1

/

의

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

CJJ/T 135-2009 English PDF (CJJT135-2009)

CJJ/T 135-2009 English PDF (CJJT135-2009)

정가

$610.00 USD

정가

할인가

$610.00 USD

단가

/

단위

배송료는 결제 시 계산됩니다.

픽업 사용 가능 여부를 로드할 수 없습니다.

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click CJJ/T 135-2009

Historical versions: CJJ/T 135-2009

Preview True-PDF (Reload/Scroll if blank)

CJJ/T 135-2009: [2023 Edition] Technical specification for pervious cement concrete pavement

CJJ/T 135-2009

UDC

CJJ

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

Record number J965-2009

Technical specification for pervious cement concrete

pavement

[2023 Edition]

ISSUED ON: NOVEMBER 16, 2009

IMPLEMENTED ON: JULY 01, 2010

Issued by: Ministry of Housing and Urban-Rural Development of the People’s

Republic of China.

Table of Contents

1 General provisions ... 6

2 Terms and symbols ... 7

2.1 Terms ... 7

2.2 Symbols ... 7

3 Materials ... 9

3.1 Raw materials ... 9

3.2 Pervious cement concrete ... 10

3.3 Pervious cement concrete mix proportions ... 10

4 Structural combination and tectonic ... 14

4.1 Structural combination design ... 14

4.2 Surface design ... 16

4.3 Drainage system design ... 16

5 Construction ... 18

5.1 General requirements ... 18

5.2 Mixing and transport ... 18

5.3 Pervious cement concrete pavement paving ... 19

5.4 Joint construction ... 21

5.5 Curing ... 21

5.6 Seasonal construction... 21

6 Acceptance ... 23

6.1 General requirements ... 23

6.2 Quality test standards ... 24

7 Maintenance ... 28

Appendix A Test method of permeability coefficient ... 29

Explanation of wording in this Specification ... 32

Normative standards ... 33

1 General provisions ... 36

2 Terms and symbols ... 36

3 Materials ... 37

4 Structural combination and tectonic ... 40

5 Construction ... 46

6 Acceptance ... 50

7 Maintenance ... 51

Appendix A Test method of permeability coefficient ... 52

Appendix B Test method for continuous void ... 53

Normative standards ... 55

Technical specification for pervious cement concrete

pavement

1 General provisions

1.0.1 This Specification is formulated in order to enhance the quality of pervious

cement concrete pavement projects and make them technologically advanced,

economical, reasonable, convenient and applicable.

1.0.2 This Specification applies to the design, construction, acceptance and

maintenance of pervious cement concrete pavements such as newly built urban light

load roads, light load roads in gardens, squares and parking lots. This Specification does

not apply to pavements in severe cold areas, collapsible loess areas, saline soil areas,

and expansive soil areas.

1.0.3 The structural form of pervious cement concrete pavement shall take into account

geological conditions, load levels, landscape requirements, environmental conditions,

construction conditions and other factors.

1.0.4 This Specification specifies the basic technical requirements for the design,

construction, acceptance and maintenance of pervious cement concrete pavement.

Where this Specification conflicts with the provisions of national laws and

administrative regulations, the provisions of national laws and administrative

regulations shall prevail.

1.0.5 The design, construction, acceptance and maintenance of pervious cement

concrete pavement shall not only comply with the provisions of this Specification, but

also comply with the provisions of the relevant current national standards.

2 Terms and symbols

2.1 Terms

2.1.1 Pervious cement concrete

Concrete, with a continuous void structure, which is formed by mixing coarse aggregate

and cement-based binder.

2.1.2 Continuous void

The percentage of the volume of continuous void existing inside pervious cement

concrete to the volume of pervious cement concrete.

2.1.3 Water-washing pervious cement concrete

Pervious cement concrete whose coarse aggregate on the surface is exposed after the

cement-based binder wrapped on the surface of the coarse aggregate is water-washed

before final setting.

2.1.4 Reinforcer

An additive used to improve the bonding performance of coarse aggregate and binder

and increase the strength of pervious cement concrete.

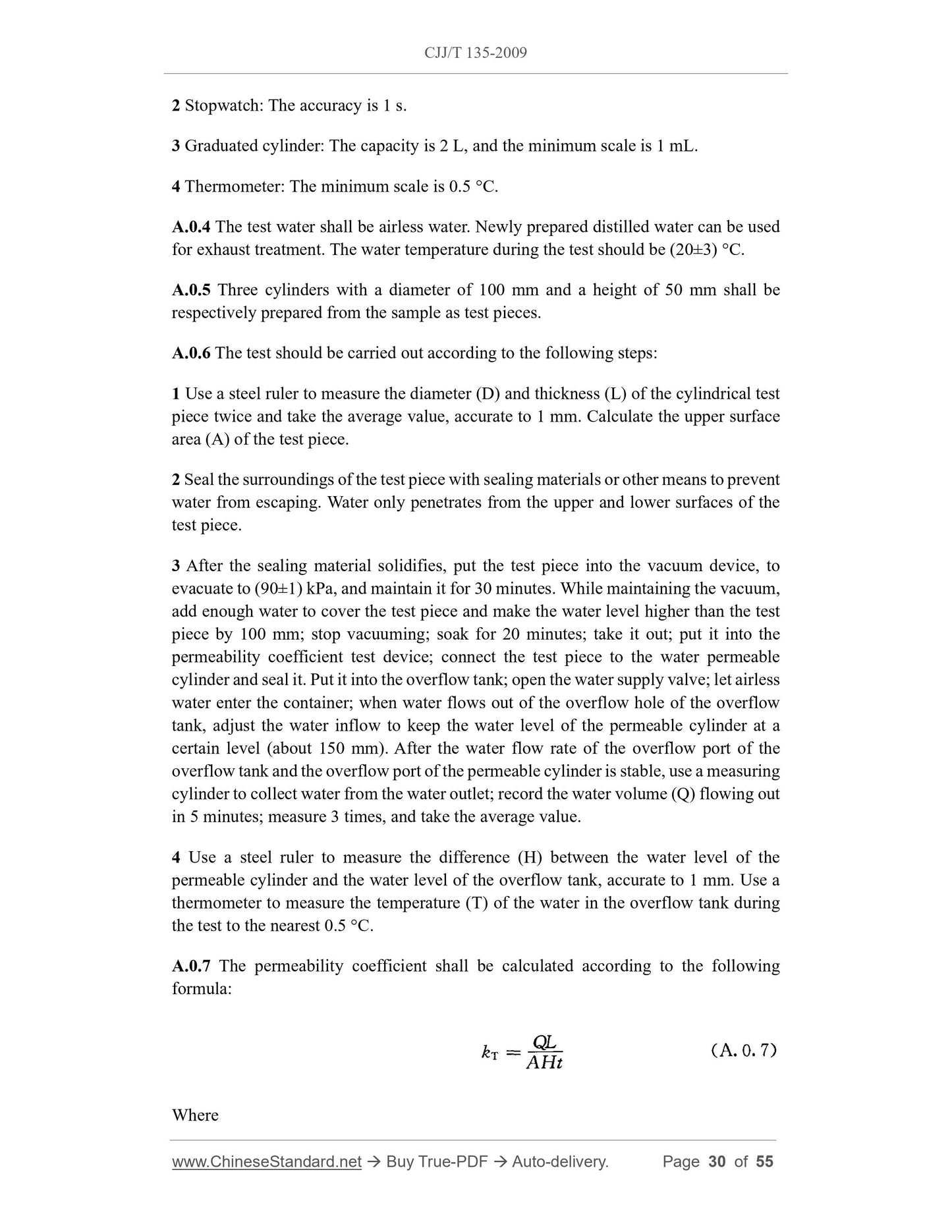

2.1.5 Permeability coefficient

An index indicating the water permeability of pervious cement concrete.

2.1.6 Light load road

Urban roads, and roads such as parking lots and residential areas, on which only

vehicles with an axle load of less than 40 kN are allowed to travel.

2.1.7 Total pervious structure

Road structure system where road surface water can directly penetrate into the subgrade

soil through the surface and base of the road.

2.1.8 Semi-pervious structure

Road structure system where road surface water can only penetrate into the surface and

not into the subgrade soil.

2.2 Symbols

h1 – pervious cement concrete pavement surface thickness;

4.2 Surface design

4.2.1 When the sidewalk design adopts a total pervious structure, its pervious cement

concrete surface strength level shall not be less than C20, and its thickness (h1) should

not be less than 80 mm. For other pavements, when using the total pervious structure,

its pervious cement concrete surface strength level shall not be less than C30, and its

thickness (h1) should not be less than 180 mm; when using the semi-pervious structure,

its pervious cement concrete surface strength level shall not be less than C30, and its

thickness (h1) should not be less than 180 mm.

4.2.2 The structure design of the pervious cement concrete pavement is divided into

monochrome layer or two-color combination layer. When the two-color combination

layer is adopted, the thickness of the surface layer shall not be less than 30 mm.

4.2.3 The pervious cement concrete pavement shall be designed with vertical and

transverse joints. The distance between vertical joints shall be determined according to

the width of the pavement in the range of 3.0 m ~ 4.5 m. The distance between

transverse joints should be 4.0 m ~ 6.0 m; the plane view size of the square should not

be greater than 25 m2, and the length-width ratio of the surface plate should not exceed

1.3. When the base has structural joints, the surface contraction joint shall be consistent

with the position of the corresponding structural joint, and flexible materials shall be

filled in the joint.

4.2.4 When the construction length of the pervious cement concrete pavement exceeds

30 m, expansion joints shall be set. Expansion joints shall be set at the connection

between the pervious cement concrete pavement and other constructions such as side

gutters, buildings, gutter inlets, surfacing blocks and asphalt pavement.

4.3 Drainage system design

4.3.1 The drainage design of pervious cement concrete pavement should comply with

the relevant provisions of the current industry standard Code for design of urban road

engineering, CJJ 37.

4.3.2 When designing the total pervious structure, drainage under the pavement shall

be considered. The drainage under the pavement can be set with drainage blind ditch

which shall be connected to the municipal drainage system during the road design. The

combination of the gutter inlet with the base and the surface shall be designed into the

pervious form to facilitate the gathering of excess water from the base to the gutter inlet.

Impervious geotextile with a width of not less than 1 m shall be set on the subgrade

surface around the gutter inlet (Figure 4.3.2).

4.3.3 When designing the drainage system, municipal drainage ditches or gutter inlets

can be used. The pervious cement concrete can be directly laid to the municipal drainage

ditches or gutter inlets. Squares of large area should be set with drainage blind ditches

(Figure 4.3.3).

5 Construction

5.1 General requirements

5.1.1 Before construction, the construction site shall be inspected, the location a...

Get QUOTATION in 1-minute: Click CJJ/T 135-2009

Historical versions: CJJ/T 135-2009

Preview True-PDF (Reload/Scroll if blank)

CJJ/T 135-2009: [2023 Edition] Technical specification for pervious cement concrete pavement

CJJ/T 135-2009

UDC

CJJ

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

Record number J965-2009

Technical specification for pervious cement concrete

pavement

[2023 Edition]

ISSUED ON: NOVEMBER 16, 2009

IMPLEMENTED ON: JULY 01, 2010

Issued by: Ministry of Housing and Urban-Rural Development of the People’s

Republic of China.

Table of Contents

1 General provisions ... 6

2 Terms and symbols ... 7

2.1 Terms ... 7

2.2 Symbols ... 7

3 Materials ... 9

3.1 Raw materials ... 9

3.2 Pervious cement concrete ... 10

3.3 Pervious cement concrete mix proportions ... 10

4 Structural combination and tectonic ... 14

4.1 Structural combination design ... 14

4.2 Surface design ... 16

4.3 Drainage system design ... 16

5 Construction ... 18

5.1 General requirements ... 18

5.2 Mixing and transport ... 18

5.3 Pervious cement concrete pavement paving ... 19

5.4 Joint construction ... 21

5.5 Curing ... 21

5.6 Seasonal construction... 21

6 Acceptance ... 23

6.1 General requirements ... 23

6.2 Quality test standards ... 24

7 Maintenance ... 28

Appendix A Test method of permeability coefficient ... 29

Explanation of wording in this Specification ... 32

Normative standards ... 33

1 General provisions ... 36

2 Terms and symbols ... 36

3 Materials ... 37

4 Structural combination and tectonic ... 40

5 Construction ... 46

6 Acceptance ... 50

7 Maintenance ... 51

Appendix A Test method of permeability coefficient ... 52

Appendix B Test method for continuous void ... 53

Normative standards ... 55

Technical specification for pervious cement concrete

pavement

1 General provisions

1.0.1 This Specification is formulated in order to enhance the quality of pervious

cement concrete pavement projects and make them technologically advanced,

economical, reasonable, convenient and applicable.

1.0.2 This Specification applies to the design, construction, acceptance and

maintenance of pervious cement concrete pavements such as newly built urban light

load roads, light load roads in gardens, squares and parking lots. This Specification does

not apply to pavements in severe cold areas, collapsible loess areas, saline soil areas,

and expansive soil areas.

1.0.3 The structural form of pervious cement concrete pavement shall take into account

geological conditions, load levels, landscape requirements, environmental conditions,

construction conditions and other factors.

1.0.4 This Specification specifies the basic technical requirements for the design,

construction, acceptance and maintenance of pervious cement concrete pavement.

Where this Specification conflicts with the provisions of national laws and

administrative regulations, the provisions of national laws and administrative

regulations shall prevail.

1.0.5 The design, construction, acceptance and maintenance of pervious cement

concrete pavement shall not only comply with the provisions of this Specification, but

also comply with the provisions of the relevant current national standards.

2 Terms and symbols

2.1 Terms

2.1.1 Pervious cement concrete

Concrete, with a continuous void structure, which is formed by mixing coarse aggregate

and cement-based binder.

2.1.2 Continuous void

The percentage of the volume of continuous void existing inside pervious cement

concrete to the volume of pervious cement concrete.

2.1.3 Water-washing pervious cement concrete

Pervious cement concrete whose coarse aggregate on the surface is exposed after the

cement-based binder wrapped on the surface of the coarse aggregate is water-washed

before final setting.

2.1.4 Reinforcer

An additive used to improve the bonding performance of coarse aggregate and binder

and increase the strength of pervious cement concrete.

2.1.5 Permeability coefficient

An index indicating the water permeability of pervious cement concrete.

2.1.6 Light load road

Urban roads, and roads such as parking lots and residential areas, on which only

vehicles with an axle load of less than 40 kN are allowed to travel.

2.1.7 Total pervious structure

Road structure system where road surface water can directly penetrate into the subgrade

soil through the surface and base of the road.

2.1.8 Semi-pervious structure

Road structure system where road surface water can only penetrate into the surface and

not into the subgrade soil.

2.2 Symbols

h1 – pervious cement concrete pavement surface thickness;

4.2 Surface design

4.2.1 When the sidewalk design adopts a total pervious structure, its pervious cement

concrete surface strength level shall not be less than C20, and its thickness (h1) should

not be less than 80 mm. For other pavements, when using the total pervious structure,

its pervious cement concrete surface strength level shall not be less than C30, and its

thickness (h1) should not be less than 180 mm; when using the semi-pervious structure,

its pervious cement concrete surface strength level shall not be less than C30, and its

thickness (h1) should not be less than 180 mm.

4.2.2 The structure design of the pervious cement concrete pavement is divided into

monochrome layer or two-color combination layer. When the two-color combination

layer is adopted, the thickness of the surface layer shall not be less than 30 mm.

4.2.3 The pervious cement concrete pavement shall be designed with vertical and

transverse joints. The distance between vertical joints shall be determined according to

the width of the pavement in the range of 3.0 m ~ 4.5 m. The distance between

transverse joints should be 4.0 m ~ 6.0 m; the plane view size of the square should not

be greater than 25 m2, and the length-width ratio of the surface plate should not exceed

1.3. When the base has structural joints, the surface contraction joint shall be consistent

with the position of the corresponding structural joint, and flexible materials shall be

filled in the joint.

4.2.4 When the construction length of the pervious cement concrete pavement exceeds

30 m, expansion joints shall be set. Expansion joints shall be set at the connection

between the pervious cement concrete pavement and other constructions such as side

gutters, buildings, gutter inlets, surfacing blocks and asphalt pavement.

4.3 Drainage system design

4.3.1 The drainage design of pervious cement concrete pavement should comply with

the relevant provisions of the current industry standard Code for design of urban road

engineering, CJJ 37.

4.3.2 When designing the total pervious structure, drainage under the pavement shall

be considered. The drainage under the pavement can be set with drainage blind ditch

which shall be connected to the municipal drainage system during the road design. The

combination of the gutter inlet with the base and the surface shall be designed into the

pervious form to facilitate the gathering of excess water from the base to the gutter inlet.

Impervious geotextile with a width of not less than 1 m shall be set on the subgrade

surface around the gutter inlet (Figure 4.3.2).

4.3.3 When designing the drainage system, municipal drainage ditches or gutter inlets

can be used. The pervious cement concrete can be directly laid to the municipal drainage

ditches or gutter inlets. Squares of large area should be set with drainage blind ditches

(Figure 4.3.3).

5 Construction

5.1 General requirements

5.1.1 Before construction, the construction site shall be inspected, the location a...

Share