1

/

の

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 9757-2001 English PDF (GBT9757-2001)

GB/T 9757-2001 English PDF (GBT9757-2001)

通常価格

$90.00 USD

通常価格

セール価格

$90.00 USD

単価

/

あたり

配送料はチェックアウト時に計算されます。

受取状況を読み込めませんでした

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 9757-2001

Historical versions: GB/T 9757-2001

Preview True-PDF (Reload/Scroll if blank)

GB/T 9757-2001: Solvent-thinned coatings for exterior wall

GB/T 9757-2001

ICS 87.040

G 51

GB

National Standard

of the People’s Republic of China

Solvent-thinned coatings for exterior wall

ISSUED ON. JUNE 09, 2001

IMPLEMENTED ON. APRIL 01, 2002

Issued by. General Administration of Quality Supervision, Inspection

and Quarantine

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Product Classification ... 6

4 Requirements... 6

5 Test methods ... 8

6 Inspection rules ... 12

7 Marking, packing and storage ... 12

Appendix A ... 14

Foreword

This Standard is the revision to recommended national standard GB/T 9757-

1988 Solvent-thinned coatings for exterior wall.

The main technical differences between this Standard and the former vision are.

— In this Standard, it divides the products into 3 grades – “superior

product”, “first grade product”, and “qualified product”; in GB/T 9757-

1988, there is no grading.

— In this Standard, it deletes the item “solid content”;

— In this Standard, it deletes the item “fineness”;

— In this Standard, it uses “contrast ratio” to replace the item “hiding rate”;

— In this Standard, the indicators “water resistance”, “alkali resistance”

and “artificial climate ageing resistance” have been increased to some

extent;

— In this Standard, the cycling number of “coating’s temperature

resistance” is changed from 10 times to 5 times.

Appendix A of this Standard is a standard Appendix.

This Standard shall replace GB/T 9757-1988 from the implementation date.

This Standard was proposed by State Bureau of Petroleum and Chemical

Industry.

This Standard shall be centralized by National Paints and Pigments

Standardization Technical Committee.

Main drafting organization of this Standard. Shanghai Watson Chemical Plant,

Nanjing Huacai Special Paint Factory, and Changzhou Coating Chemical

Research Institute of China National Chemical Construction Corporation.

Main drafters of this Standard. Wang Jianzhong, Li Hongjin, Liu Jiyuan,

Zhaoling, and Feng Shifang.

This Standard was issued first-time in 1988.

This Standard shall be explained by National Paints and Pigments

Standardization Technical Committee.

National Standard of the People’s Republic of China

Solvent-thinned coatings for exterior wall

Replacing GB/T 9757-1988

1 Scope

This Standard specifies product classification, requirements, test methods,

inspection rules, marking, packaging, and storage of solvent-thinned coatings

for exterior wall.

This Standard applies to solvent-thinned coatings for exterior wall of which the

basic material is synthetic resin; which is made of pigments, body pigments and

other auxiliaries; and after being smeared, which can form a thin coating with

flat surface. This coating applies to decoration and protection of external

surface of buildings and structures.

2 Normative references

The articles contained in the following documents have become part of this

Standard when they are quoted herein. For the dated documents so quoted, all

the modifications or revisions made thereafter shall not be applicable to this

Standard. For the undated documents so quoted, the latest editions shall be

applicable to this Standard.

GB/T 1250-1989 Rules for expression and judgment of limiting values

GB/T 1727-1992 Methods of producing films of paints, varnishes, lacquers and

related products on test plates

GB/T 1728-1979 (1989) Methods of test for drying time of coatings of paints

and putties

GB/T 1733-1993 Determination of resistance to water of films

GB/T 1766-1995 Paint and varnish - Rating schemes of degradation of coats

GB/T 1865-1997 Paints and varnishes-Artificial weathering and exposure to

artificial radiation-Filtered xenon-arc radiation (eqv ISO 11341.1994)

GB 3186-1982 (1989) Sampling paint products (neq ISO 1512.1974)

GB/T 6682-1992 Water for laboratory use; Specifications (neq ISO 3696.1987)

GB/T 9265-1988 Determination for alkali resistance of film of architectural

paints and coatings

GB/T 9266-1988 Determination of scrub resistance of film of architectural paints

and coatings

GB/T 9270-1988 Determination of contrast ratio of light colored paints (using

polyester film) (eqv ISO 3906.1980)

GB/T 9271-1988 Paints and varnishes - Standard plates for testing (eqv ISO

1514.1984)

GB 9278-1988 Temperatures and humidities for conditioning and testing of

paint specimens (eqv ISO 3270.1984)

GB/T 9750-1998 Marks for package of coating products

GB/T 13491-1992 General rule for packing of coatings

GB/T 15608-1995 The Chinese color system

HG/T 2458-1993 General Rules for the Inspection, Transportation and Storage

of Paint Products

JC/T 412-1991 Asbestos cement flat sheets for architecture

JG/T 25-1999 Determination for freeze-thaw resistance of film of building

coatings

3 Product Classification

The products are divided into 3 grades. superior product, first grade product,

and qualified product.

4 Requirements

Products shall meet the technical requirements of Table 1.

It shall be done according to GB/T 9750. If it needs dilution, diluent and dilution

rate shall be indicated.

7.2 Packaging

It shall be done according to the grade 1 packaging requirements in GB/T 13491.

7.3 Storage

Product storage shall ensure ventilation, desiccation. It shall prevent from direct

sunlight and it shall isolate the source of fire and be away from heat. According

to the type of resin, product shall formulate the storage life and indicate it on

the packaging logos.

Appendix A

(Standard appendix)

The test method of coating stain resistance

A.1 Principle

This method uses fly ash as contaminated media, and mixes it together with

water to brush on the coating plate. WASH it with water after drying. After a

specified cycle, DETERMINE the decreasing rate of reflection coefficient of

coating, so as to express the coating stain resistance.

A.2 Main material, instruments and device

A.2.1 Fly ash1)

A.2.2 Reflectance instrument

Comply with the provision 4.3 of GB/T 9270-1988.

A.2.3 Balance

Sensitivity of 0.1g.

A.2.4 Soft brush

Width of (25~50) mm.

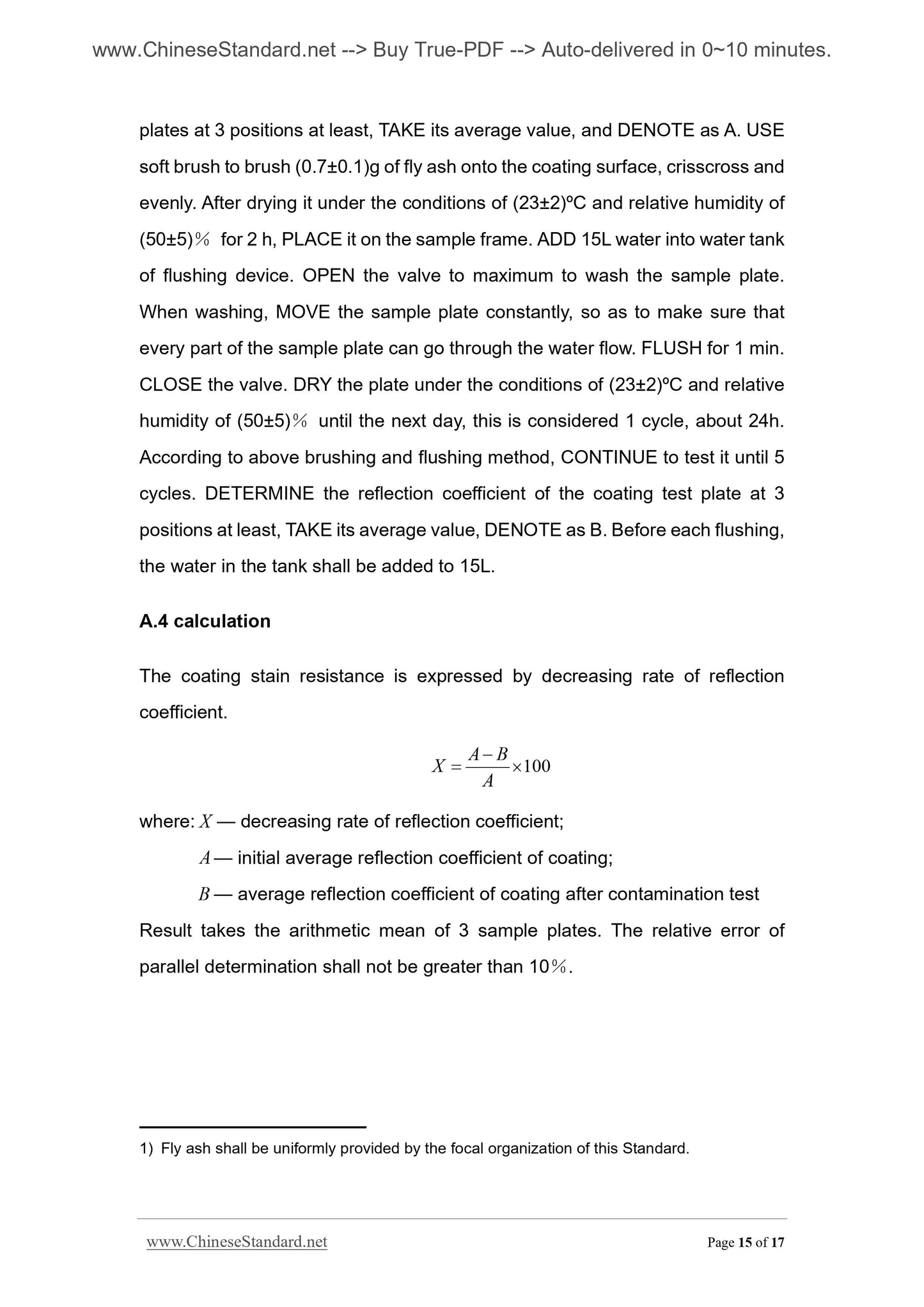

A.2.5 Flushing device

As shown in figure 1. Water tank, water pipes and sample frames are made of

rust-resistant and hard material.

A.3 Test

A.3.1 Preparation of fly-ash water

Weigh appropriate fly ash in the mixing container, and mixed it with water evenly

according to the proportion of 1.1 (mass).

A.3.2 Operation

DETERMINE the original reflection coefficient of the after-care coating test

plates at 3 positions at least, TAKE its average value, and DENOTE as A. USE

soft brush to brush (0.7±0.1)g of fly ash onto the coating surface, crisscross and

evenly. After drying it under the conditions of (23±2)ºC and relative humidity of

(50±5)% for 2 h, PLACE it on the sample frame. ADD 15L water into water tank

of flushing device. OPEN the valve to maximum to wash the sample plate.

When washing, MOVE the sample plate constantly, so as to make sure that

every part of the sample plate can go through the water flow. FLUSH for 1 min.

CLOSE the valve. DRY the plate under the conditions of (23±2)ºC and relative

humidity of (50±5)% until the next day, this is considered 1 cycle, about 24h.

According to above brushing and flushing method, CONTINUE to test it until 5

cycles. DETERMINE the reflection coefficient of the coating test plate at 3

positions at least, TAKE its average value, DENOTE as B. Befor...

Get QUOTATION in 1-minute: Click GB/T 9757-2001

Historical versions: GB/T 9757-2001

Preview True-PDF (Reload/Scroll if blank)

GB/T 9757-2001: Solvent-thinned coatings for exterior wall

GB/T 9757-2001

ICS 87.040

G 51

GB

National Standard

of the People’s Republic of China

Solvent-thinned coatings for exterior wall

ISSUED ON. JUNE 09, 2001

IMPLEMENTED ON. APRIL 01, 2002

Issued by. General Administration of Quality Supervision, Inspection

and Quarantine

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Product Classification ... 6

4 Requirements... 6

5 Test methods ... 8

6 Inspection rules ... 12

7 Marking, packing and storage ... 12

Appendix A ... 14

Foreword

This Standard is the revision to recommended national standard GB/T 9757-

1988 Solvent-thinned coatings for exterior wall.

The main technical differences between this Standard and the former vision are.

— In this Standard, it divides the products into 3 grades – “superior

product”, “first grade product”, and “qualified product”; in GB/T 9757-

1988, there is no grading.

— In this Standard, it deletes the item “solid content”;

— In this Standard, it deletes the item “fineness”;

— In this Standard, it uses “contrast ratio” to replace the item “hiding rate”;

— In this Standard, the indicators “water resistance”, “alkali resistance”

and “artificial climate ageing resistance” have been increased to some

extent;

— In this Standard, the cycling number of “coating’s temperature

resistance” is changed from 10 times to 5 times.

Appendix A of this Standard is a standard Appendix.

This Standard shall replace GB/T 9757-1988 from the implementation date.

This Standard was proposed by State Bureau of Petroleum and Chemical

Industry.

This Standard shall be centralized by National Paints and Pigments

Standardization Technical Committee.

Main drafting organization of this Standard. Shanghai Watson Chemical Plant,

Nanjing Huacai Special Paint Factory, and Changzhou Coating Chemical

Research Institute of China National Chemical Construction Corporation.

Main drafters of this Standard. Wang Jianzhong, Li Hongjin, Liu Jiyuan,

Zhaoling, and Feng Shifang.

This Standard was issued first-time in 1988.

This Standard shall be explained by National Paints and Pigments

Standardization Technical Committee.

National Standard of the People’s Republic of China

Solvent-thinned coatings for exterior wall

Replacing GB/T 9757-1988

1 Scope

This Standard specifies product classification, requirements, test methods,

inspection rules, marking, packaging, and storage of solvent-thinned coatings

for exterior wall.

This Standard applies to solvent-thinned coatings for exterior wall of which the

basic material is synthetic resin; which is made of pigments, body pigments and

other auxiliaries; and after being smeared, which can form a thin coating with

flat surface. This coating applies to decoration and protection of external

surface of buildings and structures.

2 Normative references

The articles contained in the following documents have become part of this

Standard when they are quoted herein. For the dated documents so quoted, all

the modifications or revisions made thereafter shall not be applicable to this

Standard. For the undated documents so quoted, the latest editions shall be

applicable to this Standard.

GB/T 1250-1989 Rules for expression and judgment of limiting values

GB/T 1727-1992 Methods of producing films of paints, varnishes, lacquers and

related products on test plates

GB/T 1728-1979 (1989) Methods of test for drying time of coatings of paints

and putties

GB/T 1733-1993 Determination of resistance to water of films

GB/T 1766-1995 Paint and varnish - Rating schemes of degradation of coats

GB/T 1865-1997 Paints and varnishes-Artificial weathering and exposure to

artificial radiation-Filtered xenon-arc radiation (eqv ISO 11341.1994)

GB 3186-1982 (1989) Sampling paint products (neq ISO 1512.1974)

GB/T 6682-1992 Water for laboratory use; Specifications (neq ISO 3696.1987)

GB/T 9265-1988 Determination for alkali resistance of film of architectural

paints and coatings

GB/T 9266-1988 Determination of scrub resistance of film of architectural paints

and coatings

GB/T 9270-1988 Determination of contrast ratio of light colored paints (using

polyester film) (eqv ISO 3906.1980)

GB/T 9271-1988 Paints and varnishes - Standard plates for testing (eqv ISO

1514.1984)

GB 9278-1988 Temperatures and humidities for conditioning and testing of

paint specimens (eqv ISO 3270.1984)

GB/T 9750-1998 Marks for package of coating products

GB/T 13491-1992 General rule for packing of coatings

GB/T 15608-1995 The Chinese color system

HG/T 2458-1993 General Rules for the Inspection, Transportation and Storage

of Paint Products

JC/T 412-1991 Asbestos cement flat sheets for architecture

JG/T 25-1999 Determination for freeze-thaw resistance of film of building

coatings

3 Product Classification

The products are divided into 3 grades. superior product, first grade product,

and qualified product.

4 Requirements

Products shall meet the technical requirements of Table 1.

It shall be done according to GB/T 9750. If it needs dilution, diluent and dilution

rate shall be indicated.

7.2 Packaging

It shall be done according to the grade 1 packaging requirements in GB/T 13491.

7.3 Storage

Product storage shall ensure ventilation, desiccation. It shall prevent from direct

sunlight and it shall isolate the source of fire and be away from heat. According

to the type of resin, product shall formulate the storage life and indicate it on

the packaging logos.

Appendix A

(Standard appendix)

The test method of coating stain resistance

A.1 Principle

This method uses fly ash as contaminated media, and mixes it together with

water to brush on the coating plate. WASH it with water after drying. After a

specified cycle, DETERMINE the decreasing rate of reflection coefficient of

coating, so as to express the coating stain resistance.

A.2 Main material, instruments and device

A.2.1 Fly ash1)

A.2.2 Reflectance instrument

Comply with the provision 4.3 of GB/T 9270-1988.

A.2.3 Balance

Sensitivity of 0.1g.

A.2.4 Soft brush

Width of (25~50) mm.

A.2.5 Flushing device

As shown in figure 1. Water tank, water pipes and sample frames are made of

rust-resistant and hard material.

A.3 Test

A.3.1 Preparation of fly-ash water

Weigh appropriate fly ash in the mixing container, and mixed it with water evenly

according to the proportion of 1.1 (mass).

A.3.2 Operation

DETERMINE the original reflection coefficient of the after-care coating test

plates at 3 positions at least, TAKE its average value, and DENOTE as A. USE

soft brush to brush (0.7±0.1)g of fly ash onto the coating surface, crisscross and

evenly. After drying it under the conditions of (23±2)ºC and relative humidity of

(50±5)% for 2 h, PLACE it on the sample frame. ADD 15L water into water tank

of flushing device. OPEN the valve to maximum to wash the sample plate.

When washing, MOVE the sample plate constantly, so as to make sure that

every part of the sample plate can go through the water flow. FLUSH for 1 min.

CLOSE the valve. DRY the plate under the conditions of (23±2)ºC and relative

humidity of (50±5)% until the next day, this is considered 1 cycle, about 24h.

According to above brushing and flushing method, CONTINUE to test it until 5

cycles. DETERMINE the reflection coefficient of the coating test plate at 3

positions at least, TAKE its average value, DENOTE as B. Befor...

Share