, before the

pressure-rise calibration and after the pressure-drop calibration. For the specific

relationships among reference zero, temperature and atmospheric pressure,

REFER to the instruction manual of this density relay.

4.2.2 As for the density relay whose scale starts from the minimum pressure

value, the pointer zero error under non-pressure working condition, before the

pressure-rise calibration and after the pressure-drop calibration, shall comply

with the following requirements.

a) For the absolute pressure type density relays, when the ambient temperature

is 20°C, the pointers shall point at local atmospheric pressure value. When

the ambient temperature is higher than 20°C, the pointers shall point at the

pressure which is lower than local atmospheric pressure. When the ambient

temperature is lower than 20°C, the pointers shall point at the pressure which

is higher than local atmospheric pressure. For the specific relationships

among reference zero, temperature and atmospheric pressure, REFER to

the instruction manual of the density relays.

b) For the relative pressure type density relays, when the ambient temperature

is 20°C, the pointers shall point within the width range of the zero index line.

The width of the zero index line shall not exceed twice the absolute value of

the maximum allowable basic error. When the ambient temperature is higher

than 20°C, the pointers shall point at the position below the zero. When the

ambient temperature is lower than 20°C, the pointers shall point at the

position above the zero. For the specific relationship between reference zero

and temperature, REFER to the instruction manual of the density relays.

c) For the relatively mixed pressure type density relays, when the ambient

temperature is 20°C, the pointers shall point at the difference of local

environmental atmospheric pressure minus standard atmospheric pressure.

When the ambient temperature is higher than 20°C, the pointers shall point

at the position below this difference. When the ambient temperature is lower

than 20°C, the pointers shall point at the position above this difference. For

the specific relationship between reference zero and temperature, REFER to

the instruction manual of the density relays.

d) For the absolutely mixed pressure type density relays, when the ambient

temperature is 20°C, the pointers shall point within the width range of the

0.1MPa index line. The width of the index line shall not exceed twice the

absolute value of the maximum allowable basic error. When the ambient

temperature is higher than 20°C, the pointers shall point at the position below

Under rating pressure, the hysteresis error shall not be greater than the

permissible error specified in Section 5.1.

5.4 Tapping displacement

TAP the case so that the pointer can swing freely. The variation of the pointer’s

indicating value shall not be greater than 1/2 of the absolute value of the

permissible error specified in Section 5.1.

5.5 Pointer deflection stability

Within the range of measurement, the pointer deflection shall be stable and

without obvious ...

Get QUOTATION in 1-minute: Click DL/T 259-2012

Historical versions: DL/T 259-2012

Preview True-PDF (Reload/Scroll if blank)

DL/T 259-2012: Calibration regulation for SF6 gas density monitor

DL/T 259-2012

DL

ELECTRIC POWER INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 29.120.70

K 33

Filing No.. 36413-2012

Calibration regulation for SF6 gas density relay

ISSUED ON. APRIL 6, 2012

IMPLEMENTED ON. JULY 1, 2012

Issued by. National Energy Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 General technical requirements ... 6

5 Metrological property requirements ... 10

6 Calibration conditions ... 11

7 Calibration method ... 13

8 Calibration standard, cycle and items ... 16

Annex A (Normative) Test process ... 18

Annex B (Normative) Pressure conversion method ... 19

Annex C (Informative) SF6 gas status equation ... 21

Calibration regulation for SF6 gas density relay

1 Scope

This Standard specifies the general technical requirements, metrological

property requirements, calibration items and calibration methods of the spring

tube type SF6 gas density relays (hereinafter referred to as “density relays”).

This Standard is applicable to the on-site calibration and laboratory calibration

of the spring tube type SF6 gas density relays newly produced, in use and after

repair. Other types of SF6 gas density relays can be calibrated by reference to

this Standard.

2 Normative references

The following documents are essential to the application of this Standard. For

dated references, only the editions with the dates indicated are applicable to

this Standard. For undated references, only the latest editions (including all the

amendments) are applicable to this Standard.

GB/T 2423.10 Environmental testing for electric and electronic products -

Part 2. Test methods - Test Fc. Vibration (sinusoidal) (GB/T 2423.10-2008,

IEC 60068-2-6. 1995, IDT)

GB/T 11287 Electrical relays - Part 21. Vibration, shock, bump and seismic

tests on measuring relays and protection equipment - Section one. Vibration

tests (sinusoidal) (GB/T 11287-2000, IEC 255-21-1.1988, IDT)

GB/T 22065-2008 Pressure type SF6 gas density monitor

DL/T 393 Regulations of condition-based maintenance and test for electric

equipment

3 Terms and definitions

The terms and definitions defined in DL/T 393-2010 and the following ones are

applicable to this Standard.

3.1 Rating pressure

It refers to the pressure of filling the equipment air chamber with the required

SF6 gas under standard atmospheric conditions, before the equipment is put

into operation or during air injection.

3.2 Alarm pressure

It refers to the pressure of giving alarm signals, when the SF6 gas pressure in

the equipment air chamber drops to a certain set value.

3.3 Lock pressure

It refers to the pressure of giving lock signals, when the SF6 gas pressure in the

equipment air chamber drops to a certain set value.

3.4 Overpressure alarm pressure

It refers to the pressure of giving overpressure alarm signals, when the SF6 gas

pressure in the equipment air chamber rises to a certain set value exceeding

the rating pressure.

3.5 Absolute pressure type density relay

It refers to the gas density relay indicated with absolute pressure and using

absolute vacuum as reference pressure.

3.6 Relative pressure type density relay

It refers to the gas density relay indicated with relative pressure and using

environmental atmospheric pressure as reference pressure.

3.7 Relatively mixed pressure type density relay

It refers to the gas density relay indicated with relative pressure and using

standard atmospheric pressure as reference pressure.

3.8 Absolutely mixed pressure type density relay

It refers to the gas density relay indicated with absolute pressure and using

environmental atmospheric pressure as reference pressure.

3.9 Condition-based maintenance

It refers to a kind of maintenance strategy used for arranging the maintenance

reasonably, based on the equipment status and taking the security, reliability,

environment, cost and other factors into overall consideration.

[Definition 3.1.1 in DL/T 393-2010]

4.2.1 As for the density relay equipped with a stop pin, whose scale starts

from a certain positive pressure value, when the ambient temperature is 20°C

and the atmospheric pressure is standard atmospheric pressure, the pointer

shall rest against the limit nail under non-pressure working condition, before the

pressure-rise calibration and after the pressure-drop calibration. For the specific

relationships among reference zero, temperature and atmospheric pressure,

REFER to the instruction manual of this density relay.

4.2.2 As for the density relay whose scale starts from the minimum pressure

value, the pointer zero error under non-pressure working condition, before the

pressure-rise calibration and after the pressure-drop calibration, shall comply

with the following requirements.

a) For the absolute pressure type density relays, when the ambient temperature

is 20°C, the pointers shall point at local atmospheric pressure value. When

the ambient temperature is higher than 20°C, the pointers shall point at the

pressure which is lower than local atmospheric pressure. When the ambient

temperature is lower than 20°C, the pointers shall point at the pressure which

is higher than local atmospheric pressure. For the specific relationships

among reference zero, temperature and atmospheric pressure, REFER to

the instruction manual of the density relays.

b) For the relative pressure type density relays, when the ambient temperature

is 20°C, the pointers shall point within the width range of the zero index line.

The width of the zero index line shall not exceed twice the absolute value of

the maximum allowable basic error. When the ambient temperature is higher

than 20°C, the pointers shall point at the position below the zero. When the

ambient temperature is lower than 20°C, the pointers shall point at the

position above the zero. For the specific relationship between reference zero

and temperature, REFER to the instruction manual of the density relays.

c) For the relatively mixed pressure type density relays, when the ambient

temperature is 20°C, the pointers shall point at the difference of local

environmental atmospheric pressure minus standard atmospheric pressure.

When the ambient temperature is higher than 20°C, the pointers shall point

at the position below this difference. When the ambient temperature is lower

than 20°C, the pointers shall point at the position above this difference. For

the specific relationship between reference zero and temperature, REFER to

the instruction manual of the density relays.

d) For the absolutely mixed pressure type density relays, when the ambient

temperature is 20°C, the pointers shall point within the width range of the

0.1MPa index line. The width of the index line shall not exceed twice the

absolute value of the maximum allowable basic error. When the ambient

temperature is higher than 20°C, the pointers shall point at the position below

Under rating pressure, the hysteresis error shall not be greater than the

permissible error specified in Section 5.1.

5.4 Tapping displacement

TAP the case so that the pointer can swing freely. The variation of the pointer’s

indicating value shall not be greater than 1/2 of the absolute value of the

permissible error specified in Section 5.1.

5.5 Pointer deflection stability

Within the range of measurement, the pointer deflection shall be stable and

without obvious ...

Share