1

/

의

5

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 9640-2008 English PDF (GBT9640-2008)

GB/T 9640-2008 English PDF (GBT9640-2008)

정가

$75.00 USD

정가

할인가

$75.00 USD

단가

/

단위

배송료는 결제 시 계산됩니다.

픽업 사용 가능 여부를 로드할 수 없습니다.

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 9640-2008

Historical versions: GB/T 9640-2008

Preview True-PDF (Reload/Scroll if blank)

GB/T 9640-2008: Flexible and rigid cellular polymeric materials -- Accelerated ageing tests

GB/T 9640-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.080.01

G 31

GB/T 9640-2008 / ISO 2440:1997

Replacing GB/T 9640-1988

Flexible and rigid cellular polymeric materials -Accelerated

ageing tests

(ISO 2440:1997, IDT)

ISSUED ON: AUGUST 19, 2008

IMPLEMENTED ON: MAY 01, 2009

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative reference ... 4

3 Apparatus ... 4

4 Test pieces ... 5

5 Procedure ... 6

6 Calculation and expression of results ... 7

7 Test report ... 8

Foreword

This Standard is identical to the International Standard ISO 2440:1997 Flexible and

rigid cellular polymeric materials - Accelerated ageing tests. The technical content and

standard structure are exactly the same, with only minor editorial modifications.

This Standard replaces GB/T 9640-1988, Polymeric materials, Cellular flexible -

Accelerated ageing tests.

Compared with GB/T 9640-1988, the main changes of this Standard are as follows:

⎯ In this Standard, add "and rigid" to the title, add "rigid cellular polymeric materials"

to the scope of Clause 1, and apply to "closed-cell polyurethane foams, closed-cell

polyolefin foams" at the same time;

⎯ In Clause 2 "Normative references", change the state conditioning environment

standard from citing GB 2918 to directly citing ISO 741:1995;

⎯ Add Clause 3 “Apparatus”.

This Standard was proposed by China National Light Industry Council.

This Standard shall be under the jurisdiction of National Technical Committee 48 on

Plastic Products of Standardization Administration of China.

Drafting organizations of this Standard: Jiangsu Institute of Product Quality

Supervision and Inspection, Beijing Technology and Business University, National

Engineering Composite Materials Product Quality Supervision and Inspection Center.

Main drafters of this Standard: Wang Yan, Zhu Yuhong, Chen Qian, Zheng Wei.

The previous version replaced by this Standard is:

⎯ GB/T 9640-1988.

Flexible and rigid cellular polymeric materials -Accelerated

ageing tests

1 Scope

This Standard specifies, for flexible and rigid cellular polymeric materials, laboratory

procedures which are intended to imitate the effects of naturally occurring reactions

such as oxidation or hydrolysis by humidity. The physical properties of interest are

measured before and after the application of the specified treatments.

Test conditions are only given for open cellular latex, both open- and closed-ceil

polyurethane foams, and closed-cell polyolefin foams. Conditions for other materials

will be added as required.

Note: The effect of the ageing procedures on any of the physical properties of the

material may be examined, but those normally tested are either the elongation

and tensile properties, or the compression or indentation hardness properties.

These tests do not necessarily correlate either with service behaviour or with

ageing by exposure to light.

2 Normative reference

The terms in the following documents become the terms of this Standard by reference

to this Standard. For dated references, all subsequent amendments (not including errata

content) or revisions do not apply to this standard. However, parties to agreements that

are based on this Standard are encouraged to study whether the latest versions of these

documents can be used. For undated references, the latest edition applies to this

Standard.

GB/T 2941-2006, Rubber - General procedures for preparing and conditioning test

pieces for physical test methods (ISO 23529:2004, IDT)

3 Apparatus

3.1 For heat ageing

3.1.1 Oven, with forced circulation, capable of maintaining the required temperature to

within ±1℃.

Note: It is recommended that a device be used to record the temperature, preferably

continuously.

Tolerance on temperature: ±2 ℃

Tolerance on duration of ageing: ±5 % but not more than ±2 h, the time being measured

from the time when the air in the vessel has been replaced by water vapour (or steam).

Note: in this test for resistance to hydrolysis, the use of the non-standard temperatures

of 105 ℃ and 120 ℃ is included for the following technical reasons: 105 ℃ is

used because this temperature requires the use of a closed vessel so that control

of the conditions is better than at the alternative of 100 ℃; 120 ℃ is used

because much experimental evidence has been accumulated at this temperature,

but little or none at the alternative of 125℃. Until these background data are

collected it is not considered possible to change to 125℃.

5.4 Reconditioning

After exposure to the ageing conditions, test pieces undergoing humidity ageing shall

be dried at 70 ℃± 2 ℃ for 3 h per 25 mm of thickness, subject to a minimum of 3 h.

The humidity-aged test pieces shall then be reconditioned in the atmosphere specified

in 4.2 for 3 h per 25 mm of thickness. Dry-heat-aged test pieces shall merely undergo

the reconditioning procedure.

After reconditioning, the properties of the aged test pieces shall be tested.

6 Calculation and expression of results

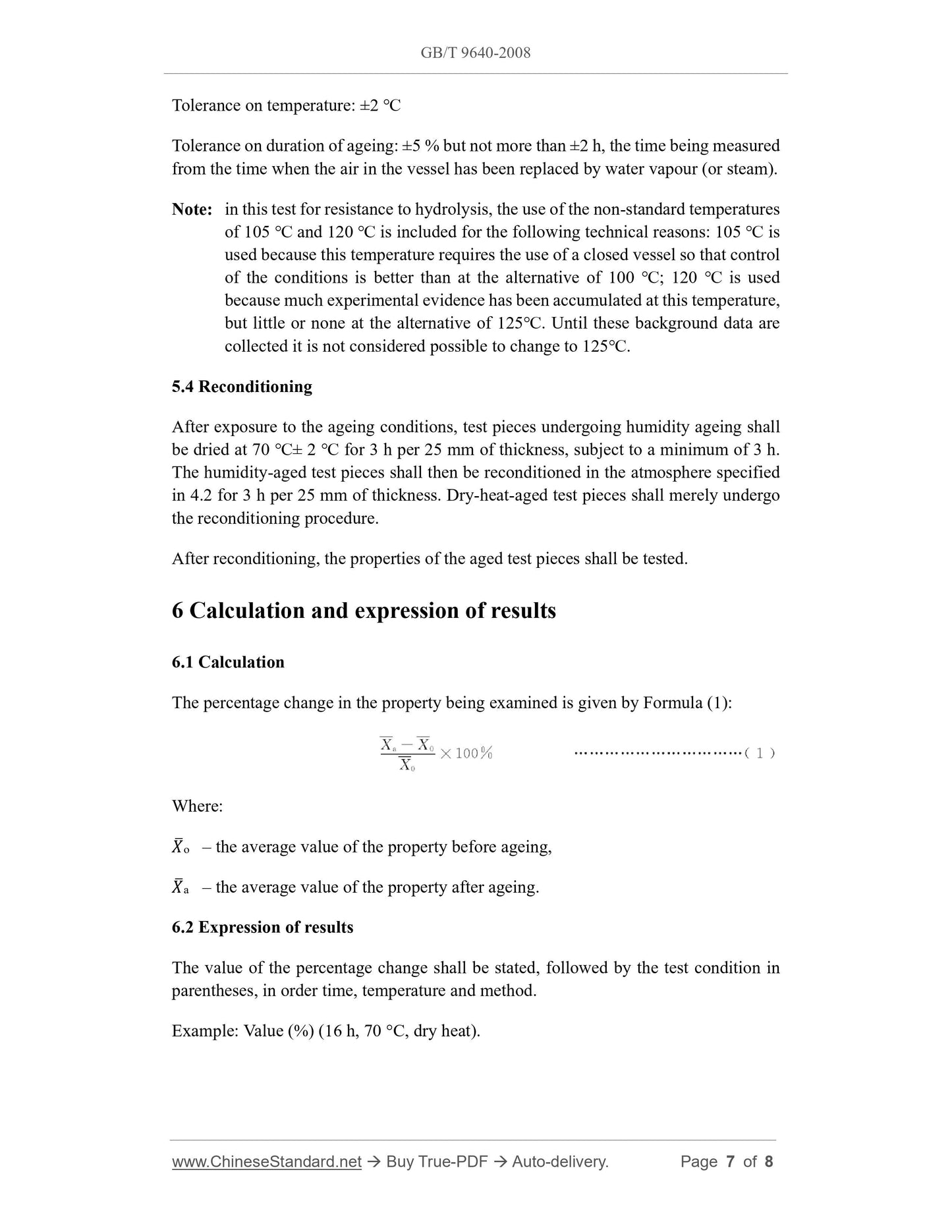

6.1 Calculation

The percentage change in the property being examined is given by Formula (1):

Where:

𝑋തo – the average value of the property before ageing,

𝑋തa – the average value of the property after ageing.

6.2 Expression of results

The value of the percentage change shall be stated, followed by the test condition in

parentheses, in order time, temperature and method.

Example: Value (%) (16 h, 70 °C, dry heat).

Chinese Standards

This is an excerpt of the PDF (Some pages are marked off intentionally)

Full-copy PDF can be purchased from 1 of 2 websites:

1. https://www.ChineseStandard.us

SEARCH the standard ID, such as GB 4943.1-2022.

Select your country (currency), for example: USA (USD); Germany (Euro).

Full-copy of PDF (text-editable, true-PDF) can be downloaded in 9 seconds.

Tax invoice can be downloaded in 9 seconds.

Receiving emails in 9 seconds (with download links).

SEARCH the standard ID, such as GB 4943.1-2022.

Full-copy of PDF (text-editable, true-PDF) can be downloaded in 9 seconds.

Receiving emails in 9 seconds (with PDFs attached, invoice and download links).

Translated by: Field Test Asia Pte. Ltd. (Incorporated and taxed in Singapore. Tax ID: 201302277C)

Linkin: https://www.linkedin.com/in/waynezhengwenrui/

------ The End ------

Get QUOTATION in 1-minute: Click GB/T 9640-2008

Historical versions: GB/T 9640-2008

Preview True-PDF (Reload/Scroll if blank)

GB/T 9640-2008: Flexible and rigid cellular polymeric materials -- Accelerated ageing tests

GB/T 9640-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.080.01

G 31

GB/T 9640-2008 / ISO 2440:1997

Replacing GB/T 9640-1988

Flexible and rigid cellular polymeric materials -Accelerated

ageing tests

(ISO 2440:1997, IDT)

ISSUED ON: AUGUST 19, 2008

IMPLEMENTED ON: MAY 01, 2009

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative reference ... 4

3 Apparatus ... 4

4 Test pieces ... 5

5 Procedure ... 6

6 Calculation and expression of results ... 7

7 Test report ... 8

Foreword

This Standard is identical to the International Standard ISO 2440:1997 Flexible and

rigid cellular polymeric materials - Accelerated ageing tests. The technical content and

standard structure are exactly the same, with only minor editorial modifications.

This Standard replaces GB/T 9640-1988, Polymeric materials, Cellular flexible -

Accelerated ageing tests.

Compared with GB/T 9640-1988, the main changes of this Standard are as follows:

⎯ In this Standard, add "and rigid" to the title, add "rigid cellular polymeric materials"

to the scope of Clause 1, and apply to "closed-cell polyurethane foams, closed-cell

polyolefin foams" at the same time;

⎯ In Clause 2 "Normative references", change the state conditioning environment

standard from citing GB 2918 to directly citing ISO 741:1995;

⎯ Add Clause 3 “Apparatus”.

This Standard was proposed by China National Light Industry Council.

This Standard shall be under the jurisdiction of National Technical Committee 48 on

Plastic Products of Standardization Administration of China.

Drafting organizations of this Standard: Jiangsu Institute of Product Quality

Supervision and Inspection, Beijing Technology and Business University, National

Engineering Composite Materials Product Quality Supervision and Inspection Center.

Main drafters of this Standard: Wang Yan, Zhu Yuhong, Chen Qian, Zheng Wei.

The previous version replaced by this Standard is:

⎯ GB/T 9640-1988.

Flexible and rigid cellular polymeric materials -Accelerated

ageing tests

1 Scope

This Standard specifies, for flexible and rigid cellular polymeric materials, laboratory

procedures which are intended to imitate the effects of naturally occurring reactions

such as oxidation or hydrolysis by humidity. The physical properties of interest are

measured before and after the application of the specified treatments.

Test conditions are only given for open cellular latex, both open- and closed-ceil

polyurethane foams, and closed-cell polyolefin foams. Conditions for other materials

will be added as required.

Note: The effect of the ageing procedures on any of the physical properties of the

material may be examined, but those normally tested are either the elongation

and tensile properties, or the compression or indentation hardness properties.

These tests do not necessarily correlate either with service behaviour or with

ageing by exposure to light.

2 Normative reference

The terms in the following documents become the terms of this Standard by reference

to this Standard. For dated references, all subsequent amendments (not including errata

content) or revisions do not apply to this standard. However, parties to agreements that

are based on this Standard are encouraged to study whether the latest versions of these

documents can be used. For undated references, the latest edition applies to this

Standard.

GB/T 2941-2006, Rubber - General procedures for preparing and conditioning test

pieces for physical test methods (ISO 23529:2004, IDT)

3 Apparatus

3.1 For heat ageing

3.1.1 Oven, with forced circulation, capable of maintaining the required temperature to

within ±1℃.

Note: It is recommended that a device be used to record the temperature, preferably

continuously.

Tolerance on temperature: ±2 ℃

Tolerance on duration of ageing: ±5 % but not more than ±2 h, the time being measured

from the time when the air in the vessel has been replaced by water vapour (or steam).

Note: in this test for resistance to hydrolysis, the use of the non-standard temperatures

of 105 ℃ and 120 ℃ is included for the following technical reasons: 105 ℃ is

used because this temperature requires the use of a closed vessel so that control

of the conditions is better than at the alternative of 100 ℃; 120 ℃ is used

because much experimental evidence has been accumulated at this temperature,

but little or none at the alternative of 125℃. Until these background data are

collected it is not considered possible to change to 125℃.

5.4 Reconditioning

After exposure to the ageing conditions, test pieces undergoing humidity ageing shall

be dried at 70 ℃± 2 ℃ for 3 h per 25 mm of thickness, subject to a minimum of 3 h.

The humidity-aged test pieces shall then be reconditioned in the atmosphere specified

in 4.2 for 3 h per 25 mm of thickness. Dry-heat-aged test pieces shall merely undergo

the reconditioning procedure.

After reconditioning, the properties of the aged test pieces shall be tested.

6 Calculation and expression of results

6.1 Calculation

The percentage change in the property being examined is given by Formula (1):

Where:

𝑋തo – the average value of the property before ageing,

𝑋തa – the average value of the property after ageing.

6.2 Expression of results

The value of the percentage change shall be stated, followed by the test condition in

parentheses, in order time, temperature and method.

Example: Value (%) (16 h, 70 °C, dry heat).

Chinese Standards

This is an excerpt of the PDF (Some pages are marked off intentionally)

Full-copy PDF can be purchased from 1 of 2 websites:

1. https://www.ChineseStandard.us

SEARCH the standard ID, such as GB 4943.1-2022.

Select your country (currency), for example: USA (USD); Germany (Euro).

Full-copy of PDF (text-editable, true-PDF) can be downloaded in 9 seconds.

Tax invoice can be downloaded in 9 seconds.

Receiving emails in 9 seconds (with download links).

SEARCH the standard ID, such as GB 4943.1-2022.

Full-copy of PDF (text-editable, true-PDF) can be downloaded in 9 seconds.

Receiving emails in 9 seconds (with PDFs attached, invoice and download links).

Translated by: Field Test Asia Pte. Ltd. (Incorporated and taxed in Singapore. Tax ID: 201302277C)

Linkin: https://www.linkedin.com/in/waynezhengwenrui/

------ The End ------

Share