1

/

の

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1302.2-2015 English PDF (YYT1302.2-2015)

YY/T 1302.2-2015 English PDF (YYT1302.2-2015)

通常価格

$150.00 USD

通常価格

セール価格

$150.00 USD

単価

/

あたり

配送料はチェックアウト時に計算されます。

受取状況を読み込めませんでした

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY/T 1302.2-2015

Historical versions: YY/T 1302.2-2015

Preview True-PDF (Reload/Scroll if blank)

YY/T 1302.2-2015: Physical requirements and microbiological performance of ethylene oxide sterilization. Part 2: Microbiological aspects

YY/T 1302.2-2015

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.080.01

C 47

Physical requirements and microbiological

performance of ethylene oxide sterilization -

Part 2: Microbiological aspects

ISSUED ON: MARCH 02, 2015

IMPLEMENTED ON: JANUARY 01, 2016

Issued by: China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Process definition ... 5

4.1 Considerations of process definition ... 5

4.2 Process definition method ... 10

4.3 Troubleshooting of the sterilization process definition ... 17

4.4 Process challenge device (PCD) ... 19

5 Validation ... 23

5.1 Microbial performance qualification (MPQ) ... 23

5.2 Sterilization loading ... 25

5.3 Simulating expected process conditions ... 27

5.4 Confirming the release of load ... 27

5.5 Small batch release ... 28

6 Maintenance of process effectiveness ... 29

6.1 Failure investigation ... 29

6.2 Re-qualification ... 31

Physical requirements and microbiological

performance of ethylene oxide sterilization -

Part 2: Microbiological aspects

1 Scope

This part of YY/T 1302 specifies process definition, validation, process

effectiveness maintenance, etc. for the microbiological aspects of ethylene

oxide sterilization.

This part applies to the ethylene oxide sterilization process for medical devices

and other related products or materials, provides solutions to various

microbiological aspects in the development and validation of ethylene oxide

(EO) sterilization processes. This part also provides additional application

guidelines for medical device manufacturers that use the ISO 11135-1:2007 and

ISO/TS 11135-2:2008 standards, including those that use outsourced

sterilization plants or outsourced sterilization operations.

This part of YY/T 1302 does not include various factors that may affect the

product's bioburden and sterilization process.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 19974-2005 Sterilization of health care products - General requirement

for characterization of a sterilization agent and the development, validation

and routine control of a sterilization process for medical devices

ISO 11135-1:2007 Sterilization of health care products - Ethylene oxide -

Part 1: Requirements for development, validation and routine control of a

sterilization process of medical devices

ISO/TS 11135-2:2008 Sterilization of health care products - Ethylene oxide -

Part 2: Guidance on the application of ISO 11135-1

ISO 11138-1:2006 Sterilization of health care products - Biological indicators

development method is based on a number of factors, including the nature of

the product's bioburden, packaging, production conditions, sterilization

equipment, cost. Usually the biological indicator (BI) / bioburden (overkill) or

other established methods are used to develop the parameters required to

achieve the sterility assurance level (SAL) as required by the product.

4.1.2 Parameters on ethylene oxide exposure

Use the cycle development information and consider the SAL of the involved

products to calculate the parameters of cyclic exposure of ethylene oxide. The

recognized SAL includes:

a) For the product that contacts compromised tissue or a sterile part of the

body, the SAL is 10-6;

b) For the product that does not contact the compromised tissue or a sterile

part of the body, the SAL is 10-3.

Note: The SAL for products labeled “sterile” is usually 10-6. SAL requirements for

products labeled as “sterile” may vary from country to country.

Products with multiple sterility assurance levels - Some products contain

components or assemblies that are different for the intended use. In the kit,

components for un-compromised skin or mucosa or that are not expected to

come into contact with the patient have different SAL requirements than

components that are expected to come into contact with internal tissues,

nervous systems or blood. Based on the intended use of the device, the

sterilization process shall achieve the required kill rate for each component.

4.1.3 Product packaging

The product package shall be breathable and resistant to changes of

vacuum/pressure rise as well as vacuum/pressure rise rates.

4.1.4 Process development method

If the product is produced in a controlled environment and the amount of

bioburden continues to be low, the process development method used to

identify sterilization parameters may be the bioburden/biological indicator

method. But it needs understanding different microbial species on the product.

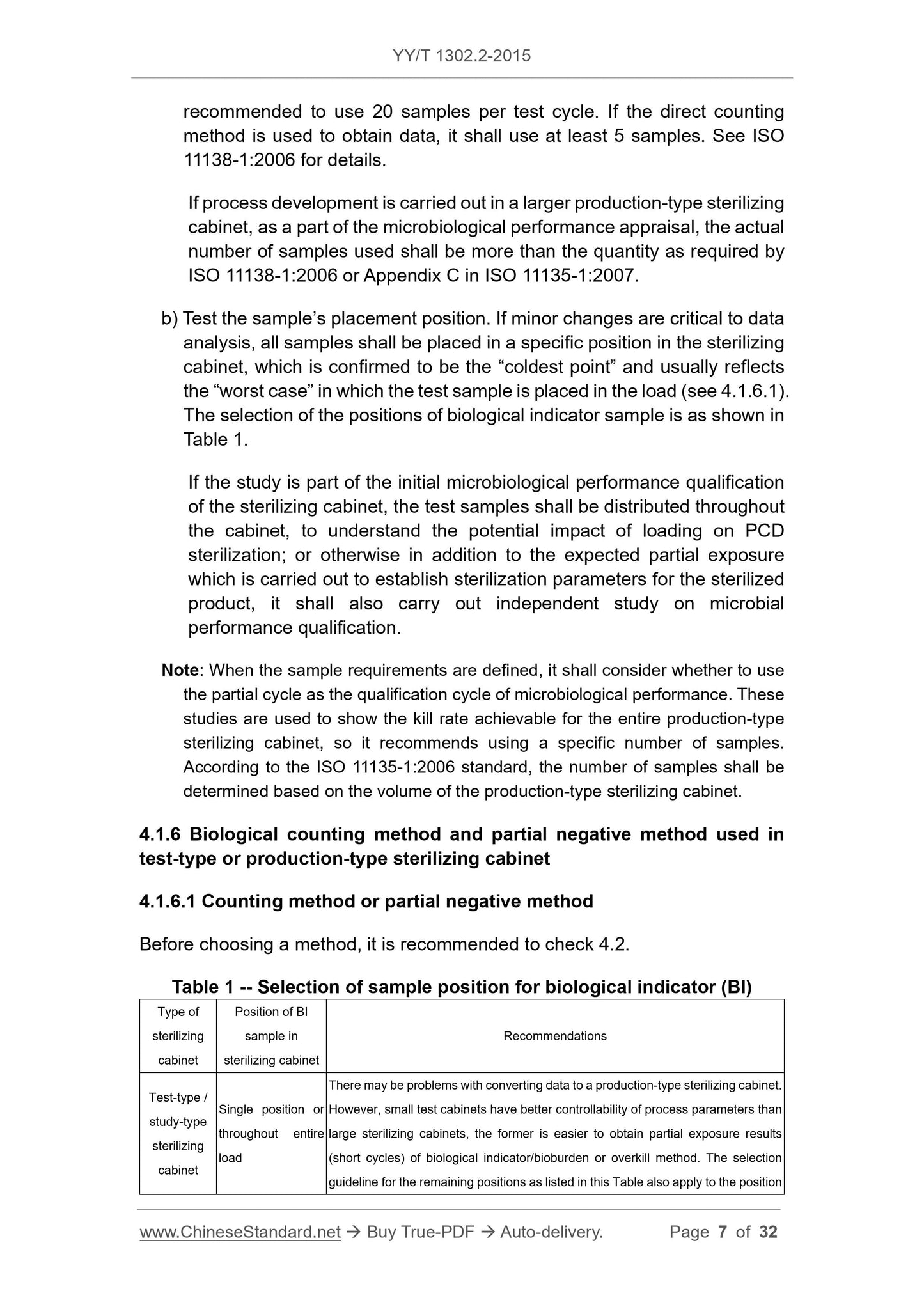

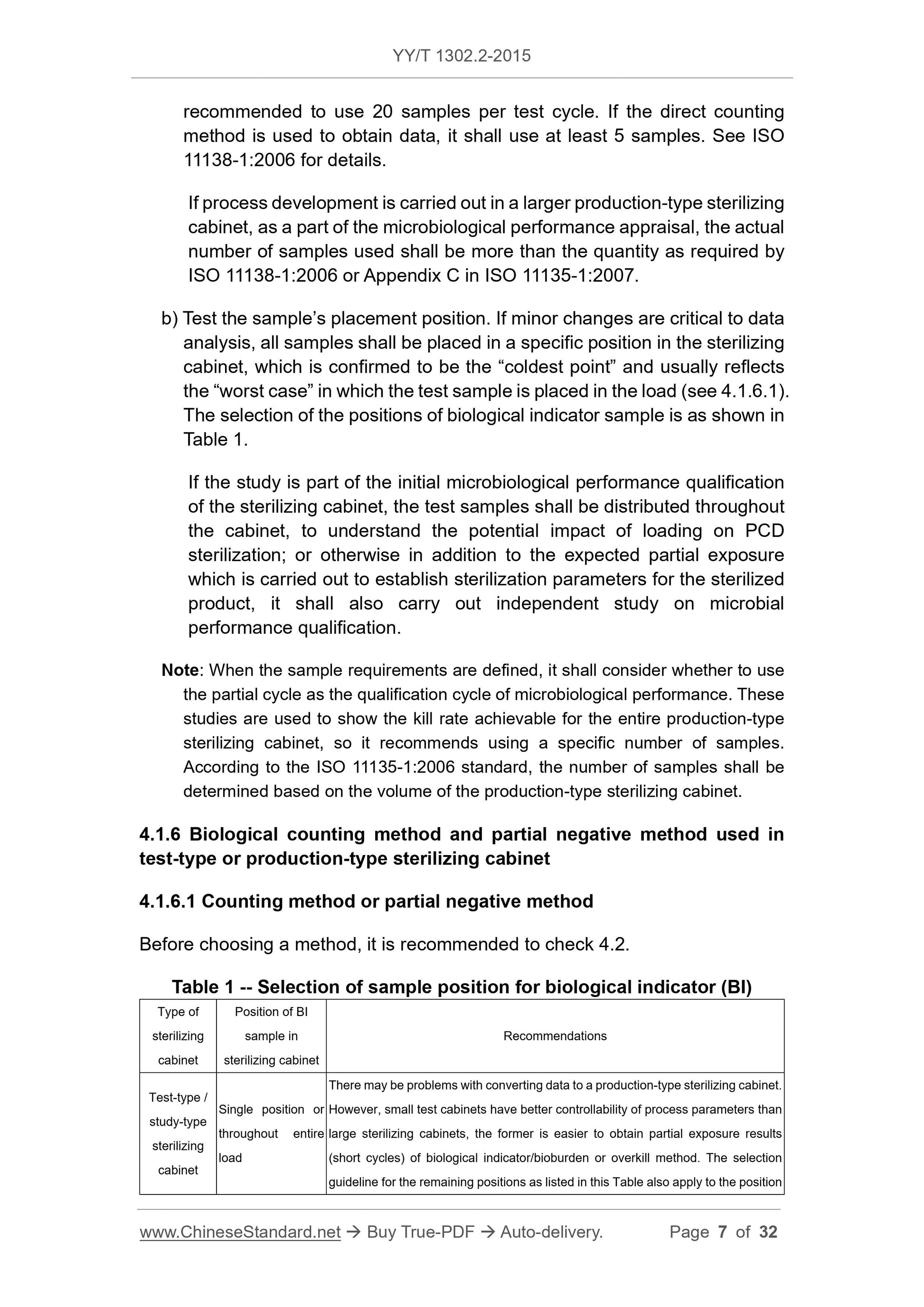

4.1.5 Considerations in sampling for process development study

Before the start of the study, the process development study shall consider the

following two factors:

a) Determine the method of use: Partial negative method or direct counting

method. If partial negative method is used to obtain data, it is

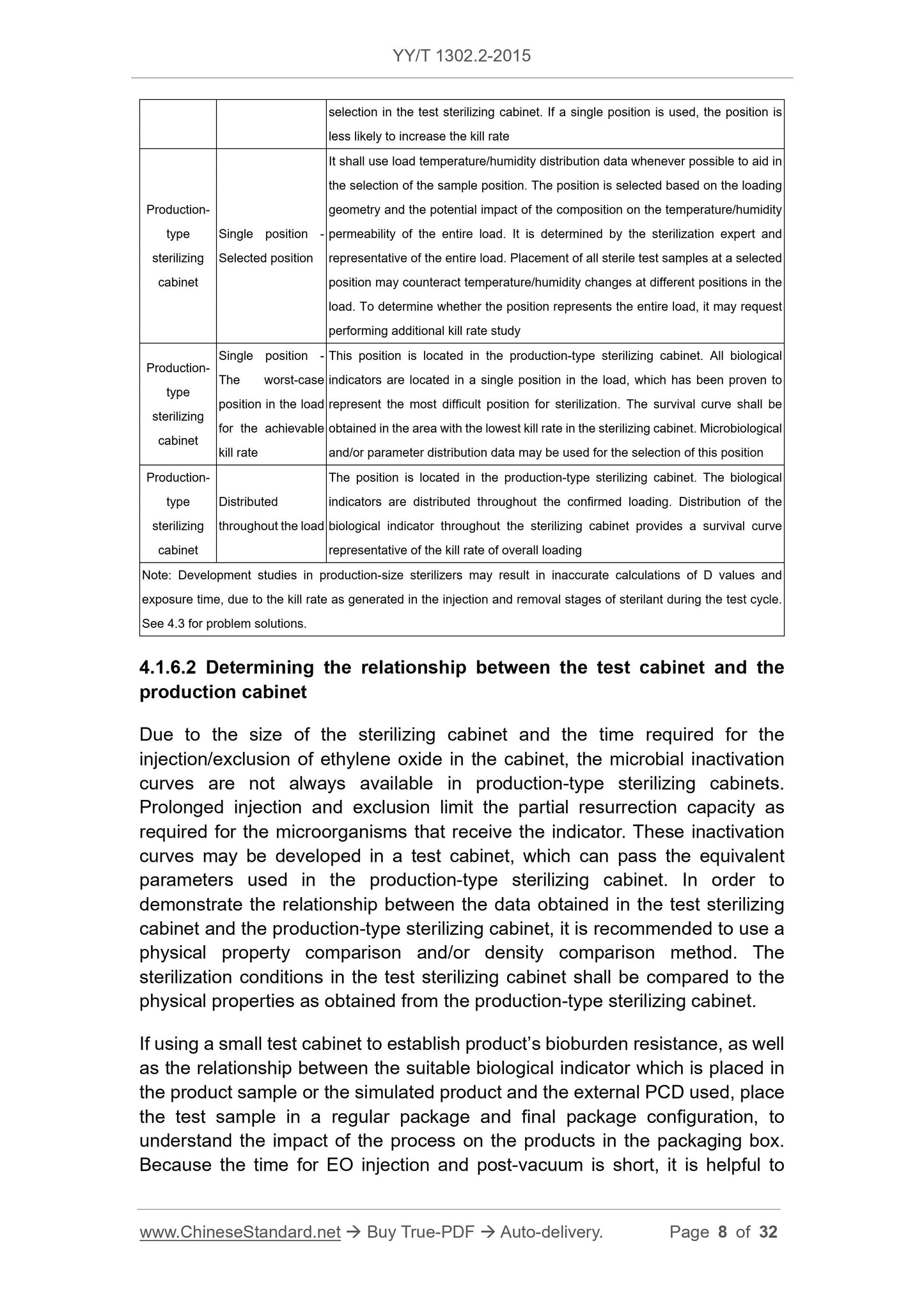

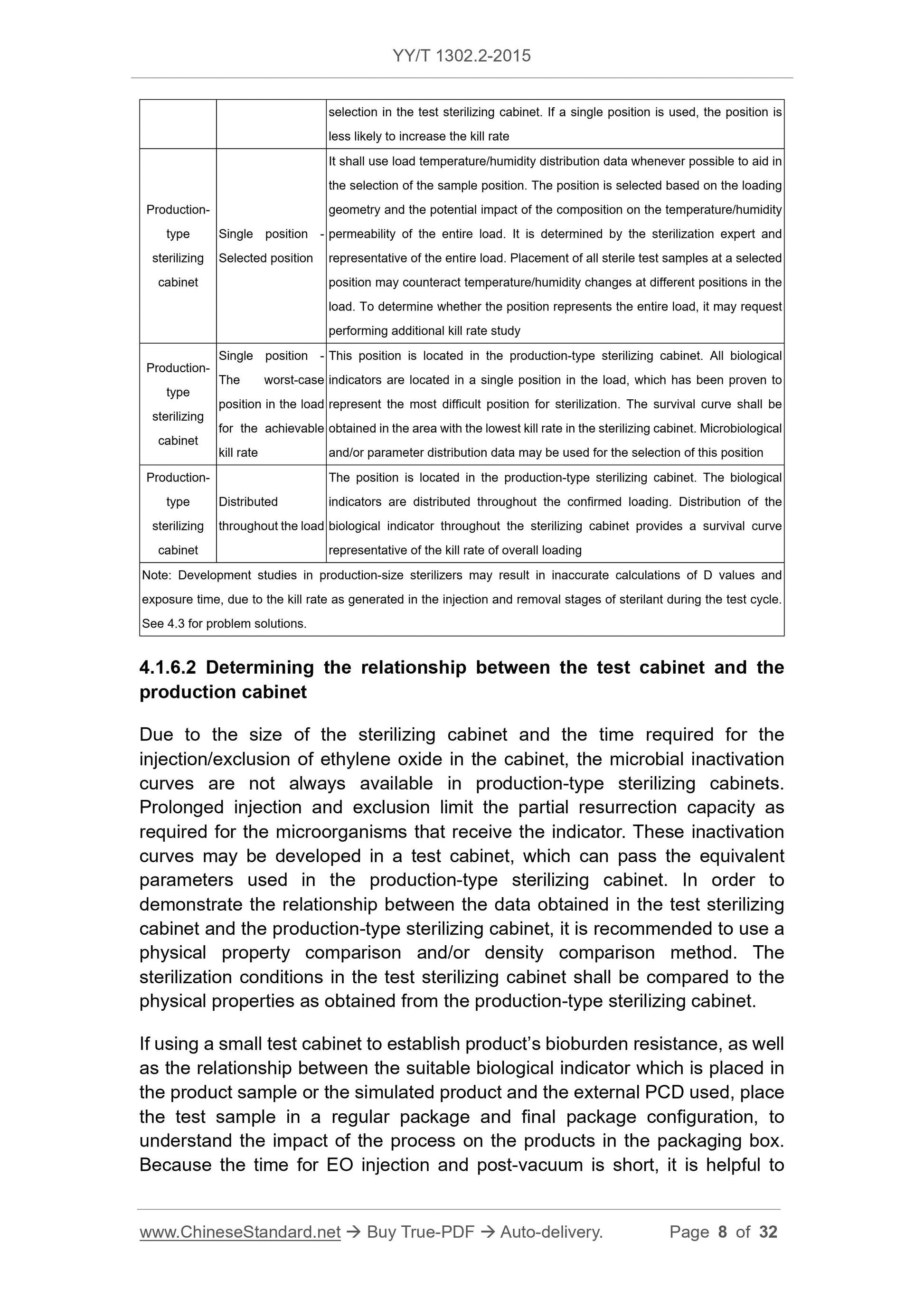

compare the suitability of BI/IPCD with the EPCD to be used for routine

monitoring. Since the multi-layer penetration of the loading of conventional

product pallet will affect the final kill rate, it takes longer to achieve the same kill

rate as obtained in the test cabinet. Therefore, all parameters developed in the

test sterilizing cabinet shall be determined in the production-type equipment as

a part of the validation process.

In addition, the ratio of the test-type load volume to the available volume of the

test-type cabinet shall represent the ratio of the load volume used in the

production-type cabinet to the volume of production-type cabinet. The

comparison between test-type load and the production-type load shall be based

on the equivalence of the load, which shall be equivalent not only in terms of

weight/volume ratio, but also in terms of the challenge of the product and the

loading configuration for the sterilization process.

4.1.6.3 Parameters

It may compare the following factors to determine the relationship between the

studies as performed in both the test-type and production-type sterilizing

cabinets:

a) Setting value and range of temperature inside the preconditioning room (if

used);

b) Setting value and range of relative humidity inside the preconditioning

room (if used);

c) Preconditioning time;

d) Setting value and range of temperature in the sterilizing cabinet;

e) Setting value and range of relative humidity in the sterilizing cabinet;

f) Setting value and range of gas concentration in the sterilizing cabinet (if

there is a gas analysis instrument in the test sterilizing cabinet);

g) The sterilant (gas mixture) used (i.e., the volume fraction of all gases);

h) Gas residence time;

i) Vacuum pressure / transfer depth and rate;

j) Microbial kill rate;

k) Setting value and range of temperature in the analysis room (if used);

l) Range of temperature and relative humidity in the load.

It is generally considered that the position of lowest temperature or the position

Note: At the end of the cycle, it shall retrieve the BI and product sample as soon as

possible. Once the sample is retrieved, follow the confirmed method to carry out the

biological test.

4.2...

Get QUOTATION in 1-minute: Click YY/T 1302.2-2015

Historical versions: YY/T 1302.2-2015

Preview True-PDF (Reload/Scroll if blank)

YY/T 1302.2-2015: Physical requirements and microbiological performance of ethylene oxide sterilization. Part 2: Microbiological aspects

YY/T 1302.2-2015

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.080.01

C 47

Physical requirements and microbiological

performance of ethylene oxide sterilization -

Part 2: Microbiological aspects

ISSUED ON: MARCH 02, 2015

IMPLEMENTED ON: JANUARY 01, 2016

Issued by: China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Process definition ... 5

4.1 Considerations of process definition ... 5

4.2 Process definition method ... 10

4.3 Troubleshooting of the sterilization process definition ... 17

4.4 Process challenge device (PCD) ... 19

5 Validation ... 23

5.1 Microbial performance qualification (MPQ) ... 23

5.2 Sterilization loading ... 25

5.3 Simulating expected process conditions ... 27

5.4 Confirming the release of load ... 27

5.5 Small batch release ... 28

6 Maintenance of process effectiveness ... 29

6.1 Failure investigation ... 29

6.2 Re-qualification ... 31

Physical requirements and microbiological

performance of ethylene oxide sterilization -

Part 2: Microbiological aspects

1 Scope

This part of YY/T 1302 specifies process definition, validation, process

effectiveness maintenance, etc. for the microbiological aspects of ethylene

oxide sterilization.

This part applies to the ethylene oxide sterilization process for medical devices

and other related products or materials, provides solutions to various

microbiological aspects in the development and validation of ethylene oxide

(EO) sterilization processes. This part also provides additional application

guidelines for medical device manufacturers that use the ISO 11135-1:2007 and

ISO/TS 11135-2:2008 standards, including those that use outsourced

sterilization plants or outsourced sterilization operations.

This part of YY/T 1302 does not include various factors that may affect the

product's bioburden and sterilization process.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 19974-2005 Sterilization of health care products - General requirement

for characterization of a sterilization agent and the development, validation

and routine control of a sterilization process for medical devices

ISO 11135-1:2007 Sterilization of health care products - Ethylene oxide -

Part 1: Requirements for development, validation and routine control of a

sterilization process of medical devices

ISO/TS 11135-2:2008 Sterilization of health care products - Ethylene oxide -

Part 2: Guidance on the application of ISO 11135-1

ISO 11138-1:2006 Sterilization of health care products - Biological indicators

development method is based on a number of factors, including the nature of

the product's bioburden, packaging, production conditions, sterilization

equipment, cost. Usually the biological indicator (BI) / bioburden (overkill) or

other established methods are used to develop the parameters required to

achieve the sterility assurance level (SAL) as required by the product.

4.1.2 Parameters on ethylene oxide exposure

Use the cycle development information and consider the SAL of the involved

products to calculate the parameters of cyclic exposure of ethylene oxide. The

recognized SAL includes:

a) For the product that contacts compromised tissue or a sterile part of the

body, the SAL is 10-6;

b) For the product that does not contact the compromised tissue or a sterile

part of the body, the SAL is 10-3.

Note: The SAL for products labeled “sterile” is usually 10-6. SAL requirements for

products labeled as “sterile” may vary from country to country.

Products with multiple sterility assurance levels - Some products contain

components or assemblies that are different for the intended use. In the kit,

components for un-compromised skin or mucosa or that are not expected to

come into contact with the patient have different SAL requirements than

components that are expected to come into contact with internal tissues,

nervous systems or blood. Based on the intended use of the device, the

sterilization process shall achieve the required kill rate for each component.

4.1.3 Product packaging

The product package shall be breathable and resistant to changes of

vacuum/pressure rise as well as vacuum/pressure rise rates.

4.1.4 Process development method

If the product is produced in a controlled environment and the amount of

bioburden continues to be low, the process development method used to

identify sterilization parameters may be the bioburden/biological indicator

method. But it needs understanding different microbial species on the product.

4.1.5 Considerations in sampling for process development study

Before the start of the study, the process development study shall consider the

following two factors:

a) Determine the method of use: Partial negative method or direct counting

method. If partial negative method is used to obtain data, it is

compare the suitability of BI/IPCD with the EPCD to be used for routine

monitoring. Since the multi-layer penetration of the loading of conventional

product pallet will affect the final kill rate, it takes longer to achieve the same kill

rate as obtained in the test cabinet. Therefore, all parameters developed in the

test sterilizing cabinet shall be determined in the production-type equipment as

a part of the validation process.

In addition, the ratio of the test-type load volume to the available volume of the

test-type cabinet shall represent the ratio of the load volume used in the

production-type cabinet to the volume of production-type cabinet. The

comparison between test-type load and the production-type load shall be based

on the equivalence of the load, which shall be equivalent not only in terms of

weight/volume ratio, but also in terms of the challenge of the product and the

loading configuration for the sterilization process.

4.1.6.3 Parameters

It may compare the following factors to determine the relationship between the

studies as performed in both the test-type and production-type sterilizing

cabinets:

a) Setting value and range of temperature inside the preconditioning room (if

used);

b) Setting value and range of relative humidity inside the preconditioning

room (if used);

c) Preconditioning time;

d) Setting value and range of temperature in the sterilizing cabinet;

e) Setting value and range of relative humidity in the sterilizing cabinet;

f) Setting value and range of gas concentration in the sterilizing cabinet (if

there is a gas analysis instrument in the test sterilizing cabinet);

g) The sterilant (gas mixture) used (i.e., the volume fraction of all gases);

h) Gas residence time;

i) Vacuum pressure / transfer depth and rate;

j) Microbial kill rate;

k) Setting value and range of temperature in the analysis room (if used);

l) Range of temperature and relative humidity in the load.

It is generally considered that the position of lowest temperature or the position

Note: At the end of the cycle, it shall retrieve the BI and product sample as soon as

possible. Once the sample is retrieved, follow the confirmed method to carry out the

biological test.

4.2...

Share