1

/

의

7

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 1031-2016 English PDF (YYT1031-2016)

YY/T 1031-2016 English PDF (YYT1031-2016)

정가

$230.00 USD

정가

할인가

$230.00 USD

단가

/

단위

배송료는 결제 시 계산됩니다.

픽업 사용 가능 여부를 로드할 수 없습니다.

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY/T 1031-2016

Historical versions: YY/T 1031-2016

Preview True-PDF (Reload/Scroll if blank)

YY/T 1031-2016: Needle holders

YY/T 1031-2016

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.30

C 31

Replacing YY/T 1031-2004

Needle Holders

持针钳

ISSUED ON: MARCH 23, 2016

IMPLEMENTED ON: JANUARY 1, 2017

Issued by: China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Classification ... 5

4 Requirements ... 9

5 Test Methods ... 11

6 Marking ... 13

7 Packaging and Storage ... 13

Appendix A (normative) Determination Method for Oscillating Quantity of Head End

of Needle Holders ... 14

Appendix B (normative) Type Inspection ... 18

Needle Holders

1 Scope

This Standard specifies the classification, requirements, test methods, marking, packaging,

storage and inspection rules of needle holders.

This Standard is applicable to needle holders for holding suture needles for suturing skin,

microvessels or tissues, etc.

2 Normative References

The following documents are indispensable to the application of this document. In terms of

references with a specified date, only versions with a specified date are applicable to this

document. In terms of references without a specified date, the latest version (including all the

modifications) is applicable to this document.

GB/T 230.1-2009 Metallic Materials - Rockwell Hardness Test - Part 1: Test Method (scales A,

B, C, D, E, F, G, H, K, N, T)

GB/T 1220-2007 Stainless Steel Bars

GB/T 4340.1-2009 Metallic Materials - Vickers Hardness Test - Part 1: Test Method

YY/T 0149-2006 Medical Instruments of Stainless Steel - Test Methods of Corrosion

Resistance

YY 0167-2005 Non-absorbable Surgical Suture

YY/T 0171-2008 Surgical Instruments - Packaging, Marking and Instructions

YY/T 0173-2010 Surgical Instruments - Gill Shaft, Bolt and Rivet

YY/T 0173.4-2005 Surgical Instruments - Teeth, Serration, Ratchet and Ellipsoid Ring

YY/T 0294.1-2005 Surgical Instruments - Metallic Materials - Part 1: Stainless Steel

YY/T 1052-2004 Marking Requirements for Surgical Instruments

JJ G 34 Dial Gauges (dial and digital)

3 Classification

3.1 The needle holders are divided into: general needle holders, insert needle holders and

microvascular needle holders.

the handle of the needle holders without cemented carbide inserts shall not be golden yellow.

4.3 Surface Roughness

The surface of the needle holders can be made with gloss or without gloss, and the value of the

surface roughness parameter Ra shall not be greater than: with gloss: 0.4 m, without gloss: 0.8

m.

4.4 Elasticity and Firmness

4.4.1 The needle holders shall have good elasticity and firmness.

4.4.2 The connection between the cemented carbide inserts and the base of the insert needle

holders shall be firm.

4.5 Clamping Performance

The needle holders shall have good clamping performance.

4.6 Tooth Contact

When the finger rings of the needle holders bump against each other, or when the locking teeth

are all locked, no less than three-fifths of the tooth surface of the head serration shall be in

contact.

4.7 Gill Flexibility

The opening and closing of the gill joints of the needle holders shall be flexible, and with

appropriate tightness.

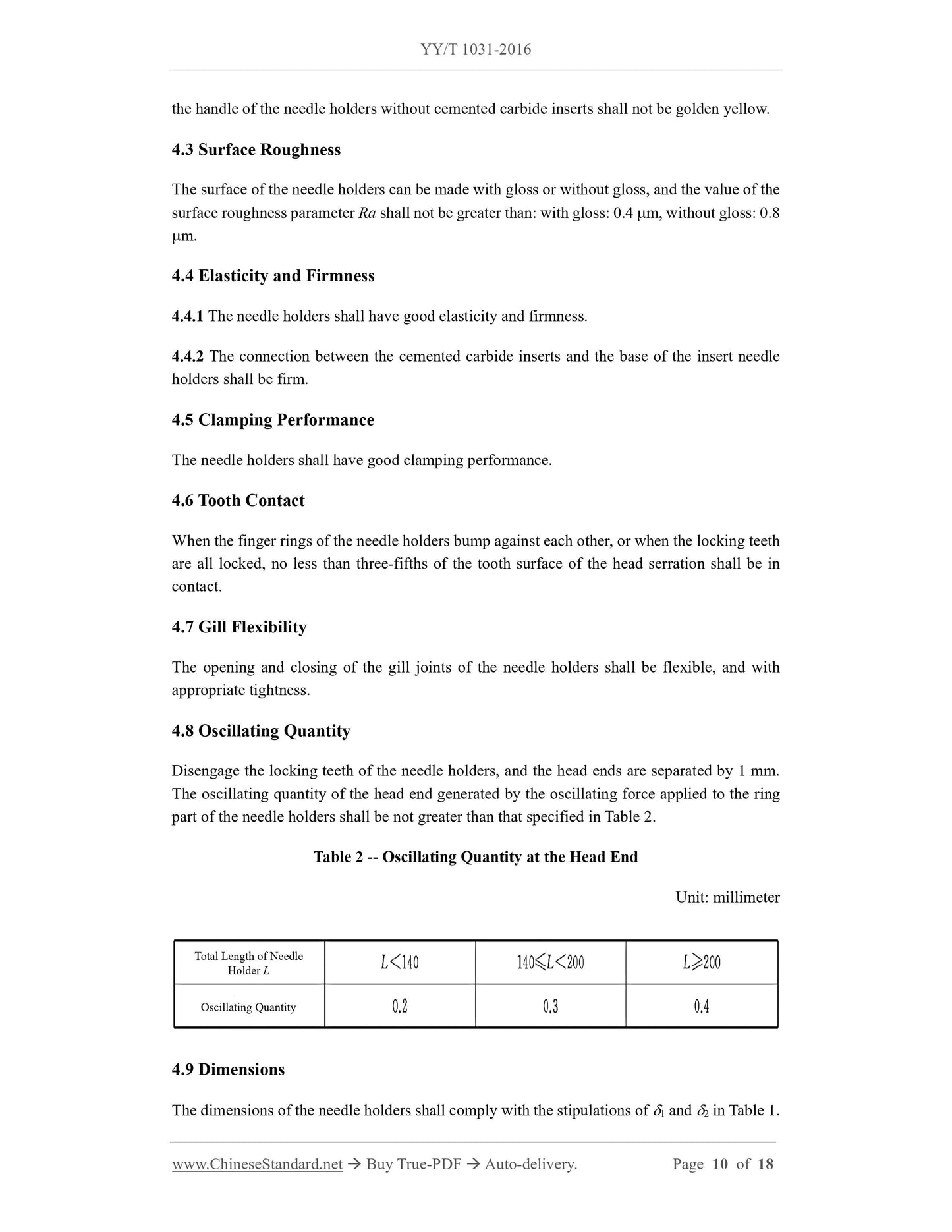

4.8 Oscillating Quantity

Disengage the locking teeth of the needle holders, and the head ends are separated by 1 mm.

The oscillating quantity of the head end generated by the oscillating force applied to the ring

part of the needle holders shall be not greater than that specified in Table 2.

Table 2 -- Oscillating Quantity at the Head End

Unit: millimeter

4.9 Dimensions

The dimensions of the needle holders shall comply with the stipulations of 1 and 2 in Table 1.

Total Length of Needle

Holder L

Oscillating Quantity

4.10 Hardness

4.10.1 The needle holders shall be subjected to thermal treatment, and their hardness shall

comply with the stipulations of Table 3.

4.10.2 The hardness of the cemented carbide insert shall not be less than 923HV0.5; the

difference between two pieces shall not be greater than 50HV0.5.

4.11 Corrosion Resistance

The corrosion resistance of the appearance of the needle holders shall not be lower than the

stipulations of Grade-b in the boiling water test method in YY/T 0149-2006.

5 Test Methods

5.1 Appearance

Use normal or corrected vision to examine it and use hands to touch and feel it, which shall

comply with the stipulations of 4.1.1 and 4.1.2.

5.2 Color Scale of the Handle

Use normal or corrected vision to examine it, which shall comply with the stipulations of 4.2.

5.3 Surface Roughness

The surface roughness of the needle holder shall be examined by the sample piece comparison

method. Under the condition of magnification by 5 ~ 10 times, compare it with the sample piece,

and use normal or corrected vision to examine it, which shall comply with the stipulations of

4.3.

5.4 Elasticity and Firmness

5.4.1 Place a stainless steel wire that complies with the stipulations of Table 4 on the front end

of the head of the needle holder. The needle holder is completely closed, then loosened; repeat

3 times; observe the body of the instrument, which shall comply with the stipulations of 4.4.1.

5.4.2 After the insert needle holder is subjected to the elasticity and firmness test (5.4.1),

observe the insert, which shall comply with the stipulations of 4.4.2.

5.5 Clamping Performance

At one third of the front end of the head of the needle holder, clamp the 3-0 Class I uncoated

medical suture specified in YY 0167-2005; pull it hard, until the suture breaks; observe the

clamped suture, which shall comply with the stipulations of 4.5.

5.6 Tooth Contact

Imitate the action of use, which shall comply with the requirements of 4.6.

5.7 Gill Flexibility

Imitate the action of use, which shall comply with the stipulations of 4.7.

5.8 Oscillating Quantity

Perform the test in accordance with the method specified in Appendix A, which shall comply

with the stipulations of 4.8.

5.9 Dimensions

Use a general measuring instrument to measure them, which shall comply with the stipulations

of 4.9.

5.10 Hardness

5.10.1 In accordance with the stipulations of GB/T 230.1-2009, determine the hardness.

Respectively measure three points on each of the two pieces of the needle holder (except for

the cemented carbide insert); respectively calculate the arithmetic mean, which shall comply

with the stipulations of 4.10.1.

5.10.2 In accordance with the stipulations of GB/T 4340.1-2009, determine the hardness.

Respectively measure three points on each of the two cemented carbide inserts; respectively

calculate the arithmetic mean, which shall comply with the stipulations of 4.10.2.

5.11 Corrosion Resistance

Appendix A

(normative)

Determination Method for Oscillating Quantity of Head End of Needle Holders

A.1 Terms

A.1.1 Oscillating quantity of head end

The head ends of the two pieces are separated by a specified position, and under the action of a

specified force, the two pieces are oscillated relative to each other. Oscillating quantity of head

end refers to the maximum displacement generated between the head ends of the two pieces.

A.1.2 Fixing piece

The female piece of the needle holder.

A.1.3 Oscillating piece

The male piece of the needle holder.

A.1.4 Downward oscillating force

The force applied at the head end of the oscillating piece to oscillate the head end downward.

A.1.5 Upward oscillating force

Get QUOTATION in 1-minute: Click YY/T 1031-2016

Historical versions: YY/T 1031-2016

Preview True-PDF (Reload/Scroll if blank)

YY/T 1031-2016: Needle holders

YY/T 1031-2016

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.30

C 31

Replacing YY/T 1031-2004

Needle Holders

持针钳

ISSUED ON: MARCH 23, 2016

IMPLEMENTED ON: JANUARY 1, 2017

Issued by: China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Classification ... 5

4 Requirements ... 9

5 Test Methods ... 11

6 Marking ... 13

7 Packaging and Storage ... 13

Appendix A (normative) Determination Method for Oscillating Quantity of Head End

of Needle Holders ... 14

Appendix B (normative) Type Inspection ... 18

Needle Holders

1 Scope

This Standard specifies the classification, requirements, test methods, marking, packaging,

storage and inspection rules of needle holders.

This Standard is applicable to needle holders for holding suture needles for suturing skin,

microvessels or tissues, etc.

2 Normative References

The following documents are indispensable to the application of this document. In terms of

references with a specified date, only versions with a specified date are applicable to this

document. In terms of references without a specified date, the latest version (including all the

modifications) is applicable to this document.

GB/T 230.1-2009 Metallic Materials - Rockwell Hardness Test - Part 1: Test Method (scales A,

B, C, D, E, F, G, H, K, N, T)

GB/T 1220-2007 Stainless Steel Bars

GB/T 4340.1-2009 Metallic Materials - Vickers Hardness Test - Part 1: Test Method

YY/T 0149-2006 Medical Instruments of Stainless Steel - Test Methods of Corrosion

Resistance

YY 0167-2005 Non-absorbable Surgical Suture

YY/T 0171-2008 Surgical Instruments - Packaging, Marking and Instructions

YY/T 0173-2010 Surgical Instruments - Gill Shaft, Bolt and Rivet

YY/T 0173.4-2005 Surgical Instruments - Teeth, Serration, Ratchet and Ellipsoid Ring

YY/T 0294.1-2005 Surgical Instruments - Metallic Materials - Part 1: Stainless Steel

YY/T 1052-2004 Marking Requirements for Surgical Instruments

JJ G 34 Dial Gauges (dial and digital)

3 Classification

3.1 The needle holders are divided into: general needle holders, insert needle holders and

microvascular needle holders.

the handle of the needle holders without cemented carbide inserts shall not be golden yellow.

4.3 Surface Roughness

The surface of the needle holders can be made with gloss or without gloss, and the value of the

surface roughness parameter Ra shall not be greater than: with gloss: 0.4 m, without gloss: 0.8

m.

4.4 Elasticity and Firmness

4.4.1 The needle holders shall have good elasticity and firmness.

4.4.2 The connection between the cemented carbide inserts and the base of the insert needle

holders shall be firm.

4.5 Clamping Performance

The needle holders shall have good clamping performance.

4.6 Tooth Contact

When the finger rings of the needle holders bump against each other, or when the locking teeth

are all locked, no less than three-fifths of the tooth surface of the head serration shall be in

contact.

4.7 Gill Flexibility

The opening and closing of the gill joints of the needle holders shall be flexible, and with

appropriate tightness.

4.8 Oscillating Quantity

Disengage the locking teeth of the needle holders, and the head ends are separated by 1 mm.

The oscillating quantity of the head end generated by the oscillating force applied to the ring

part of the needle holders shall be not greater than that specified in Table 2.

Table 2 -- Oscillating Quantity at the Head End

Unit: millimeter

4.9 Dimensions

The dimensions of the needle holders shall comply with the stipulations of 1 and 2 in Table 1.

Total Length of Needle

Holder L

Oscillating Quantity

4.10 Hardness

4.10.1 The needle holders shall be subjected to thermal treatment, and their hardness shall

comply with the stipulations of Table 3.

4.10.2 The hardness of the cemented carbide insert shall not be less than 923HV0.5; the

difference between two pieces shall not be greater than 50HV0.5.

4.11 Corrosion Resistance

The corrosion resistance of the appearance of the needle holders shall not be lower than the

stipulations of Grade-b in the boiling water test method in YY/T 0149-2006.

5 Test Methods

5.1 Appearance

Use normal or corrected vision to examine it and use hands to touch and feel it, which shall

comply with the stipulations of 4.1.1 and 4.1.2.

5.2 Color Scale of the Handle

Use normal or corrected vision to examine it, which shall comply with the stipulations of 4.2.

5.3 Surface Roughness

The surface roughness of the needle holder shall be examined by the sample piece comparison

method. Under the condition of magnification by 5 ~ 10 times, compare it with the sample piece,

and use normal or corrected vision to examine it, which shall comply with the stipulations of

4.3.

5.4 Elasticity and Firmness

5.4.1 Place a stainless steel wire that complies with the stipulations of Table 4 on the front end

of the head of the needle holder. The needle holder is completely closed, then loosened; repeat

3 times; observe the body of the instrument, which shall comply with the stipulations of 4.4.1.

5.4.2 After the insert needle holder is subjected to the elasticity and firmness test (5.4.1),

observe the insert, which shall comply with the stipulations of 4.4.2.

5.5 Clamping Performance

At one third of the front end of the head of the needle holder, clamp the 3-0 Class I uncoated

medical suture specified in YY 0167-2005; pull it hard, until the suture breaks; observe the

clamped suture, which shall comply with the stipulations of 4.5.

5.6 Tooth Contact

Imitate the action of use, which shall comply with the requirements of 4.6.

5.7 Gill Flexibility

Imitate the action of use, which shall comply with the stipulations of 4.7.

5.8 Oscillating Quantity

Perform the test in accordance with the method specified in Appendix A, which shall comply

with the stipulations of 4.8.

5.9 Dimensions

Use a general measuring instrument to measure them, which shall comply with the stipulations

of 4.9.

5.10 Hardness

5.10.1 In accordance with the stipulations of GB/T 230.1-2009, determine the hardness.

Respectively measure three points on each of the two pieces of the needle holder (except for

the cemented carbide insert); respectively calculate the arithmetic mean, which shall comply

with the stipulations of 4.10.1.

5.10.2 In accordance with the stipulations of GB/T 4340.1-2009, determine the hardness.

Respectively measure three points on each of the two cemented carbide inserts; respectively

calculate the arithmetic mean, which shall comply with the stipulations of 4.10.2.

5.11 Corrosion Resistance

Appendix A

(normative)

Determination Method for Oscillating Quantity of Head End of Needle Holders

A.1 Terms

A.1.1 Oscillating quantity of head end

The head ends of the two pieces are separated by a specified position, and under the action of a

specified force, the two pieces are oscillated relative to each other. Oscillating quantity of head

end refers to the maximum displacement generated between the head ends of the two pieces.

A.1.2 Fixing piece

The female piece of the needle holder.

A.1.3 Oscillating piece

The male piece of the needle holder.

A.1.4 Downward oscillating force

The force applied at the head end of the oscillating piece to oscillate the head end downward.

A.1.5 Upward oscillating force

Share