1

/

の

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

DL/T 805.2-2016 English PDF (DLT805.2-2016)

DL/T 805.2-2016 English PDF (DLT805.2-2016)

通常価格

$130.00 USD

通常価格

セール価格

$130.00 USD

単価

/

あたり

配送料はチェックアウト時に計算されます。

受取状況を読み込めませんでした

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click DL/T 805.2-2016

Historical versions: DL/T 805.2-2016

Preview True-PDF (Reload/Scroll if blank)

DL/T 805.2-2016: Guideline for cycle chemistry in fossil plants - Part 2: Phosphate treatment for drum units

DL/T 805.2-2016

DL

NATIONAL POWER INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 27.100

F 24

Record No.. 53886-2016

Replacing DL/T 805.2-2004

Guideline for Cycle Chemistry in Fossil Plants –

Part 2. Phosphate Treatment for Drum Units

ISSUED ON. JANUARY 07, 2016

IMPLEMENTED ON. JUNE 01, 2016

Issued by. National Energy Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 6

4 Role and Usage Conditions ... 6

5 Boiler Water Quality Standard ... 7

6 Selection of Treatment Methods for Steam Drum Boiler Water ... 8

7 Inspection Methods ... 10

8 Drug Purity ... 11

9 Boiler Water Sampling and Dosing ... 11

10 Treatment Measures when the Quality of the Boiler Water Deteriorates 12

Foreword

DL/T 805 Guideline for Cycle Chemistry in Fossil Plant can be divided into the following

5 parts.

--- Part 1. Oxygenated Treatment for Feed-Water System of Boiler;

--- Part 2. Phosphate Treatment for Drum Units;

--- Part 3. Caustic Treatment for Drum Units;

--- Part 4. Feedwater Treatment;

--- Part 5. All Volatile Treatment for Drum Units.

This Part belongs to Part 2 of DL/T 805. Compared with DL/T 805.2-2004, this Part

has the major revisions as follows besides the editorial modifications.

--- Modify the pressure rating of the boiler steam drum in the phosphate treatment;

--- Modify the definition of the low phosphate treatment.

--- Delete the coordinated pH-phosphate treatment (CPT);

--- Delete the water quality indicators of the boiler water treatment related to the

segmented evaporation boiler;

--- Modify the boiler water quality indicator during the phosphate treatment (PT);

--- Modify the boiler water quality indicators during the low phosphate treatment

(LPT);

--- Delete the equilibrium phosphate treatment (EPT);

--- Modify the flow chart for selecting the boiler water treatment of steam drum boiler;

--- Modify the treatment value when the boiler water quality is abnormal.

This Standard was drafted as per the rules specified in GB/T 1.1-2009.

This Part was proposed by China Electricity Council.

This Part shall be under the jurisdiction of Technical Committee for Standardization of

Power Plant Chemical of Power Industry.

Chief drafting organizations of this Part. Xi’an Thermal Power Research Institute Co.,

Ltd., and Jilin Electric Power Research Institute Co., Ltd.

Guideline for Cycle Chemistry in Fossil Plants -

Part 2. Phosphate Treatment for Drum Units

1 Scope

This Part of DL/T 805 gives the conditions, principles and control indicators for the

boiler water phosphate treatment in fossil plant.

This Part is applicable to the boiler water treatment of steam drum boiler with steam

drum pressure of 3.8MPa~18.3MPa in the fossil plant.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 6904 Water Used in Industrial Circulating Cooling System and Boiler -

Determination of Ph

GB/T 6908 Analysis of Water Used in Boil and Cooling System-Determination of

Electrical Conductivity

GB/T 6913 Analysis of Water Used in Boiler and Cooling System - Determination

of Phosphorus

GB/T 12146 Analysis of Water Used in Boil and Cooling System – Determination

of Ammonia - Phenol Method

GB/T 12149 Determination of Silica in Water for Industrial Circulating Cooling

System and Boiler

GB/T 15453 Water for Industrial Circulating Cooling System and Boiler-

Determination of Chloride

DL/T 954 Analysis of Water and Steam in Fossil Fuel Power Plant Determination

of Fluoride Acetate Formate Chloride Nitrite Nitrate Phosphate and Sulfate by Ion

Chromatography

DL/T 1115 Guide for Chemistry Check - up of Unit Maintenance in Fossil Fuel

Power Plant

3 Terms and Definitions

The following terms and definitions are applicable to this Part of DL/T 805.

3.1 Free sodium hydroxide

The total amount of sodium hydroxide in the boiler water exceeds that produced by the

hydrolysis equilibrium reaction of trisodium phosphate.

3.2 Phosphate treatment (PT)

The treatment adding appropriate amount of trisodium phosphate to the boiler water

to prevent the generation of calcium and magnesium scale in the furnace and reduce

the corrosion on the water-cooled wall tube.

3.3 Low phosphate treatment (LPT)

The treatment adding a small amount of trisodium phosphate to the boiler water.

3.4 Caustic treatment (CT)

The treatment adding sodium hydroxide to the boiler water.

3.5 All volatile treatment (AVT)

The treatment only adding ammonia and hydrazine to the boiler, adding no chemicals

to the boiler water.

4 Role and Usage Conditions

4.1 The role of boiler water phosphate treatment

a) Prevent the generation of calcium and magnesium scales on the inner wall of the

water-cooled wall tube;

b) Increase the cushioning property of the boiler water to prevent the acid or alkaline

corrosion of the water-cooled wall tube;

c) Reduce the vapor carrying against the silicon dioxide; improve the chemical

properties of turbine deposits; and reduce turbine corrosion.

4.2 The problem of boiler water phosphate treatment

The boiler water phosphate treatment can cause the following problems.

a) Phosphate hiding phenomenon, causing acid phosphate corrosion of water-

the length of the steam drum.

For the forced circulation steam drum boiler, the boiler water dosing point can be set

at the inlet of the boiler water circulation pump.

10 Treatment Measures when the Quality of the Boiler

Water Deteriorates

10.1 Classification and treatment principles of boiler water quality

deterioration

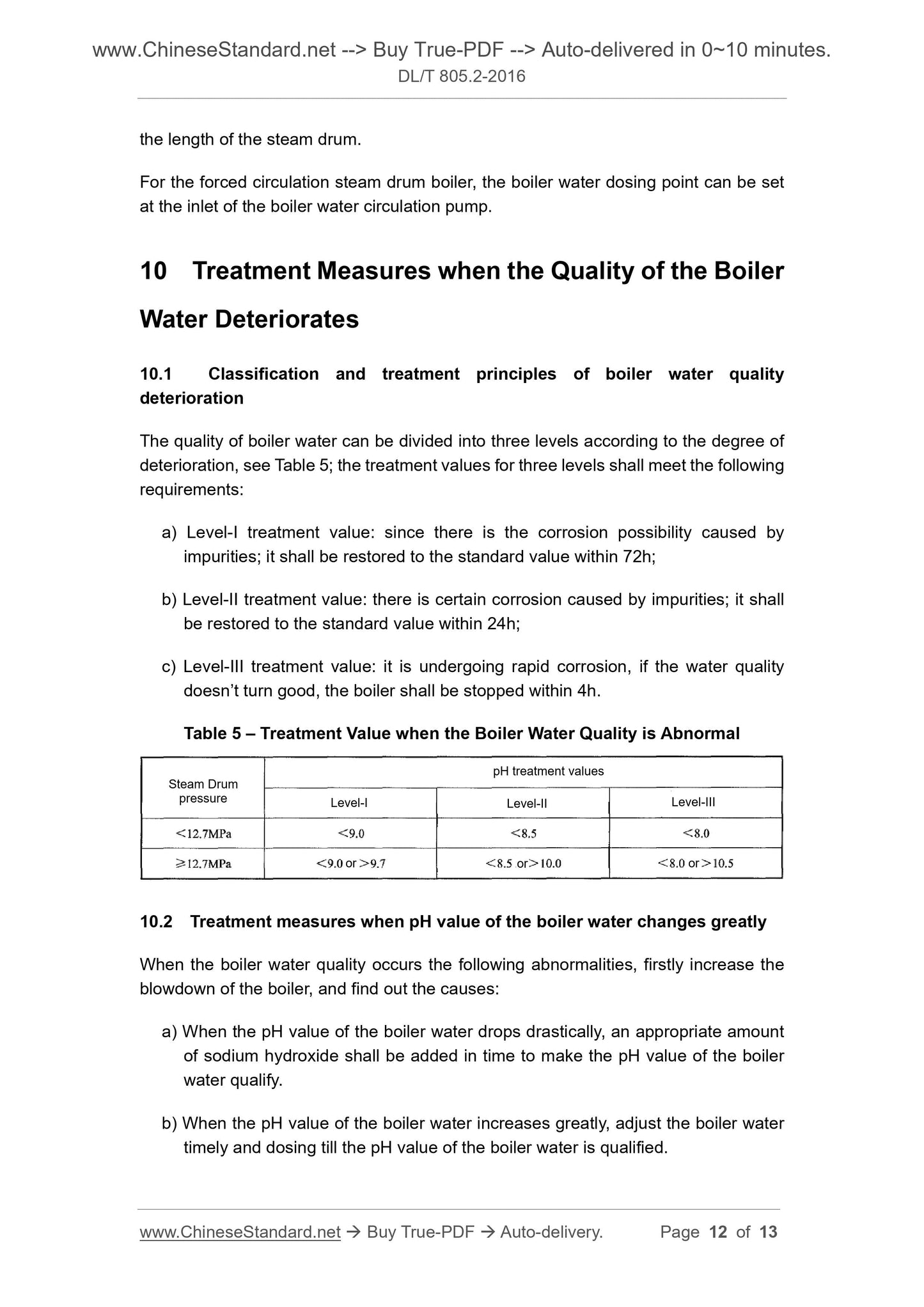

The quality of boiler water can be divided into three levels according to the degree of

deterioration, see Table 5; the treatment values for three levels shall meet the following

requirements.

a) Level-I treatment value. since there is the corrosion possibility caused by

impurities; it shall be restored to the standard value within 72h;

b) Level-II treatment value. there is certain corrosion caused by impurities; it shall

be restored to the standard value within 24h;

c) Level-III treatment value. it is undergoing rapid corrosion, if the water quality

doesn’t turn good, the boiler shall be stopped within 4h.

Table 5 – Treatment Value when the Boiler Water Quality is Abnormal

10.2 Treatment measures when pH value of the boiler water changes greatly

When the boiler water quality occurs the following abnormalities, firstly increase the

blowdown of the boiler, and find out the causes.

a) When the pH value of the boiler water drops drastically, an appropriate amount

of sodium hydroxide shall be added in time to make the pH value of the boiler

water qualify.

b) When the pH value of the boiler water increases greatly, adjust the boiler water

timely and dosing till the pH value of the boiler water is qualified.

Steam Drum

pressure

pH treatment values

Level-I Level-II Level-III

or or or

Get QUOTATION in 1-minute: Click DL/T 805.2-2016

Historical versions: DL/T 805.2-2016

Preview True-PDF (Reload/Scroll if blank)

DL/T 805.2-2016: Guideline for cycle chemistry in fossil plants - Part 2: Phosphate treatment for drum units

DL/T 805.2-2016

DL

NATIONAL POWER INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 27.100

F 24

Record No.. 53886-2016

Replacing DL/T 805.2-2004

Guideline for Cycle Chemistry in Fossil Plants –

Part 2. Phosphate Treatment for Drum Units

ISSUED ON. JANUARY 07, 2016

IMPLEMENTED ON. JUNE 01, 2016

Issued by. National Energy Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 6

4 Role and Usage Conditions ... 6

5 Boiler Water Quality Standard ... 7

6 Selection of Treatment Methods for Steam Drum Boiler Water ... 8

7 Inspection Methods ... 10

8 Drug Purity ... 11

9 Boiler Water Sampling and Dosing ... 11

10 Treatment Measures when the Quality of the Boiler Water Deteriorates 12

Foreword

DL/T 805 Guideline for Cycle Chemistry in Fossil Plant can be divided into the following

5 parts.

--- Part 1. Oxygenated Treatment for Feed-Water System of Boiler;

--- Part 2. Phosphate Treatment for Drum Units;

--- Part 3. Caustic Treatment for Drum Units;

--- Part 4. Feedwater Treatment;

--- Part 5. All Volatile Treatment for Drum Units.

This Part belongs to Part 2 of DL/T 805. Compared with DL/T 805.2-2004, this Part

has the major revisions as follows besides the editorial modifications.

--- Modify the pressure rating of the boiler steam drum in the phosphate treatment;

--- Modify the definition of the low phosphate treatment.

--- Delete the coordinated pH-phosphate treatment (CPT);

--- Delete the water quality indicators of the boiler water treatment related to the

segmented evaporation boiler;

--- Modify the boiler water quality indicator during the phosphate treatment (PT);

--- Modify the boiler water quality indicators during the low phosphate treatment

(LPT);

--- Delete the equilibrium phosphate treatment (EPT);

--- Modify the flow chart for selecting the boiler water treatment of steam drum boiler;

--- Modify the treatment value when the boiler water quality is abnormal.

This Standard was drafted as per the rules specified in GB/T 1.1-2009.

This Part was proposed by China Electricity Council.

This Part shall be under the jurisdiction of Technical Committee for Standardization of

Power Plant Chemical of Power Industry.

Chief drafting organizations of this Part. Xi’an Thermal Power Research Institute Co.,

Ltd., and Jilin Electric Power Research Institute Co., Ltd.

Guideline for Cycle Chemistry in Fossil Plants -

Part 2. Phosphate Treatment for Drum Units

1 Scope

This Part of DL/T 805 gives the conditions, principles and control indicators for the

boiler water phosphate treatment in fossil plant.

This Part is applicable to the boiler water treatment of steam drum boiler with steam

drum pressure of 3.8MPa~18.3MPa in the fossil plant.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 6904 Water Used in Industrial Circulating Cooling System and Boiler -

Determination of Ph

GB/T 6908 Analysis of Water Used in Boil and Cooling System-Determination of

Electrical Conductivity

GB/T 6913 Analysis of Water Used in Boiler and Cooling System - Determination

of Phosphorus

GB/T 12146 Analysis of Water Used in Boil and Cooling System – Determination

of Ammonia - Phenol Method

GB/T 12149 Determination of Silica in Water for Industrial Circulating Cooling

System and Boiler

GB/T 15453 Water for Industrial Circulating Cooling System and Boiler-

Determination of Chloride

DL/T 954 Analysis of Water and Steam in Fossil Fuel Power Plant Determination

of Fluoride Acetate Formate Chloride Nitrite Nitrate Phosphate and Sulfate by Ion

Chromatography

DL/T 1115 Guide for Chemistry Check - up of Unit Maintenance in Fossil Fuel

Power Plant

3 Terms and Definitions

The following terms and definitions are applicable to this Part of DL/T 805.

3.1 Free sodium hydroxide

The total amount of sodium hydroxide in the boiler water exceeds that produced by the

hydrolysis equilibrium reaction of trisodium phosphate.

3.2 Phosphate treatment (PT)

The treatment adding appropriate amount of trisodium phosphate to the boiler water

to prevent the generation of calcium and magnesium scale in the furnace and reduce

the corrosion on the water-cooled wall tube.

3.3 Low phosphate treatment (LPT)

The treatment adding a small amount of trisodium phosphate to the boiler water.

3.4 Caustic treatment (CT)

The treatment adding sodium hydroxide to the boiler water.

3.5 All volatile treatment (AVT)

The treatment only adding ammonia and hydrazine to the boiler, adding no chemicals

to the boiler water.

4 Role and Usage Conditions

4.1 The role of boiler water phosphate treatment

a) Prevent the generation of calcium and magnesium scales on the inner wall of the

water-cooled wall tube;

b) Increase the cushioning property of the boiler water to prevent the acid or alkaline

corrosion of the water-cooled wall tube;

c) Reduce the vapor carrying against the silicon dioxide; improve the chemical

properties of turbine deposits; and reduce turbine corrosion.

4.2 The problem of boiler water phosphate treatment

The boiler water phosphate treatment can cause the following problems.

a) Phosphate hiding phenomenon, causing acid phosphate corrosion of water-

the length of the steam drum.

For the forced circulation steam drum boiler, the boiler water dosing point can be set

at the inlet of the boiler water circulation pump.

10 Treatment Measures when the Quality of the Boiler

Water Deteriorates

10.1 Classification and treatment principles of boiler water quality

deterioration

The quality of boiler water can be divided into three levels according to the degree of

deterioration, see Table 5; the treatment values for three levels shall meet the following

requirements.

a) Level-I treatment value. since there is the corrosion possibility caused by

impurities; it shall be restored to the standard value within 72h;

b) Level-II treatment value. there is certain corrosion caused by impurities; it shall

be restored to the standard value within 24h;

c) Level-III treatment value. it is undergoing rapid corrosion, if the water quality

doesn’t turn good, the boiler shall be stopped within 4h.

Table 5 – Treatment Value when the Boiler Water Quality is Abnormal

10.2 Treatment measures when pH value of the boiler water changes greatly

When the boiler water quality occurs the following abnormalities, firstly increase the

blowdown of the boiler, and find out the causes.

a) When the pH value of the boiler water drops drastically, an appropriate amount

of sodium hydroxide shall be added in time to make the pH value of the boiler

water qualify.

b) When the pH value of the boiler water increases greatly, adjust the boiler water

timely and dosing till the pH value of the boiler water is qualified.

Steam Drum

pressure

pH treatment values

Level-I Level-II Level-III

or or or

Share