1

/

of

7

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JJG 975-2002 English PDF

JJG 975-2002 English PDF

Regular price

$160.00 USD

Regular price

Sale price

$160.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JJG 975-2002

Historical versions: JJG 975-2002

Preview True-PDF (Reload/Scroll if blank)

JJG 975-2002: Verification regulation of chemical oxygen demand (COD) meters

JJG 975-2002

JJG

NATIONAL METROLOGY VERIFICATION

REGULATION OF THE PEOPLE’S REPUBLIC OF CHINA

Chemical Oxygen Demand (COD) Meters

ISSUED ON. NOVEMBER 04, 2002

IMPLEMENTED ON. FEBRUARY 04, 2003

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Overview ... 4

3 Requirements for Metrological Performance ... 5

3.1 Type-A instrument ... 5

3.2 Type B instrument ... 6

4 General Technical Conditions ... 6

4.1 Appearance... 6

4.2 Safety performance ... 6

5 Metrological Apparatus Control ... 6

5.1 Verification conditions ... 6

5.2 Verification items ... 7

5.3 Verification method ... 8

5.4 Treatment of verification result ... 11

5.5 Verification cycle ... 11

Appendix A Verification Record Format (Type-A Instrument) ... 12

Appendix B Verification Record Format (Type-B Instrument) ... 14

Appendix C Internal Page Format of Verification Certificate (Type-A Instrument) ... 15

Appendix D Internal Page Format of Verification Certificate (Type-B Instrument) ... 16

Appendix E Internal Page Format of Verification Result Notice (Type-A Instrument) ... 17

Appendix F Internal Page Format of Verification Result Notice (Type-B Instrument) ... 18

Verification Regulation of

Chemical Oxygen Demand (COD) Meters

1 Scope

This Regulation is applicable to the first-time verification, follow-up verification, and in-

service inspection of the chemical oxygen demand meters; while the calibration of

online chemical oxygen demand meters can refer to this Regulation for implementation.

2 Overview

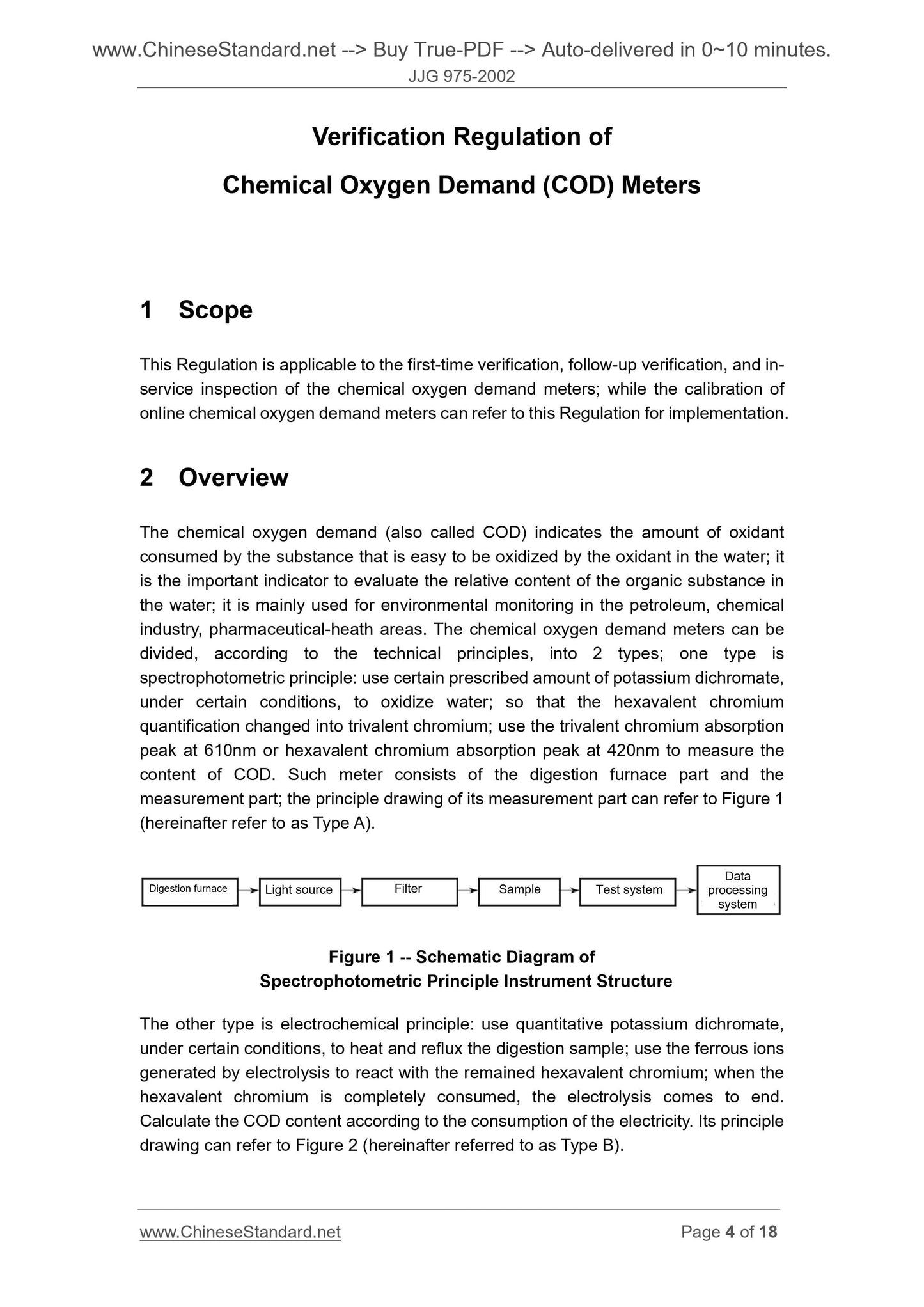

The chemical oxygen demand (also called COD) indicates the amount of oxidant

consumed by the substance that is easy to be oxidized by the oxidant in the water; it

is the important indicator to evaluate the relative content of the organic substance in

the water; it is mainly used for environmental monitoring in the petroleum, chemical

industry, pharmaceutical-heath areas. The chemical oxygen demand meters can be

divided, according to the technical principles, into 2 types; one type is

spectrophotometric principle. use certain prescribed amount of potassium dichromate,

under certain conditions, to oxidize water; so that the hexavalent chromium

quantification changed into trivalent chromium; use the trivalent chromium absorption

peak at 610nm or hexavalent chromium absorption peak at 420nm to measure the

content of COD. Such meter consists of the digestion furnace part and the

measurement part; the principle drawing of its measurement part can refer to Figure 1

(hereinafter refer to as Type A).

Figure 1 -- Schematic Diagram of

Spectrophotometric Principle Instrument Structure

The other type is electrochemical principle. use quantitative potassium dichromate,

under certain conditions, to heat and reflux the digestion sample; use the ferrous ions

generated by electrolysis to react with the remained hexavalent chromium; when the

hexavalent chromium is completely consumed, the electrolysis comes to end.

Calculate the COD content according to the consumption of the electricity. Its principle

drawing can refer to Figure 2 (hereinafter referred to as Type B).

Data

processing

system

Test system Sample Filter Light source Digestion furnace

3.2 Type B instrument

3.2.1 Indication error

Under the prescribed conditions, the instrument’s indication error shall not exceed

±2.0mg/L.

3.2.2 Repeatability

Under the prescribed conditions, the measurement repeatability shall be no greater

than 2%.

4 General Technical Conditions

4.1 Appearance

The instrument shall have the following signs. instrument name, model, exit-factory

number, manufacturer name, exit-factory date, sign, working voltage and

frequency, etc.; the instrument appearance is exempted from the damage that shall

affect the normal work.

4.2 Safety performance

The insulation resistance of instrument shall be no less than 20MΩ.

5 Metrological Apparatus Control

The metrological apparatus control includes first-time verification, follow-up verification

and in-service inspection.

5.1 Verification conditions

5.1.1 Equipment for verification

5.1.1.1 Thermometer. measuring range is 100~200°C (Grade-0.5).

5.1.1.2 50, 100, 300, 1000 mg/L COD solution standard substance; its uncertainty

shall be no greater than 3% (k=2).

5.1.1.3 0.05mol/L 1/6K2Cr2O7 solution standard substance; its uncertainty shall be no

greater than 1.0% (k=2).

5.3 Verification method

5.3.1 Appearance and routine requirements

It shall be performed through visual examination.

5.3.2 Access the insulation resistance meter to the power incoming line end and the

housing; turn on the instrument switch, measure the insulation resistance.

5.3.3 Type-A instrument verification method

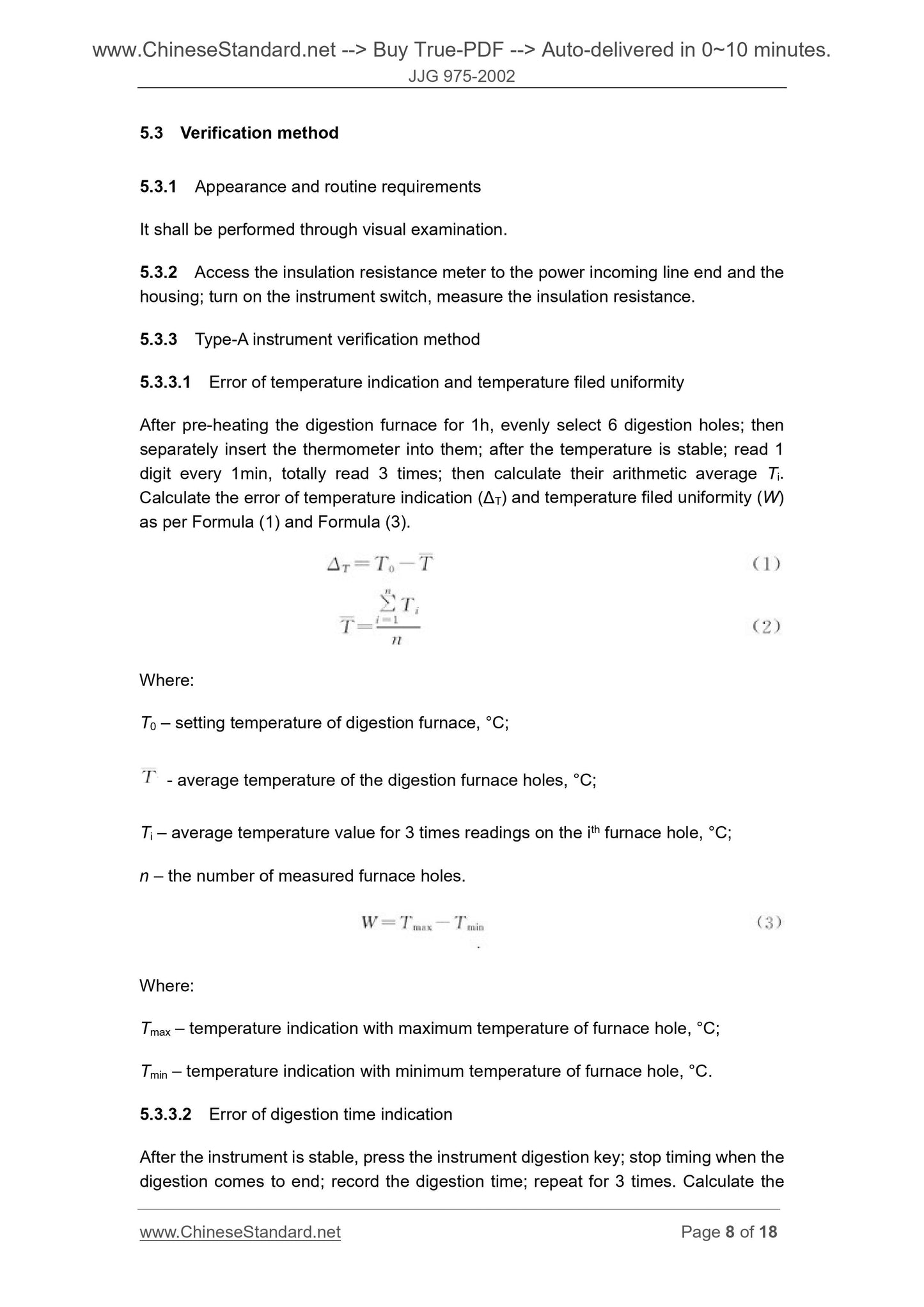

5.3.3.1 Error of temperature indication and temperature filed uniformity

After pre-heating the digestion furnace for 1h, evenly select 6 digestion holes; then

separately insert the thermometer into them; after the temperature is stable; read 1

digit every 1min, totally read 3 times; then calculate their arithmetic average Ti.

Calculate the error of temperature indication (ΔT) and temperature filed uniformity (W)

as per Formula (1) and Formula (3).

Where.

T0 – setting temperature of digestion furnace, °C;

- average temperature of the digestion furnace holes, °C;

Ti – average temperature value for 3 times readings on the ith furnace hole, °C;

n – the number of measured furnace holes.

Where.

Tmax – temperature indication with maximum temperature of furnace hole, °C;

Tmin – temperature indication with minimum temperature of furnace hole, °C.

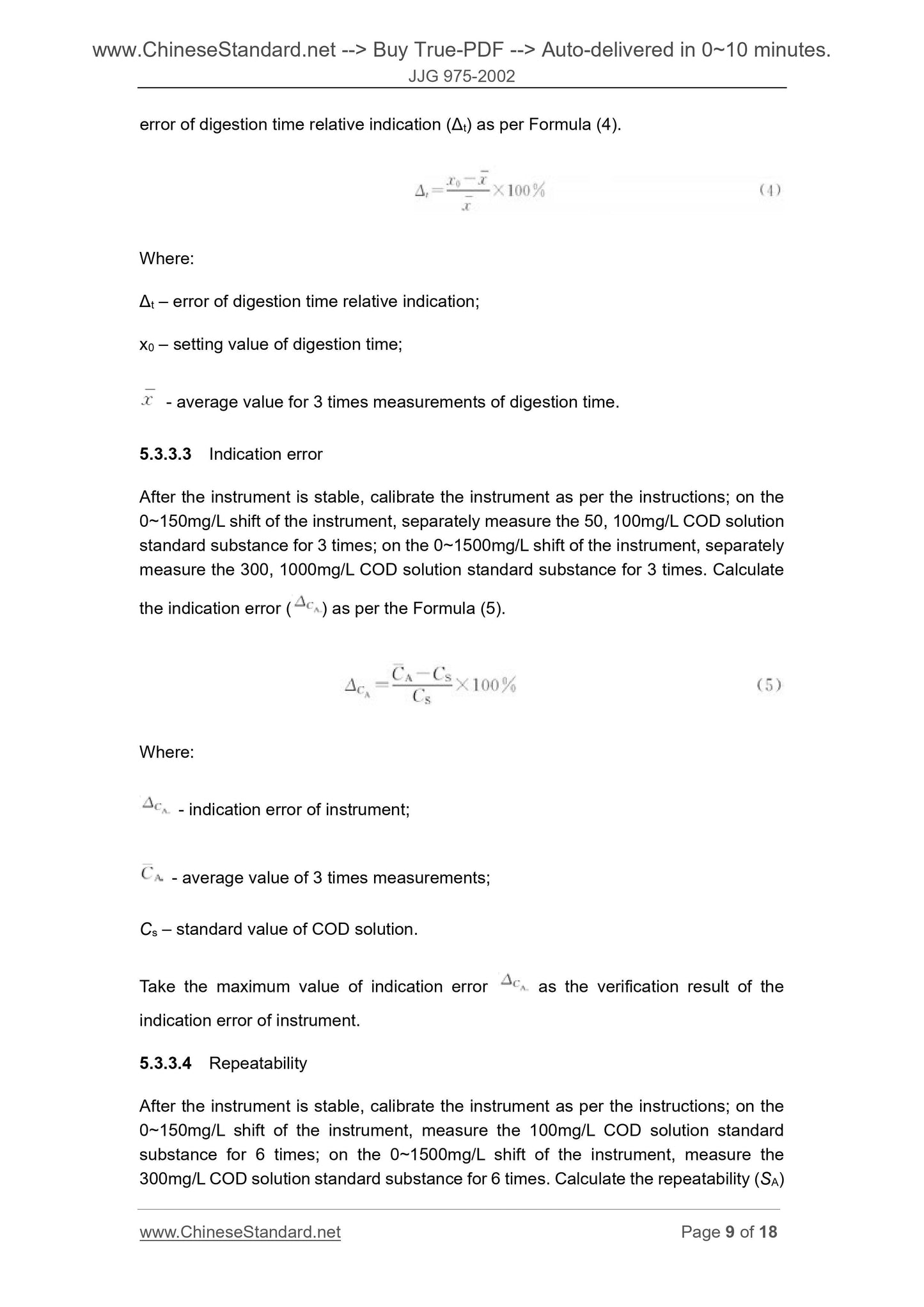

5.3.3.2 Error of digestion time indication

After the instrument is stable, press the instrument digestion key; stop timing when the

digestion comes to end; record the digestion time; repeat for 3 times. Calculate the

error of digestion time relative indication (Δt) as per Formula (4).

Where.

Δt – error of digestion time relative indication;

x0 – setting value of digestion time;

- average value for 3 times measurements of digestion time.

5.3.3.3 Indication error

After the instrument is stable, calibrate the instrument as per the instructions; on the

0~150mg/L shift of the instrument, separately measure the 50, 100mg/L COD solution

standard substance for 3 times; on the 0~1500mg/L shift of the instrument, separately

measure the 300, 1000mg/L COD solution standard substance for 3 times. Calculate

the indication error ( ) as per the Formula (5).

Where.

- indication error of instrument;

- average value of 3 times measurements;

Cs – standard value of COD solution.

Take the maximum value of indication error as the verification result of the

indication error of instrument.

5.3.3.4 Repeatability

After the instrument is stable, calibrate the instrument as per the instructions; on the

0~150mg/L shift of the instrument, measure the 100mg/L COD solution standard

substance for 6 times; on the 0~1500mg/L shift of the instrument, measure the

300mg/L COD solution standard substance for 6 times. Calculate the repeatability (SA)

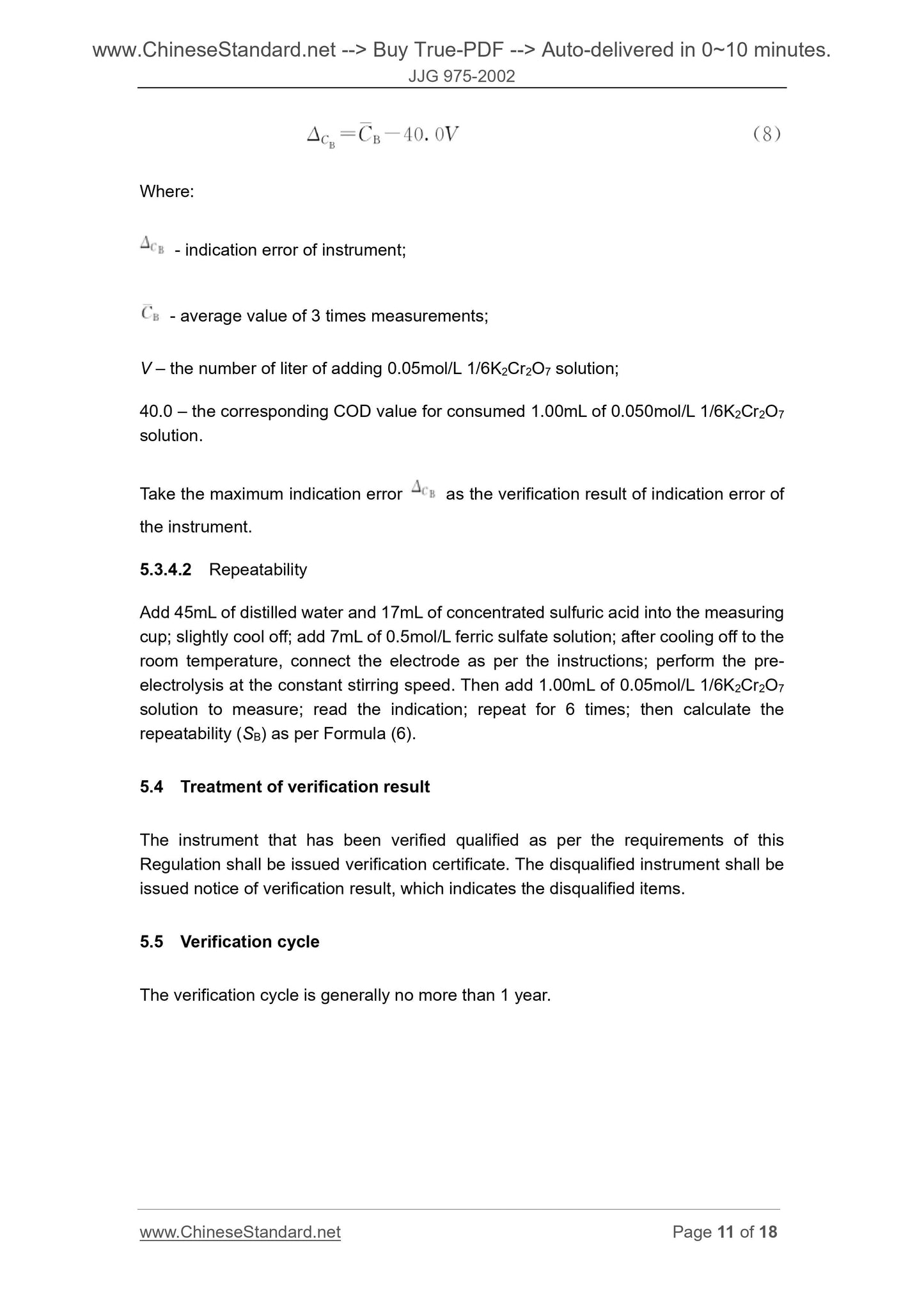

Where.

- indication error of instrument;

- average value of 3 times measurements;

V – the number of liter of adding 0.05mol/L 1/6K2Cr2O7 solution;

40.0 – the corresponding COD value for con...

Get QUOTATION in 1-minute: Click JJG 975-2002

Historical versions: JJG 975-2002

Preview True-PDF (Reload/Scroll if blank)

JJG 975-2002: Verification regulation of chemical oxygen demand (COD) meters

JJG 975-2002

JJG

NATIONAL METROLOGY VERIFICATION

REGULATION OF THE PEOPLE’S REPUBLIC OF CHINA

Chemical Oxygen Demand (COD) Meters

ISSUED ON. NOVEMBER 04, 2002

IMPLEMENTED ON. FEBRUARY 04, 2003

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Overview ... 4

3 Requirements for Metrological Performance ... 5

3.1 Type-A instrument ... 5

3.2 Type B instrument ... 6

4 General Technical Conditions ... 6

4.1 Appearance... 6

4.2 Safety performance ... 6

5 Metrological Apparatus Control ... 6

5.1 Verification conditions ... 6

5.2 Verification items ... 7

5.3 Verification method ... 8

5.4 Treatment of verification result ... 11

5.5 Verification cycle ... 11

Appendix A Verification Record Format (Type-A Instrument) ... 12

Appendix B Verification Record Format (Type-B Instrument) ... 14

Appendix C Internal Page Format of Verification Certificate (Type-A Instrument) ... 15

Appendix D Internal Page Format of Verification Certificate (Type-B Instrument) ... 16

Appendix E Internal Page Format of Verification Result Notice (Type-A Instrument) ... 17

Appendix F Internal Page Format of Verification Result Notice (Type-B Instrument) ... 18

Verification Regulation of

Chemical Oxygen Demand (COD) Meters

1 Scope

This Regulation is applicable to the first-time verification, follow-up verification, and in-

service inspection of the chemical oxygen demand meters; while the calibration of

online chemical oxygen demand meters can refer to this Regulation for implementation.

2 Overview

The chemical oxygen demand (also called COD) indicates the amount of oxidant

consumed by the substance that is easy to be oxidized by the oxidant in the water; it

is the important indicator to evaluate the relative content of the organic substance in

the water; it is mainly used for environmental monitoring in the petroleum, chemical

industry, pharmaceutical-heath areas. The chemical oxygen demand meters can be

divided, according to the technical principles, into 2 types; one type is

spectrophotometric principle. use certain prescribed amount of potassium dichromate,

under certain conditions, to oxidize water; so that the hexavalent chromium

quantification changed into trivalent chromium; use the trivalent chromium absorption

peak at 610nm or hexavalent chromium absorption peak at 420nm to measure the

content of COD. Such meter consists of the digestion furnace part and the

measurement part; the principle drawing of its measurement part can refer to Figure 1

(hereinafter refer to as Type A).

Figure 1 -- Schematic Diagram of

Spectrophotometric Principle Instrument Structure

The other type is electrochemical principle. use quantitative potassium dichromate,

under certain conditions, to heat and reflux the digestion sample; use the ferrous ions

generated by electrolysis to react with the remained hexavalent chromium; when the

hexavalent chromium is completely consumed, the electrolysis comes to end.

Calculate the COD content according to the consumption of the electricity. Its principle

drawing can refer to Figure 2 (hereinafter referred to as Type B).

Data

processing

system

Test system Sample Filter Light source Digestion furnace

3.2 Type B instrument

3.2.1 Indication error

Under the prescribed conditions, the instrument’s indication error shall not exceed

±2.0mg/L.

3.2.2 Repeatability

Under the prescribed conditions, the measurement repeatability shall be no greater

than 2%.

4 General Technical Conditions

4.1 Appearance

The instrument shall have the following signs. instrument name, model, exit-factory

number, manufacturer name, exit-factory date, sign, working voltage and

frequency, etc.; the instrument appearance is exempted from the damage that shall

affect the normal work.

4.2 Safety performance

The insulation resistance of instrument shall be no less than 20MΩ.

5 Metrological Apparatus Control

The metrological apparatus control includes first-time verification, follow-up verification

and in-service inspection.

5.1 Verification conditions

5.1.1 Equipment for verification

5.1.1.1 Thermometer. measuring range is 100~200°C (Grade-0.5).

5.1.1.2 50, 100, 300, 1000 mg/L COD solution standard substance; its uncertainty

shall be no greater than 3% (k=2).

5.1.1.3 0.05mol/L 1/6K2Cr2O7 solution standard substance; its uncertainty shall be no

greater than 1.0% (k=2).

5.3 Verification method

5.3.1 Appearance and routine requirements

It shall be performed through visual examination.

5.3.2 Access the insulation resistance meter to the power incoming line end and the

housing; turn on the instrument switch, measure the insulation resistance.

5.3.3 Type-A instrument verification method

5.3.3.1 Error of temperature indication and temperature filed uniformity

After pre-heating the digestion furnace for 1h, evenly select 6 digestion holes; then

separately insert the thermometer into them; after the temperature is stable; read 1

digit every 1min, totally read 3 times; then calculate their arithmetic average Ti.

Calculate the error of temperature indication (ΔT) and temperature filed uniformity (W)

as per Formula (1) and Formula (3).

Where.

T0 – setting temperature of digestion furnace, °C;

- average temperature of the digestion furnace holes, °C;

Ti – average temperature value for 3 times readings on the ith furnace hole, °C;

n – the number of measured furnace holes.

Where.

Tmax – temperature indication with maximum temperature of furnace hole, °C;

Tmin – temperature indication with minimum temperature of furnace hole, °C.

5.3.3.2 Error of digestion time indication

After the instrument is stable, press the instrument digestion key; stop timing when the

digestion comes to end; record the digestion time; repeat for 3 times. Calculate the

error of digestion time relative indication (Δt) as per Formula (4).

Where.

Δt – error of digestion time relative indication;

x0 – setting value of digestion time;

- average value for 3 times measurements of digestion time.

5.3.3.3 Indication error

After the instrument is stable, calibrate the instrument as per the instructions; on the

0~150mg/L shift of the instrument, separately measure the 50, 100mg/L COD solution

standard substance for 3 times; on the 0~1500mg/L shift of the instrument, separately

measure the 300, 1000mg/L COD solution standard substance for 3 times. Calculate

the indication error ( ) as per the Formula (5).

Where.

- indication error of instrument;

- average value of 3 times measurements;

Cs – standard value of COD solution.

Take the maximum value of indication error as the verification result of the

indication error of instrument.

5.3.3.4 Repeatability

After the instrument is stable, calibrate the instrument as per the instructions; on the

0~150mg/L shift of the instrument, measure the 100mg/L COD solution standard

substance for 6 times; on the 0~1500mg/L shift of the instrument, measure the

300mg/L COD solution standard substance for 6 times. Calculate the repeatability (SA)

Where.

- indication error of instrument;

- average value of 3 times measurements;

V – the number of liter of adding 0.05mol/L 1/6K2Cr2O7 solution;

40.0 – the corresponding COD value for con...

Share