1

/

van

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

QB/T 2472-2000 English PDF (QBT2472-2000)

QB/T 2472-2000 English PDF (QBT2472-2000)

Normale prijs

$150.00 USD

Normale prijs

Aanbiedingsprijs

$150.00 USD

Eenheidsprijs

/

per

Verzendkosten worden berekend bij de checkout.

Kan beschikbaarheid voor afhalen niet laden

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QB/T 2472-2000

Historical versions: QB/T 2472-2000

Preview True-PDF (Reload/Scroll if blank)

QB/T 2472-2000: Agricultural Flexible PVC Calendering and Stentering Film

QB/T 2472-2000

QB

LIGHT INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

Classification number: G33

Filing number: 6916-2000

Agricultural flexible PVC calendering and stentering

film

ISSUED ON: MARCH 30, 2000

IMPLEMENTED ON: AUGUST 01, 2000

Issued by: State Light Industry Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Product classification ... 4

4 Requirements ... 5

5 Test method ... 6

6 Inspection rules ... 11

7 Marking, packaging, transportation and storage ... 13

Agricultural flexible PVC calendering and stentering

film

1 Scope

This standard specifies the product classification, requirements, test methods,

inspection rules and markings, packaging, transportation, storage of agricultural

flexible PVC calendering and stentering film.

This standard applies to agricultural flexible PVC calendering and stentering

film (hereinafter referred to as "films") that are mainly made of polyvinyl chloride

resin, added with plasticizers, stabilizers and other auxiliaries, produced by the

calendering and stentering method.

2 Normative references

The clauses contained in the following standards constitute the clauses of this

standard by being quoted in this standard. At the time of publication, the editions

indicated were valid. All standards will be revised, and all parties using this

standard shall explore the possibility of using the latest version of the following

standards.

GB/T 2828-1987 Sampling procedures and tables for lot-by-lot inspection by

attributes (Apply to inspection of successive lots or batches)

GB/T 2918-1998 Plastics - Standard atmospheres for conditioning and

testing

GB/T 6673-1986 Plastics - Film and sheeting - Determination of length and

width

GB/T 13022-1991 Plastics - Test method for tensile properties

QB/T 1130-1991 Plastics angle tear performance test method

HG 2-163-1965 Low-temperature elongation test method for plastics

3 Product classification

3.1 The classification of the film is as shown in Table 1.

5.1.1 The sample must be randomly selected from each delivery batch of film.

Remove the three surface layers (about 2 m) from the film roll. Cut the specimen.

Indicate the longitudinal direction of the film.

5.1.2 The thickness and width shall be taken as specified in Table 6. One roll

shall be subject to visual inspection and the other roll shall be subject to the

testing of physical and mechanical properties and drip-free performance.

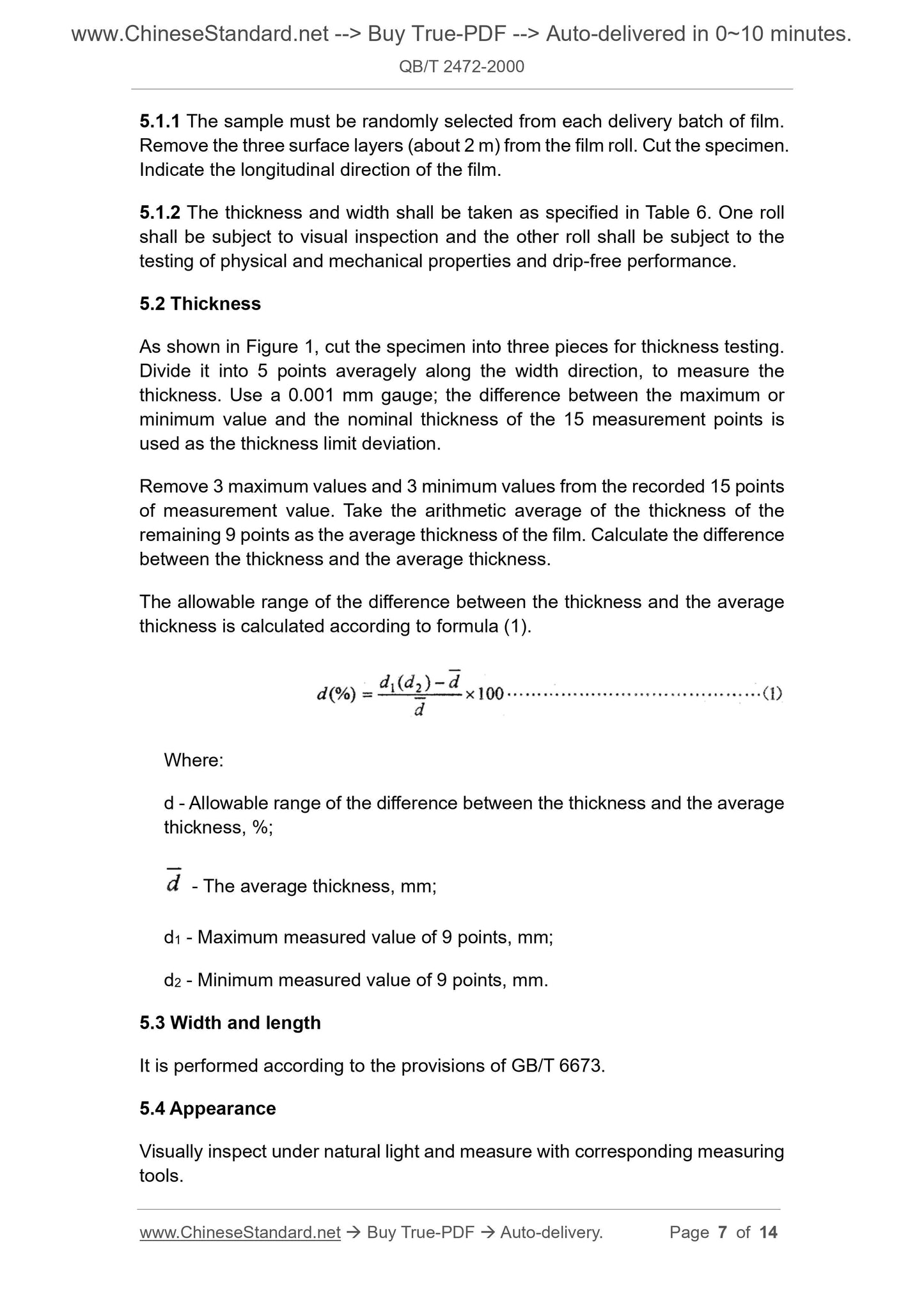

5.2 Thickness

As shown in Figure 1, cut the specimen into three pieces for thickness testing.

Divide it into 5 points averagely along the width direction, to measure the

thickness. Use a 0.001 mm gauge; the difference between the maximum or

minimum value and the nominal thickness of the 15 measurement points is

used as the thickness limit deviation.

Remove 3 maximum values and 3 minimum values from the recorded 15 points

of measurement value. Take the arithmetic average of the thickness of the

remaining 9 points as the average thickness of the film. Calculate the difference

between the thickness and the average thickness.

The allowable range of the difference between the thickness and the average

thickness is calculated according to formula (1).

Where:

d - Allowable range of the difference between the thickness and the average

thickness, %;

- The average thickness, mm;

d1 - Maximum measured value of 9 points, mm;

d2 - Minimum measured value of 9 points, mm.

5.3 Width and length

It is performed according to the provisions of GB/T 6673.

5.4 Appearance

Visually inspect under natural light and measure with corresponding measuring

tools.

It is performed according to the provisions of QB/T 1130.

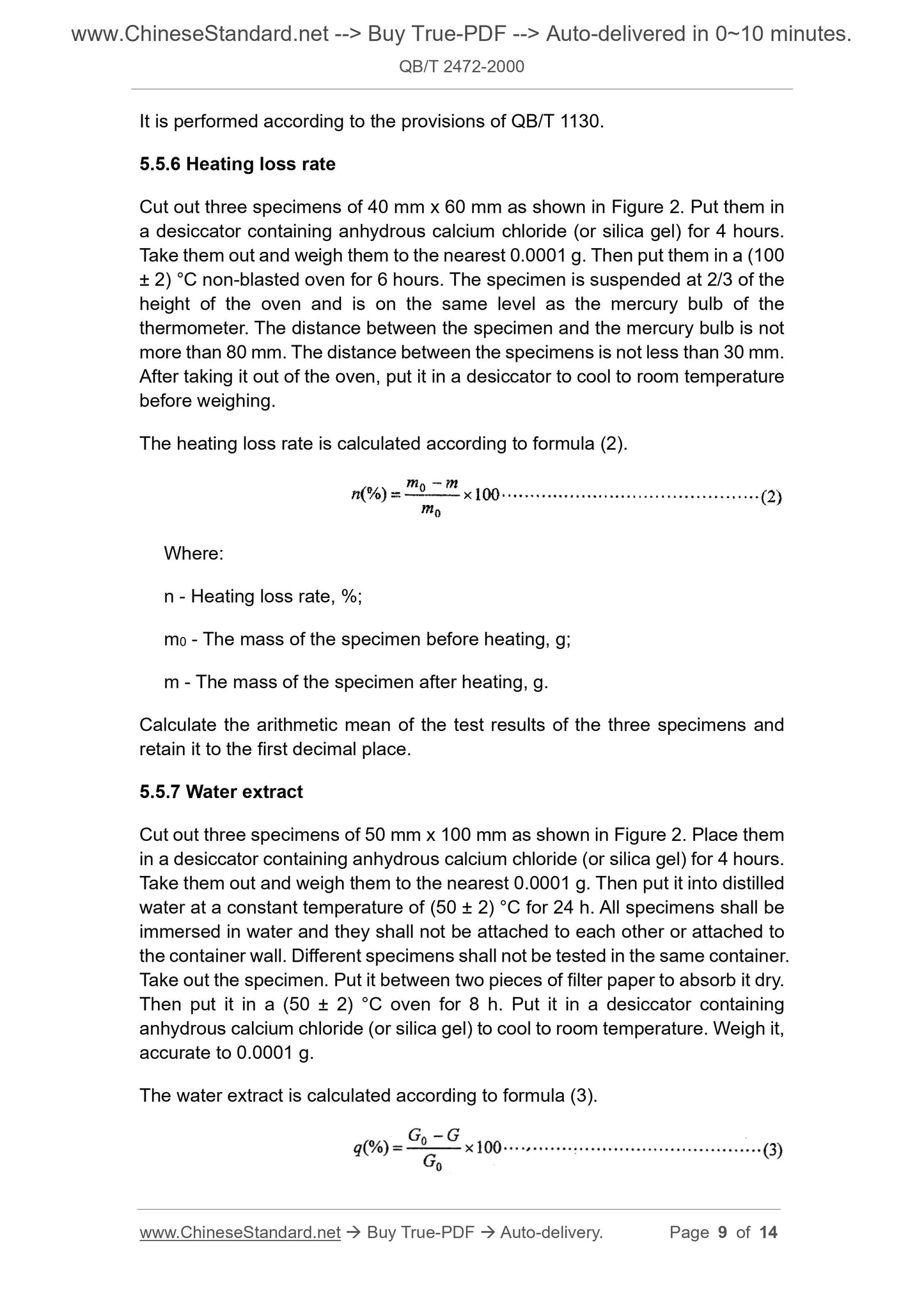

5.5.6 Heating loss rate

Cut out three specimens of 40 mm x 60 mm as shown in Figure 2. Put them in

a desiccator containing anhydrous calcium chloride (or silica gel) for 4 hours.

Take them out and weigh them to the nearest 0.0001 g. Then put them in a (100

± 2) °C non-blasted oven for 6 hours. The specimen is suspended at 2/3 of the

height of the oven and is on the same level as the mercury bulb of the

thermometer. The distance between the specimen and the mercury bulb is not

more than 80 mm. The distance between the specimens is not less than 30 mm.

After taking it out of the oven, put it in a desiccator to cool to room temperature

before weighing.

The heating loss rate is calculated according to formula (2).

Where:

n - Heating loss rate, %;

m0 - The mass of the specimen before heating, g;

m - The mass of the specimen after heating, g.

Calculate the arithmetic mean of the test results of the three specimens and

retain it to the first decimal place.

5.5.7 Water extract

Cut out three specimens of 50 mm x 100 mm as shown in Figure 2. Place them

in a desiccator containing anhydrous calcium chloride (or silica gel) for 4 hours.

Take them out and weigh them to the nearest 0.0001 g. Then put it into distilled

water at a constant temperature of (50 ± 2) °C for 24 h. All specimens shall be

immersed in water and they shall not be attached to each other or attached to

the container wall. Different specimens shall not be tested in the same container.

Take out the specimen. Put it between two pieces of filter paper to absorb it dry.

Then put it in a (50 ± 2) °C oven for 8 h. Put it in a desiccator containing

anhydrous calcium chloride (or silica gel) to cool to room temperature. Weigh it,

accurate to 0.0001 g.

The water extract is calculated according to formula (3).

Films are inspected on a batch basis. The films less than 50 t which are

continuously produced by the same raw materials, the same formula, the same

process, the same specification form a batch.

6.2 Sampling

Use the random sampling method.

The specifications and appearance are in accordance with GB/T 2828. It uses

the normal inspection sub-sampling plan. The general inspection level is II and

the acceptance quality level (AQL) is 6.5, as shown in Table 6.

6.3 Inspection classification

6.3.1 Exit-factory inspection

The exit-factory inspection items are all items except water extract, heating loss

rate and drip-free performance of drip-free film within 6 months of use.

6.3.2 Type inspection

Perform inspections in accordance with all technical requirements specified in

this standard. During normal production, at least once every three months;

when one of the conditions occur, type inspection shall also be carried out.

a) During normal production, if major changes in raw materials and

processes may affect product performance;

b) When the production is resumed after long term suspension;

c) When the new product is type-finalized, or the old product is transferring

plant for production;

d) When the relevant inspection results of the exit-factory inspection and the

last type inspection are significantly different;

e) When the national quality supervision agency requests for type inspection.

Get QUOTATION in 1-minute: Click QB/T 2472-2000

Historical versions: QB/T 2472-2000

Preview True-PDF (Reload/Scroll if blank)

QB/T 2472-2000: Agricultural Flexible PVC Calendering and Stentering Film

QB/T 2472-2000

QB

LIGHT INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

Classification number: G33

Filing number: 6916-2000

Agricultural flexible PVC calendering and stentering

film

ISSUED ON: MARCH 30, 2000

IMPLEMENTED ON: AUGUST 01, 2000

Issued by: State Light Industry Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Product classification ... 4

4 Requirements ... 5

5 Test method ... 6

6 Inspection rules ... 11

7 Marking, packaging, transportation and storage ... 13

Agricultural flexible PVC calendering and stentering

film

1 Scope

This standard specifies the product classification, requirements, test methods,

inspection rules and markings, packaging, transportation, storage of agricultural

flexible PVC calendering and stentering film.

This standard applies to agricultural flexible PVC calendering and stentering

film (hereinafter referred to as "films") that are mainly made of polyvinyl chloride

resin, added with plasticizers, stabilizers and other auxiliaries, produced by the

calendering and stentering method.

2 Normative references

The clauses contained in the following standards constitute the clauses of this

standard by being quoted in this standard. At the time of publication, the editions

indicated were valid. All standards will be revised, and all parties using this

standard shall explore the possibility of using the latest version of the following

standards.

GB/T 2828-1987 Sampling procedures and tables for lot-by-lot inspection by

attributes (Apply to inspection of successive lots or batches)

GB/T 2918-1998 Plastics - Standard atmospheres for conditioning and

testing

GB/T 6673-1986 Plastics - Film and sheeting - Determination of length and

width

GB/T 13022-1991 Plastics - Test method for tensile properties

QB/T 1130-1991 Plastics angle tear performance test method

HG 2-163-1965 Low-temperature elongation test method for plastics

3 Product classification

3.1 The classification of the film is as shown in Table 1.

5.1.1 The sample must be randomly selected from each delivery batch of film.

Remove the three surface layers (about 2 m) from the film roll. Cut the specimen.

Indicate the longitudinal direction of the film.

5.1.2 The thickness and width shall be taken as specified in Table 6. One roll

shall be subject to visual inspection and the other roll shall be subject to the

testing of physical and mechanical properties and drip-free performance.

5.2 Thickness

As shown in Figure 1, cut the specimen into three pieces for thickness testing.

Divide it into 5 points averagely along the width direction, to measure the

thickness. Use a 0.001 mm gauge; the difference between the maximum or

minimum value and the nominal thickness of the 15 measurement points is

used as the thickness limit deviation.

Remove 3 maximum values and 3 minimum values from the recorded 15 points

of measurement value. Take the arithmetic average of the thickness of the

remaining 9 points as the average thickness of the film. Calculate the difference

between the thickness and the average thickness.

The allowable range of the difference between the thickness and the average

thickness is calculated according to formula (1).

Where:

d - Allowable range of the difference between the thickness and the average

thickness, %;

- The average thickness, mm;

d1 - Maximum measured value of 9 points, mm;

d2 - Minimum measured value of 9 points, mm.

5.3 Width and length

It is performed according to the provisions of GB/T 6673.

5.4 Appearance

Visually inspect under natural light and measure with corresponding measuring

tools.

It is performed according to the provisions of QB/T 1130.

5.5.6 Heating loss rate

Cut out three specimens of 40 mm x 60 mm as shown in Figure 2. Put them in

a desiccator containing anhydrous calcium chloride (or silica gel) for 4 hours.

Take them out and weigh them to the nearest 0.0001 g. Then put them in a (100

± 2) °C non-blasted oven for 6 hours. The specimen is suspended at 2/3 of the

height of the oven and is on the same level as the mercury bulb of the

thermometer. The distance between the specimen and the mercury bulb is not

more than 80 mm. The distance between the specimens is not less than 30 mm.

After taking it out of the oven, put it in a desiccator to cool to room temperature

before weighing.

The heating loss rate is calculated according to formula (2).

Where:

n - Heating loss rate, %;

m0 - The mass of the specimen before heating, g;

m - The mass of the specimen after heating, g.

Calculate the arithmetic mean of the test results of the three specimens and

retain it to the first decimal place.

5.5.7 Water extract

Cut out three specimens of 50 mm x 100 mm as shown in Figure 2. Place them

in a desiccator containing anhydrous calcium chloride (or silica gel) for 4 hours.

Take them out and weigh them to the nearest 0.0001 g. Then put it into distilled

water at a constant temperature of (50 ± 2) °C for 24 h. All specimens shall be

immersed in water and they shall not be attached to each other or attached to

the container wall. Different specimens shall not be tested in the same container.

Take out the specimen. Put it between two pieces of filter paper to absorb it dry.

Then put it in a (50 ± 2) °C oven for 8 h. Put it in a desiccator containing

anhydrous calcium chloride (or silica gel) to cool to room temperature. Weigh it,

accurate to 0.0001 g.

The water extract is calculated according to formula (3).

Films are inspected on a batch basis. The films less than 50 t which are

continuously produced by the same raw materials, the same formula, the same

process, the same specification form a batch.

6.2 Sampling

Use the random sampling method.

The specifications and appearance are in accordance with GB/T 2828. It uses

the normal inspection sub-sampling plan. The general inspection level is II and

the acceptance quality level (AQL) is 6.5, as shown in Table 6.

6.3 Inspection classification

6.3.1 Exit-factory inspection

The exit-factory inspection items are all items except water extract, heating loss

rate and drip-free performance of drip-free film within 6 months of use.

6.3.2 Type inspection

Perform inspections in accordance with all technical requirements specified in

this standard. During normal production, at least once every three months;

when one of the conditions occur, type inspection shall also be carried out.

a) During normal production, if major changes in raw materials and

processes may affect product performance;

b) When the production is resumed after long term suspension;

c) When the new product is type-finalized, or the old product is transferring

plant for production;

d) When the relevant inspection results of the exit-factory inspection and the

last type inspection are significantly different;

e) When the national quality supervision agency requests for type inspection.

Share