1

/

van

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 1165-2022 English PDF (QCT1165-2022)

QC/T 1165-2022 English PDF (QCT1165-2022)

Normale prijs

$230.00 USD

Normale prijs

Aanbiedingsprijs

$230.00 USD

Eenheidsprijs

/

per

Verzendkosten worden berekend bij de checkout.

Kan beschikbaarheid voor afhalen niet laden

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1165-2022

Historical versions: QC/T 1165-2022

Preview True-PDF (Reload/Scroll if blank)

QC/T 1165-2022: Carbon canister air filter for gasoline passenger car

QC/T 1165-2022

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.060.40

CCS T 13

Carbon canister air filter for gasoline passenger car

ISSUED ON: APRIL 08, 2022

IMPLEMENTED ON: OCTOBER 01, 2022

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 6

1 Scope ... 7

2 Normative references ... 7

3 Terms and definitions ... 8

4 Technical requirements ... 8

5 Test method ... 9

6 Inspection rules ... 14

7 Marking, packaging, transportation, storage ... 15

Carbon canister air filter for gasoline passenger car

1 Scope

This document specifies the technical requirements, test methods, inspection rules,

marking, packaging, transportation and storage of carbon canister air filter for gasoline

passenger car.

This document is applicable to carbon canister air filter for gasoline passenger car,

which has a rated volume flow rate of 22.7 L/min ~ 70 L/min (referred to as canister air

filters). Other canister air filters can also be used as a reference.

2 Normative references

The contents of the following documents constitute the essential provisions of this

document through normative references in the text. Among them, for dated references,

only the version corresponding to the date applies to this document; for undated

references, the latest version (including all amendments) applies to this document.

GB/T 2423.1-2008 Environmental testing - Part 2: Test methods - Tests A: Cold

GB/T 2423.2-2008 Environmental testing - Part 2: Test methods - Tests B: Dry heat

GB/T 2423.55-2006 Environmental testing for electric and electronic products - Part

2: Test methods - Test Eh: hammer tests

GB/T 2828.1-2012 Sampling procedures for inspection by attributes - Part 1:

Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot

inspection

GB/T 14041.1-2001 Hydraulic fluid power - Filter elements - Part 1: Verification of

fabrication integrity and determination of the first bubble point

GB/T 28949-2012 Inlet air cleaning equipment for internal combustion engines and

compressors - Performance testing

GB/T 28950.1-2012 Road vehicles and internal combustion engines - Filter

vocabulary - Part 1: Definitions of filters and filter components

GB/T 28950.2-2012 Road vehicles and internal combustion engines - Filter

vocabulary - Part 2: Definitions of characteristics of filters and their components

GB/T 28957.1-2012 Road vehicles - Test dust for filter evaluation - Part 1: Silicon

dioxide test dust

3 Terms and definitions

The terms and definitions, which are defined in GB/T 28949-2012, GB/T 28950.1-2012,

GB/T 28950.2-2012, as well as the following terms and definitions, apply to this

document.

3.1

Carbon canister air filter

A filter, which is specially designed, to filter the dusty air drawn into the canister.

3.2

Filtration efficiency

The percentage -- of the mass of the dust filtered by the test piece TO the mass of

the added dust.

4 Technical requirements

4.1 General requirements

The technical requirements of the canister air filter shall comply with the provisions of

this document.

4.2 Original resistance

Under the rated air volume flow rate, the original resistance of the canister air filter

shall not be greater than 150 Pa.

4.3 Filtration efficiency

Under the rated air volume flow rate, when the intake resistance reaches 750 Pa, the

filtration efficiency of the canister air filter shall not be less than 99%.

4.4 Ash capacity

Under the rated air volume flow rate, when the air intake resistance reaches 750 Pa, the

ash holding capacity of the canister air filter shall not be less than 21 g, OR as agreed

upon by the supplier and the buyer.

4.5 Structural integrity of filter element

The initial bubbling pressure of the carbon canister's air filter element shall be as

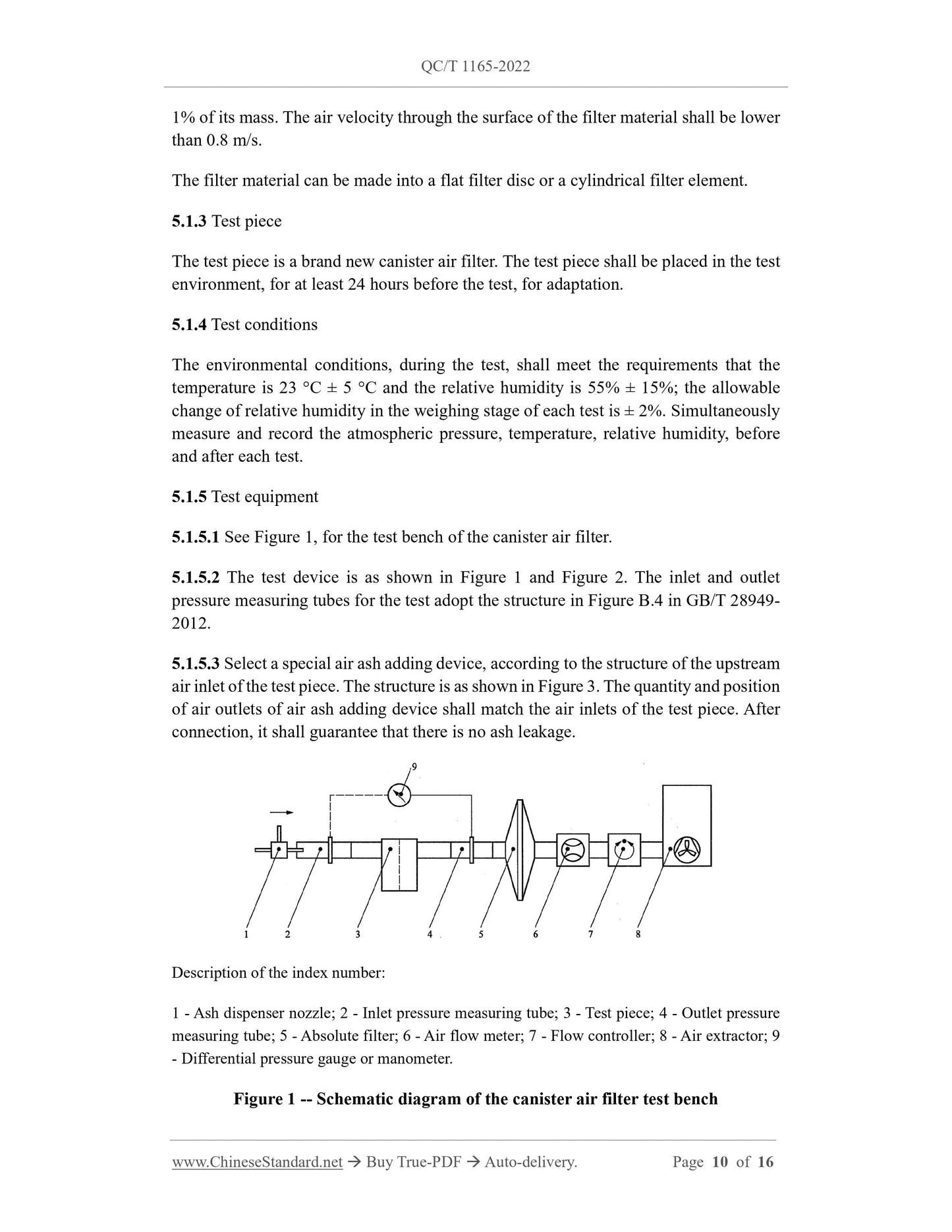

5.1.6.1.3 The original resistance is the static pressure value, which is measured at the

pressure measuring point, downstream of the test piece. During the test, measure and

record the static pressure value of the downstream pressure measuring point, under each

air flow, based on 50%, 75%, 100%, 125%, 150% of the rated air flow (or as agreed

between the supplier and the buyer).

5.1.6.1.4 Record the ambient temperature, relative humidity, atmospheric pressure

during the test.

5.1.6.2 Filtration efficiency

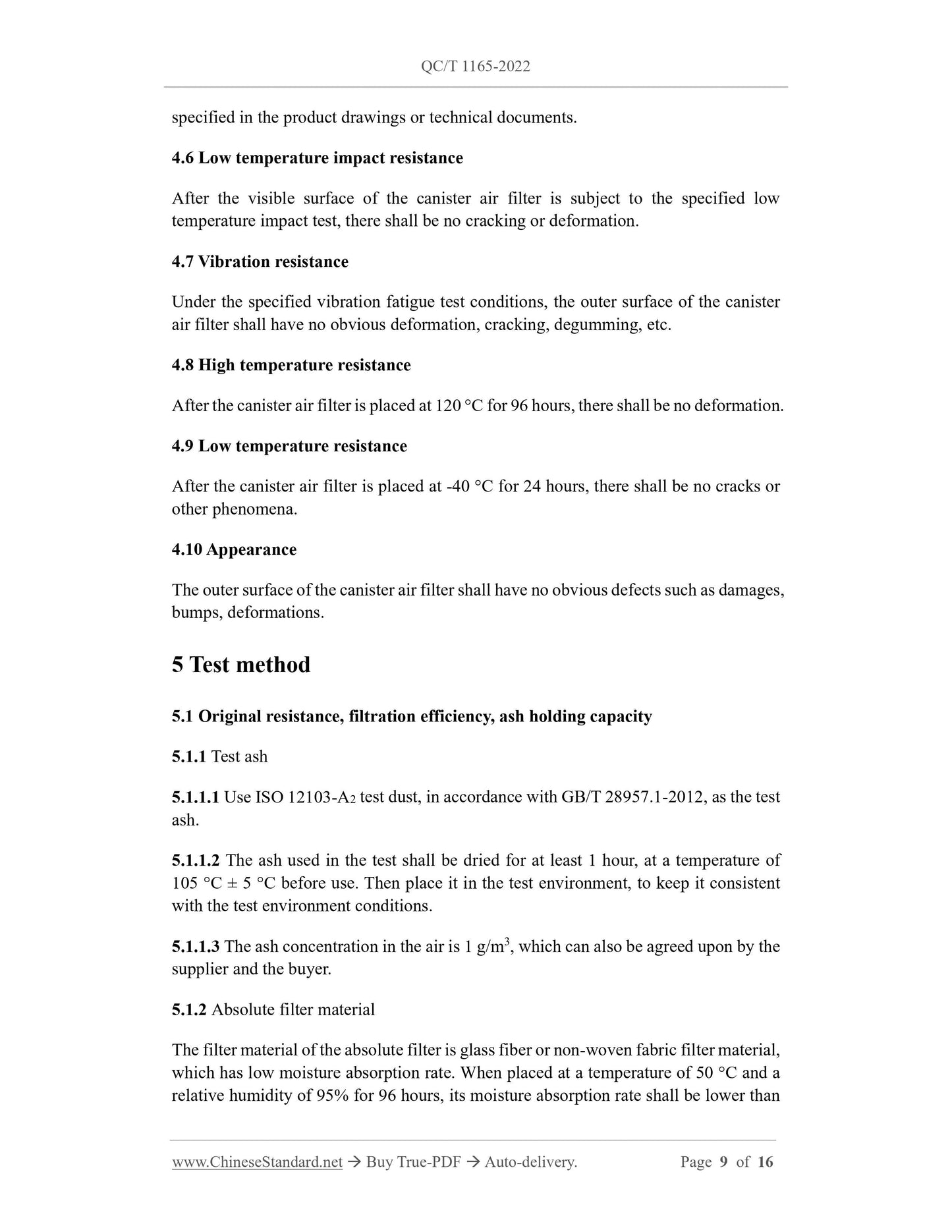

5.1.6.2.1 Properly connect the test piece with the test bench, according to Figure 1.

5.1.6.2.2 Start the air extractor, to pump air at the rated air flow rate for at least 15

minutes, to stabilize the state of the test piece.

5.1.6.2.3 Weigh the test piece and the absolute filter. Record the initial mass of the test

piece and the absolute filter.

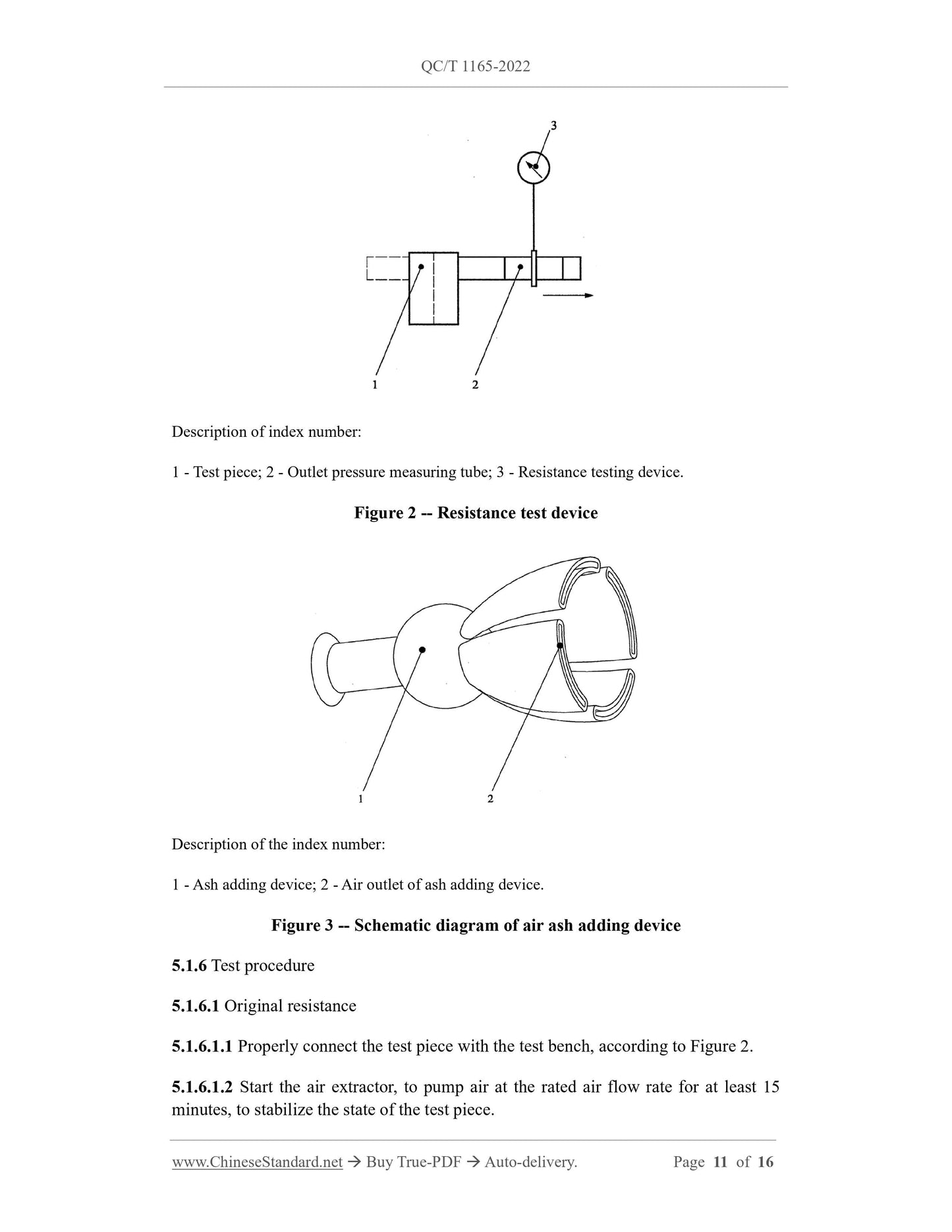

5.1.6.2.4 Properly connect the ash adding tooling, test piece and test equipment.

5.1.6.2.5 Start the test bench. Adjust the flow rate to the test flow rate and make it stable.

Record the resistance value.

5.1.6.2.6 Start to add ash to the air. The ash concentration is l g/m3, OR according to

the ash concentration, which is agreed upon by the supplier and the buyer.

5.1.6.2.7 Continue the test, until it reaches the specified test termination resistance value

of 750 Pa.

5.1.6.2.8 Weigh the test piece and the absolute filter. Record the mass of the test piece

and the absolute filter, after the test. Calculate the mass increment of the test piece and

the absolute filter.

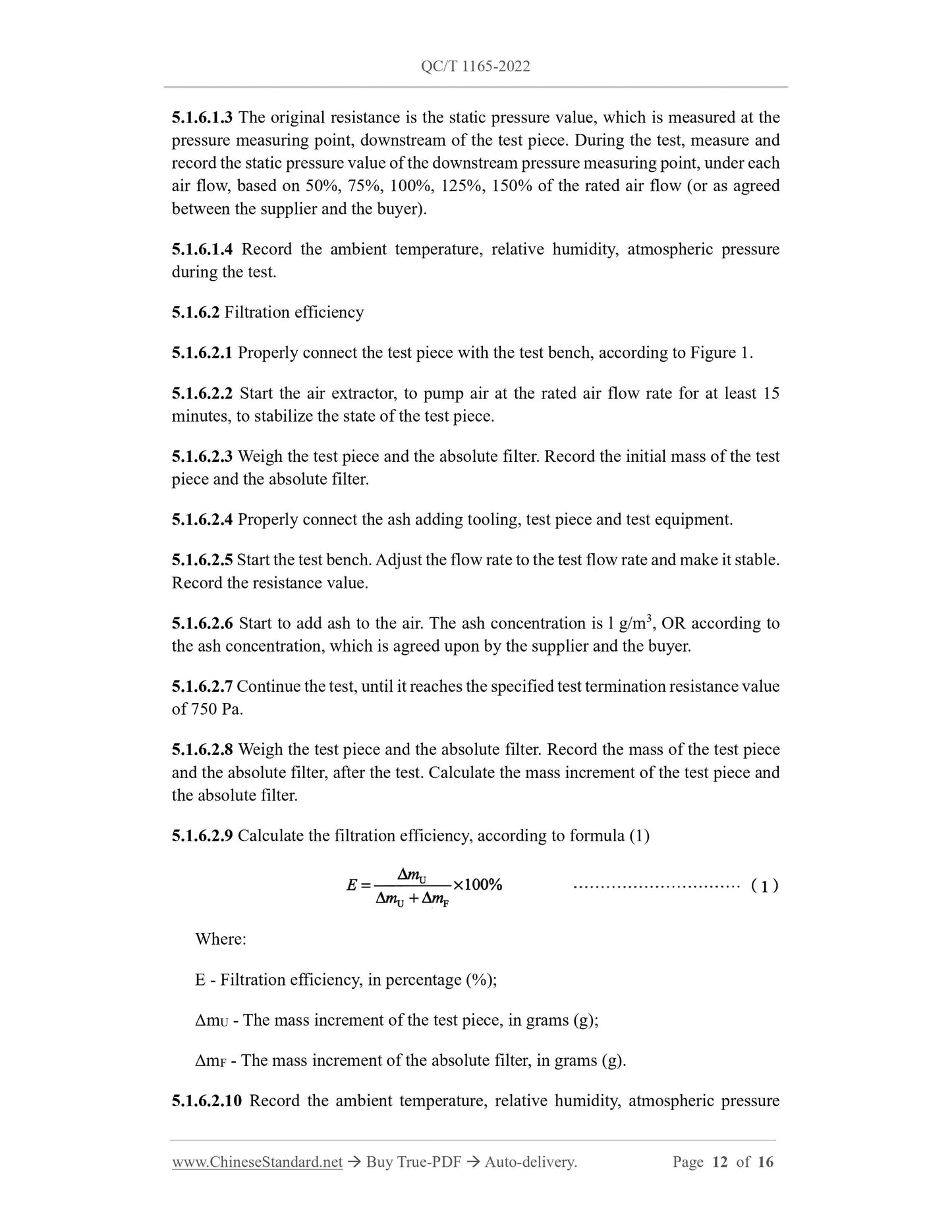

5.1.6.2.9 Calculate the filtration efficiency, according to formula (1)

Where:

E - Filtration efficiency, in percentage (%);

ΔmU - The mass increment of the test piece, in grams (g);

ΔmF - The mass increment of the absolute filter, in grams (g).

5.1.6.2.10 Record the ambient temperature, relative humidity, atmospheric pressure

during the test.

5.1.6.3 Ash capacity

5.1.6.3.1 The ash holding capacity test can be carried out, simultaneously with the

filtration efficiency test.

5.1.6.3.2 Weigh the test piece and the absolute filter. Record the initial mass of the test

piece and the absolute filter.

5.1.6.3.3 Properly connect the ash adding tooling, test piece, test equipment.

5.1.6.3.4 Start the test bench. Adjust the flow rate to the test flow rate and make it stable.

Record the pressure difference.

5.1.6.3.5 Start to add ash to the air. The ash concentration is 1 g/m3, OR according to

the ash concentration agreed upon by the supplier and the buyer.

5.1.6.3.6 Continue the test, until the specified test termination resistance value is

reached.

5.1.6.3.7 Weigh the test piece and the absolute filter. Record the mass of the test piece

and the absolute filter, after the test.

5.1.6.3.8 Calculate the ash capacity C, according to formula (2):

Where:

C - Ash capacity, in gram (g);

B - The mass of the test piece after the test, in grams (g);

D - The mass of the test piece before the test, in grams (g).

5.1.6.3.9 Record the ambient temperature, relative humidity, atmospheric pressure

during the test.

5.2 Low temperature impact resistance

Place the canister air filter in a low-temperature box at -30 °C ± 2 °C for 4 hours. Within

30 seconds after taking out, according to the requirements of the test Ehc: vertical drop

weight in Chapter 6 of GB/T2423.55-2006, carry out the drop weight impact test on the

visible surface of the canister air filter, at room temperature. The standard drop weight

is a steel ball, which has a mass of 500 g and a free fall height of 0.4 m. The drop weight

impact point is at a v...

Get QUOTATION in 1-minute: Click QC/T 1165-2022

Historical versions: QC/T 1165-2022

Preview True-PDF (Reload/Scroll if blank)

QC/T 1165-2022: Carbon canister air filter for gasoline passenger car

QC/T 1165-2022

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.060.40

CCS T 13

Carbon canister air filter for gasoline passenger car

ISSUED ON: APRIL 08, 2022

IMPLEMENTED ON: OCTOBER 01, 2022

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 6

1 Scope ... 7

2 Normative references ... 7

3 Terms and definitions ... 8

4 Technical requirements ... 8

5 Test method ... 9

6 Inspection rules ... 14

7 Marking, packaging, transportation, storage ... 15

Carbon canister air filter for gasoline passenger car

1 Scope

This document specifies the technical requirements, test methods, inspection rules,

marking, packaging, transportation and storage of carbon canister air filter for gasoline

passenger car.

This document is applicable to carbon canister air filter for gasoline passenger car,

which has a rated volume flow rate of 22.7 L/min ~ 70 L/min (referred to as canister air

filters). Other canister air filters can also be used as a reference.

2 Normative references

The contents of the following documents constitute the essential provisions of this

document through normative references in the text. Among them, for dated references,

only the version corresponding to the date applies to this document; for undated

references, the latest version (including all amendments) applies to this document.

GB/T 2423.1-2008 Environmental testing - Part 2: Test methods - Tests A: Cold

GB/T 2423.2-2008 Environmental testing - Part 2: Test methods - Tests B: Dry heat

GB/T 2423.55-2006 Environmental testing for electric and electronic products - Part

2: Test methods - Test Eh: hammer tests

GB/T 2828.1-2012 Sampling procedures for inspection by attributes - Part 1:

Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot

inspection

GB/T 14041.1-2001 Hydraulic fluid power - Filter elements - Part 1: Verification of

fabrication integrity and determination of the first bubble point

GB/T 28949-2012 Inlet air cleaning equipment for internal combustion engines and

compressors - Performance testing

GB/T 28950.1-2012 Road vehicles and internal combustion engines - Filter

vocabulary - Part 1: Definitions of filters and filter components

GB/T 28950.2-2012 Road vehicles and internal combustion engines - Filter

vocabulary - Part 2: Definitions of characteristics of filters and their components

GB/T 28957.1-2012 Road vehicles - Test dust for filter evaluation - Part 1: Silicon

dioxide test dust

3 Terms and definitions

The terms and definitions, which are defined in GB/T 28949-2012, GB/T 28950.1-2012,

GB/T 28950.2-2012, as well as the following terms and definitions, apply to this

document.

3.1

Carbon canister air filter

A filter, which is specially designed, to filter the dusty air drawn into the canister.

3.2

Filtration efficiency

The percentage -- of the mass of the dust filtered by the test piece TO the mass of

the added dust.

4 Technical requirements

4.1 General requirements

The technical requirements of the canister air filter shall comply with the provisions of

this document.

4.2 Original resistance

Under the rated air volume flow rate, the original resistance of the canister air filter

shall not be greater than 150 Pa.

4.3 Filtration efficiency

Under the rated air volume flow rate, when the intake resistance reaches 750 Pa, the

filtration efficiency of the canister air filter shall not be less than 99%.

4.4 Ash capacity

Under the rated air volume flow rate, when the air intake resistance reaches 750 Pa, the

ash holding capacity of the canister air filter shall not be less than 21 g, OR as agreed

upon by the supplier and the buyer.

4.5 Structural integrity of filter element

The initial bubbling pressure of the carbon canister's air filter element shall be as

5.1.6.1.3 The original resistance is the static pressure value, which is measured at the

pressure measuring point, downstream of the test piece. During the test, measure and

record the static pressure value of the downstream pressure measuring point, under each

air flow, based on 50%, 75%, 100%, 125%, 150% of the rated air flow (or as agreed

between the supplier and the buyer).

5.1.6.1.4 Record the ambient temperature, relative humidity, atmospheric pressure

during the test.

5.1.6.2 Filtration efficiency

5.1.6.2.1 Properly connect the test piece with the test bench, according to Figure 1.

5.1.6.2.2 Start the air extractor, to pump air at the rated air flow rate for at least 15

minutes, to stabilize the state of the test piece.

5.1.6.2.3 Weigh the test piece and the absolute filter. Record the initial mass of the test

piece and the absolute filter.

5.1.6.2.4 Properly connect the ash adding tooling, test piece and test equipment.

5.1.6.2.5 Start the test bench. Adjust the flow rate to the test flow rate and make it stable.

Record the resistance value.

5.1.6.2.6 Start to add ash to the air. The ash concentration is l g/m3, OR according to

the ash concentration, which is agreed upon by the supplier and the buyer.

5.1.6.2.7 Continue the test, until it reaches the specified test termination resistance value

of 750 Pa.

5.1.6.2.8 Weigh the test piece and the absolute filter. Record the mass of the test piece

and the absolute filter, after the test. Calculate the mass increment of the test piece and

the absolute filter.

5.1.6.2.9 Calculate the filtration efficiency, according to formula (1)

Where:

E - Filtration efficiency, in percentage (%);

ΔmU - The mass increment of the test piece, in grams (g);

ΔmF - The mass increment of the absolute filter, in grams (g).

5.1.6.2.10 Record the ambient temperature, relative humidity, atmospheric pressure

during the test.

5.1.6.3 Ash capacity

5.1.6.3.1 The ash holding capacity test can be carried out, simultaneously with the

filtration efficiency test.

5.1.6.3.2 Weigh the test piece and the absolute filter. Record the initial mass of the test

piece and the absolute filter.

5.1.6.3.3 Properly connect the ash adding tooling, test piece, test equipment.

5.1.6.3.4 Start the test bench. Adjust the flow rate to the test flow rate and make it stable.

Record the pressure difference.

5.1.6.3.5 Start to add ash to the air. The ash concentration is 1 g/m3, OR according to

the ash concentration agreed upon by the supplier and the buyer.

5.1.6.3.6 Continue the test, until the specified test termination resistance value is

reached.

5.1.6.3.7 Weigh the test piece and the absolute filter. Record the mass of the test piece

and the absolute filter, after the test.

5.1.6.3.8 Calculate the ash capacity C, according to formula (2):

Where:

C - Ash capacity, in gram (g);

B - The mass of the test piece after the test, in grams (g);

D - The mass of the test piece before the test, in grams (g).

5.1.6.3.9 Record the ambient temperature, relative humidity, atmospheric pressure

during the test.

5.2 Low temperature impact resistance

Place the canister air filter in a low-temperature box at -30 °C ± 2 °C for 4 hours. Within

30 seconds after taking out, according to the requirements of the test Ehc: vertical drop

weight in Chapter 6 of GB/T2423.55-2006, carry out the drop weight impact test on the

visible surface of the canister air filter, at room temperature. The standard drop weight

is a steel ball, which has a mass of 500 g and a free fall height of 0.4 m. The drop weight

impact point is at a v...

Share