1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

Q/BQB 131-2018 English PDF

Q/BQB 131-2018 English PDF

Regular price

$230.00 USD

Regular price

Sale price

$230.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click Q/BQB 131-2018

Historical versions: Q/BQB 131-2018

Preview True-PDF (Reload/Scroll if blank)

Q/BQB 131-2018: Continuous casting slab

Q/BQB 131-2018

BQB

ENTERPRISE STANDARD OF BAOSTEEL

Replacing Q/BQB 131-2014

Continuous Casting Slab

连铸板坯

ISSUED ON. JANUARY 15, 2018

IMPLEMENTED ON. APRIL 10, 2018

Issued by. Baoshan Iron and Steel Co., Ltd.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 information Required for Ordering ... 5

4 Size, Shape, Weight and Allowable Deviation ... 6

5 Technical Requirements ... 7

6 Inspection and Test ... 10

7 Marking and Inspection Document ... 11

Foreword

This Standard was drafted as per the requirements and format specified in GB/T 1.1-

2009 Directives for Standardization – Part 1. Structure and Drafting of Standards.

This Standard is based on the characteristics of our company’s products and

processes.

Please note that some contents of this Standard may involve patents. The issuing

organization of this Standard does not assume the responsibility for identifying these

patents.

This Standard replaces Q/BQB 131-2014. Compared with Q/BQB 131-2014, this

Standard has the major changes as follows.

--- Add “Clause 2 Normative References”;

--- Delete the thickness specifications of 150mm, 200mm, 210mm, 220mm; add the

thickness specification of 360mm;

--- Delete the provision of general length range in Table 1;

--- Refer to YB/T 2012-2014, the width allowable deviation is changed from “-

10mm~+15mm” to altering as the nominal width range in Table 2;

--- In Table 1, for the slab with thickness specification of 250mm, the specified length

range is changed from “6800mm~12000mm” to “6000mm~11800mm”; for the

slab with thickness specification of 230mm, the width is changed from

“800mm~1930mm” to “900mm~2300mm”, while the specified length is changed

from “8000mm~12000mm” to “6000mm~11000mm”;

--- Add “the allowable deviation of the size and shape of the continuous casting slab

can be appropriately adjusted after negotiation between the supplier and the

purchaser. The size and allowable deviation of the slab that needs to be cleaned

by the whole surface shall be determined through the negotiation between the

supplier and the purchaser.”;

--- Add macrostructure inspection requirements for on-demand selection;

--- Modify the surface quality requirements by referring to YB/T 2012-2014;

--- Referring to YB/T 2012-2014, change the width wedge type from “∣W -

W2∣≤20 mm” to “∣W-W2∣≤10 mm, for the head and tail blank ≤50mm”;

--- Add the Clause on Test Method and Table 4;

Continuous Casting Slab

1 Scope

This Standard specifies the size, shape, weight and allowable deviation, technical

requirements, inspection and test, marking and inspection document, etc. of

continuous casting slab.

This Standard is applicable to the continuous casting slab for hot rolling and thick

plates. The slab must not be cut longitudinally.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 226-2015 Test Method for Macrostructure and Defect of Steel by Etching

GB/T 2101-2017 General Requirement of Acceptance Packaging Marking and

Certification for Section Steel

GB/T 4236-2016 Steel Examination by Sulphur Print (Baumann Method)

YB/T 4003-2016 Standard Diagrams for Macrostructure and Defect in Continuous

Casting Slab

3 information Required for Ordering

When ordering, the users shall provide the following information.

a) This enterprise standard number;

b) Grade;

c) Specification;

d) Weight;

4.3 Weight

The slab shall be delivered by actual weight.

5 Technical Requirements

5.1 Grade and chemical composition

The grade and chemical composition (melting analysis) of steel shall conform to the

provisions of Baosteel enterprise standard or other relevant standards.

5.2 Smelting method

The steel is smelted by an oxygen converter.

5.3 Delivery state

The slab shall be delivered in as-cast condition.

5.4 Macrostructure inspection

According to the demand of the purchaser, the supplier and the purchaser shall

negotiate and indicate in the contract that the continuous casting slab may be

subjected to Sulphur printing or macrostructure inspection. The test method and

acceptance criteria shall be determined through the negotiation between the supplier

and the purchaser; if there is no agreement, then it shall be determined by the supplier,

see Table 4.

5.5 Surface quality

5.5.1 The slab cross-sections shall be free of the shrinkage holes, subcutaneous

bubbles, cracks that may affect he use.

5.5.2 The slab surface shall be free of reconnections, overlaps, bumbling, crusting,

slag; 3mm-above-deep-or-high scratches, indentations, abrasions, stomata, cold

splashes, wrinkles, bumps, dimples; 2mm-above-deep cracks; as well as other defects

that may affect the rolling quality. There must be no flame cutting tumors greater than

5mm in height.

5.5.3 If the above defects are present on the surface of the slab, they are allowed to

be removed. The removal shall be carried out along the rolling direction; the removal

position shall be smooth without corners. The removal depth on one side shall be no

greater than 10% of nominal thickness; the sum of the removal depths of the two

opposite surfaces shall be no greater than 15% of the nominal thickness. The removal

width shall be greater than 6 times of the removal depth; while the removal length shall

be greater than 10 times of the removal depth. The removal depth shall be calculated

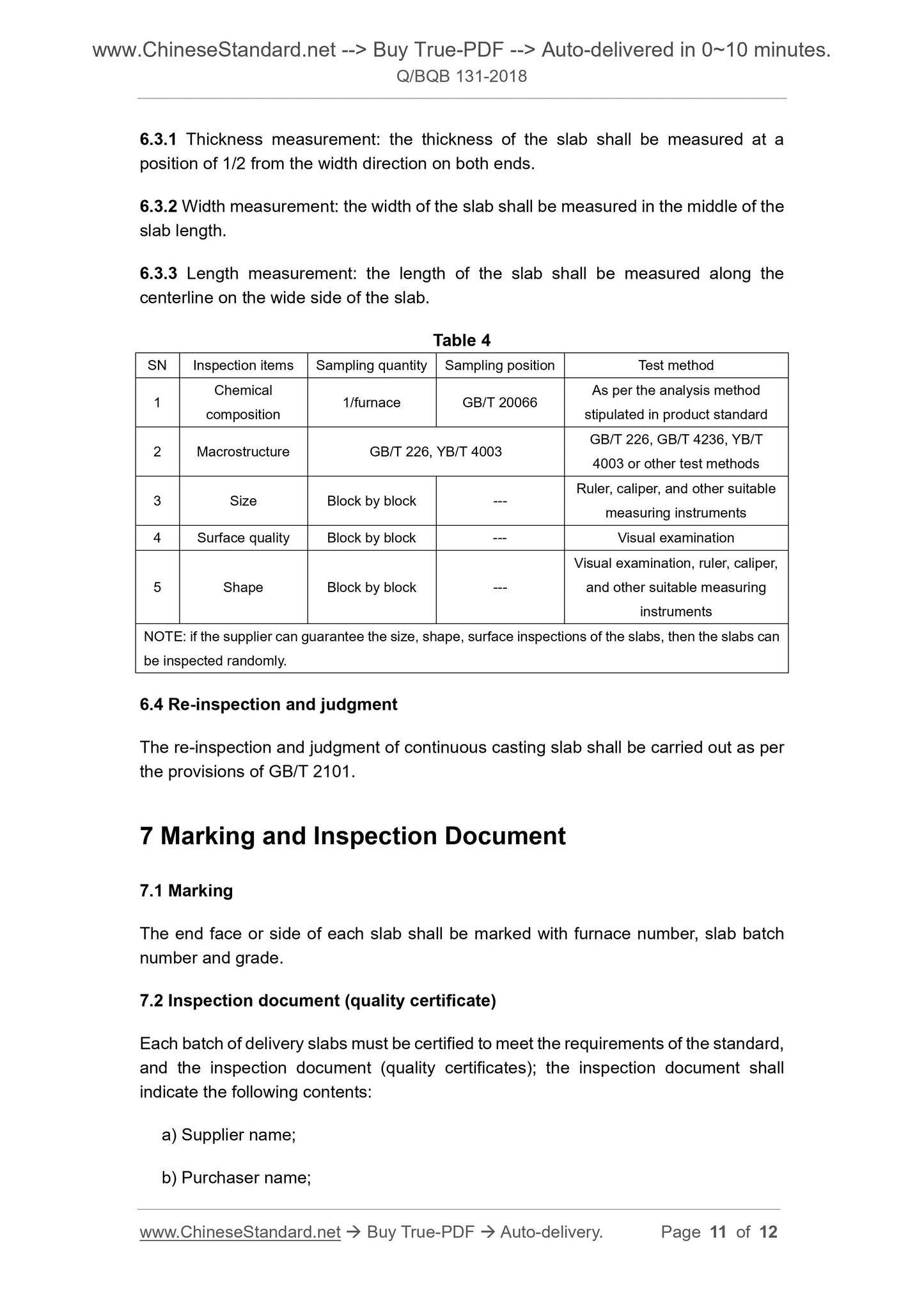

6.3.1 Thickness measurement. the thickness of the slab shall be measured at a

position of 1/2 from the width direction on both ends.

6.3.2 Width measurement. the width of the slab shall be measured in the middle of the

slab length.

6.3.3 Length measurement. the length of the slab shall be measured along the

centerline on the wide side of the slab.

Table 4

SN Inspection items Sampling quantity Sampling position Test method

1 Chemical composition 1/furnace GB/T 20066

As per the analysis method

stipulated in product standard

2 Macrostructure GB/T 226, YB/T 4003 GB/T 226, GB/T 4236, YB/T 4003 or other test methods

3 Size Block by block --- Ruler, caliper, and other suitable measuring instruments

4 Surface quality Block by block --- Visual examination

5 Shape Block by block ---

Visual examination, ruler, caliper,

and other suitable measuring

instruments

NOTE. if the supplier can guarantee the size, shape, surface inspections of the slabs, then the slabs can

be inspected randomly.

6.4 Re-inspection and judgment

The re-inspection and judgment of continuous casting slab shall be carried out as per

the provisions of GB/T 2101.

7 Marking and Inspection Document

7.1 Marking

The end face or side of each slab shall be marked with furnace number, slab batch

number and grade.

7.2 Inspection document (quality certificate)

Each batch of delivery slabs must be certified to meet the requirements of the standard,

and the inspection document (quality certificates); the inspection document shall

indicate the following contents.

a) Supplier name;

b) Purchaser name;

Get QUOTATION in 1-minute: Click Q/BQB 131-2018

Historical versions: Q/BQB 131-2018

Preview True-PDF (Reload/Scroll if blank)

Q/BQB 131-2018: Continuous casting slab

Q/BQB 131-2018

BQB

ENTERPRISE STANDARD OF BAOSTEEL

Replacing Q/BQB 131-2014

Continuous Casting Slab

连铸板坯

ISSUED ON. JANUARY 15, 2018

IMPLEMENTED ON. APRIL 10, 2018

Issued by. Baoshan Iron and Steel Co., Ltd.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 information Required for Ordering ... 5

4 Size, Shape, Weight and Allowable Deviation ... 6

5 Technical Requirements ... 7

6 Inspection and Test ... 10

7 Marking and Inspection Document ... 11

Foreword

This Standard was drafted as per the requirements and format specified in GB/T 1.1-

2009 Directives for Standardization – Part 1. Structure and Drafting of Standards.

This Standard is based on the characteristics of our company’s products and

processes.

Please note that some contents of this Standard may involve patents. The issuing

organization of this Standard does not assume the responsibility for identifying these

patents.

This Standard replaces Q/BQB 131-2014. Compared with Q/BQB 131-2014, this

Standard has the major changes as follows.

--- Add “Clause 2 Normative References”;

--- Delete the thickness specifications of 150mm, 200mm, 210mm, 220mm; add the

thickness specification of 360mm;

--- Delete the provision of general length range in Table 1;

--- Refer to YB/T 2012-2014, the width allowable deviation is changed from “-

10mm~+15mm” to altering as the nominal width range in Table 2;

--- In Table 1, for the slab with thickness specification of 250mm, the specified length

range is changed from “6800mm~12000mm” to “6000mm~11800mm”; for the

slab with thickness specification of 230mm, the width is changed from

“800mm~1930mm” to “900mm~2300mm”, while the specified length is changed

from “8000mm~12000mm” to “6000mm~11000mm”;

--- Add “the allowable deviation of the size and shape of the continuous casting slab

can be appropriately adjusted after negotiation between the supplier and the

purchaser. The size and allowable deviation of the slab that needs to be cleaned

by the whole surface shall be determined through the negotiation between the

supplier and the purchaser.”;

--- Add macrostructure inspection requirements for on-demand selection;

--- Modify the surface quality requirements by referring to YB/T 2012-2014;

--- Referring to YB/T 2012-2014, change the width wedge type from “∣W -

W2∣≤20 mm” to “∣W-W2∣≤10 mm, for the head and tail blank ≤50mm”;

--- Add the Clause on Test Method and Table 4;

Continuous Casting Slab

1 Scope

This Standard specifies the size, shape, weight and allowable deviation, technical

requirements, inspection and test, marking and inspection document, etc. of

continuous casting slab.

This Standard is applicable to the continuous casting slab for hot rolling and thick

plates. The slab must not be cut longitudinally.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 226-2015 Test Method for Macrostructure and Defect of Steel by Etching

GB/T 2101-2017 General Requirement of Acceptance Packaging Marking and

Certification for Section Steel

GB/T 4236-2016 Steel Examination by Sulphur Print (Baumann Method)

YB/T 4003-2016 Standard Diagrams for Macrostructure and Defect in Continuous

Casting Slab

3 information Required for Ordering

When ordering, the users shall provide the following information.

a) This enterprise standard number;

b) Grade;

c) Specification;

d) Weight;

4.3 Weight

The slab shall be delivered by actual weight.

5 Technical Requirements

5.1 Grade and chemical composition

The grade and chemical composition (melting analysis) of steel shall conform to the

provisions of Baosteel enterprise standard or other relevant standards.

5.2 Smelting method

The steel is smelted by an oxygen converter.

5.3 Delivery state

The slab shall be delivered in as-cast condition.

5.4 Macrostructure inspection

According to the demand of the purchaser, the supplier and the purchaser shall

negotiate and indicate in the contract that the continuous casting slab may be

subjected to Sulphur printing or macrostructure inspection. The test method and

acceptance criteria shall be determined through the negotiation between the supplier

and the purchaser; if there is no agreement, then it shall be determined by the supplier,

see Table 4.

5.5 Surface quality

5.5.1 The slab cross-sections shall be free of the shrinkage holes, subcutaneous

bubbles, cracks that may affect he use.

5.5.2 The slab surface shall be free of reconnections, overlaps, bumbling, crusting,

slag; 3mm-above-deep-or-high scratches, indentations, abrasions, stomata, cold

splashes, wrinkles, bumps, dimples; 2mm-above-deep cracks; as well as other defects

that may affect the rolling quality. There must be no flame cutting tumors greater than

5mm in height.

5.5.3 If the above defects are present on the surface of the slab, they are allowed to

be removed. The removal shall be carried out along the rolling direction; the removal

position shall be smooth without corners. The removal depth on one side shall be no

greater than 10% of nominal thickness; the sum of the removal depths of the two

opposite surfaces shall be no greater than 15% of the nominal thickness. The removal

width shall be greater than 6 times of the removal depth; while the removal length shall

be greater than 10 times of the removal depth. The removal depth shall be calculated

6.3.1 Thickness measurement. the thickness of the slab shall be measured at a

position of 1/2 from the width direction on both ends.

6.3.2 Width measurement. the width of the slab shall be measured in the middle of the

slab length.

6.3.3 Length measurement. the length of the slab shall be measured along the

centerline on the wide side of the slab.

Table 4

SN Inspection items Sampling quantity Sampling position Test method

1 Chemical composition 1/furnace GB/T 20066

As per the analysis method

stipulated in product standard

2 Macrostructure GB/T 226, YB/T 4003 GB/T 226, GB/T 4236, YB/T 4003 or other test methods

3 Size Block by block --- Ruler, caliper, and other suitable measuring instruments

4 Surface quality Block by block --- Visual examination

5 Shape Block by block ---

Visual examination, ruler, caliper,

and other suitable measuring

instruments

NOTE. if the supplier can guarantee the size, shape, surface inspections of the slabs, then the slabs can

be inspected randomly.

6.4 Re-inspection and judgment

The re-inspection and judgment of continuous casting slab shall be carried out as per

the provisions of GB/T 2101.

7 Marking and Inspection Document

7.1 Marking

The end face or side of each slab shall be marked with furnace number, slab batch

number and grade.

7.2 Inspection document (quality certificate)

Each batch of delivery slabs must be certified to meet the requirements of the standard,

and the inspection document (quality certificates); the inspection document shall

indicate the following contents.

a) Supplier name;

b) Purchaser name;

Share