1

/

の

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1813-2022 English PDF (YYT1813-2022)

YY/T 1813-2022 English PDF (YYT1813-2022)

通常価格

$320.00 USD

通常価格

セール価格

$320.00 USD

単価

/

あたり

配送料はチェックアウト時に計算されます。

受取状況を読み込めませんでした

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY/T 1813-2022

Historical versions: YY/T 1813-2022

Preview True-PDF (Reload/Scroll if blank)

YY/T 1813-2022: Methods for operational reliability information collection and evaluation of medical electrical equipment

YY/T 1813-2022

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040

CCS C 30

Method for Operational Reliability Information Collection

and Evaluation of Medical Electrical Equipment

ISSUED ON: MAY 18, 2022

IMPLEMENTED ON: JUNE 01, 2023

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Collection of Operational Reliability Information of ME Equipment and ME Systems

... 8

4.1 Sources of operational reliability information ... 8

4.2 Contents of operational reliability information ... 9

4.3 Fault judgment and record ... 12

5 Assessment of Operational Reliability of ME Equipment and ME Systems ... 14

5.1 Overview ... 14

5.2 Determining the assessment indicators of operational reliability ... 14

5.3 Determination of samples ... 14

5.4 Preliminary collation of operational reliability information ... 15

5.5 Inspection method of distribution type ... 16

5.6 Parameter estimation for continuous distributions ... 16

5.7 Preparation of assessment report of operational reliability ... 16

Appendix A (Informative) Collection Form of Operational Reliability Information of

ME Equipment and ME Systems ... 17

Appendix B (Informative) Description of Other Relevant Operational Reliability

Parameters for ME Equipment and ME Systems ... 19

Appendix C (Informative) Introduction to Relevant Distribution Models ... 24

Appendix D (informative) Inspection of Relevant Distribution Type ... 27

Bibliography ... 29

Method for Operational Reliability Information Collection

and Evaluation of Medical Electrical Equipment

1 Scope

This Document specifies the methods for collecting operational reliability information and

assessing the operational reliability of medical electrical equipment and medical electrical

systems (hereinafter referred to as ME equipment and ME systems) within the period of use

specified by the manufacturer.

This Document is applicable to the collection of operational reliability information and

assessment of operational reliability assessment of ME equipment and ME systems.

2 Normative References

The provisions in following documents become the essential provisions of this Document

through reference in this Document. For the dated documents, only the versions with the dates

indicated are applicable to this Document; for the undated documents, only the latest version

(including all the amendments) is applicable to this Document.

GB 9706.1-2020 Medical Electrical Equipment - Part 1: General Requirements for Basic

Safety and Essential Performance

YY/T 1837-2022 Medical Electrical Equipment - General Requirements for Reliability

3 Terms and Definitions

For the purposes of this Document, the terms and definitions given in GB 9706.1-2020 and

YY/T 1837-2022 and the following apply.

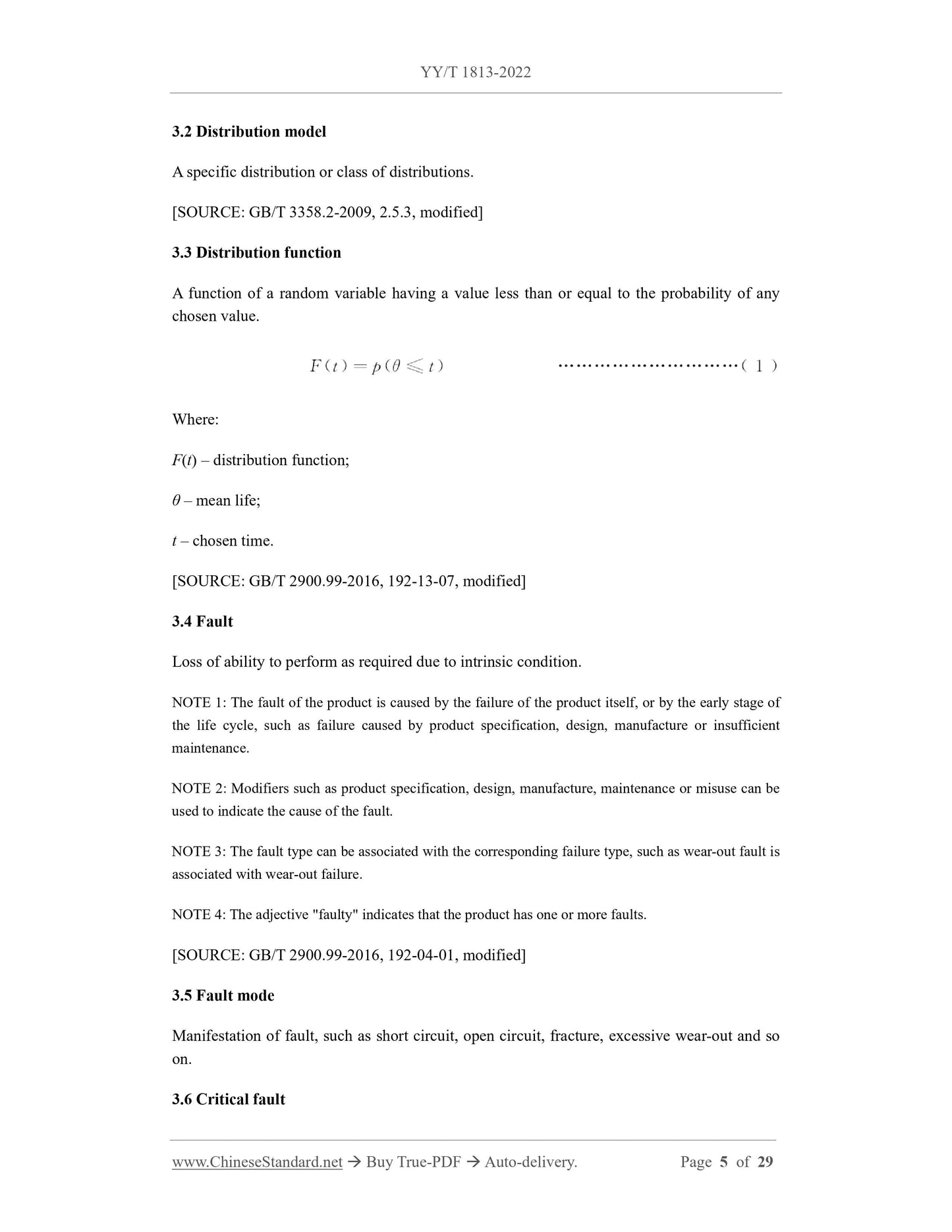

3.1 Parameter estimation

Infer unknown total distribution parameters from a sample.

The process of estimating parameters or parameter functions used to characterize reliability

indicators in the analysis of operational reliability data of ME equipment and ME systems.

[SOURCE: GB/T 17560-1998, 3.1.1, modified]

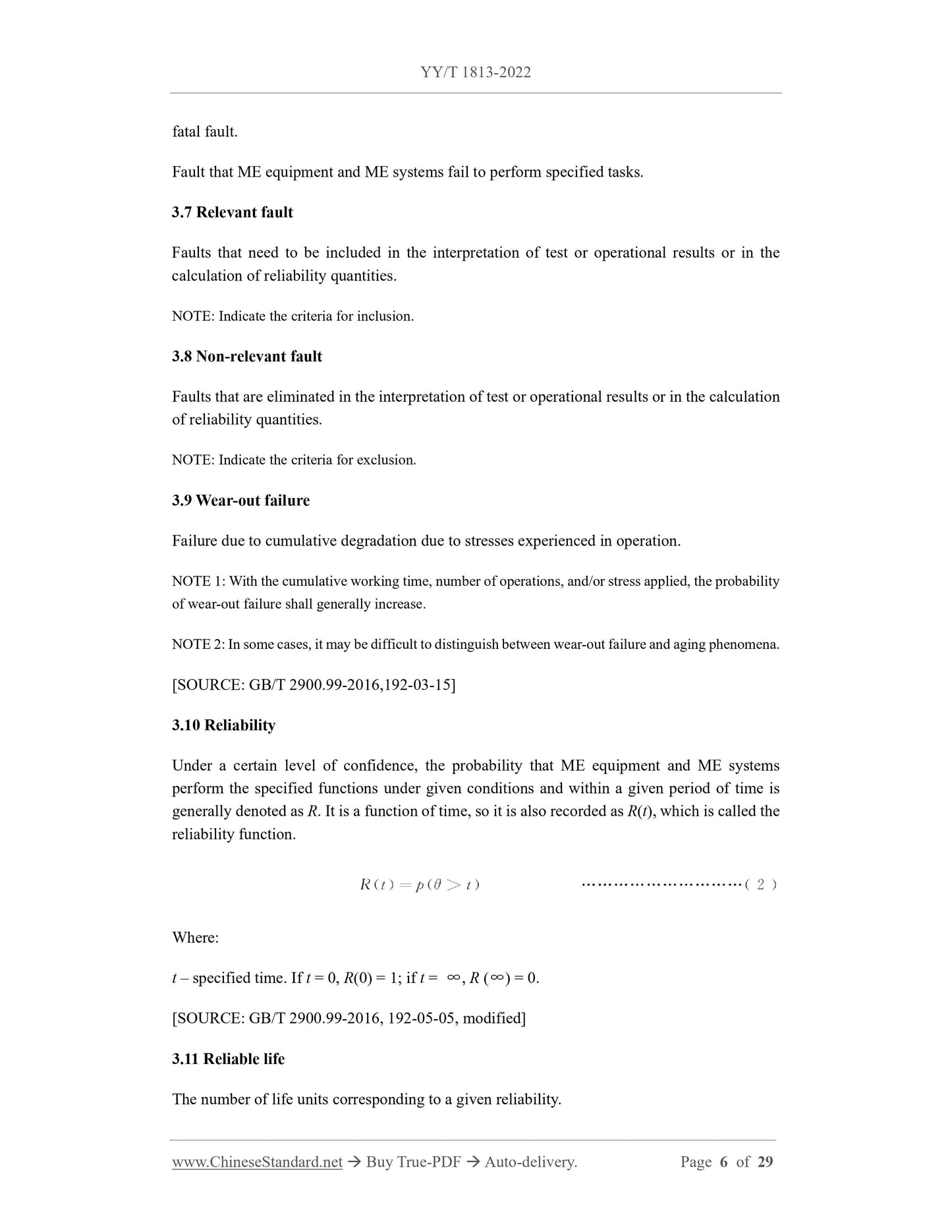

At different times, the reliability shall have different reliability levels r. When the reliability of

the ME equipment and the ME systems drop to a given reliability level r, this time is called the

reliable life of the ME equipment and the ME systems, denoted as tr.

For example, the median life refers to the time corresponding to the reliability level r=0.5, that

is, R (t0.5) = 0.5.

3.12 Useful life

The period of time between ME equipment and ME systems from their first use until they no

longer meet the user's requirements due to economics of operation and maintenance or

obsolescence.

[SOURCE: GB/T 2900.99-2016, 192-02-27, modified]

3.13 Life unit

Use duration units of measure for ME equipment and ME systems. Such as hours, kilometers,

times, etc.

3.14 Mean time between failures; MTBF; TBF

A basic reliability parameter for repairable ME equipment and ME systems. Its measurement

method is: the ratio of the total number life units to the total number of failures of ME

equipment and ME systems under specified conditions and within a specified period.

3.15 Mean time between critical failures; MTBCF; TBCF

A reliability parameter that is related to a task. Its measurement method is: in a series of

specified task profiles, the ratio of the total task time to the total number of critical faults of ME

equipment and ME systems. Formerly known as task time between fatal faults.

3.16 Mean time between maintenances; MITBM; TBM

A reliability parameter that is related to maintenance policy. Its measurement method is: under

specified conditions and within a specified time, the ratio of the total number of life units to the

total number of planned/unplanned maintenance events of the ME equipment and ME systems.

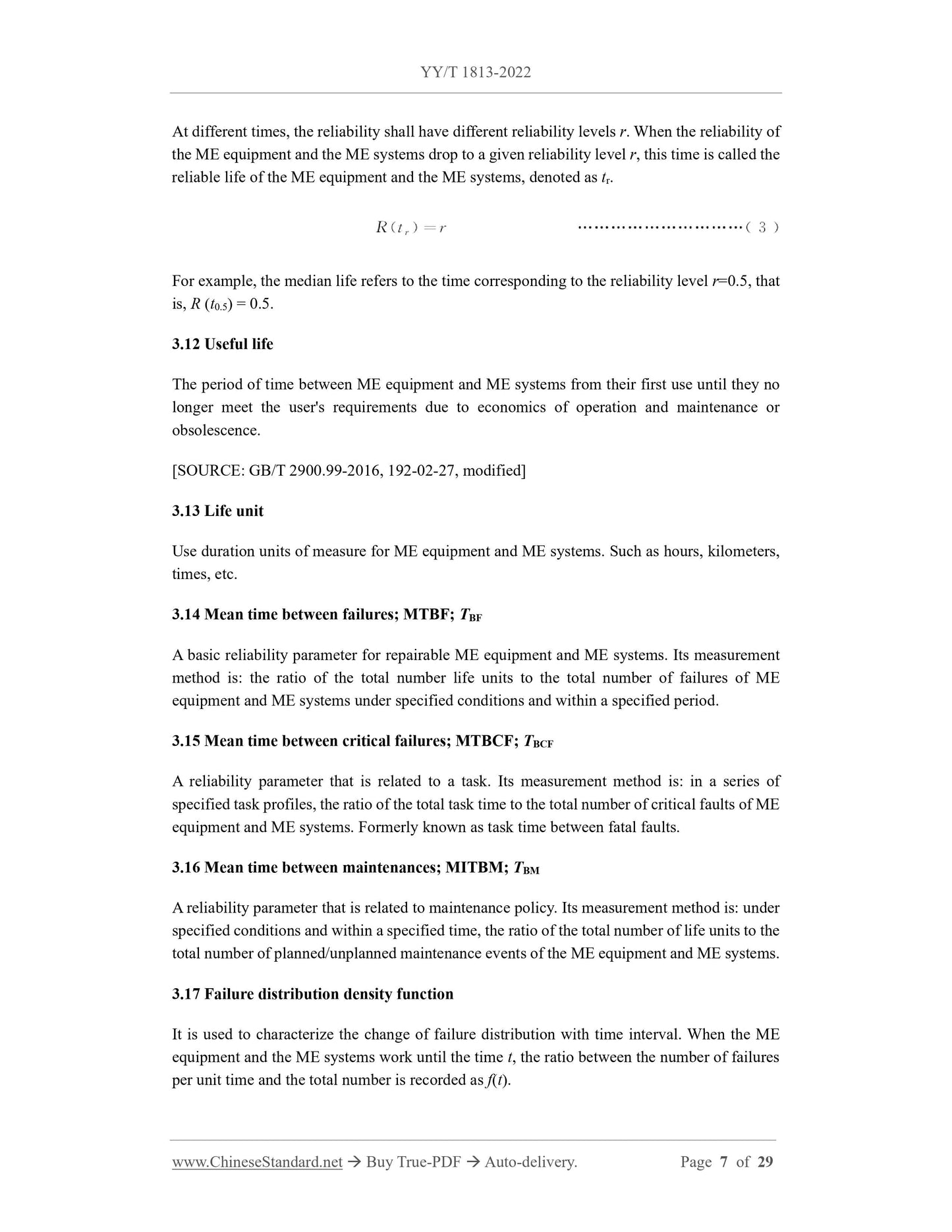

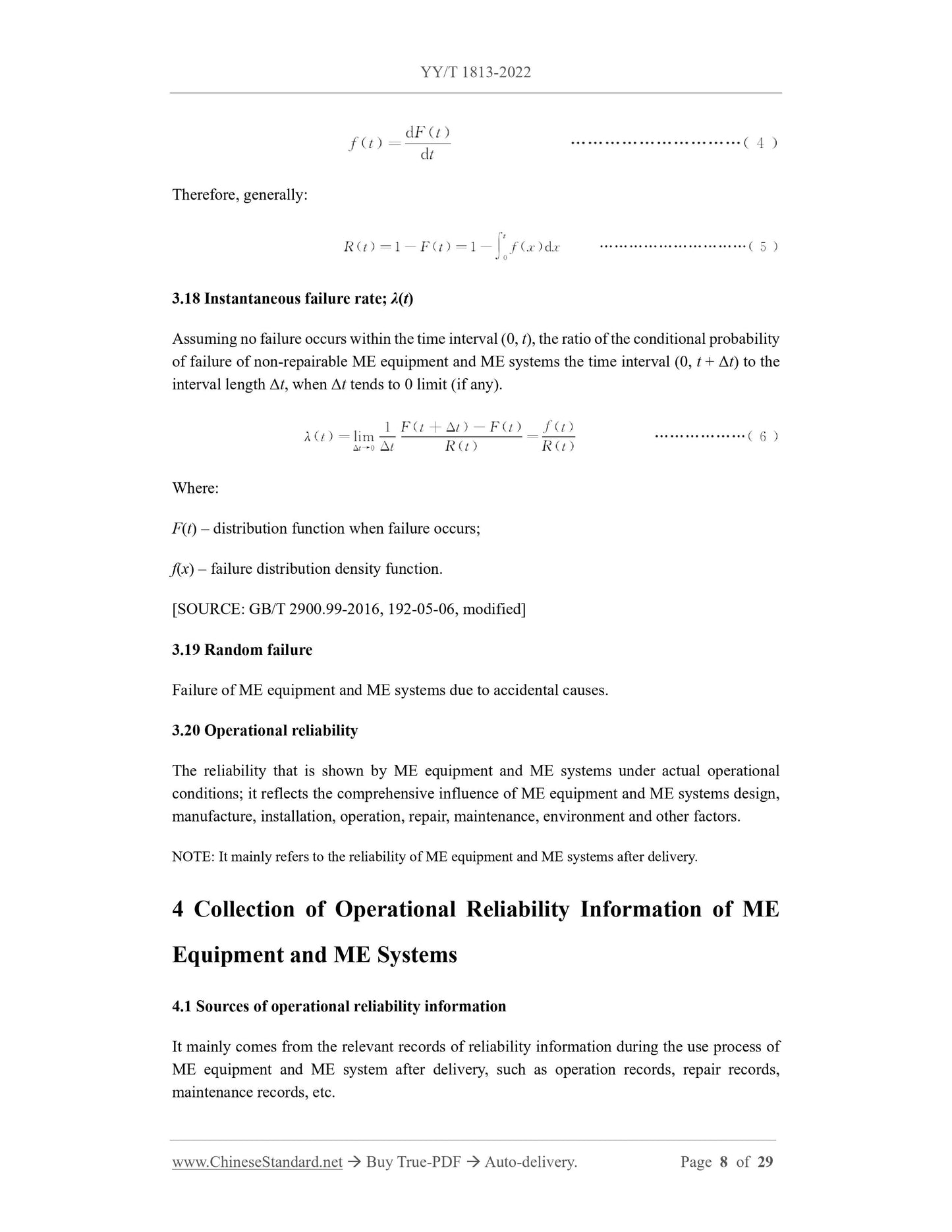

3.17 Failure distribution density function

It is used to characterize the change of failure distribution with time interval. When the ME

equipment and the ME systems work until the time t, the ratio between the number of failures

per unit time and the total number is recorded as f(t).

4.2 Contents of operational reliability information

4.2.1 ME equipment and ME systems information

Names, model specifications, serial numbers, production batch numbers, and other information

of equipment, systems, components, and accessories.

4.2.2 User information

After obtaining the relevant authorization, the relevant information of the user can be collected:

a) address of use;

b) User organization information;

c) The frequency of movement within the place where the equipment and system are used,

such as the location is fixed and basically does not move, and it moves every time it is

used, etc.;

d) Information such as operators and operating habits.

4.2.3 Environmental condition information

Environmental conditions for ME equipment and ME systems include temperature, humidity,

atmospheric pressure, etc. The following factors also need to be recorded if they affect the

reliability of ME equipment and ME system.

a) Climate environment:

1) For ME equipment and ME systems working in a controlled environment, the climate

environment factors mainly refer to the following information:

● Salt spray factor;

● Illumination and radiation factors: indirect solar radiation, ultraviolet lamp

irradiation, incandescent lamp irradiation, etc.

2) For ME equipment and ME systems working in an uncontrolled environment, the

climate environment factors may include the following aspects in addition to the

above points:

● Acid rain factors: pH value, type, etc.;

● water factor;

● direct solar radiation;

● Air pollution factors: particle size and nature of dust and smog.

b) biochemical environment:

1) Insects, microorganisms, rodents, etc.;

2) Chemical atmosphere: cleaning agents, disinfectants, body fluids, excrement,

chemical reagents, etc.

c) Mechanical environment:

1) Vibration factor: whether it is at or close to the vibration source;

2) Mechanical shock factor;

3) Noise factor.

d) Power supply and electromagnetic field:

1) Information such as power supply quality, power load capacity, and power outages,

etc.;

2) Non-ionizing electromagnetic radiation disturbance.

e) High-energy radiation environment: ionizing radiation.

Refer to Appendix A for the ...

Get QUOTATION in 1-minute: Click YY/T 1813-2022

Historical versions: YY/T 1813-2022

Preview True-PDF (Reload/Scroll if blank)

YY/T 1813-2022: Methods for operational reliability information collection and evaluation of medical electrical equipment

YY/T 1813-2022

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040

CCS C 30

Method for Operational Reliability Information Collection

and Evaluation of Medical Electrical Equipment

ISSUED ON: MAY 18, 2022

IMPLEMENTED ON: JUNE 01, 2023

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Collection of Operational Reliability Information of ME Equipment and ME Systems

... 8

4.1 Sources of operational reliability information ... 8

4.2 Contents of operational reliability information ... 9

4.3 Fault judgment and record ... 12

5 Assessment of Operational Reliability of ME Equipment and ME Systems ... 14

5.1 Overview ... 14

5.2 Determining the assessment indicators of operational reliability ... 14

5.3 Determination of samples ... 14

5.4 Preliminary collation of operational reliability information ... 15

5.5 Inspection method of distribution type ... 16

5.6 Parameter estimation for continuous distributions ... 16

5.7 Preparation of assessment report of operational reliability ... 16

Appendix A (Informative) Collection Form of Operational Reliability Information of

ME Equipment and ME Systems ... 17

Appendix B (Informative) Description of Other Relevant Operational Reliability

Parameters for ME Equipment and ME Systems ... 19

Appendix C (Informative) Introduction to Relevant Distribution Models ... 24

Appendix D (informative) Inspection of Relevant Distribution Type ... 27

Bibliography ... 29

Method for Operational Reliability Information Collection

and Evaluation of Medical Electrical Equipment

1 Scope

This Document specifies the methods for collecting operational reliability information and

assessing the operational reliability of medical electrical equipment and medical electrical

systems (hereinafter referred to as ME equipment and ME systems) within the period of use

specified by the manufacturer.

This Document is applicable to the collection of operational reliability information and

assessment of operational reliability assessment of ME equipment and ME systems.

2 Normative References

The provisions in following documents become the essential provisions of this Document

through reference in this Document. For the dated documents, only the versions with the dates

indicated are applicable to this Document; for the undated documents, only the latest version

(including all the amendments) is applicable to this Document.

GB 9706.1-2020 Medical Electrical Equipment - Part 1: General Requirements for Basic

Safety and Essential Performance

YY/T 1837-2022 Medical Electrical Equipment - General Requirements for Reliability

3 Terms and Definitions

For the purposes of this Document, the terms and definitions given in GB 9706.1-2020 and

YY/T 1837-2022 and the following apply.

3.1 Parameter estimation

Infer unknown total distribution parameters from a sample.

The process of estimating parameters or parameter functions used to characterize reliability

indicators in the analysis of operational reliability data of ME equipment and ME systems.

[SOURCE: GB/T 17560-1998, 3.1.1, modified]

At different times, the reliability shall have different reliability levels r. When the reliability of

the ME equipment and the ME systems drop to a given reliability level r, this time is called the

reliable life of the ME equipment and the ME systems, denoted as tr.

For example, the median life refers to the time corresponding to the reliability level r=0.5, that

is, R (t0.5) = 0.5.

3.12 Useful life

The period of time between ME equipment and ME systems from their first use until they no

longer meet the user's requirements due to economics of operation and maintenance or

obsolescence.

[SOURCE: GB/T 2900.99-2016, 192-02-27, modified]

3.13 Life unit

Use duration units of measure for ME equipment and ME systems. Such as hours, kilometers,

times, etc.

3.14 Mean time between failures; MTBF; TBF

A basic reliability parameter for repairable ME equipment and ME systems. Its measurement

method is: the ratio of the total number life units to the total number of failures of ME

equipment and ME systems under specified conditions and within a specified period.

3.15 Mean time between critical failures; MTBCF; TBCF

A reliability parameter that is related to a task. Its measurement method is: in a series of

specified task profiles, the ratio of the total task time to the total number of critical faults of ME

equipment and ME systems. Formerly known as task time between fatal faults.

3.16 Mean time between maintenances; MITBM; TBM

A reliability parameter that is related to maintenance policy. Its measurement method is: under

specified conditions and within a specified time, the ratio of the total number of life units to the

total number of planned/unplanned maintenance events of the ME equipment and ME systems.

3.17 Failure distribution density function

It is used to characterize the change of failure distribution with time interval. When the ME

equipment and the ME systems work until the time t, the ratio between the number of failures

per unit time and the total number is recorded as f(t).

4.2 Contents of operational reliability information

4.2.1 ME equipment and ME systems information

Names, model specifications, serial numbers, production batch numbers, and other information

of equipment, systems, components, and accessories.

4.2.2 User information

After obtaining the relevant authorization, the relevant information of the user can be collected:

a) address of use;

b) User organization information;

c) The frequency of movement within the place where the equipment and system are used,

such as the location is fixed and basically does not move, and it moves every time it is

used, etc.;

d) Information such as operators and operating habits.

4.2.3 Environmental condition information

Environmental conditions for ME equipment and ME systems include temperature, humidity,

atmospheric pressure, etc. The following factors also need to be recorded if they affect the

reliability of ME equipment and ME system.

a) Climate environment:

1) For ME equipment and ME systems working in a controlled environment, the climate

environment factors mainly refer to the following information:

● Salt spray factor;

● Illumination and radiation factors: indirect solar radiation, ultraviolet lamp

irradiation, incandescent lamp irradiation, etc.

2) For ME equipment and ME systems working in an uncontrolled environment, the

climate environment factors may include the following aspects in addition to the

above points:

● Acid rain factors: pH value, type, etc.;

● water factor;

● direct solar radiation;

● Air pollution factors: particle size and nature of dust and smog.

b) biochemical environment:

1) Insects, microorganisms, rodents, etc.;

2) Chemical atmosphere: cleaning agents, disinfectants, body fluids, excrement,

chemical reagents, etc.

c) Mechanical environment:

1) Vibration factor: whether it is at or close to the vibration source;

2) Mechanical shock factor;

3) Noise factor.

d) Power supply and electromagnetic field:

1) Information such as power supply quality, power load capacity, and power outages,

etc.;

2) Non-ionizing electromagnetic radiation disturbance.

e) High-energy radiation environment: ionizing radiation.

Refer to Appendix A for the ...

Share