1

/

of

8

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB 1886.64-2015 English PDF

GB 1886.64-2015 English PDF

Regular price

$205.00 USD

Regular price

Sale price

$205.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 1886.64-2015

Historical versions: GB 1886.64-2015

Preview True-PDF (Reload/Scroll if blank)

GB 1886.64-2015: National Food Safety Standard -- Food Additives -- Caramel color

GB 1886.64-2015

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard – Food additives – Caramel

color

ISSUED ON: NOVEMBER 13, 2015

IMPLEMENTED ON: MAY 13, 2016

Issued by: National Health and Family Planning Commission of the People’s

Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Terms and definitions ... 4

3 Technical requirements ... 4

Appendix A Test methods ... 6

National food safety standard – Food additives – Caramel

color

1 Scope

This Standard applies to the food additive caramel color made from sucrose, starch

syrup, xylose mother liquor, etc. using plain caramel, caustic sulfite caramel, ammonia

caramel or sulfite ammonia caramel.

2 Terms and definitions

2.1 plain caramel color

It is made using carbohydrates as the main raw material, with or without the addition

of acid (base), and without the use of ammonia compounds and sulfites.

2.2 caustic sulfite caramel color

It is made using carbohydrates as the main raw material, in the presence of sulfite, with

or without the addition of acid (base), and without the use of ammonia compounds.

2.3 ammonia caramel color

It is made using carbohydrates as the main raw material, in the presence of ammonia

compounds, with or without the addition of acid (base), and without the use of sulfites.

2.4 sulfite ammonia caramel color

It is made using carbohydrates as the main raw material, in the presence of ammonia

compounds and sulfites, with or without the addition of acid (base).

3 Technical requirements

3.1 Sensory requirements

Sensory requirements shall be in accordance with Table 1.

Appendix A

Test methods

A.1 General

Unless otherwise specified in this Standard, the purity of the reagents used shall be

analytically pure. The standard titration solutions, standard solutions for impurity

determination, preparations and products used shall be prepared in accordance with the

provisions of GB/T 601, GB/T 602 and GB/T 603. The test water shall comply with the

provisions of Grade 3 water in GB/T 6682. The solutions used in the test shall refer to

aqueous solutions unless the solvent used is specified.

A.2 Determination of absorbance E0.1% 1 cm (610 nm)

A.2.1 Instruments and apparatuses

Spectrophotometer.

A.2.2 Analysis steps

Weigh about 0.5 g of the sample, accurate to 0.002 g; dissolve it in water; transfer it to

a 500 mL volumetric flask; add water to dilute it to the mark; shake it well. If the

solution is turbid, centrifuge it to obtain the sample solution. Place this sample solution

in a 1 cm colorimetric dish; use water as a blank control; use a spectrophotometer to

measure its absorbance at 610 nm (it is recommended to control the absorbance at 0.2

~ 0.8, otherwise, adjust the sample solution concentration and measure the absorbance

again).

A.2.3 Result calculation

Calculate the absorbance E0.1% 1 cm (610 nm) according to Formula (A.1):

Where:

A – absorbance of the sample being measured;

c – concentration of the sample solution being measured, in grams per milliliter (g/mL);

1 000 – concentration conversion coefficient.

The test result is based on the arithmetic mean of the parallel determination results. The

ratio of the absolute difference between two independent determination results obtained

under repeatability conditions and the arithmetic mean shall not exceed 5%.

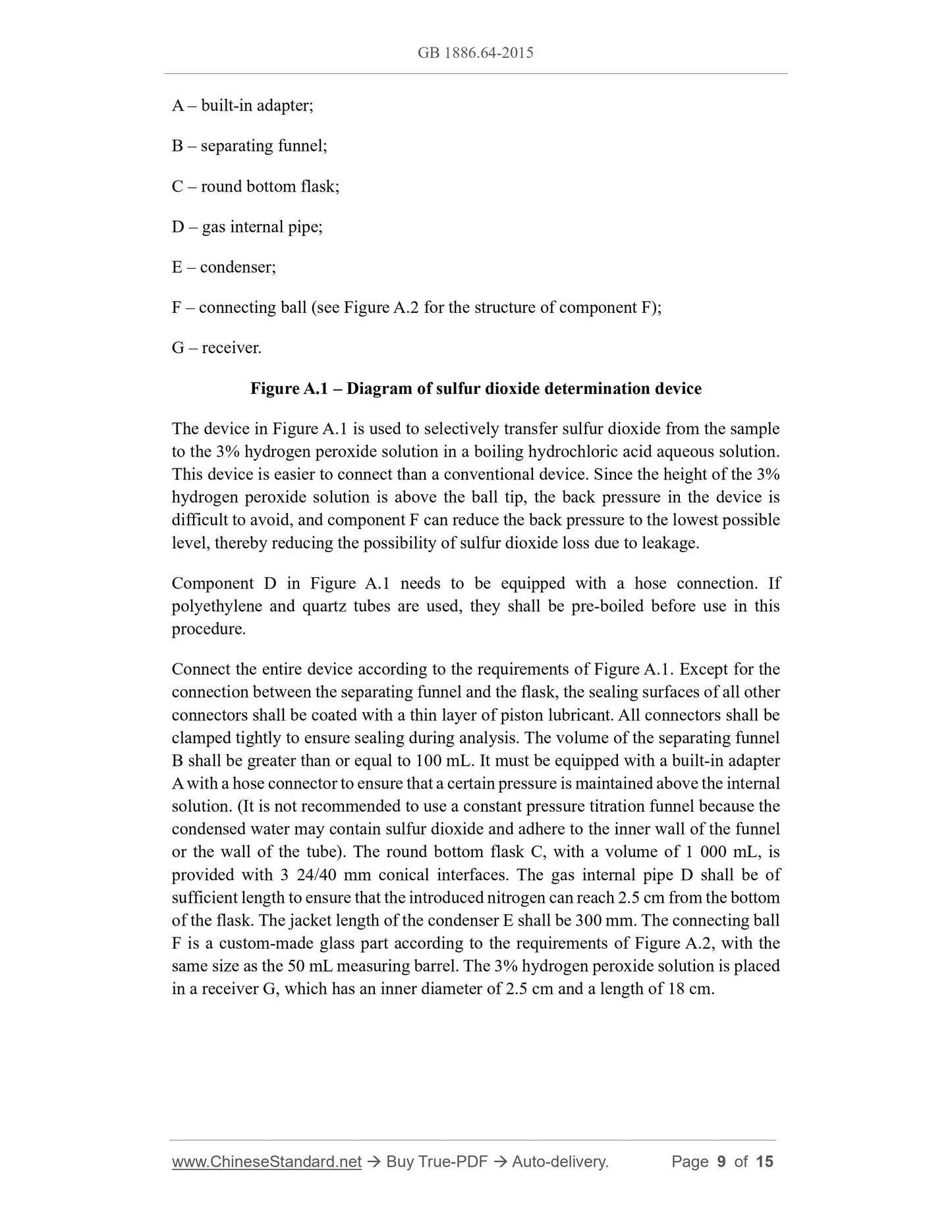

A – built-in adapter;

B – separating funnel;

C – round bottom flask;

D – gas internal pipe;

E – condenser;

F – connecting ball (see Figure A.2 for the structure of component F);

G – receiver.

Figure A.1 – Diagram of sulfur dioxide determination device

The device in Figure A.1 is used to selectively transfer sulfur dioxide from the sample

to the 3% hydrogen peroxide solution in a boiling hydrochloric acid aqueous solution.

This device is easier to connect than a conventional device. Since the height of the 3%

hydrogen peroxide solution is above the ball tip, the back pressure in the device is

difficult to avoid, and component F can reduce the back pressure to the lowest possible

level, thereby reducing the possibility of sulfur dioxide loss due to leakage.

Component D in Figure A.1 needs to be equipped with a hose connection. If

polyethylene and quartz tubes are used, they shall be pre-boiled before use in this

procedure.

Connect the entire device according to the requirements of Figure A.1. Except for the

connection between the separating funnel and the flask, the sealing surfaces of all other

connectors shall be coated with a thin layer of piston lubricant. All connectors shall be

clamped tightly to ensure sealing during analysis. The volume of the separating funnel

B shall be greater than or equal to 100 mL. It must be equipped with a built-in adapter

A with a hose connector to ensure that a certain pressure is maintained above the internal

solution. (It is not recommended to use a constant pressure titration funnel because the

condensed water may contain sulfur dioxide and adhere to the inner wall of the funnel

or the wall of the tube). The round bottom flask C, with a volume of 1 000 mL, is

provided with 3 24/40 mm conical interfaces. The gas internal pipe D shall be of

sufficient length to ensure that the introduced nitrogen can reach 2.5 cm from the bottom

of the flask. The jacket length of the condenser E shall be 300 mm. The connecting ball

F is a custom-made glass part according to the requirements of Figure A.2, with the

same size as the 50 mL measuring barrel. The 3% hydrogen peroxide solution is placed

in a receiver G, which has an inner diameter of 2.5 cm and a length of 18 cm.

connection is completed, the nitrogen flow through the 3% hydrogen peroxide solution

shall be restored immediately, and the connection shall be checked to ensure it is sealed.

The rubber ball above the separating funnel is equipped with a valve to ensure that there

is sufficient pressure above the hydrochloric acid solution. Open the separating funnel

valve to allow the hydrochloric acid solution to flow into the flask. Continue to ensure

that there is sufficient pressure above the solution. If necessary, the valve can be

temporarily closed to replenish the pressure. To prevent sulfur dioxide from escaping

into the separating funnel, the valve shall be closed before the last few milliliters flow

out of the separating funnel.

Connect the power supply for heating, and control the heating rate so that the reflux

liquid is 80 ~ 90 drops per minute. After distillation for 105 minutes, cool the contents

in the 1 000 mL flask at the above reflux rate. Transfer the contents in receiver G.

A.4.4.4 Titration

Add 3 drops of methyl red indicator solution and use standard titration solution to titrate

the above solution to the yellow end point; ensure that it does not fade within 20 seconds.

A.4.5 Result calculation

Calculate the mass fraction w2 of sulfur dioxide (as SO2) according to Formula (A.3):

Where:

M – molar mass of sulfur dioxide, in grams per mole (g/mol), [M (SO2) = 64.06];

V – volume of the sodium hydroxide standard titration solution consumed in the

titration, in milliliters (mL);

c – concentration of the sodium hydroxide standard titration solution, in moles per liter

(mol/L);

0.1 – conversion coefficient;

2 – conversion coefficient;

m – mass of the sample added to the 1 000 mL flask, in grams (g);

1 000 – conversion coefficient;

A610 – absorbance of the sample at 610 nm.

A.5....

Get QUOTATION in 1-minute: Click GB 1886.64-2015

Historical versions: GB 1886.64-2015

Preview True-PDF (Reload/Scroll if blank)

GB 1886.64-2015: National Food Safety Standard -- Food Additives -- Caramel color

GB 1886.64-2015

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard – Food additives – Caramel

color

ISSUED ON: NOVEMBER 13, 2015

IMPLEMENTED ON: MAY 13, 2016

Issued by: National Health and Family Planning Commission of the People’s

Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Terms and definitions ... 4

3 Technical requirements ... 4

Appendix A Test methods ... 6

National food safety standard – Food additives – Caramel

color

1 Scope

This Standard applies to the food additive caramel color made from sucrose, starch

syrup, xylose mother liquor, etc. using plain caramel, caustic sulfite caramel, ammonia

caramel or sulfite ammonia caramel.

2 Terms and definitions

2.1 plain caramel color

It is made using carbohydrates as the main raw material, with or without the addition

of acid (base), and without the use of ammonia compounds and sulfites.

2.2 caustic sulfite caramel color

It is made using carbohydrates as the main raw material, in the presence of sulfite, with

or without the addition of acid (base), and without the use of ammonia compounds.

2.3 ammonia caramel color

It is made using carbohydrates as the main raw material, in the presence of ammonia

compounds, with or without the addition of acid (base), and without the use of sulfites.

2.4 sulfite ammonia caramel color

It is made using carbohydrates as the main raw material, in the presence of ammonia

compounds and sulfites, with or without the addition of acid (base).

3 Technical requirements

3.1 Sensory requirements

Sensory requirements shall be in accordance with Table 1.

Appendix A

Test methods

A.1 General

Unless otherwise specified in this Standard, the purity of the reagents used shall be

analytically pure. The standard titration solutions, standard solutions for impurity

determination, preparations and products used shall be prepared in accordance with the

provisions of GB/T 601, GB/T 602 and GB/T 603. The test water shall comply with the

provisions of Grade 3 water in GB/T 6682. The solutions used in the test shall refer to

aqueous solutions unless the solvent used is specified.

A.2 Determination of absorbance E0.1% 1 cm (610 nm)

A.2.1 Instruments and apparatuses

Spectrophotometer.

A.2.2 Analysis steps

Weigh about 0.5 g of the sample, accurate to 0.002 g; dissolve it in water; transfer it to

a 500 mL volumetric flask; add water to dilute it to the mark; shake it well. If the

solution is turbid, centrifuge it to obtain the sample solution. Place this sample solution

in a 1 cm colorimetric dish; use water as a blank control; use a spectrophotometer to

measure its absorbance at 610 nm (it is recommended to control the absorbance at 0.2

~ 0.8, otherwise, adjust the sample solution concentration and measure the absorbance

again).

A.2.3 Result calculation

Calculate the absorbance E0.1% 1 cm (610 nm) according to Formula (A.1):

Where:

A – absorbance of the sample being measured;

c – concentration of the sample solution being measured, in grams per milliliter (g/mL);

1 000 – concentration conversion coefficient.

The test result is based on the arithmetic mean of the parallel determination results. The

ratio of the absolute difference between two independent determination results obtained

under repeatability conditions and the arithmetic mean shall not exceed 5%.

A – built-in adapter;

B – separating funnel;

C – round bottom flask;

D – gas internal pipe;

E – condenser;

F – connecting ball (see Figure A.2 for the structure of component F);

G – receiver.

Figure A.1 – Diagram of sulfur dioxide determination device

The device in Figure A.1 is used to selectively transfer sulfur dioxide from the sample

to the 3% hydrogen peroxide solution in a boiling hydrochloric acid aqueous solution.

This device is easier to connect than a conventional device. Since the height of the 3%

hydrogen peroxide solution is above the ball tip, the back pressure in the device is

difficult to avoid, and component F can reduce the back pressure to the lowest possible

level, thereby reducing the possibility of sulfur dioxide loss due to leakage.

Component D in Figure A.1 needs to be equipped with a hose connection. If

polyethylene and quartz tubes are used, they shall be pre-boiled before use in this

procedure.

Connect the entire device according to the requirements of Figure A.1. Except for the

connection between the separating funnel and the flask, the sealing surfaces of all other

connectors shall be coated with a thin layer of piston lubricant. All connectors shall be

clamped tightly to ensure sealing during analysis. The volume of the separating funnel

B shall be greater than or equal to 100 mL. It must be equipped with a built-in adapter

A with a hose connector to ensure that a certain pressure is maintained above the internal

solution. (It is not recommended to use a constant pressure titration funnel because the

condensed water may contain sulfur dioxide and adhere to the inner wall of the funnel

or the wall of the tube). The round bottom flask C, with a volume of 1 000 mL, is

provided with 3 24/40 mm conical interfaces. The gas internal pipe D shall be of

sufficient length to ensure that the introduced nitrogen can reach 2.5 cm from the bottom

of the flask. The jacket length of the condenser E shall be 300 mm. The connecting ball

F is a custom-made glass part according to the requirements of Figure A.2, with the

same size as the 50 mL measuring barrel. The 3% hydrogen peroxide solution is placed

in a receiver G, which has an inner diameter of 2.5 cm and a length of 18 cm.

connection is completed, the nitrogen flow through the 3% hydrogen peroxide solution

shall be restored immediately, and the connection shall be checked to ensure it is sealed.

The rubber ball above the separating funnel is equipped with a valve to ensure that there

is sufficient pressure above the hydrochloric acid solution. Open the separating funnel

valve to allow the hydrochloric acid solution to flow into the flask. Continue to ensure

that there is sufficient pressure above the solution. If necessary, the valve can be

temporarily closed to replenish the pressure. To prevent sulfur dioxide from escaping

into the separating funnel, the valve shall be closed before the last few milliliters flow

out of the separating funnel.

Connect the power supply for heating, and control the heating rate so that the reflux

liquid is 80 ~ 90 drops per minute. After distillation for 105 minutes, cool the contents

in the 1 000 mL flask at the above reflux rate. Transfer the contents in receiver G.

A.4.4.4 Titration

Add 3 drops of methyl red indicator solution and use standard titration solution to titrate

the above solution to the yellow end point; ensure that it does not fade within 20 seconds.

A.4.5 Result calculation

Calculate the mass fraction w2 of sulfur dioxide (as SO2) according to Formula (A.3):

Where:

M – molar mass of sulfur dioxide, in grams per mole (g/mol), [M (SO2) = 64.06];

V – volume of the sodium hydroxide standard titration solution consumed in the

titration, in milliliters (mL);

c – concentration of the sodium hydroxide standard titration solution, in moles per liter

(mol/L);

0.1 – conversion coefficient;

2 – conversion coefficient;

m – mass of the sample added to the 1 000 mL flask, in grams (g);

1 000 – conversion coefficient;

A610 – absorbance of the sample at 610 nm.

A.5....

Share