1

/

van

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

QB/T 2485-2023 English PDF (QBT2485-2023)

QB/T 2485-2023 English PDF (QBT2485-2023)

Normale prijs

$185.00 USD

Normale prijs

Aanbiedingsprijs

$185.00 USD

Eenheidsprijs

/

per

Verzendkosten worden berekend bij de checkout.

Kan beschikbaarheid voor afhalen niet laden

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click QB/T 2485-2023 (Self-service in 1-minute)

Historical versions (Master-website): QB/T 2485-2023

Preview True-PDF (Reload/Scroll-down if blank)

QB/T 2485-2023: Toilet soap

QB/T 2485-2023

QB

LIGHT INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 71.100.40

CCS Y 43

Replacing QB/T 2485-2008

Toilet soap

香皂

ISSUED ON: APRIL 21, 2023

IMPLEMENTED ON: NOVEMBER 01, 2023

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Classification and marking ... 6

5 Requirements ... 6

6 Test method ... 7

7 Inspection rules ... 10

8 Marking, packaging, transportation, storage ... 11

9 Shelf life ... 11

Appendix A (Normative) Determination of dry sodium soap - Simplified method ... 12

Toilet soap

1 Scope

This document specifies the requirements for soaps; describes the corresponding test

methods; specifies the inspection rules, marking, packaging, transportation, storage and

shelf life; provides classifications for technical provisions.

This document is applicable to the production, inspection, sale of fatty acid salt soaps

produced by milling or other processes, as well as solids made of fatty acid salts with

additional functional agents.

2 Normative references

The contents of the following documents constitute essential provisions of this

document through normative references in the text. Among them, for referenced

documents with dates, only the version corresponding to that date applies to this

document; for referenced documents without dates, the latest version (including all

amendments) applies to this document.

GB/T 6682 Water for analytical laboratory use - Specification and test methods

GB/T 13173 Surface active agents - Test methods for detergents

GB/T 24314 Beeswax

GB/T 36970 Instruction for use of consumer products - Labelling for detergents

QB/T 1913-2004 Transparent soaps

QB/T 2623.1 Test methods of soaps - Determination of free caustic alkali content in

soaps

QB/T 2623.2 Test methods of soaps - Determination of total free alkali content in

soaps

QB/T 2623.3 Test methods of soaps - Determination of total alkali content and total

fatty matter content in soaps

QB/T 2623.4 Test methods of soaps - Determination of moisture and volatile matter

content in soaps - Oven method

QB/T 2623.6 Test methods of soaps - Determination of chloride content in soaps

QB/T 2623.8 Test methods of soaps - Determination of phosphate content in soaps

QB/T 2623.9 Test methods of soaps - Determination of total effective matter content

in soaps

QB/T 2739 Preparations of standard volumetric solutions of general test methods

for washing products

QB/T 2951 Inspecting rules for detergent products

QB/T 2952 Requirements for detergent marks and packaging

JF 1070.1 Rules of metrological testing for net quantity of soap products in

prepackages with fixed content

3 Terms and definitions

There are no terms and definitions that need to be defined in this document.

4 Classification and marking

Products are divided into the following categories according to their ingredients:

- Soap type (indicated by type I): Products containing only fatty acid salts and

additives. Marked as "QB/T 2485 type I".

- Compound type (indicated by type II): Products containing fatty acid salts and/or

other surfactants, functional additives, additives. Marked as "QB/T 2485 type II".

5 Requirements

5.1 Sensory requirements

5.1.1 Soap appearance

It shall be uniform in color, without obvious impurities and stains, except for products

with special appearance requirements (such as colored patterns, colored particles, etc.).

5.1.2 Odor

Shall have a stable aroma, without unpleasant odors such as rancid oil.

5.2 Physical and chemical indicators

Shall comply with the requirements of Table 1.

Determine according to QB/T 2623.9; the reported result is calculated according to

formula (2).

The arithmetic mean of the results of 2 parallel determinations is expressed to the

integer as the determination result.

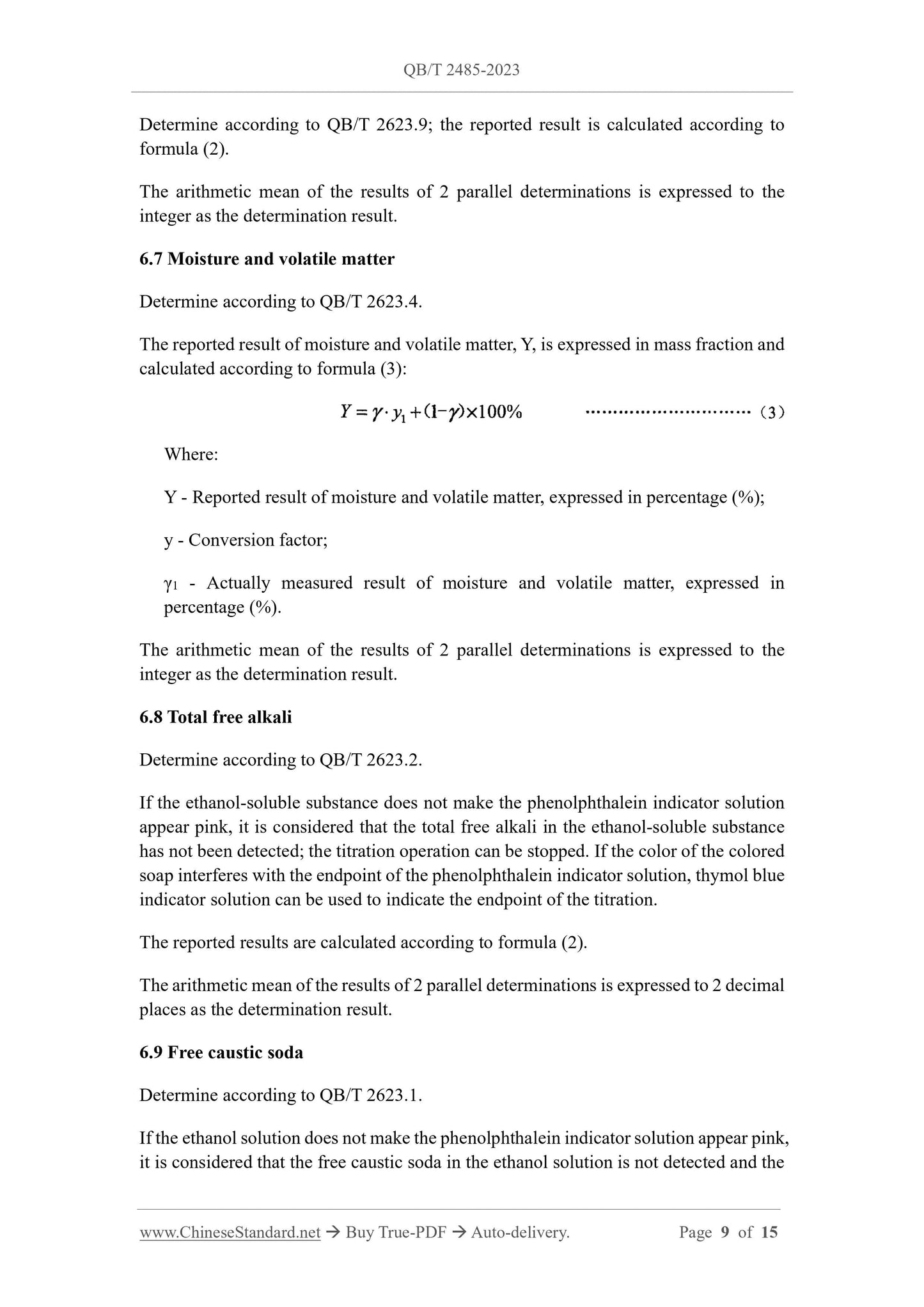

6.7 Moisture and volatile matter

Determine according to QB/T 2623.4.

The reported result of moisture and volatile matter, Y, is expressed in mass fraction and

calculated according to formula (3):

Where:

Y - Reported result of moisture and volatile matter, expressed in percentage (%);

y - Conversion factor;

γ1 - Actually measured result of moisture and volatile matter, expressed in

percentage (%).

The arithmetic mean of the results of 2 parallel determinations is expressed to the

integer as the determination result.

6.8 Total free alkali

Determine according to QB/T 2623.2.

If the ethanol-soluble substance does not make the phenolphthalein indicator solution

appear pink, it is considered that the total free alkali in the ethanol-soluble substance

has not been detected; the titration operation can be stopped. If the color of the colored

soap interferes with the endpoint of the phenolphthalein indicator solution, thymol blue

indicator solution can be used to indicate the endpoint of the titration.

The reported results are calculated according to formula (2).

The arithmetic mean of the results of 2 parallel determinations is expressed to 2 decimal

places as the determination result.

6.9 Free caustic soda

Determine according to QB/T 2623.1.

If the ethanol solution does not make the phenolphthalein indicator solution appear pink,

it is considered that the free caustic soda in the ethanol solution is not detected and the

titration operation can be stopped. If the color of the colored soap interferes with the

endpoint of the phenolphthalein indicator solution, thymol blue indicator solution can

be used to indicate the endpoint of the titration.

The reported results are calculated according to formula (2).

The arithmetic mean of the results of 2 parallel determinations is expressed to 2 decimal

places as the determination result.

6.10 Chloride

Determine according to QB/T 2623.6.

The reported results are calculated according to formula (2).

The arithmetic mean of the results of 2 parallel determinations shall be expressed to one

decimal place as the determination result.

6.11 Total phosphorus pentoxide

Determine according to QB/T 2623.8 and filter if necessary.

Report the result according to formula (2).

The arithmetic mean of the results of 2 parallel determinations shall be expressed to one

decimal place as the determination result.

6.12 Transparency

After constant temperature at (25 ± 2) °C for 24 hours, determine according to Appendix

A of QB/T 1913-2004.

6.13 Net content

According to JJF 1070.1.

7 Inspection rules

The inspection rules shall be implemented in accordance with QB/T 2951.

Dry sodium soap or total effective matter shall be determined according to the product

type indicated on the package; when the product type is not indicated on the package,

it shall be determined according to "Type I dry sodium soap content ≥ 83%".

The exit-factory inspection items are 5.1, 5.3 and the dry sodium soap content or total

effective matter content, free caustic alkali in Table 1; transparency is added for

transparent products.

Appendix A

(Normative)

Determination of dry sodium soap - Simplified method

A.1 Principle

Soap samples are acidified to generate fatty acids, which are insoluble in water. They

are separated from other inorganic additives in soap. The weight and molecular weight

of fatty acids can be measured, to calculate the dry soap content (content of sodium

fatty acids).

The results of this method include fat matter, average relative molecular mass,

unsaponifiable matter, unsaponifiable oils and fats, and other organic matter insoluble

in water in soap.

A.2 Reagents

A.2.1 95% ethanol: Neutralize with alkali until it is neutral to phenolphthalein indicator

solution.

A.2.2 Sulfuric acid: Aqueous solution with a volume fraction of 1:1.

A.2.3 Sodium hydroxide: c(NaOH) = 0.5 mol/L standard titration solution, prepared

according to the relevant provisions of QB/T 2739.

A.2.4 Methyl orange indicator solution: 1 g/L.

A.2.5 Phenolphthalein indicator solution: 10 g/L.

A.2.6 Semi-refined paraffin: No.60.

A.2.7 Wax block: Take water, semi-refined paraffin (A.2.6) and beeswax (GB/T 24314)

in an aluminum pot in a weight ratio of about 10:4:1; place on an electric stove and heat

until slightly boiling. Pour the wax block into a porcelain plate to make a cake; cool it;

take out the wax block and dry it; cut it into pieces, so that each piece is about 7 g.

A.3 Instruments

A.3.1 Analytical balance: Resolution 0.0002 g.

A.3.2 Beaker: 50 mL, 250 mL.

A.3.3 Conical flask: 250 mL.

A.3.4 Measuring cylinder: 10 mL.

A.3.5 Burette without stopper (B grade): 25 mL.

A.3.6 Watch glass: φ(85 ± 5) mm.

A.3.7 Oven: Can be controlled at (103 ± 2) °C.

A.3.8 Boiling water bath.

A.4 Steps

A.4.1 Determination of total fatty acids

Weigh about 10 g of the test portion (6.2) (weighed to 0.001 g) and the homemade wax

block (A.2.7) (weighed to 0.001 g), respectively. Place the test portion in a 250 mL

beaker. Insert a glass rod.

Add 200 mL of water at about 50 °C to the beaker; place it in a boiling water bath (A.3.8)

and heat until the sample is dissolved. Measure 10 mL of sulfuric acid (A.2.2) (If

necessary, add more sulfuric acid to fully acidify the sample). Slowly add it to the

beaker while stirring. Start timing after stirring evenly; add a wax block (A.2.7) of

known weight after the fatty acids are clarified. After 1 hour, take out the beaker and

put it in a water tank to cool (if there are bubbles in the fatty acid, it must be heated and

dissolved again until the bubbles are driven away).

Take out the mixed wax block; absorb the water with filter paper; use a knife to scrape

the mixed wax on the beaker wall and the glass rod; place it on the analytical balance

to weigh (accurate to 0.001 g).

The soap shall not be placed in a boiling water bath for too long for heating and

decomposition; the test shall be completed within 2 hours.

For some soaps with inorganic substances, about 2 g of sodium fluoride can be added

during the test to ensure that the surface of the mixed wax cake is firm. The total fatty

acid content W, expressed as mass fraction, is calculated according to formula (A.1):

W - Total fatty acid content;

m2 - Mass of mixed wax block, in grams (g);

m1 - Mass of wax block, in grams (g);

m0 - Mass of test portion, in grams (g);

A - Correction value (generally not more than 0.5%).

Get Quotation: Click QB/T 2485-2023 (Self-service in 1-minute)

Historical versions (Master-website): QB/T 2485-2023

Preview True-PDF (Reload/Scroll-down if blank)

QB/T 2485-2023: Toilet soap

QB/T 2485-2023

QB

LIGHT INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 71.100.40

CCS Y 43

Replacing QB/T 2485-2008

Toilet soap

香皂

ISSUED ON: APRIL 21, 2023

IMPLEMENTED ON: NOVEMBER 01, 2023

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Classification and marking ... 6

5 Requirements ... 6

6 Test method ... 7

7 Inspection rules ... 10

8 Marking, packaging, transportation, storage ... 11

9 Shelf life ... 11

Appendix A (Normative) Determination of dry sodium soap - Simplified method ... 12

Toilet soap

1 Scope

This document specifies the requirements for soaps; describes the corresponding test

methods; specifies the inspection rules, marking, packaging, transportation, storage and

shelf life; provides classifications for technical provisions.

This document is applicable to the production, inspection, sale of fatty acid salt soaps

produced by milling or other processes, as well as solids made of fatty acid salts with

additional functional agents.

2 Normative references

The contents of the following documents constitute essential provisions of this

document through normative references in the text. Among them, for referenced

documents with dates, only the version corresponding to that date applies to this

document; for referenced documents without dates, the latest version (including all

amendments) applies to this document.

GB/T 6682 Water for analytical laboratory use - Specification and test methods

GB/T 13173 Surface active agents - Test methods for detergents

GB/T 24314 Beeswax

GB/T 36970 Instruction for use of consumer products - Labelling for detergents

QB/T 1913-2004 Transparent soaps

QB/T 2623.1 Test methods of soaps - Determination of free caustic alkali content in

soaps

QB/T 2623.2 Test methods of soaps - Determination of total free alkali content in

soaps

QB/T 2623.3 Test methods of soaps - Determination of total alkali content and total

fatty matter content in soaps

QB/T 2623.4 Test methods of soaps - Determination of moisture and volatile matter

content in soaps - Oven method

QB/T 2623.6 Test methods of soaps - Determination of chloride content in soaps

QB/T 2623.8 Test methods of soaps - Determination of phosphate content in soaps

QB/T 2623.9 Test methods of soaps - Determination of total effective matter content

in soaps

QB/T 2739 Preparations of standard volumetric solutions of general test methods

for washing products

QB/T 2951 Inspecting rules for detergent products

QB/T 2952 Requirements for detergent marks and packaging

JF 1070.1 Rules of metrological testing for net quantity of soap products in

prepackages with fixed content

3 Terms and definitions

There are no terms and definitions that need to be defined in this document.

4 Classification and marking

Products are divided into the following categories according to their ingredients:

- Soap type (indicated by type I): Products containing only fatty acid salts and

additives. Marked as "QB/T 2485 type I".

- Compound type (indicated by type II): Products containing fatty acid salts and/or

other surfactants, functional additives, additives. Marked as "QB/T 2485 type II".

5 Requirements

5.1 Sensory requirements

5.1.1 Soap appearance

It shall be uniform in color, without obvious impurities and stains, except for products

with special appearance requirements (such as colored patterns, colored particles, etc.).

5.1.2 Odor

Shall have a stable aroma, without unpleasant odors such as rancid oil.

5.2 Physical and chemical indicators

Shall comply with the requirements of Table 1.

Determine according to QB/T 2623.9; the reported result is calculated according to

formula (2).

The arithmetic mean of the results of 2 parallel determinations is expressed to the

integer as the determination result.

6.7 Moisture and volatile matter

Determine according to QB/T 2623.4.

The reported result of moisture and volatile matter, Y, is expressed in mass fraction and

calculated according to formula (3):

Where:

Y - Reported result of moisture and volatile matter, expressed in percentage (%);

y - Conversion factor;

γ1 - Actually measured result of moisture and volatile matter, expressed in

percentage (%).

The arithmetic mean of the results of 2 parallel determinations is expressed to the

integer as the determination result.

6.8 Total free alkali

Determine according to QB/T 2623.2.

If the ethanol-soluble substance does not make the phenolphthalein indicator solution

appear pink, it is considered that the total free alkali in the ethanol-soluble substance

has not been detected; the titration operation can be stopped. If the color of the colored

soap interferes with the endpoint of the phenolphthalein indicator solution, thymol blue

indicator solution can be used to indicate the endpoint of the titration.

The reported results are calculated according to formula (2).

The arithmetic mean of the results of 2 parallel determinations is expressed to 2 decimal

places as the determination result.

6.9 Free caustic soda

Determine according to QB/T 2623.1.

If the ethanol solution does not make the phenolphthalein indicator solution appear pink,

it is considered that the free caustic soda in the ethanol solution is not detected and the

titration operation can be stopped. If the color of the colored soap interferes with the

endpoint of the phenolphthalein indicator solution, thymol blue indicator solution can

be used to indicate the endpoint of the titration.

The reported results are calculated according to formula (2).

The arithmetic mean of the results of 2 parallel determinations is expressed to 2 decimal

places as the determination result.

6.10 Chloride

Determine according to QB/T 2623.6.

The reported results are calculated according to formula (2).

The arithmetic mean of the results of 2 parallel determinations shall be expressed to one

decimal place as the determination result.

6.11 Total phosphorus pentoxide

Determine according to QB/T 2623.8 and filter if necessary.

Report the result according to formula (2).

The arithmetic mean of the results of 2 parallel determinations shall be expressed to one

decimal place as the determination result.

6.12 Transparency

After constant temperature at (25 ± 2) °C for 24 hours, determine according to Appendix

A of QB/T 1913-2004.

6.13 Net content

According to JJF 1070.1.

7 Inspection rules

The inspection rules shall be implemented in accordance with QB/T 2951.

Dry sodium soap or total effective matter shall be determined according to the product

type indicated on the package; when the product type is not indicated on the package,

it shall be determined according to "Type I dry sodium soap content ≥ 83%".

The exit-factory inspection items are 5.1, 5.3 and the dry sodium soap content or total

effective matter content, free caustic alkali in Table 1; transparency is added for

transparent products.

Appendix A

(Normative)

Determination of dry sodium soap - Simplified method

A.1 Principle

Soap samples are acidified to generate fatty acids, which are insoluble in water. They

are separated from other inorganic additives in soap. The weight and molecular weight

of fatty acids can be measured, to calculate the dry soap content (content of sodium

fatty acids).

The results of this method include fat matter, average relative molecular mass,

unsaponifiable matter, unsaponifiable oils and fats, and other organic matter insoluble

in water in soap.

A.2 Reagents

A.2.1 95% ethanol: Neutralize with alkali until it is neutral to phenolphthalein indicator

solution.

A.2.2 Sulfuric acid: Aqueous solution with a volume fraction of 1:1.

A.2.3 Sodium hydroxide: c(NaOH) = 0.5 mol/L standard titration solution, prepared

according to the relevant provisions of QB/T 2739.

A.2.4 Methyl orange indicator solution: 1 g/L.

A.2.5 Phenolphthalein indicator solution: 10 g/L.

A.2.6 Semi-refined paraffin: No.60.

A.2.7 Wax block: Take water, semi-refined paraffin (A.2.6) and beeswax (GB/T 24314)

in an aluminum pot in a weight ratio of about 10:4:1; place on an electric stove and heat

until slightly boiling. Pour the wax block into a porcelain plate to make a cake; cool it;

take out the wax block and dry it; cut it into pieces, so that each piece is about 7 g.

A.3 Instruments

A.3.1 Analytical balance: Resolution 0.0002 g.

A.3.2 Beaker: 50 mL, 250 mL.

A.3.3 Conical flask: 250 mL.

A.3.4 Measuring cylinder: 10 mL.

A.3.5 Burette without stopper (B grade): 25 mL.

A.3.6 Watch glass: φ(85 ± 5) mm.

A.3.7 Oven: Can be controlled at (103 ± 2) °C.

A.3.8 Boiling water bath.

A.4 Steps

A.4.1 Determination of total fatty acids

Weigh about 10 g of the test portion (6.2) (weighed to 0.001 g) and the homemade wax

block (A.2.7) (weighed to 0.001 g), respectively. Place the test portion in a 250 mL

beaker. Insert a glass rod.

Add 200 mL of water at about 50 °C to the beaker; place it in a boiling water bath (A.3.8)

and heat until the sample is dissolved. Measure 10 mL of sulfuric acid (A.2.2) (If

necessary, add more sulfuric acid to fully acidify the sample). Slowly add it to the

beaker while stirring. Start timing after stirring evenly; add a wax block (A.2.7) of

known weight after the fatty acids are clarified. After 1 hour, take out the beaker and

put it in a water tank to cool (if there are bubbles in the fatty acid, it must be heated and

dissolved again until the bubbles are driven away).

Take out the mixed wax block; absorb the water with filter paper; use a knife to scrape

the mixed wax on the beaker wall and the glass rod; place it on the analytical balance

to weigh (accurate to 0.001 g).

The soap shall not be placed in a boiling water bath for too long for heating and

decomposition; the test shall be completed within 2 hours.

For some soaps with inorganic substances, about 2 g of sodium fluoride can be added

during the test to ensure that the surface of the mixed wax cake is firm. The total fatty

acid content W, expressed as mass fraction, is calculated according to formula (A.1):

W - Total fatty acid content;

m2 - Mass of mixed wax block, in grams (g);

m1 - Mass of wax block, in grams (g);

m0 - Mass of test portion, in grams (g);

A - Correction value (generally not more than 0.5%).

Share