1

/

の

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 9914.2-2013 English PDF (GBT9914.2-2013)

GB/T 9914.2-2013 English PDF (GBT9914.2-2013)

通常価格

$155.00 USD

通常価格

セール価格

$155.00 USD

単価

/

あたり

配送料はチェックアウト時に計算されます。

受取状況を読み込めませんでした

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click GB/T 9914.2-2013 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 9914.2-2013

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 9914.2-2013: Test method for reinforcement products -- Part 2: Determination of combustible-matter content for glass fibre

GB/T 9914.2-2013

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.100.10

Q 36

Replacing GB/T 9914.2-2001

Test method for reinforcement products - Part 2:

Determination of combustible-matter content for glass fiber

(ISO 1887:1995, Textile glass - Determination of combustible-matter content,

MOD)

ISSUED ON: NOVEMBER 27, 2013

IMPLEMENTED ON: AUGUST 01, 2014

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

National Standardization Administration.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Terms and definitions ... 5

3 Principle ... 5

4 Instruments ... 5

5 Specimens ... 6

6 Operation ... 8

7 Result expression ... 9

8 Precision ... 10

9 Test report ... 10

Test method for reinforcement products - Part 2:

Determination of combustible-matter content for glass fiber

1 Scope

This Part of GB/T 9914 specifies the method for determining the combustible-matter

content of glass fiber products.

This method is applicable to continuous fiber yarn, fixed-length fiber yarn, untwisted

roving, chopped strands, milled fiber, fabric, chopped strand mat, continuous strand mat

and other forms of reinforcement products.

2 Terms and definitions

The following terms and definitions apply to this document.

2.1

Combustible-matter content

The ratio of the loss on ignition of dry glass fiber products to the mass of dry

products.

Note: The ratio is expressed as a percentage. When the sizing agent or treatment agent on

the glass fiber product is completely burned without residue (i.e., the original organic

matter), this value is equal to the content of the sizing agent or treatment agent.

3 Principle

Under specified conditions, place the dry specimen at a temperature of (625 ± 20) °C

and burn it. Weigh the mass of the specimen before and after burning. For glass that is

unstable at this temperature, a temperature of 500 °C ~ 600 °C can be selected, which

shall be constant within the range of ±20 °C of the selected temperature.

4 Instruments

4.1 Ventilated oven: The temperature can be controlled at (105 ± 3) °C or the selected

temperature ±3 °C (see 6.3).

4.2 Muffle furnace: The temperature can be controlled at (625 ± 20) °C or the selected

The mass of each specimen shall be not less than 5 g, preferably within 15 g ~ 30 g.

5.1.4 Fabric

The mass of each specimen shall be not less than 5 g.

Cut a specimen with an area of 100 cm2. If the specimen mass is less than 5 g, a larger

specimen shall be cut or several adjacent specimens with an area of 100 cm2 shall be

taken.

The specimen size can be the same as the specimen for measuring the mass per unit

area.

The woven fabric specimen shall be cut at least 10 mm away from the edge of the cloth

or the selvedge. If the specimen must be folded, it shall not hinder the flow of air over

the entire specimen surface. It is recommended to use a template (4.7) and a shearing

tool or a punching device (4.8) to cut the specimen to avoid material loss.

5.1.5 Felt

The mass of the specimen shall be at least 5 g. The recommended specimen is a 316

mm × 316 mm square (0.1 m2); other specimens with a surface area close to 0.1 m2 may

also be used. If other specimen shapes are used, the following specimen preparation

process shall be modified appropriately.

If more than one squares must be used to achieve the minimum specimen mass, the

square specimens shall be cut along the same straight line along the length of the felt

roll.

Cut a felt strip at least 316 mm long across the width of the felt and cut the specimens

from the felt strip using a template (4.7) and a cutting tool (4.8):

a) Cut a 316 mm × 316 mm specimen at each end of the felt strip (for felt strips

with trimmed edges, at least 10 mm from the edge).

b) Cut as many 316 mm × 316 mm specimens as possible between the specimens

at the two ends (these specimens shall be evenly distributed).

5.2 Number of specimens

Unless the product specification or the test client has different or more detailed

instructions (i.e., quantity and location), the number of specimens per unit product shall

be as specified in Table 2.

Note: The number of specimens for the determination of combustible-matter content may vary

depending on the form of the unit product. In addition, the test may be repeated at one or more

locations depending on the mass (chopped strands, milled fibers) or length (fabric, felt) of the

unit product being tested. Additional information on the number of specimens and the sampling

Heat the specimen for at least 30 minutes.

Take the specimen dish and the specimen out of the oven and place them in a desiccator

(4.3) to cool for 30 minutes.

Weigh the total mass of the specimen dish and the dried specimen; record it as m1,

accurate to 0.1 mg.

Repeat heating, cooling, weighing, until the mass is constant (see Note 3).

6.4 Weigh the mass of the specimen and the specimen dish after burning

Place the specimen dish and the dried specimen in a muffle furnace (4.2); control the

furnace temperature at (625 ± 20) °C or any selected temperature within 500 °C ~

600 °C (see 6.2).

Open the furnace door; let the specimen burn for 5 minutes (see Notes 1 and 2). Then

close the furnace door and burn for another 30 minutes. If the selected temperature is

lower than 625 °C, the burning time after closing the furnace door shall be increased to

at least 1 hour.

Move the specimen and the specimen dish from the muffle furnace into a desiccator

(4.3); cool to room temperature.

Weigh the total mass of the specimen dish and the specimen after burning; record it as

m2, accurate to 0.1 mg.

Repeat heating, cooling, weighing, until the mass is constant (see Note 3).

Note 1: Open the furnace door to allow volatiles to escape from the furnace, to prevent

condensation from depositing on the specimen or specimen dish.

Note 2: If a ventilated muffle furnace is used, the furnace door does not need to be opened.

Note 3: This method requires that all weighing shall be repeated for drying and burning to

ensure constant mass. If the material is tested frequently, the shortest time for the drying and

burning stages can be determined experimentally to ensure constant mass.

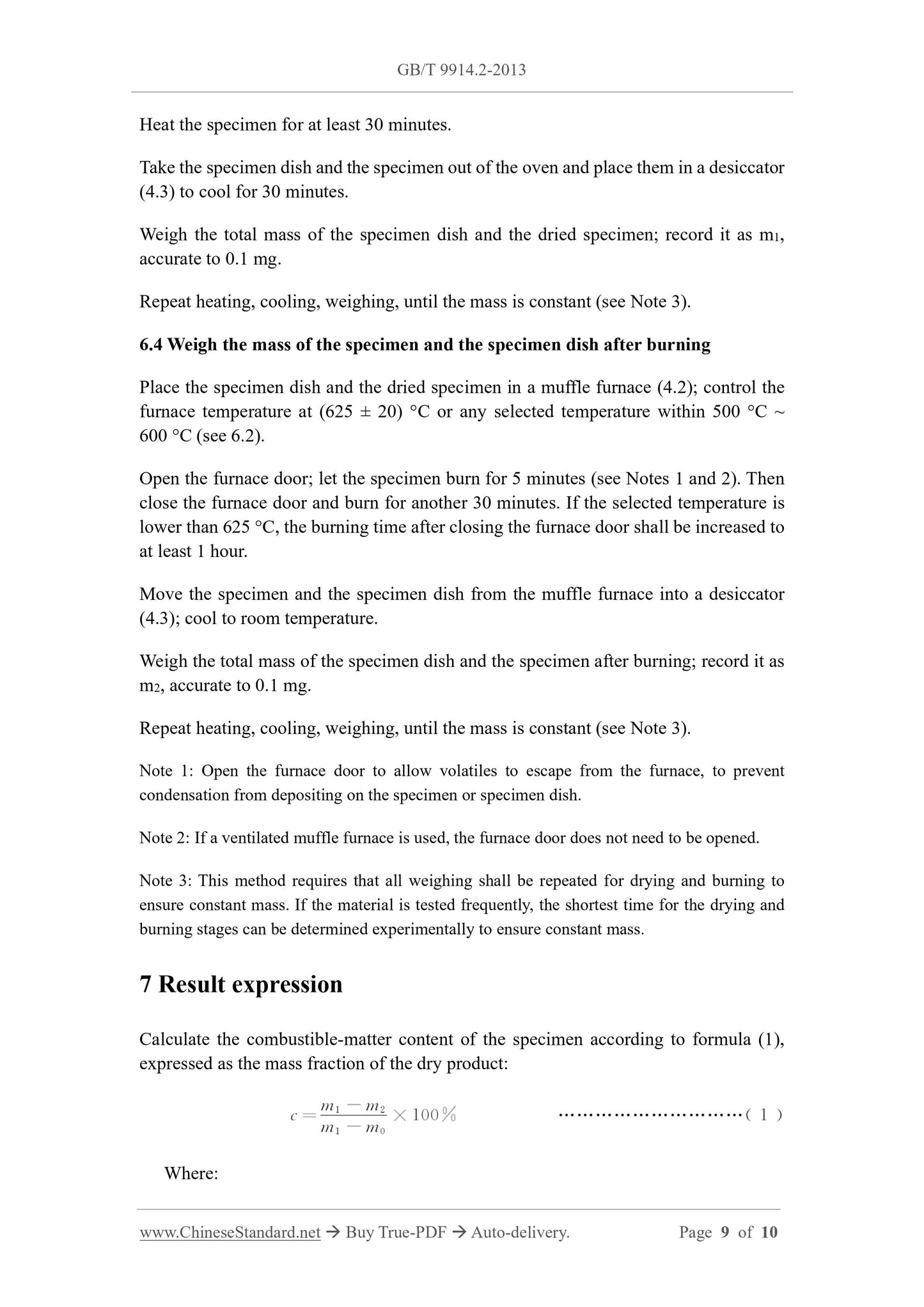

7 Result expression

Calculate the combustible-matter content of the specimen according to formula (1),

expressed as the mass fraction of the dry product:

Where:

Get Quotation: Click GB/T 9914.2-2013 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 9914.2-2013

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 9914.2-2013: Test method for reinforcement products -- Part 2: Determination of combustible-matter content for glass fibre

GB/T 9914.2-2013

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.100.10

Q 36

Replacing GB/T 9914.2-2001

Test method for reinforcement products - Part 2:

Determination of combustible-matter content for glass fiber

(ISO 1887:1995, Textile glass - Determination of combustible-matter content,

MOD)

ISSUED ON: NOVEMBER 27, 2013

IMPLEMENTED ON: AUGUST 01, 2014

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

National Standardization Administration.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Terms and definitions ... 5

3 Principle ... 5

4 Instruments ... 5

5 Specimens ... 6

6 Operation ... 8

7 Result expression ... 9

8 Precision ... 10

9 Test report ... 10

Test method for reinforcement products - Part 2:

Determination of combustible-matter content for glass fiber

1 Scope

This Part of GB/T 9914 specifies the method for determining the combustible-matter

content of glass fiber products.

This method is applicable to continuous fiber yarn, fixed-length fiber yarn, untwisted

roving, chopped strands, milled fiber, fabric, chopped strand mat, continuous strand mat

and other forms of reinforcement products.

2 Terms and definitions

The following terms and definitions apply to this document.

2.1

Combustible-matter content

The ratio of the loss on ignition of dry glass fiber products to the mass of dry

products.

Note: The ratio is expressed as a percentage. When the sizing agent or treatment agent on

the glass fiber product is completely burned without residue (i.e., the original organic

matter), this value is equal to the content of the sizing agent or treatment agent.

3 Principle

Under specified conditions, place the dry specimen at a temperature of (625 ± 20) °C

and burn it. Weigh the mass of the specimen before and after burning. For glass that is

unstable at this temperature, a temperature of 500 °C ~ 600 °C can be selected, which

shall be constant within the range of ±20 °C of the selected temperature.

4 Instruments

4.1 Ventilated oven: The temperature can be controlled at (105 ± 3) °C or the selected

temperature ±3 °C (see 6.3).

4.2 Muffle furnace: The temperature can be controlled at (625 ± 20) °C or the selected

The mass of each specimen shall be not less than 5 g, preferably within 15 g ~ 30 g.

5.1.4 Fabric

The mass of each specimen shall be not less than 5 g.

Cut a specimen with an area of 100 cm2. If the specimen mass is less than 5 g, a larger

specimen shall be cut or several adjacent specimens with an area of 100 cm2 shall be

taken.

The specimen size can be the same as the specimen for measuring the mass per unit

area.

The woven fabric specimen shall be cut at least 10 mm away from the edge of the cloth

or the selvedge. If the specimen must be folded, it shall not hinder the flow of air over

the entire specimen surface. It is recommended to use a template (4.7) and a shearing

tool or a punching device (4.8) to cut the specimen to avoid material loss.

5.1.5 Felt

The mass of the specimen shall be at least 5 g. The recommended specimen is a 316

mm × 316 mm square (0.1 m2); other specimens with a surface area close to 0.1 m2 may

also be used. If other specimen shapes are used, the following specimen preparation

process shall be modified appropriately.

If more than one squares must be used to achieve the minimum specimen mass, the

square specimens shall be cut along the same straight line along the length of the felt

roll.

Cut a felt strip at least 316 mm long across the width of the felt and cut the specimens

from the felt strip using a template (4.7) and a cutting tool (4.8):

a) Cut a 316 mm × 316 mm specimen at each end of the felt strip (for felt strips

with trimmed edges, at least 10 mm from the edge).

b) Cut as many 316 mm × 316 mm specimens as possible between the specimens

at the two ends (these specimens shall be evenly distributed).

5.2 Number of specimens

Unless the product specification or the test client has different or more detailed

instructions (i.e., quantity and location), the number of specimens per unit product shall

be as specified in Table 2.

Note: The number of specimens for the determination of combustible-matter content may vary

depending on the form of the unit product. In addition, the test may be repeated at one or more

locations depending on the mass (chopped strands, milled fibers) or length (fabric, felt) of the

unit product being tested. Additional information on the number of specimens and the sampling

Heat the specimen for at least 30 minutes.

Take the specimen dish and the specimen out of the oven and place them in a desiccator

(4.3) to cool for 30 minutes.

Weigh the total mass of the specimen dish and the dried specimen; record it as m1,

accurate to 0.1 mg.

Repeat heating, cooling, weighing, until the mass is constant (see Note 3).

6.4 Weigh the mass of the specimen and the specimen dish after burning

Place the specimen dish and the dried specimen in a muffle furnace (4.2); control the

furnace temperature at (625 ± 20) °C or any selected temperature within 500 °C ~

600 °C (see 6.2).

Open the furnace door; let the specimen burn for 5 minutes (see Notes 1 and 2). Then

close the furnace door and burn for another 30 minutes. If the selected temperature is

lower than 625 °C, the burning time after closing the furnace door shall be increased to

at least 1 hour.

Move the specimen and the specimen dish from the muffle furnace into a desiccator

(4.3); cool to room temperature.

Weigh the total mass of the specimen dish and the specimen after burning; record it as

m2, accurate to 0.1 mg.

Repeat heating, cooling, weighing, until the mass is constant (see Note 3).

Note 1: Open the furnace door to allow volatiles to escape from the furnace, to prevent

condensation from depositing on the specimen or specimen dish.

Note 2: If a ventilated muffle furnace is used, the furnace door does not need to be opened.

Note 3: This method requires that all weighing shall be repeated for drying and burning to

ensure constant mass. If the material is tested frequently, the shortest time for the drying and

burning stages can be determined experimentally to ensure constant mass.

7 Result expression

Calculate the combustible-matter content of the specimen according to formula (1),

expressed as the mass fraction of the dry product:

Where:

Share