1

/

of

11

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

QC/T 1091-2023 English PDF (QCT1091-2023)

QC/T 1091-2023 English PDF (QCT1091-2023)

Regular price

$500.00 USD

Regular price

Sale price

$500.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1091-2023

Historical versions: QC/T 1091-2023

Preview True-PDF (Reload/Scroll if blank)

QC/T 1091-2023: Air Cleaner for Passenger coach

QC/T 1091-2023

QC

AUTOMOBILE INDUSTRY STANDARD

ICS 43.080.20

CCS T 42

Replacing QC/T 1091-2017

Air cleaner for bus

ISSUED ON. DECEMBER 20, 2023

IMPLEMENTED ON. JULY 01, 2024

Issued by. Ministry of Industry and Information Technology of the PRC

Table of Contents

Foreword... 7

1 Scope... 9

2 Normative references... 9

3 Terms and definitions... 10

4 General requirements... 12

5 Purification requirements... 13

6 Test method... 14

7 Inspection rules... 19

8 Marking, packaging, transportation, storage... 20

Appendix A (Informative) Test chamber... 23

Appendix B (Normative) Calculation method of decay constant... 26

Appendix C (Normative) Determination of volatile organic compounds - Gas

chromatography mass spectrometry... 28

References... 34

Air cleaner for bus

1 Scope

This document specifies the general requirements, purification requirements, test

methods, inspection rules and marking, packaging, transportation and storage of air

cleaner for bus.

This document is applicable to air cleaners installed in categories M2 and M3 buses.

Other vehicles can refer to it.

2 Normative references

The contents of the following documents constitute the essential terms of this document

through normative references in the text. Among them, for dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 191 Packaging - Pictorial marking for handling of goods

GB/T 13306 Plates

GB/T 13554 High efficiency particulate air filter

GB/T 14295 Air filter

GB/T 15089 Classification of power-driven vehicles and trailers

GB/T 21087-2020 Energy recovery ventilators for outdoor air handling

GB 21551.3-2010 Antibacterial and cleaning function for household and similar

electrical appliances - Particular requirements of air cleaner

GB/T 30512 Requirements for prohibited substances on automobiles

GB 34660 Road vehicles - Requirements and test methods of electromagnetic

compatibility

GB 38262 Flammability of interior materials for buses

HJ/T 400-2007 Determination of volatile organic compounds and carbonyl

compounds in cabin vehicles

4 General requirements

4.1 Basic requirements

4.1.1 The rated voltage of the air cleaner for bus (hereinafter referred to as the "air

cleaner") shall be DC 12 V or DC 24 V.

4.1.2 The air cleaner shall be safe and odor-free.

4.1.3 The air cleaner shall be cleanable; the replaceable parts shall be easy to

disassemble and assemble.

4.1.4 The surface of the air cleaner shall be smooth and flat, without scratches, rust

spots, indentations, damage. The spray layer shall be uniform, without flow marks,

bubbles, peeling.

4.1.5 The parts shall be tight and not loose. The filter material, separator, protective net

and other parts shall not be deformed; the sealing gasket shall not be loose.

4.1.6 The outer shell of the air cleaner shall be marked with electrical safety warning

signs.

4.1.7 The materials used in the air cleaner shall meet the requirements for prohibited

substances in GB/T 30512.

4.2 Performance requirements

4.2.1 The air filter in the air cleaner shall comply with the relevant provisions of GB/T

14295 and GB/T 13554.

4.2.2 The combustion characteristics of non-metallic materials in the air cleaner shall

comply with the relevant provisions of GB 38262.

4.2.3 The basic technical requirements of air cleaners shall comply with the relevant

provisions of QC/T 413.

4.2.4 The electromagnetic compatibility of air cleaners shall comply with the relevant

provisions of GB 34660.

4.3 Rated power

The rated power of air cleaners shall meet the following requirements.

a) For nominal values not exceeding 30 W, the test results shall not exceed 120% of

the nominal value;

b) For nominal values exceeding 30 W, the test results shall not exceed 110% of the

specify, the highest wind speed and maximum air outlet state shall prevail). After

normal operation, turn off the air cleaner.

b) Arrange a sampling point. The sampling point shall avoid the air inlet and outlet,

at a distance from the chamber wall of no less than 0.5 m and a distance from the

laboratory floor of 1.1 m ~ 1.3 m. The sampling point is connected to the sampler

outside the test chamber through a pipeline.

c) Turn on the air filter to purify the air in the test chamber; start the temperature and

humidity control device at the same time, to make the temperature and relative

humidity of the test chamber reach the specified state.

d) After the temperature and relative humidity in the test chamber reach the specified

state, turn off the air filter and temperature and humidity control device; turn on

the stirring fan and circulation fan.

e) Put the cigarette (tar content is 8 mg ~ 11 mg) into the cigarette burner; connect

the burner to the low-pressure air source; connect the smoke outlet of the burner

to a pipe that passes through the test chamber wall. Light the cigarette; cover the

burner; after burning for a period of time, close the valve of the smoke delivery

pipe; run the stirring fan for another 10 minutes, to mix the particulate pollutants

evenly.

f) After the stirring fan stops rotating, record the initial concentration C0, which shall

be within the initial concentration range specified in Table 1, corresponding to t

= 0 min. Turn on the air cleaner to be tested at the same time. After that, measure

and record the concentration of particulate matter every 10 minutes. Measure

continuously for 60 minutes.

g) Calculate the total decay constant ke of particulate matter in accordance with the

provisions of Appendix B; calculate the correlation coefficient R2, requiring R2 ≥

0.98.

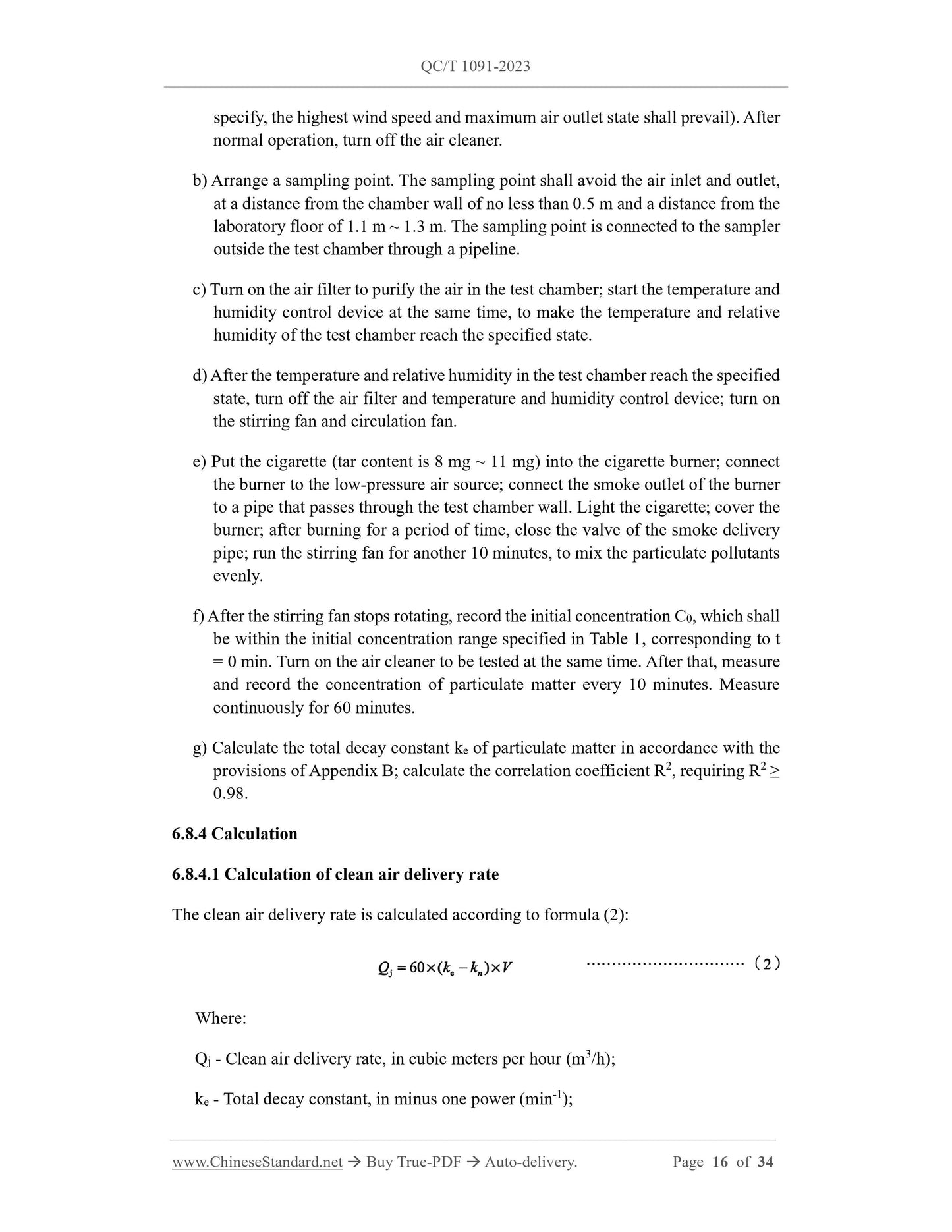

6.8.4 Calculation

6.8.4.1 Calculation of clean air delivery rate

The clean air delivery rate is calculated according to formula (2).

Where.

Qj - Clean air delivery rate, in cubic meters per hour (m3/h);

ke - Total decay constant, in minus one power (min-1);

c) Sampling pump, calibrated with a primary flow meter to ensure that the flow

deviation before and after sampling does not exceed 5%;

d) Sampling tank, which is a stainless steel tank with an inert inner wall.

6.9.3 Test steps

6.9.3.1 Test run

The test run steps of the air cleaner shall be carried out in accordance with 6.8.3.1.

6.9.3.2 Total decay test of gaseous pollutants

The total decay test of gaseous pollutants shall be carried out in accordance with the

following steps.

a) The adjustment of the air cleaner, the arrangement of sampling points, the

determination of record files, the setting of the cabin environment shall be carried

out in accordance with a) ~ d) in 6.8.3.2.

b) Connect the gaseous pollutant generator to a pipe that passes through the test cabin

wall, so that the generated gaseous pollutants enter the test chamber through the

pipe. After the generated gaseous pollutants are delivered for a period of time,

turn off the generator. Run the stirring fan for another 10 minutes, to mix the

gaseous pollutants evenly; then turn off the stirring fan.

c) After the stirring fan stops rotating, collect the gaseous pollutants in the test

chamber. The initial concentration of the gaseous pollutants is C0, which shall be

within the initial concentration range specified in Table 1.

d) The initial concentration in the test chamber is collected, corresponding to t = 0

min; the air c...

Get QUOTATION in 1-minute: Click QC/T 1091-2023

Historical versions: QC/T 1091-2023

Preview True-PDF (Reload/Scroll if blank)

QC/T 1091-2023: Air Cleaner for Passenger coach

QC/T 1091-2023

QC

AUTOMOBILE INDUSTRY STANDARD

ICS 43.080.20

CCS T 42

Replacing QC/T 1091-2017

Air cleaner for bus

ISSUED ON. DECEMBER 20, 2023

IMPLEMENTED ON. JULY 01, 2024

Issued by. Ministry of Industry and Information Technology of the PRC

Table of Contents

Foreword... 7

1 Scope... 9

2 Normative references... 9

3 Terms and definitions... 10

4 General requirements... 12

5 Purification requirements... 13

6 Test method... 14

7 Inspection rules... 19

8 Marking, packaging, transportation, storage... 20

Appendix A (Informative) Test chamber... 23

Appendix B (Normative) Calculation method of decay constant... 26

Appendix C (Normative) Determination of volatile organic compounds - Gas

chromatography mass spectrometry... 28

References... 34

Air cleaner for bus

1 Scope

This document specifies the general requirements, purification requirements, test

methods, inspection rules and marking, packaging, transportation and storage of air

cleaner for bus.

This document is applicable to air cleaners installed in categories M2 and M3 buses.

Other vehicles can refer to it.

2 Normative references

The contents of the following documents constitute the essential terms of this document

through normative references in the text. Among them, for dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 191 Packaging - Pictorial marking for handling of goods

GB/T 13306 Plates

GB/T 13554 High efficiency particulate air filter

GB/T 14295 Air filter

GB/T 15089 Classification of power-driven vehicles and trailers

GB/T 21087-2020 Energy recovery ventilators for outdoor air handling

GB 21551.3-2010 Antibacterial and cleaning function for household and similar

electrical appliances - Particular requirements of air cleaner

GB/T 30512 Requirements for prohibited substances on automobiles

GB 34660 Road vehicles - Requirements and test methods of electromagnetic

compatibility

GB 38262 Flammability of interior materials for buses

HJ/T 400-2007 Determination of volatile organic compounds and carbonyl

compounds in cabin vehicles

4 General requirements

4.1 Basic requirements

4.1.1 The rated voltage of the air cleaner for bus (hereinafter referred to as the "air

cleaner") shall be DC 12 V or DC 24 V.

4.1.2 The air cleaner shall be safe and odor-free.

4.1.3 The air cleaner shall be cleanable; the replaceable parts shall be easy to

disassemble and assemble.

4.1.4 The surface of the air cleaner shall be smooth and flat, without scratches, rust

spots, indentations, damage. The spray layer shall be uniform, without flow marks,

bubbles, peeling.

4.1.5 The parts shall be tight and not loose. The filter material, separator, protective net

and other parts shall not be deformed; the sealing gasket shall not be loose.

4.1.6 The outer shell of the air cleaner shall be marked with electrical safety warning

signs.

4.1.7 The materials used in the air cleaner shall meet the requirements for prohibited

substances in GB/T 30512.

4.2 Performance requirements

4.2.1 The air filter in the air cleaner shall comply with the relevant provisions of GB/T

14295 and GB/T 13554.

4.2.2 The combustion characteristics of non-metallic materials in the air cleaner shall

comply with the relevant provisions of GB 38262.

4.2.3 The basic technical requirements of air cleaners shall comply with the relevant

provisions of QC/T 413.

4.2.4 The electromagnetic compatibility of air cleaners shall comply with the relevant

provisions of GB 34660.

4.3 Rated power

The rated power of air cleaners shall meet the following requirements.

a) For nominal values not exceeding 30 W, the test results shall not exceed 120% of

the nominal value;

b) For nominal values exceeding 30 W, the test results shall not exceed 110% of the

specify, the highest wind speed and maximum air outlet state shall prevail). After

normal operation, turn off the air cleaner.

b) Arrange a sampling point. The sampling point shall avoid the air inlet and outlet,

at a distance from the chamber wall of no less than 0.5 m and a distance from the

laboratory floor of 1.1 m ~ 1.3 m. The sampling point is connected to the sampler

outside the test chamber through a pipeline.

c) Turn on the air filter to purify the air in the test chamber; start the temperature and

humidity control device at the same time, to make the temperature and relative

humidity of the test chamber reach the specified state.

d) After the temperature and relative humidity in the test chamber reach the specified

state, turn off the air filter and temperature and humidity control device; turn on

the stirring fan and circulation fan.

e) Put the cigarette (tar content is 8 mg ~ 11 mg) into the cigarette burner; connect

the burner to the low-pressure air source; connect the smoke outlet of the burner

to a pipe that passes through the test chamber wall. Light the cigarette; cover the

burner; after burning for a period of time, close the valve of the smoke delivery

pipe; run the stirring fan for another 10 minutes, to mix the particulate pollutants

evenly.

f) After the stirring fan stops rotating, record the initial concentration C0, which shall

be within the initial concentration range specified in Table 1, corresponding to t

= 0 min. Turn on the air cleaner to be tested at the same time. After that, measure

and record the concentration of particulate matter every 10 minutes. Measure

continuously for 60 minutes.

g) Calculate the total decay constant ke of particulate matter in accordance with the

provisions of Appendix B; calculate the correlation coefficient R2, requiring R2 ≥

0.98.

6.8.4 Calculation

6.8.4.1 Calculation of clean air delivery rate

The clean air delivery rate is calculated according to formula (2).

Where.

Qj - Clean air delivery rate, in cubic meters per hour (m3/h);

ke - Total decay constant, in minus one power (min-1);

c) Sampling pump, calibrated with a primary flow meter to ensure that the flow

deviation before and after sampling does not exceed 5%;

d) Sampling tank, which is a stainless steel tank with an inert inner wall.

6.9.3 Test steps

6.9.3.1 Test run

The test run steps of the air cleaner shall be carried out in accordance with 6.8.3.1.

6.9.3.2 Total decay test of gaseous pollutants

The total decay test of gaseous pollutants shall be carried out in accordance with the

following steps.

a) The adjustment of the air cleaner, the arrangement of sampling points, the

determination of record files, the setting of the cabin environment shall be carried

out in accordance with a) ~ d) in 6.8.3.2.

b) Connect the gaseous pollutant generator to a pipe that passes through the test cabin

wall, so that the generated gaseous pollutants enter the test chamber through the

pipe. After the generated gaseous pollutants are delivered for a period of time,

turn off the generator. Run the stirring fan for another 10 minutes, to mix the

gaseous pollutants evenly; then turn off the stirring fan.

c) After the stirring fan stops rotating, collect the gaseous pollutants in the test

chamber. The initial concentration of the gaseous pollutants is C0, which shall be

within the initial concentration range specified in Table 1.

d) The initial concentration in the test chamber is collected, corresponding to t = 0

min; the air c...

Share