1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 1096-2018 English PDF (QCT1096-2018)

QC/T 1096-2018 English PDF (QCT1096-2018)

Regular price

$200.00 USD

Regular price

Sale price

$200.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1096-2018

Historical versions: QC/T 1096-2018

Preview True-PDF (Reload/Scroll if blank)

QC/T 1096-2018: Bench test methods of fatigue life for torsion beam rear axle of passenger cars

QC/T 1096-2018

QC

AUTOMOBILE INDUSTRY STANDARD

OF THEPEOPLE’S REPUBLIC OF CHINA

ICS 43.040.60

T 20

Bench test methods of fatigue life for torsion beam rear axle

of passenger cars

ISSUED ON: JULY 04, 2018

IMPLEMENTED ON: JANUARY 01, 2019

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 6

4 Technical requirements ... 7

5 Test method ... 9

Appendix A (Informative) Corresponding relationship between specimen quantity and

cycle life ... 15

Bench test methods of fatigue life for torsion beam rear axle

of passenger cars

1 Scope

1.1 This standard specifies the bench test method for the fatigue life of torsion beam

rear axles for passenger cars.

1.2 This standard applies to torsion beam rear axles for passenger vehicles, which are

powered by internal combustion engines.

2 Normative references

The following documents are essential to the application of this document. For the dated

documents, only the versions with the dates indicated are applicable to this document;

for the undated documents, only the latest version (including all the amendments) is

applicable to this standard.

GB 11551 The protection of the occupants in the event of a frontal collision for

motor vehicle

GB/T 3730.1 China standard audiovisual number - Part 1: Audiovisual work

identifier

GB/T 3730.2 China standard audiovisual number - Part 2: Version identifier

GB/T 3730.3 Motor vehicles and towed vehicles - Dimensions of vehicles - Terms

and definitions

3 Terms and definitions

The terms and definitions, as defined in GB 11551, GB/T 3730.1, GB/T 3730.2, GB/T

3730.3, as well as the following terms and definitions, apply to this standard.

Test accompanied parts of torsion beam rear axle

Parts required to ensure that the torsion beam rear axle is installed on the bench, in the

same state as on the actual vehicle.

Test load expression: Test load = mean ± amplitude.

4.1.9 All calculated loads in this standard are allowed to retain to the single digit when

loading.

4.1.10 The test shall be monitored; abnormal situations shall be recorded. If cracks are

observed in the test piece, the observation time, crack length, corresponding cycle times

shall be recorded; the test shall be stopped, after reaching the failure criterion.

4.1.11 Both the supplier and the buyer can agree or adjust the test method of the product,

according to their own product characteristics.

4.2 Performance requirements

4.2.1 Test items

4.2.1.1 Fatigue life test under torsional loading

Carry out the test according to 5.1; the test frequency is not less than 1.0 Hz; the number

of loading N is 300000.

4.2.1.2 Fatigue life test under lateral loading

Carry out the test according to 5.2; the test frequency is not less than 1.0 Hz; the number

of loading N is 200000.

4.2.1.3 Fatigue life test under longitudinal loading

Carry out the test according to 5.3; the test frequency is not less than 1.0 Hz; the number

of loading N is 300000.

4.2.1.4 Fatigue life test of spring disk

Carry out the test according to 5.4; the test frequency is not less than 1.0 Hz; the number

of loading N is 300000.

4.2.1.5 Fatigue life test of shock absorber bracket

Carry out the test according to 5.5; the test frequency is not less than 1.0 Hz; the number

of loading N is 300000.

4.2.2 Failure criteria

4.2.2.1 The crack length, which is measured along the crack propagation direction on

the part surface, is equal to 10 mm.

4.2.2.2 The crack length, which is measured along the crack propagation direction at

the weld, is greater than or equal to 20 mm or 20% of the weld length (whichever is

smaller).

4.2.3 Evaluation indicators

The cycle life of the specimen shall meet the 95% reliability requirement, at the 50%

confidence level. See Appendix A for the selection of the number of specimens.

5 Test method

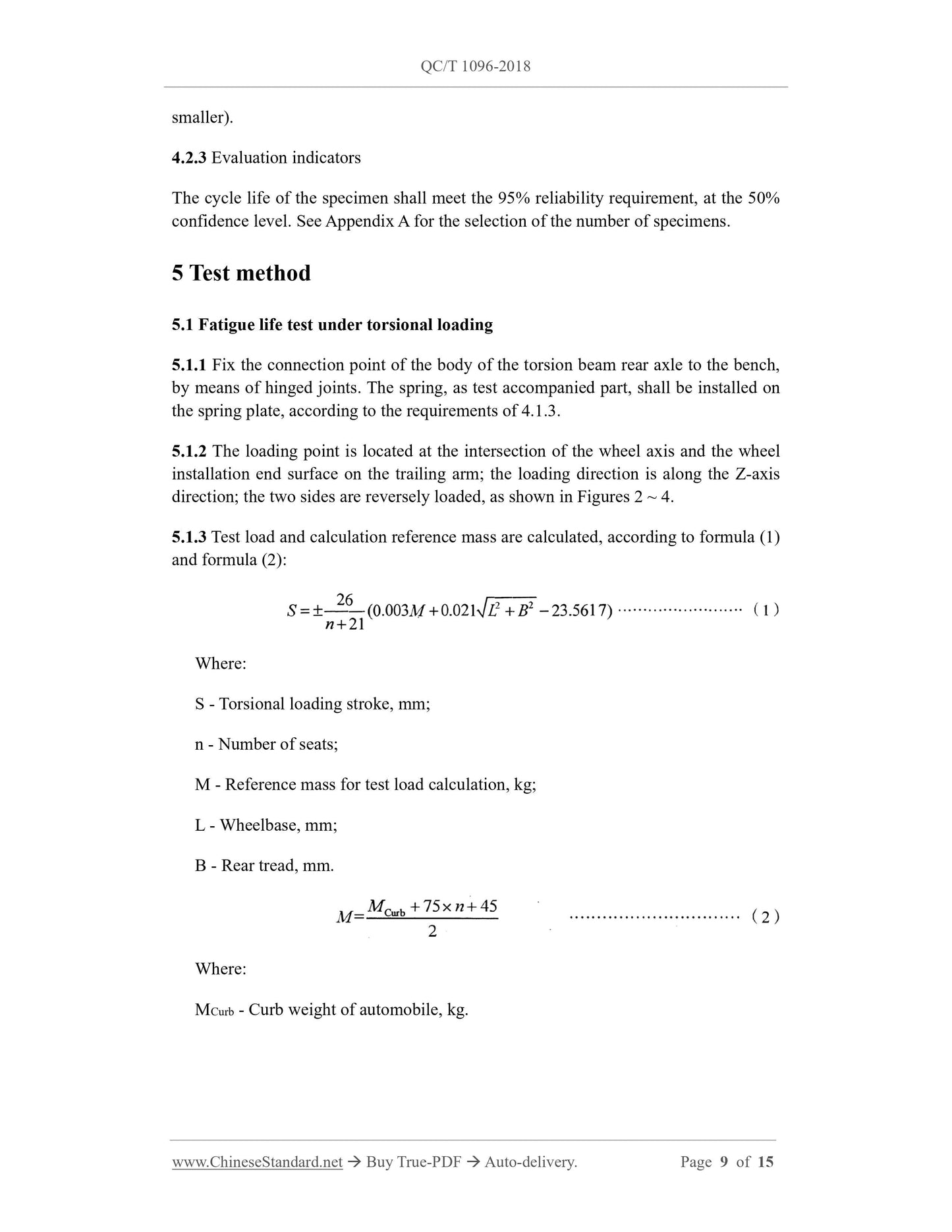

5.1 Fatigue life test under torsional loading

5.1.1 Fix the connection point of the body of the torsion beam rear axle to the bench,

by means of hinged joints. The spring, as test accompanied part, shall be installed on

the spring plate, according to the requirements of 4.1.3.

5.1.2 The loading point is located at the intersection of the wheel axis and the wheel

installation end surface on the trailing arm; the loading direction is along the Z-axis

direction; the two sides are reversely loaded, as shown in Figures 2 ~ 4.

5.1.3 Test load and calculation reference mass are calculated, according to formula (1)

and formula (2):

Where:

S - Torsional loading stroke, mm;

n - Number of seats;

M - Reference mass for test load calculation, kg;

L - Wheelbase, mm;

B - Rear tread, mm.

Where:

MCurb - Curb weight of automobile, kg.

Get QUOTATION in 1-minute: Click QC/T 1096-2018

Historical versions: QC/T 1096-2018

Preview True-PDF (Reload/Scroll if blank)

QC/T 1096-2018: Bench test methods of fatigue life for torsion beam rear axle of passenger cars

QC/T 1096-2018

QC

AUTOMOBILE INDUSTRY STANDARD

OF THEPEOPLE’S REPUBLIC OF CHINA

ICS 43.040.60

T 20

Bench test methods of fatigue life for torsion beam rear axle

of passenger cars

ISSUED ON: JULY 04, 2018

IMPLEMENTED ON: JANUARY 01, 2019

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 6

4 Technical requirements ... 7

5 Test method ... 9

Appendix A (Informative) Corresponding relationship between specimen quantity and

cycle life ... 15

Bench test methods of fatigue life for torsion beam rear axle

of passenger cars

1 Scope

1.1 This standard specifies the bench test method for the fatigue life of torsion beam

rear axles for passenger cars.

1.2 This standard applies to torsion beam rear axles for passenger vehicles, which are

powered by internal combustion engines.

2 Normative references

The following documents are essential to the application of this document. For the dated

documents, only the versions with the dates indicated are applicable to this document;

for the undated documents, only the latest version (including all the amendments) is

applicable to this standard.

GB 11551 The protection of the occupants in the event of a frontal collision for

motor vehicle

GB/T 3730.1 China standard audiovisual number - Part 1: Audiovisual work

identifier

GB/T 3730.2 China standard audiovisual number - Part 2: Version identifier

GB/T 3730.3 Motor vehicles and towed vehicles - Dimensions of vehicles - Terms

and definitions

3 Terms and definitions

The terms and definitions, as defined in GB 11551, GB/T 3730.1, GB/T 3730.2, GB/T

3730.3, as well as the following terms and definitions, apply to this standard.

Test accompanied parts of torsion beam rear axle

Parts required to ensure that the torsion beam rear axle is installed on the bench, in the

same state as on the actual vehicle.

Test load expression: Test load = mean ± amplitude.

4.1.9 All calculated loads in this standard are allowed to retain to the single digit when

loading.

4.1.10 The test shall be monitored; abnormal situations shall be recorded. If cracks are

observed in the test piece, the observation time, crack length, corresponding cycle times

shall be recorded; the test shall be stopped, after reaching the failure criterion.

4.1.11 Both the supplier and the buyer can agree or adjust the test method of the product,

according to their own product characteristics.

4.2 Performance requirements

4.2.1 Test items

4.2.1.1 Fatigue life test under torsional loading

Carry out the test according to 5.1; the test frequency is not less than 1.0 Hz; the number

of loading N is 300000.

4.2.1.2 Fatigue life test under lateral loading

Carry out the test according to 5.2; the test frequency is not less than 1.0 Hz; the number

of loading N is 200000.

4.2.1.3 Fatigue life test under longitudinal loading

Carry out the test according to 5.3; the test frequency is not less than 1.0 Hz; the number

of loading N is 300000.

4.2.1.4 Fatigue life test of spring disk

Carry out the test according to 5.4; the test frequency is not less than 1.0 Hz; the number

of loading N is 300000.

4.2.1.5 Fatigue life test of shock absorber bracket

Carry out the test according to 5.5; the test frequency is not less than 1.0 Hz; the number

of loading N is 300000.

4.2.2 Failure criteria

4.2.2.1 The crack length, which is measured along the crack propagation direction on

the part surface, is equal to 10 mm.

4.2.2.2 The crack length, which is measured along the crack propagation direction at

the weld, is greater than or equal to 20 mm or 20% of the weld length (whichever is

smaller).

4.2.3 Evaluation indicators

The cycle life of the specimen shall meet the 95% reliability requirement, at the 50%

confidence level. See Appendix A for the selection of the number of specimens.

5 Test method

5.1 Fatigue life test under torsional loading

5.1.1 Fix the connection point of the body of the torsion beam rear axle to the bench,

by means of hinged joints. The spring, as test accompanied part, shall be installed on

the spring plate, according to the requirements of 4.1.3.

5.1.2 The loading point is located at the intersection of the wheel axis and the wheel

installation end surface on the trailing arm; the loading direction is along the Z-axis

direction; the two sides are reversely loaded, as shown in Figures 2 ~ 4.

5.1.3 Test load and calculation reference mass are calculated, according to formula (1)

and formula (2):

Where:

S - Torsional loading stroke, mm;

n - Number of seats;

M - Reference mass for test load calculation, kg;

L - Wheelbase, mm;

B - Rear tread, mm.

Where:

MCurb - Curb weight of automobile, kg.

Share