1

/

の

6

Sales@ChineseStandard.net (Field Test Asia Pte. Ltd.)

FZ/T 54023-2009 English PDF (FZT54023-2009)

FZ/T 54023-2009 English PDF (FZT54023-2009)

通常価格

$155.00 USD

通常価格

セール価格

$155.00 USD

単価

/

あたり

配送料はチェックアウト時に計算されます。

受取状況を読み込めませんでした

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click FZ/T 54023-2009

Historical versions: FZ/T 54023-2009

Preview True-PDF (Reload/Scroll if blank)

FZ/T 54023-2009: Polyamide 66 industrial filament yarns for air bag

FZ/T 54023-2009

FZ

TEXTILE INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 59.060.20

W 52

FZ/T 54023-2009

Polyamide 66 industrial filament yarns for air bag

ISSUED ON: JANUARY 20, 2010

IMPLEMENTED ON: JUNE 01, 2010

Issued by: Ministry of Industry and Information Technology of the People’s

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Product specifications and identification ... 5

5 Technical requirements ... 6

6 Test methods ... 7

7 Inspection rules ... 11

8 Re-inspection rules ... 11

9 Marking, packaging, transportation, storage ... 12

Polyamide 66 industrial filament yarns for air bag

1 Scope

This Standard specifies the terms and definitions, product specifications and

identification, technical requirements, test methods, inspection rules and marking,

packaging, transportation and storage requirements of polyamide 66 industrial filament

yarns for air bags.

This Standard applies to polyamide 66 industrial filament yarns for air bags, made from

polyamide 66 chips as raw materials. This product is mainly used in industries such as

automobile safety air bags, and its linear density ranges from 200 dtex to 800 dtex.

Other categories of products use this as a reference.

2 Normative references

The following documents contain the provisions which, through reference in this

Standard, become the provisions of this Standard. For dated references, their

subsequent amendments (excluding corrigendum) or revisions do not apply to this

Standard. However, the parties who enter into agreement based on this Standard are

encouraged to investigate whether the latest versions of these documents are applicable.

For undated reference documents, the latest versions apply to this Standard.

GB/T 2828.1-2003 Sampling procedures for inspection by attributes - Part 1:

Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot

inspection

GB/T 3291.1 Textiles - Terms of textile material properties and test - Part 1: Fibre

and yarn

GB/T 3291.3 Textiles - Terms of textile material properties and test - Part 3: General

GB/T 4146.1 Textiles - Man-made fibres - Part 1: Generic names

GB/T 6502 Sampling method of man-made filament yarns

GB/T 6504 Testing method for oil content of man-made fibres

GB/T 8170 Rules of rounding off for numerical values and expression and judgement

of limiting values

GB/T 14343 Testing method for linear density of man-made filament yarns

GB/T 14344 Man-made fibre - Test method for tensile properties of filament yarns

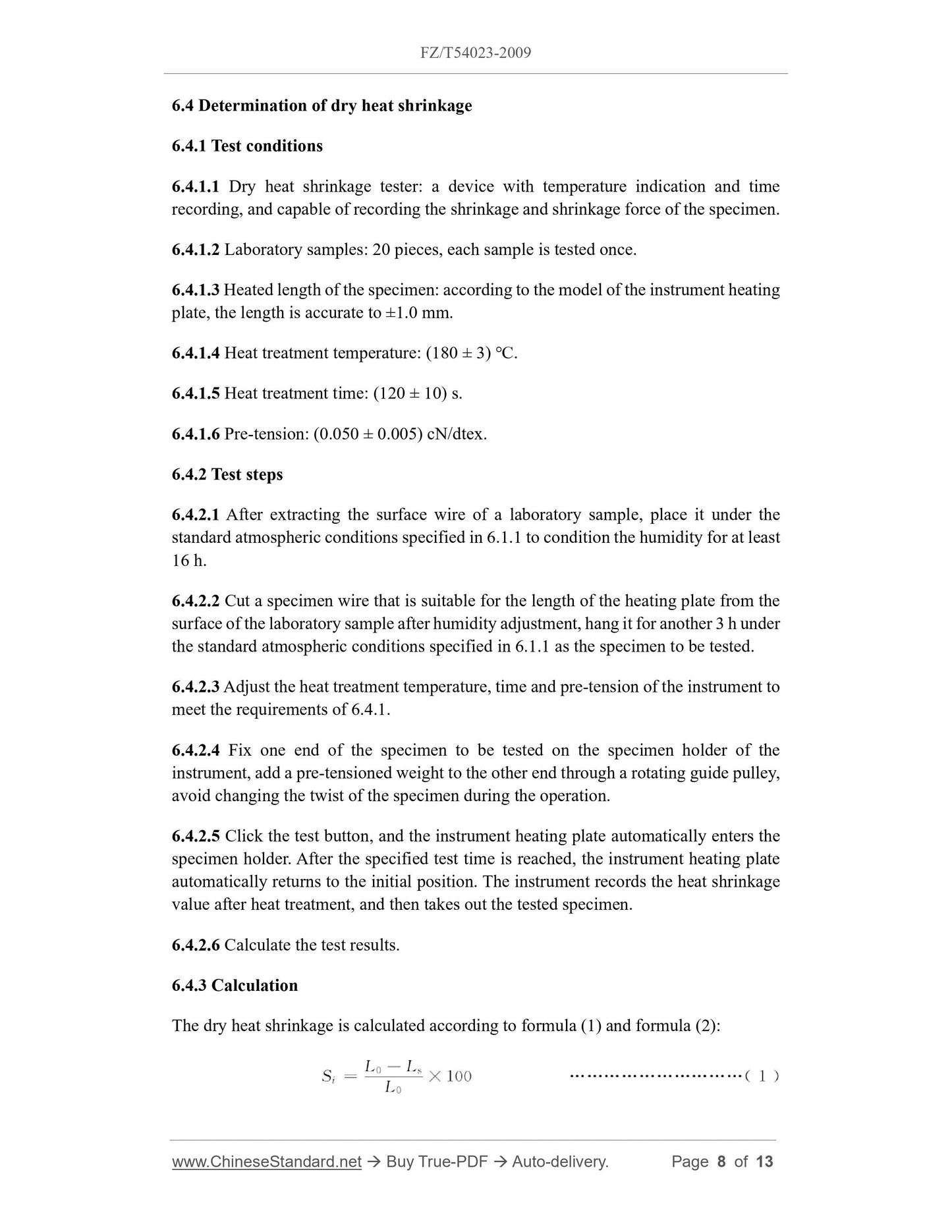

6.4 Determination of dry heat shrinkage

6.4.1 Test conditions

6.4.1.1 Dry heat shrinkage tester: a device with temperature indication and time

recording, and capable of recording the shrinkage and shrinkage force of the specimen.

6.4.1.2 Laboratory samples: 20 pieces, each sample is tested once.

6.4.1.3 Heated length of the specimen: according to the model of the instrument heating

plate, the length is accurate to ±1.0 mm.

6.4.1.4 Heat treatment temperature: (180 ± 3) ℃.

6.4.1.5 Heat treatment time: (120 ± 10) s.

6.4.1.6 Pre-tension: (0.050 ± 0.005) cN/dtex.

6.4.2 Test steps

6.4.2.1 After extracting the surface wire of a laboratory sample, place it under the

standard atmospheric conditions specified in 6.1.1 to condition the humidity for at least

16 h.

6.4.2.2 Cut a specimen wire that is suitable for the length of the heating plate from the

surface of the laboratory sample after humidity adjustment, hang it for another 3 h under

the standard atmospheric conditions specified in 6.1.1 as the specimen to be tested.

6.4.2.3 Adjust the heat treatment temperature, time and pre-tension of the instrument to

meet the requirements of 6.4.1.

6.4.2.4 Fix one end of the specimen to be tested on the specimen holder of the

instrument, add a pre-tensioned weight to the other end through a rotating guide pulley,

avoid changing the twist of the specimen during the operation.

6.4.2.5 Click the test button, and the instrument heating plate automatically enters the

specimen holder. After the specified test time is reached, the instrument heating plate

automatically returns to the initial position. The instrument records the heat shrinkage

value after heat treatment, and then takes out the tested specimen.

6.4.2.6 Calculate the test results.

6.4.3 Calculation

The dry heat shrinkage is calculated according to formula (1) and formula (2):

6.7.5 Record the results.

7 Inspection rules

7.1 Inspection type

Both physical performance and appearance quality requirements are factory-exit

inspection items.

7.2 Inspection items

Physical performance indicators are inspected according to the items specified in Table

1, and appearance quality requirements are inspected bobbin by bobbin according to

the items specified in Table 2.

7.3 Batch rules

Periodic sampling is used within a certain range to form a test batch. A product batch

can be composed of one test batch or several test batches.

7.4 Sampling regulations

7.4.1 All appearance items are inspected.

7.4.2 Laboratory samples of physical performance items shall be sampled according to

the provisions of GB/T 6502.

7.4.3 The damaged roll packages shall not be sampled.

7.5 Comprehensive evaluation

7.5.1 The measured or calculated values of the physical performance test items shall be

compared with the index limit values in Table 1 according to the rounded off value

comparison method in GB/T 8170 to evaluate the grade.

7.5.2 The appearance test items shall be compared with the requirements of Table 2

after inspection in accordance with 6.7 and evaluated bobbin by bobbin.

7.5.3 Products that meet the qualified product requirements of 7.5.1 and 7.5.2 at the

same time shall be judged as qualified products. If one of the performance does not

meet the qualified product requirements of 7.5.1 or 7.5.2, they shall be judged as

unqualified products.

8 Re-inspection rules

8.1 General rules

Within three months after a batch of products arrives at the consignee, a re-inspection

may be requested for acceptance or if there is any objection to the quality. If more than

one-third of the quantity of the batch of products has been used, re-inspection shall not

be applied. If the quality of the batch of products affects the quality of the post-

processing products and causes serious losses, the supply and demand parties shall

analyze the reasons, clarify the responsibilities, and negotiate to deal with it.

8.2 Inspection items

Same as 7.2.

8.3 Batch regulations

Batch according to product batches.

8.4 Sampling regulations

8.4.1 Appearance is a sampling inspection. According to the batch size, the sample size

(code) is determined according to the general inspection level II in Table 1 of GB/T

2828.1-2003.

8.4.2 Laboratory samples of physical performance inspection items are sampled for

inspection according to 7.4.2.

8.5 Comprehensive evaluation

8.5.1 Appearance is based on the sample size of 8.4.1, and then according to the

acceptance quality level AQL value of 4.0 in the “normal inspection single sampling

plan” in Table 2-A of GB/T 2828.1-2003, determine the qualified acceptance number

Ac and the unqualified rejection number Re. According to the provisions of 5.3, if the

number of unqualified roll packages is ≤ Ac, it is judged as qualified; if the number of

unqualified roll packages is ≥ Re, it is...

Get QUOTATION in 1-minute: Click FZ/T 54023-2009

Historical versions: FZ/T 54023-2009

Preview True-PDF (Reload/Scroll if blank)

FZ/T 54023-2009: Polyamide 66 industrial filament yarns for air bag

FZ/T 54023-2009

FZ

TEXTILE INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 59.060.20

W 52

FZ/T 54023-2009

Polyamide 66 industrial filament yarns for air bag

ISSUED ON: JANUARY 20, 2010

IMPLEMENTED ON: JUNE 01, 2010

Issued by: Ministry of Industry and Information Technology of the People’s

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Product specifications and identification ... 5

5 Technical requirements ... 6

6 Test methods ... 7

7 Inspection rules ... 11

8 Re-inspection rules ... 11

9 Marking, packaging, transportation, storage ... 12

Polyamide 66 industrial filament yarns for air bag

1 Scope

This Standard specifies the terms and definitions, product specifications and

identification, technical requirements, test methods, inspection rules and marking,

packaging, transportation and storage requirements of polyamide 66 industrial filament

yarns for air bags.

This Standard applies to polyamide 66 industrial filament yarns for air bags, made from

polyamide 66 chips as raw materials. This product is mainly used in industries such as

automobile safety air bags, and its linear density ranges from 200 dtex to 800 dtex.

Other categories of products use this as a reference.

2 Normative references

The following documents contain the provisions which, through reference in this

Standard, become the provisions of this Standard. For dated references, their

subsequent amendments (excluding corrigendum) or revisions do not apply to this

Standard. However, the parties who enter into agreement based on this Standard are

encouraged to investigate whether the latest versions of these documents are applicable.

For undated reference documents, the latest versions apply to this Standard.

GB/T 2828.1-2003 Sampling procedures for inspection by attributes - Part 1:

Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot

inspection

GB/T 3291.1 Textiles - Terms of textile material properties and test - Part 1: Fibre

and yarn

GB/T 3291.3 Textiles - Terms of textile material properties and test - Part 3: General

GB/T 4146.1 Textiles - Man-made fibres - Part 1: Generic names

GB/T 6502 Sampling method of man-made filament yarns

GB/T 6504 Testing method for oil content of man-made fibres

GB/T 8170 Rules of rounding off for numerical values and expression and judgement

of limiting values

GB/T 14343 Testing method for linear density of man-made filament yarns

GB/T 14344 Man-made fibre - Test method for tensile properties of filament yarns

6.4 Determination of dry heat shrinkage

6.4.1 Test conditions

6.4.1.1 Dry heat shrinkage tester: a device with temperature indication and time

recording, and capable of recording the shrinkage and shrinkage force of the specimen.

6.4.1.2 Laboratory samples: 20 pieces, each sample is tested once.

6.4.1.3 Heated length of the specimen: according to the model of the instrument heating

plate, the length is accurate to ±1.0 mm.

6.4.1.4 Heat treatment temperature: (180 ± 3) ℃.

6.4.1.5 Heat treatment time: (120 ± 10) s.

6.4.1.6 Pre-tension: (0.050 ± 0.005) cN/dtex.

6.4.2 Test steps

6.4.2.1 After extracting the surface wire of a laboratory sample, place it under the

standard atmospheric conditions specified in 6.1.1 to condition the humidity for at least

16 h.

6.4.2.2 Cut a specimen wire that is suitable for the length of the heating plate from the

surface of the laboratory sample after humidity adjustment, hang it for another 3 h under

the standard atmospheric conditions specified in 6.1.1 as the specimen to be tested.

6.4.2.3 Adjust the heat treatment temperature, time and pre-tension of the instrument to

meet the requirements of 6.4.1.

6.4.2.4 Fix one end of the specimen to be tested on the specimen holder of the

instrument, add a pre-tensioned weight to the other end through a rotating guide pulley,

avoid changing the twist of the specimen during the operation.

6.4.2.5 Click the test button, and the instrument heating plate automatically enters the

specimen holder. After the specified test time is reached, the instrument heating plate

automatically returns to the initial position. The instrument records the heat shrinkage

value after heat treatment, and then takes out the tested specimen.

6.4.2.6 Calculate the test results.

6.4.3 Calculation

The dry heat shrinkage is calculated according to formula (1) and formula (2):

6.7.5 Record the results.

7 Inspection rules

7.1 Inspection type

Both physical performance and appearance quality requirements are factory-exit

inspection items.

7.2 Inspection items

Physical performance indicators are inspected according to the items specified in Table

1, and appearance quality requirements are inspected bobbin by bobbin according to

the items specified in Table 2.

7.3 Batch rules

Periodic sampling is used within a certain range to form a test batch. A product batch

can be composed of one test batch or several test batches.

7.4 Sampling regulations

7.4.1 All appearance items are inspected.

7.4.2 Laboratory samples of physical performance items shall be sampled according to

the provisions of GB/T 6502.

7.4.3 The damaged roll packages shall not be sampled.

7.5 Comprehensive evaluation

7.5.1 The measured or calculated values of the physical performance test items shall be

compared with the index limit values in Table 1 according to the rounded off value

comparison method in GB/T 8170 to evaluate the grade.

7.5.2 The appearance test items shall be compared with the requirements of Table 2

after inspection in accordance with 6.7 and evaluated bobbin by bobbin.

7.5.3 Products that meet the qualified product requirements of 7.5.1 and 7.5.2 at the

same time shall be judged as qualified products. If one of the performance does not

meet the qualified product requirements of 7.5.1 or 7.5.2, they shall be judged as

unqualified products.

8 Re-inspection rules

8.1 General rules

Within three months after a batch of products arrives at the consignee, a re-inspection

may be requested for acceptance or if there is any objection to the quality. If more than

one-third of the quantity of the batch of products has been used, re-inspection shall not

be applied. If the quality of the batch of products affects the quality of the post-

processing products and causes serious losses, the supply and demand parties shall

analyze the reasons, clarify the responsibilities, and negotiate to deal with it.

8.2 Inspection items

Same as 7.2.

8.3 Batch regulations

Batch according to product batches.

8.4 Sampling regulations

8.4.1 Appearance is a sampling inspection. According to the batch size, the sample size

(code) is determined according to the general inspection level II in Table 1 of GB/T

2828.1-2003.

8.4.2 Laboratory samples of physical performance inspection items are sampled for

inspection according to 7.4.2.

8.5 Comprehensive evaluation

8.5.1 Appearance is based on the sample size of 8.4.1, and then according to the

acceptance quality level AQL value of 4.0 in the “normal inspection single sampling

plan” in Table 2-A of GB/T 2828.1-2003, determine the qualified acceptance number

Ac and the unqualified rejection number Re. According to the provisions of 5.3, if the

number of unqualified roll packages is ≤ Ac, it is judged as qualified; if the number of

unqualified roll packages is ≥ Re, it is...

Share