1

/

の

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

NB/T 47010-2017 English PDF (NB/T47010-2017)

NB/T 47010-2017 English PDF (NB/T47010-2017)

通常価格

$245.00 USD

通常価格

セール価格

$245.00 USD

単価

/

あたり

配送料はチェックアウト時に計算されます。

受取状況を読み込めませんでした

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click NB/T 47010-2017

Historical versions: NB/T 47010-2017

Preview True-PDF (Reload/Scroll if blank)

NB/T 47010-2017: Stainless and heat-resisting steel forgings for pressure equipment

NB/T 47010-2017

NB

ENERGY INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.85

J 32

Replacing NB/T 47010-2010, JB/T 9626-1999

Stainless and heat-resisting steel forgings for

pressure equipment

ISSUED ON: MARCH 28, 2017

IMPLEMENTED ON: AUGUST 01, 2017

Issued by: National Energy Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Order content ... 8

5 Technical requirements ... 9

6 Test method ... 16

7 Inspection rules ... 17

8 Markings and quality certificates ... 20

Appendix A (Informative) Forgings for boiler's matching valves AND special

components ... 21

Appendix B (Normative) Additional requirements ... 22

Appendix C (Informative) High temperature mechanical properties ... 24

Stainless and heat-resisting steel forgings for

pressure equipment

1 Scope

This standard specifies the terms and definitions, order content, technical

requirements, test methods, inspection rules, markings and quality certificates,

of stainless steel and heat-resisting steel forgings for pressure equipment.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) is applicable to this standard.

GB/T 222 Permissible tolerances for chemical composition of steel products

GB/T 223 Steel, iron and alloy - Chemical analysis method (applicable part)

GB/T 226 Test method for macrostructure and defect of steel by etching

GB/T 228.1 Metallic materials - Tensile testing - Part 1: Method of test at

room temperature

GB/T 228.2 Metallic materials - Tensile testing - Part 2: Method of test at

elevated temperature

GB/T 231.1 Metallic materials - Brinell hardness test - Part 1: Test method

GB/T 6394 Metal - Methods for estimating the average grain size

GB/T 10561 Steel - Determination of content of non-metallic inclusion -

Micrographic method using standard diagrams

GB/T 11170 Stainless steel - Determination of multi-element contents -

Spark discharge atomic emission spectrometric method (Routine method)

GB/T 13298 Inspection methods of microstructure for metals

GB/T 13305 Micrographic method for determining area content of the α-

phases in stainless steels

GB/T 20066 Steel and iron - Sampling and preparation of samples for the

determination of chemical composition

GB/T 20123 Steel and iron - Determination of total carbon and sulfur content

Infrared absorption method after combustion in an induction furnace (routine

method)

GB/T 20124 Steel and iron - Determination of nitrogen content - Thermal

conductimetric method after fusion in a current of inert gas

NB/T 47013.3 Nondestructive testing of pressure equipment - Part 3:

Ultrasonic testing

NB/T 47013.5 Nondestructive testing of pressure equipment - Part 5:

Penetrant testing

3 Terms and definitions

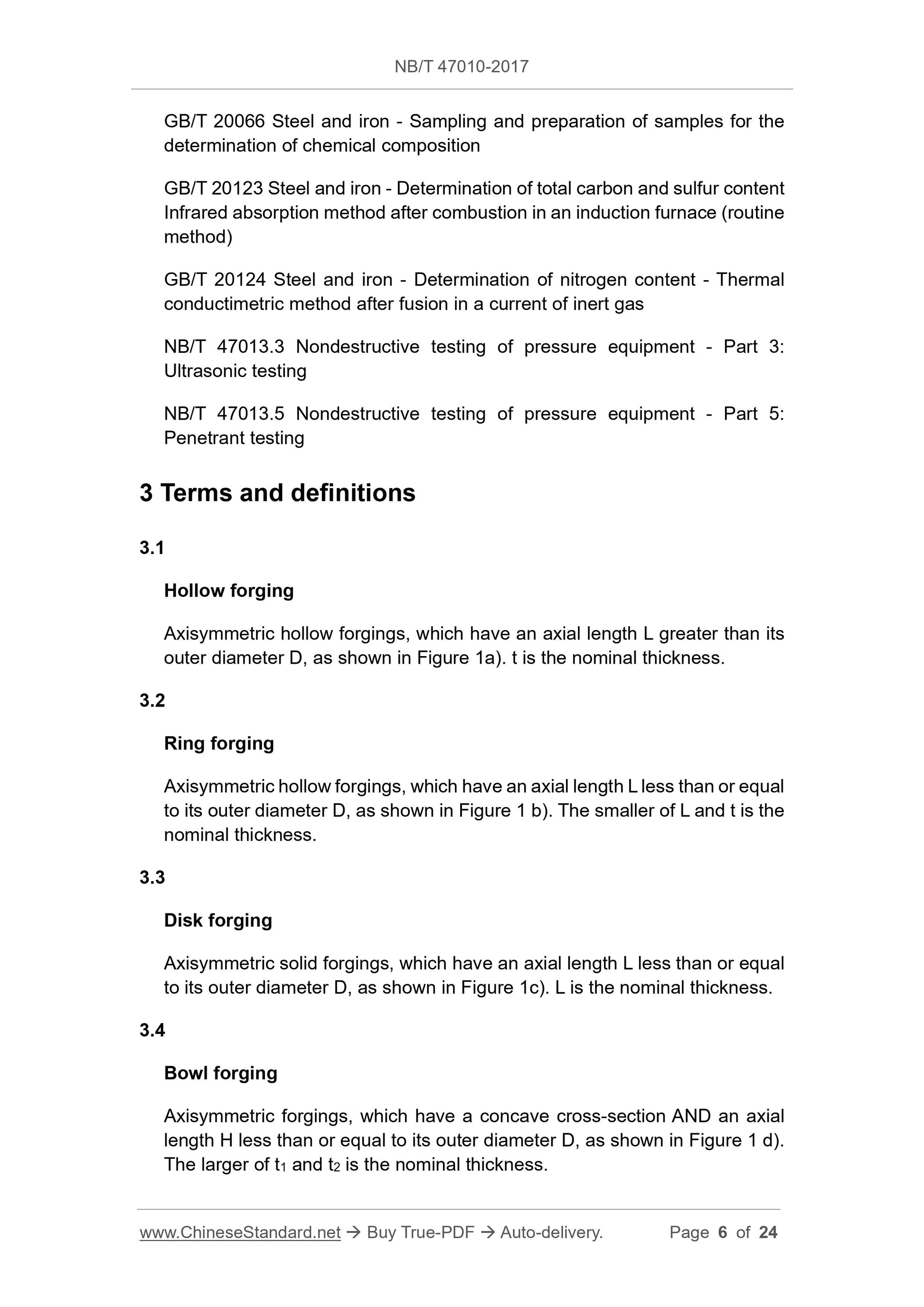

3.1

Hollow forging

Axisymmetric hollow forgings, which have an axial length L greater than its

outer diameter D, as shown in Figure 1a). t is the nominal thickness.

3.2

Ring forging

Axisymmetric hollow forgings, which have an axial length L less than or equal

to its outer diameter D, as shown in Figure 1 b). The smaller of L and t is the

nominal thickness.

3.3

Disk forging

Axisymmetric solid forgings, which have an axial length L less than or equal

to its outer diameter D, as shown in Figure 1c). L is the nominal thickness.

3.4

Bowl forging

Axisymmetric forgings, which have a concave cross-section AND an axial

length H less than or equal to its outer diameter D, as shown in Figure 1 d).

The larger of t1 and t2 is the nominal thickness.

5.10.1 The shape, size, surface quality of the forging shall meet the

requirements of the order drawing.

5.10.2 The outer surface of the forging shall be free of harmful defects, such as

cracks, interlayers, folds, inclusions, etc., that are visible to the naked eye.

5.10.3 Defects, on the appearance of forgings, can be removed by machining

or grinding. The grinding part shall have a smooth transition. The grinding depth

shall meet the following requirements:

a) For non-machined surfaces, the grinding depth shall not exceed the lower

deviation of the nominal size, at this place;

b) For the machined surface, the grinding depth shall not exceed 75% of the

thickness allowance.

5.11 Welding repairs

5.11.1 Welding repairs for steel forgings are not allowed, without the consent of

the buyer.

5.11.2 With the consent of the purchaser, the welding repair of steel forgings

shall comply with the relevant regulations and standards. The position, depth,

area, welding consumables, welding process, welder qualification requirements,

non-destructive testing methods before and after welding repair, qualification

level, etc., shall be negotiated, between the supplier and the buyer.

5.11.3 The supplier shall provide the purchaser, with a schematic diagram of

the location, depth and area of the welding repair for forgings, welding materials,

welding process parameters, as well as non-destructive test reports.

5.12 Additional requirements

According to the requirements of the buyer, as negotiated between the supplier

and the buyer, AND indicated in the contract, it may add other inspection items

in Appendix B.

6 Test method

6.1 Chemical analysis

Chemical analysis is in accordance with GB/T 223 or GB/T 11170, GB/T 20123,

GB/T 20124. The arbitration test is in accordance with GB/T 223.

6.2 Tensile test

The room temperature tensile test is in accordance with the provisions of GB/T

228.1. The high temperature tensile test is in accordance with the provisions of

GB/T 228.2.

6.3 Hardness test

The hardness test is in accordance with GB/T 231.1.

6.4 Macroscopic inspection

The macroscopic inspection shall be in accordance with the provisions of GB/T

226.

6.5 Metallographic inspection

The grain size inspection is in accordance with the provisions of GB/T 6394.

The inspection of non-metallic inclusions shall be graded in accordance with

the method A in GB/T 10561. The microstructure inspection shall be in

accordance with the provisions of GB/T 13298. For the phase ratio inspection

of duplex steel, it may use GB/T 13305 to determine the ferrite content.

6.6 Ultrasonic testing

Ultrasonic testing is in accordance with NB/T 47013.3.

6.7 Visual inspection

The appearance inspection of forgings shall be visually inspected, under

sufficient lighting conditions.

7 Inspection rules

7.1 Inspection

The inspection of forgings is carried out by the supplier's inspection department.

7.2 Specimen requirements

7.2.1 The specimens, for chemical analysis, shall be prepared, in accordance

with the provisions of GB/T 20066.

7.2.2 The tensile specimen shall be the No. R4 specimen in GB/T 228.1. If

limited by the sampling size, according to the agreement between the supplier

and the buyer, it may also use the No. R7 specimen in GB/T 228.1.

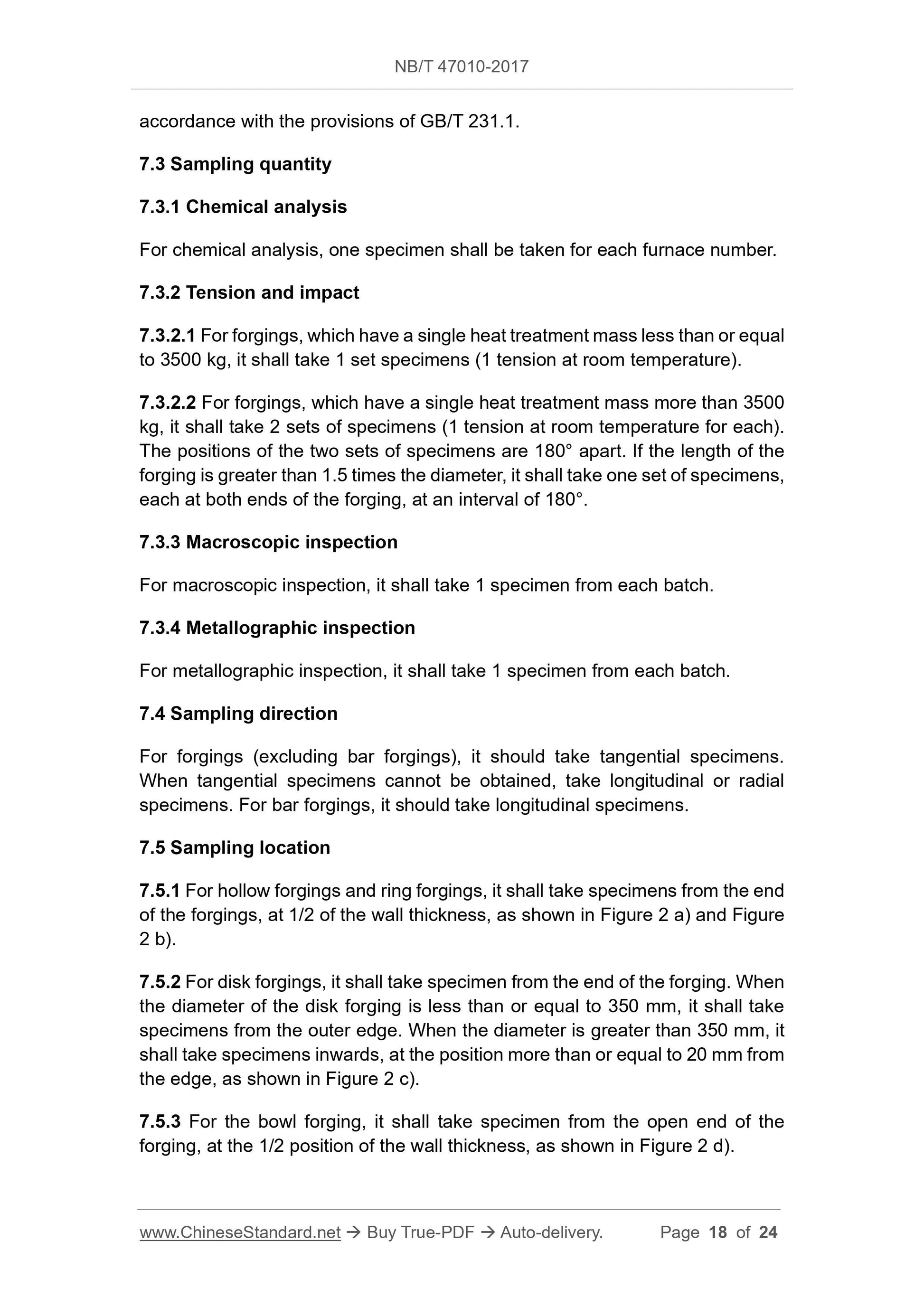

7.2.3 The hardness test of level I forgings can be carried out, on the rough

surface of the forging blank AND at the sampling position, as shown in Figure

2. The hardness test specimens of other levels of forgings shall be prepared, in

accordance with the provisions of GB/T 231.1.

7.3 Sampling quantity

Get QUOTATION in 1-minute: Click NB/T 47010-2017

Historical versions: NB/T 47010-2017

Preview True-PDF (Reload/Scroll if blank)

NB/T 47010-2017: Stainless and heat-resisting steel forgings for pressure equipment

NB/T 47010-2017

NB

ENERGY INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.85

J 32

Replacing NB/T 47010-2010, JB/T 9626-1999

Stainless and heat-resisting steel forgings for

pressure equipment

ISSUED ON: MARCH 28, 2017

IMPLEMENTED ON: AUGUST 01, 2017

Issued by: National Energy Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Order content ... 8

5 Technical requirements ... 9

6 Test method ... 16

7 Inspection rules ... 17

8 Markings and quality certificates ... 20

Appendix A (Informative) Forgings for boiler's matching valves AND special

components ... 21

Appendix B (Normative) Additional requirements ... 22

Appendix C (Informative) High temperature mechanical properties ... 24

Stainless and heat-resisting steel forgings for

pressure equipment

1 Scope

This standard specifies the terms and definitions, order content, technical

requirements, test methods, inspection rules, markings and quality certificates,

of stainless steel and heat-resisting steel forgings for pressure equipment.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) is applicable to this standard.

GB/T 222 Permissible tolerances for chemical composition of steel products

GB/T 223 Steel, iron and alloy - Chemical analysis method (applicable part)

GB/T 226 Test method for macrostructure and defect of steel by etching

GB/T 228.1 Metallic materials - Tensile testing - Part 1: Method of test at

room temperature

GB/T 228.2 Metallic materials - Tensile testing - Part 2: Method of test at

elevated temperature

GB/T 231.1 Metallic materials - Brinell hardness test - Part 1: Test method

GB/T 6394 Metal - Methods for estimating the average grain size

GB/T 10561 Steel - Determination of content of non-metallic inclusion -

Micrographic method using standard diagrams

GB/T 11170 Stainless steel - Determination of multi-element contents -

Spark discharge atomic emission spectrometric method (Routine method)

GB/T 13298 Inspection methods of microstructure for metals

GB/T 13305 Micrographic method for determining area content of the α-

phases in stainless steels

GB/T 20066 Steel and iron - Sampling and preparation of samples for the

determination of chemical composition

GB/T 20123 Steel and iron - Determination of total carbon and sulfur content

Infrared absorption method after combustion in an induction furnace (routine

method)

GB/T 20124 Steel and iron - Determination of nitrogen content - Thermal

conductimetric method after fusion in a current of inert gas

NB/T 47013.3 Nondestructive testing of pressure equipment - Part 3:

Ultrasonic testing

NB/T 47013.5 Nondestructive testing of pressure equipment - Part 5:

Penetrant testing

3 Terms and definitions

3.1

Hollow forging

Axisymmetric hollow forgings, which have an axial length L greater than its

outer diameter D, as shown in Figure 1a). t is the nominal thickness.

3.2

Ring forging

Axisymmetric hollow forgings, which have an axial length L less than or equal

to its outer diameter D, as shown in Figure 1 b). The smaller of L and t is the

nominal thickness.

3.3

Disk forging

Axisymmetric solid forgings, which have an axial length L less than or equal

to its outer diameter D, as shown in Figure 1c). L is the nominal thickness.

3.4

Bowl forging

Axisymmetric forgings, which have a concave cross-section AND an axial

length H less than or equal to its outer diameter D, as shown in Figure 1 d).

The larger of t1 and t2 is the nominal thickness.

5.10.1 The shape, size, surface quality of the forging shall meet the

requirements of the order drawing.

5.10.2 The outer surface of the forging shall be free of harmful defects, such as

cracks, interlayers, folds, inclusions, etc., that are visible to the naked eye.

5.10.3 Defects, on the appearance of forgings, can be removed by machining

or grinding. The grinding part shall have a smooth transition. The grinding depth

shall meet the following requirements:

a) For non-machined surfaces, the grinding depth shall not exceed the lower

deviation of the nominal size, at this place;

b) For the machined surface, the grinding depth shall not exceed 75% of the

thickness allowance.

5.11 Welding repairs

5.11.1 Welding repairs for steel forgings are not allowed, without the consent of

the buyer.

5.11.2 With the consent of the purchaser, the welding repair of steel forgings

shall comply with the relevant regulations and standards. The position, depth,

area, welding consumables, welding process, welder qualification requirements,

non-destructive testing methods before and after welding repair, qualification

level, etc., shall be negotiated, between the supplier and the buyer.

5.11.3 The supplier shall provide the purchaser, with a schematic diagram of

the location, depth and area of the welding repair for forgings, welding materials,

welding process parameters, as well as non-destructive test reports.

5.12 Additional requirements

According to the requirements of the buyer, as negotiated between the supplier

and the buyer, AND indicated in the contract, it may add other inspection items

in Appendix B.

6 Test method

6.1 Chemical analysis

Chemical analysis is in accordance with GB/T 223 or GB/T 11170, GB/T 20123,

GB/T 20124. The arbitration test is in accordance with GB/T 223.

6.2 Tensile test

The room temperature tensile test is in accordance with the provisions of GB/T

228.1. The high temperature tensile test is in accordance with the provisions of

GB/T 228.2.

6.3 Hardness test

The hardness test is in accordance with GB/T 231.1.

6.4 Macroscopic inspection

The macroscopic inspection shall be in accordance with the provisions of GB/T

226.

6.5 Metallographic inspection

The grain size inspection is in accordance with the provisions of GB/T 6394.

The inspection of non-metallic inclusions shall be graded in accordance with

the method A in GB/T 10561. The microstructure inspection shall be in

accordance with the provisions of GB/T 13298. For the phase ratio inspection

of duplex steel, it may use GB/T 13305 to determine the ferrite content.

6.6 Ultrasonic testing

Ultrasonic testing is in accordance with NB/T 47013.3.

6.7 Visual inspection

The appearance inspection of forgings shall be visually inspected, under

sufficient lighting conditions.

7 Inspection rules

7.1 Inspection

The inspection of forgings is carried out by the supplier's inspection department.

7.2 Specimen requirements

7.2.1 The specimens, for chemical analysis, shall be prepared, in accordance

with the provisions of GB/T 20066.

7.2.2 The tensile specimen shall be the No. R4 specimen in GB/T 228.1. If

limited by the sampling size, according to the agreement between the supplier

and the buyer, it may also use the No. R7 specimen in GB/T 228.1.

7.2.3 The hardness test of level I forgings can be carried out, on the rough

surface of the forging blank AND at the sampling position, as shown in Figure

2. The hardness test specimens of other levels of forgings shall be prepared, in

accordance with the provisions of GB/T 231.1.

7.3 Sampling quantity

Share