1

/

of

12

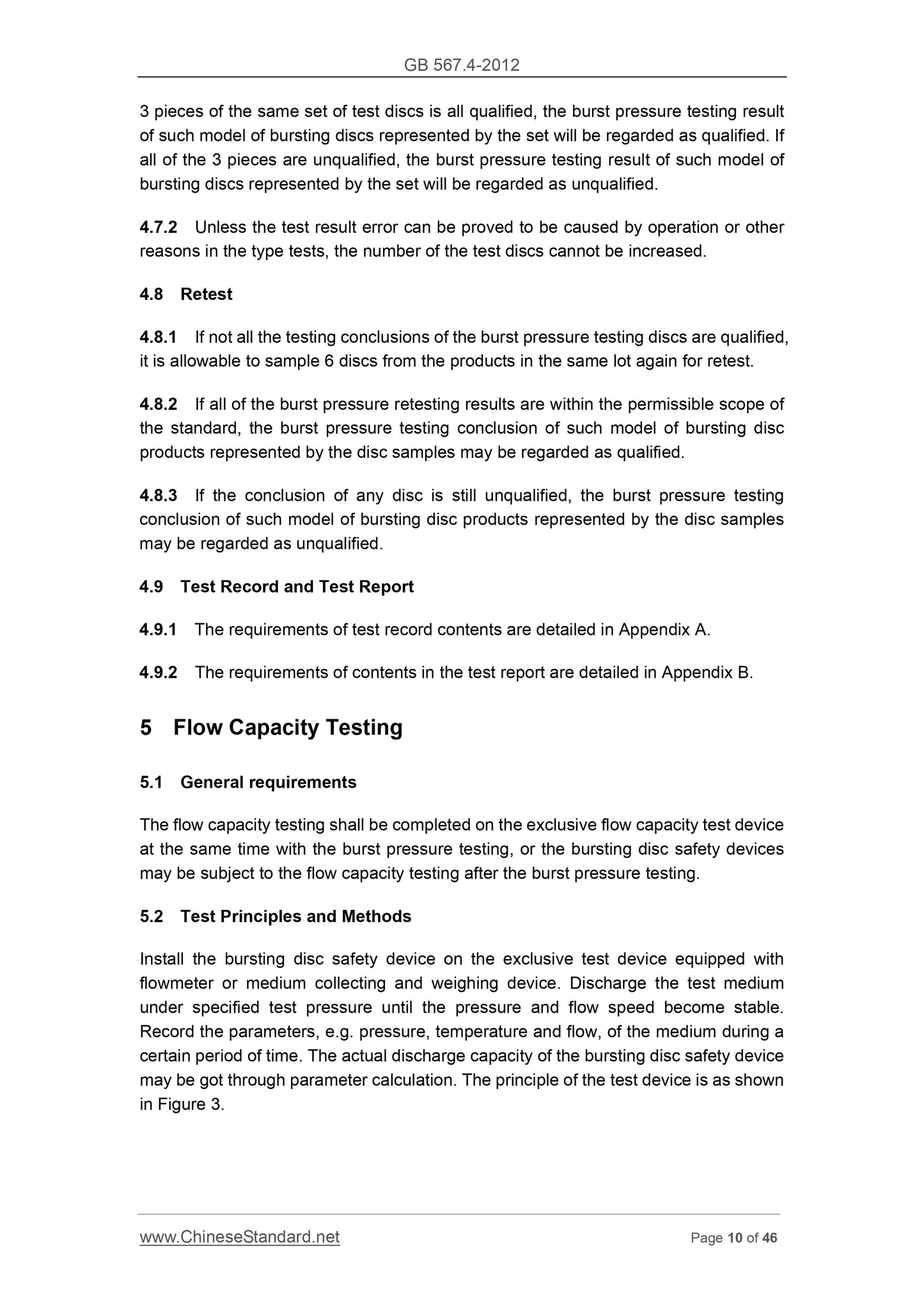

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 567.4-2012 English PDF

GB 567.4-2012 English PDF

Regular price

$145.00 USD

Regular price

Sale price

$145.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 567.4-2012

Historical versions: GB 567.4-2012

Preview True-PDF (Reload/Scroll if blank)

GB 567.4-2012: [GB/T 567.4-2012] Bursting disc safety devices -- Part 4: Type test

GB 567.4-2012

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 13.240

J 74

Bursting Disc Safety Devices -

Part 4. Type Test

ISSUED ON. MAY 11, 2012

IMPLEMENTED ON. MARCH 1, 2013

Jointly Issued by. General Administration of Quality Supervision,

Inspection and Quarantine;

Standardization Administration of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 5

4 Burst Pressure Testing ... 6

5 Flow Capacity Testing ... 10

6 Fatigue Testing ... 18

7 Flow Resistance Testing ... 21

8 Uncertainty Of Measurement ... 31

Appendix A (Informative) Table of Test Records and Test Results ... 33

Foreword

Appendixes A and B of this Part are recommendatory; the rest are mandatory.

"Bursting Disc Safety Devices" (GB 567) is divided into 4 parts.

— Part 1. Basic requirement;

— Part 2. Application, selection and installation;

— Part 3. Classification and mounting dimensions;

— Part 4. Type test.

This Part is Part 4 of GB 567.

This Part was drafted according to the rules specified in GB/T 1.1-2009.

This Part was proposed by and shall be under the jurisdiction of the National

Technical Committee on Boilers and Pressure Vessels of Standardization

Administration of China (SAC/TC 262).

Chief drafting organizations of this Part. Shenyang Institute of Special Equipment

Inspection and Research, Shanghai Gas Industry Association, China Special Equipment

Inspection and Research Institute, Shanghai Huayi Engineering Co., Ltd., Bureau of

Safety Supervision of Special Equipment (SESA) of AQSIQ, Shenyang Aerospace

Xinguang Security Systems, Inc., Dalian Ligong Safety Equipment Co., Ltd., Chengdu

Chenghang Industrial Safety System Co., Ltd., Shanghai Huali Safety Device Co.,

Ltd., and Shanghai Institute of Special Equipment Inspection and Technical Research

Chief drafting staffs of this Part. Zhang Zhiyi, Xu Ziping, Song Xuxian, Zhou Weiming,

Shou Binan, Gao Jixuan, Chen Chaohui, Liu Duo, Han Fengjuan, Li Yue, Xiang

Dongliang, Yang Xiuxia, Wang Zhenggang, Xu Weipu, and Wei Yongbiao.

Bursting Disc Safety Devices -

Part 4. Type Test

1 Scope

1.1 This Part of GB 567 specifies technical requirements for test principles and

methods, test devices and instruments, test conditions and test preparation, test rules,

test procedures, data processing and measurement uncertainty calculation, etc. for

burst pressure testing, flow capacity testing, fatigue testing and flow resistance testing

in terms of type tests of bursting disc safety devices.

1.2 This Part is applicable to the following bursting disc safety devices.

— This Part is applicable to the bursting disc safety devices used for pressure

vessels, pressure pipes or other sealing pressure equipment (hereinafter

referred to as pressure equipment) to prevent overpressure or excess vacuum;

— As for the bursting discs in the bursting disc safety devices applicable in this

Part, the bursting pressure shall not be greater than 500MPa and not less than

0.001MPa.

1.3 This Part is not applicable to the following bursting disc safety devices.

— Pressure equipment, possible to increase pressure abruptly in the operation,

reaching reaction rate at detonation degree.

— Bursting disc safety devices under the special requirements in the defense

military equipment.

Note. Phenomenon that is generated very differently from the common burning and explosion

when the burning rate of the material is quickly, above 1 000m/s, is known as detonation.

2 Normative References

The following documents are indispensable for the application of this standard. For

dated references, only the dated edition is applicable to this document. For undated

references, the latest editions of the normative documents (including all the

amendments) are applicable to this document.

GB 567.1 Bursting disc safety devices - Part 1 Basic requirements

GB 567.2 Bursting disc safety devices P art 2. Application, selection and

installation

GB 567.3 Bursting disc safety devices - Part 3. Classification and installation

dimension

GB/T 2624 Measurement of fluid flow by means of orifice plates, nozzles and

Venturi tubes inserted in circular cross-section conduits running full

GB/T 21188 Measurement of gas flow by means of critical flow Venturi nozzles

3 Terms and Definitions

For the purposes of this Part, the following terms and definitions as well as those

established in GB 567.1, GB 567.2 and GB 567.3 shall apply.

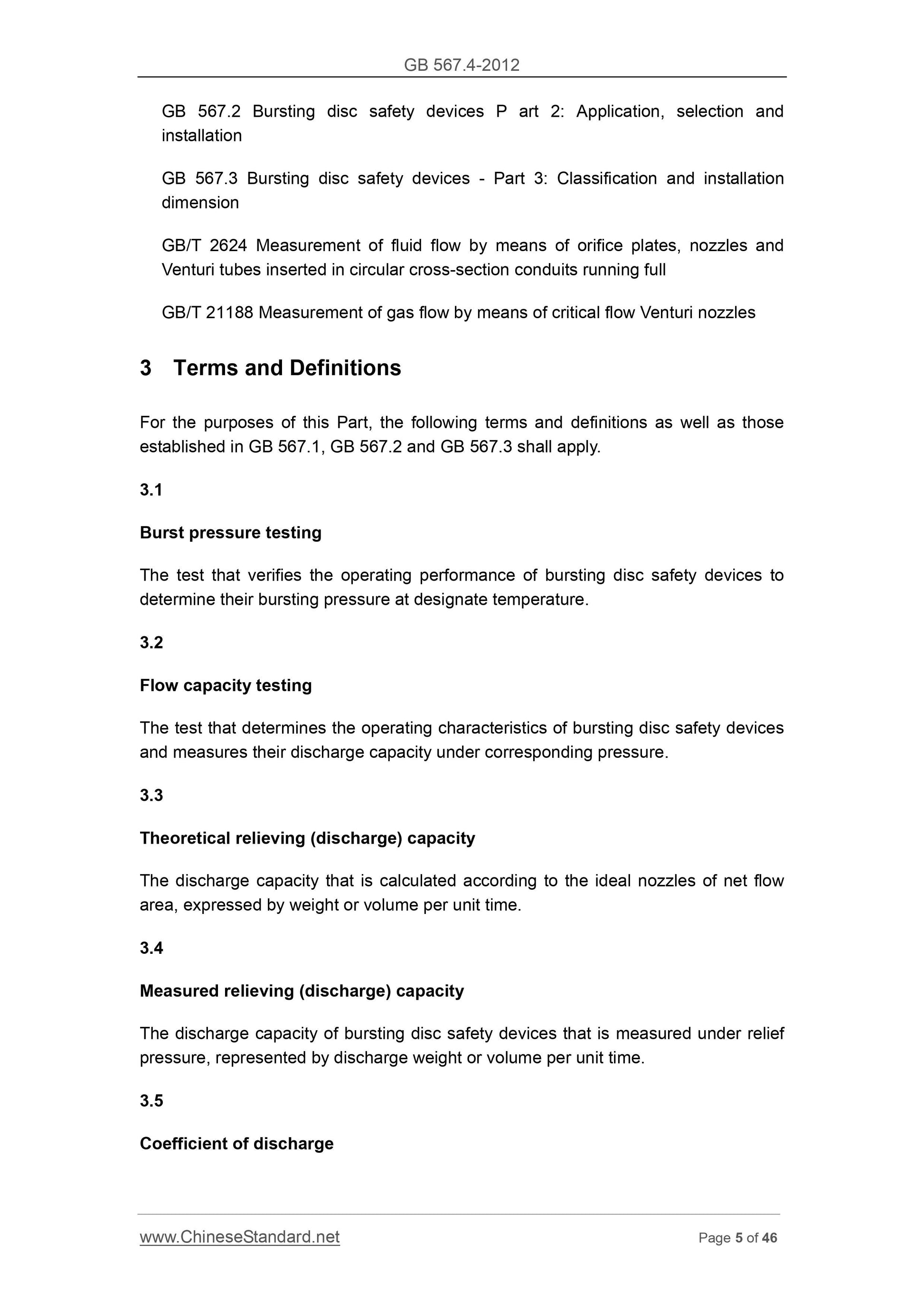

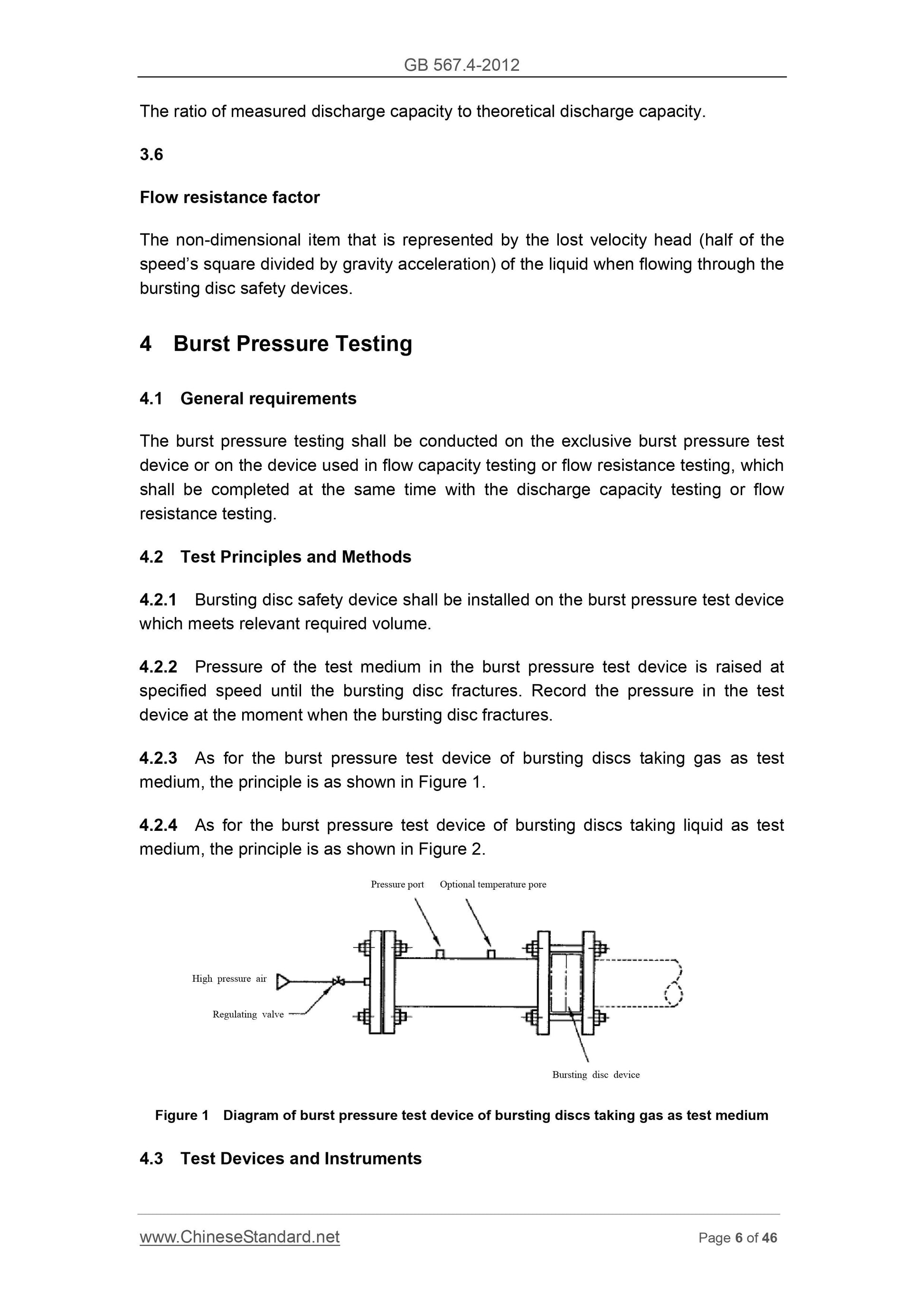

3.1

Burst pressure testing

The test that verifies the operating performance of bursting disc safety devices to

determine their bursting pressure at designate temperature.

3.2

Flow capacity testing

The test that determines the operating characteristics of bursting disc safety devices

and measures their discharge capacity under corresponding pressure.

3.3

Theoretical relieving (discharge) capacity

The discharge capacity that is calculated according to the ideal nozzles of net flow

area, expressed by weight or volume per unit time.

3.4

Measured relieving (discharge) capacity

The discharge capacity of bursting disc safety devices that is measured under relief

pressure, represented by discharge weight or volume per unit time.

3.5

Coefficient of discharge

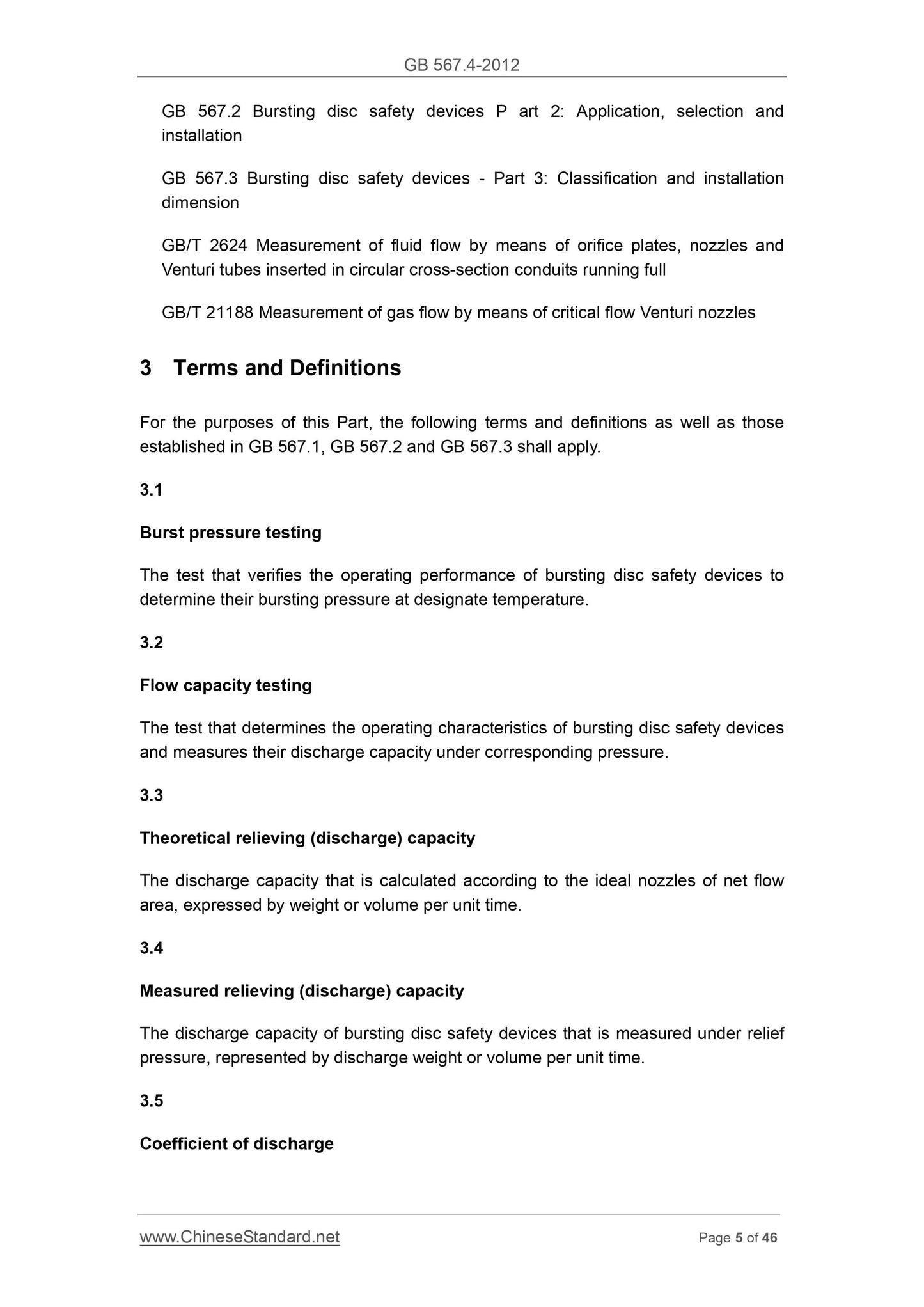

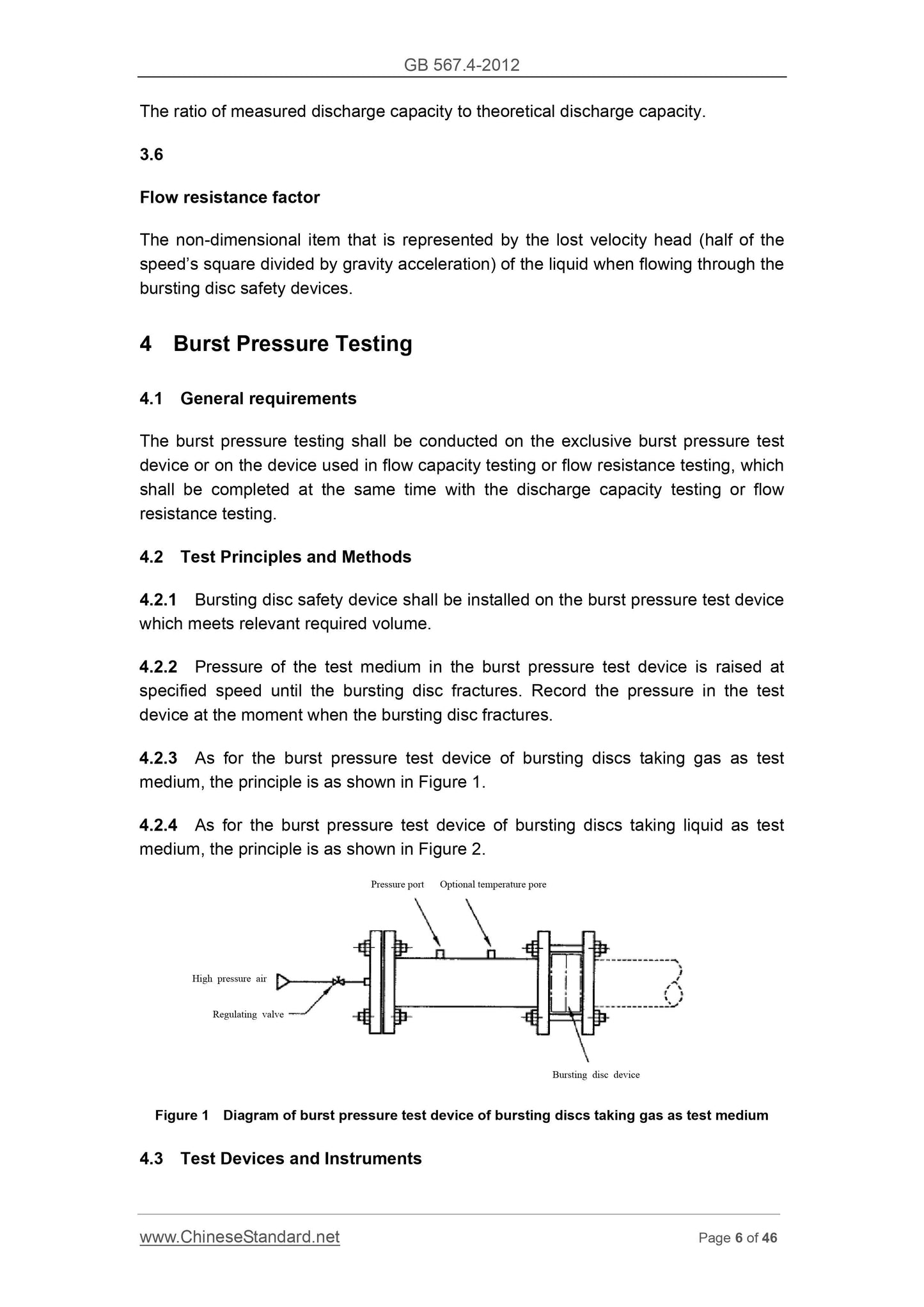

4.3.2 Temperature measurement

Thermocouple, thermal resistance or other devices that are able to accurately

measure the bursting disc temperature shall be adopted to measure the test

temperature of the bursting disc. The resolution of the temperature measuring

instruments shall not be below 0.5°C. All the leading wires and transmitters or

instruments shall be covered when calibrated.

4.3.3 Pressure measurement

The pressure measurement point shall be as close as possible to the tested bursting

disc. Pressure gauge or pressure transmitter whose accuracy grade is not below 0.4

and measuring range is 1.5~3 times of the test pressure value shall be adopted.

4.4 Test conditions and test preparation

4.4.1 Test medium

In general, the test medium shall be compressed air, water or hydraulic oil. However,

the test medium under high pressure or high temperature shall be nitrogen, hydraulic

oil or heat-transfer oil.

4.4.2 Test preparation

Test preparation shall meet the following requirements.

a) Check and make sure the burst pressure test device is in normal condition.

The accuracy and measuring range of the measuring instruments and sensors

are in coinciding with the parameters of the test disc;

b) Conduct preliminary test to ensure that the burst pressure test device be able

to reach the test requirements and make the operation personnel get fully

aware of the concrete test details;

c) All the process of the actual test shall be covered in the preliminary test and

the necessary data shall be recorded and the instruments and sensors shall

be calibrated.

4.5 Test rules

4.5.1 Sampling

Sampling of bursting discs for test shall be selected at random from the same lot in

the lot production; the number of samples shall be 4.

4.5.2 Test number

Randomly select 3 pieces from the sampled bursting disc devices for burst pressure

testing.

4.5.3 Test temperature

4.5.3.1 Where the test temperature of bursting discs is normal, the test temperature

shall be controlled within (15-30) °C.

4.5.3.2 Where the test temperature of the bursting disc is a little higher or lower, the

permissible...

Get QUOTATION in 1-minute: Click GB 567.4-2012

Historical versions: GB 567.4-2012

Preview True-PDF (Reload/Scroll if blank)

GB 567.4-2012: [GB/T 567.4-2012] Bursting disc safety devices -- Part 4: Type test

GB 567.4-2012

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 13.240

J 74

Bursting Disc Safety Devices -

Part 4. Type Test

ISSUED ON. MAY 11, 2012

IMPLEMENTED ON. MARCH 1, 2013

Jointly Issued by. General Administration of Quality Supervision,

Inspection and Quarantine;

Standardization Administration of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 5

4 Burst Pressure Testing ... 6

5 Flow Capacity Testing ... 10

6 Fatigue Testing ... 18

7 Flow Resistance Testing ... 21

8 Uncertainty Of Measurement ... 31

Appendix A (Informative) Table of Test Records and Test Results ... 33

Foreword

Appendixes A and B of this Part are recommendatory; the rest are mandatory.

"Bursting Disc Safety Devices" (GB 567) is divided into 4 parts.

— Part 1. Basic requirement;

— Part 2. Application, selection and installation;

— Part 3. Classification and mounting dimensions;

— Part 4. Type test.

This Part is Part 4 of GB 567.

This Part was drafted according to the rules specified in GB/T 1.1-2009.

This Part was proposed by and shall be under the jurisdiction of the National

Technical Committee on Boilers and Pressure Vessels of Standardization

Administration of China (SAC/TC 262).

Chief drafting organizations of this Part. Shenyang Institute of Special Equipment

Inspection and Research, Shanghai Gas Industry Association, China Special Equipment

Inspection and Research Institute, Shanghai Huayi Engineering Co., Ltd., Bureau of

Safety Supervision of Special Equipment (SESA) of AQSIQ, Shenyang Aerospace

Xinguang Security Systems, Inc., Dalian Ligong Safety Equipment Co., Ltd., Chengdu

Chenghang Industrial Safety System Co., Ltd., Shanghai Huali Safety Device Co.,

Ltd., and Shanghai Institute of Special Equipment Inspection and Technical Research

Chief drafting staffs of this Part. Zhang Zhiyi, Xu Ziping, Song Xuxian, Zhou Weiming,

Shou Binan, Gao Jixuan, Chen Chaohui, Liu Duo, Han Fengjuan, Li Yue, Xiang

Dongliang, Yang Xiuxia, Wang Zhenggang, Xu Weipu, and Wei Yongbiao.

Bursting Disc Safety Devices -

Part 4. Type Test

1 Scope

1.1 This Part of GB 567 specifies technical requirements for test principles and

methods, test devices and instruments, test conditions and test preparation, test rules,

test procedures, data processing and measurement uncertainty calculation, etc. for

burst pressure testing, flow capacity testing, fatigue testing and flow resistance testing

in terms of type tests of bursting disc safety devices.

1.2 This Part is applicable to the following bursting disc safety devices.

— This Part is applicable to the bursting disc safety devices used for pressure

vessels, pressure pipes or other sealing pressure equipment (hereinafter

referred to as pressure equipment) to prevent overpressure or excess vacuum;

— As for the bursting discs in the bursting disc safety devices applicable in this

Part, the bursting pressure shall not be greater than 500MPa and not less than

0.001MPa.

1.3 This Part is not applicable to the following bursting disc safety devices.

— Pressure equipment, possible to increase pressure abruptly in the operation,

reaching reaction rate at detonation degree.

— Bursting disc safety devices under the special requirements in the defense

military equipment.

Note. Phenomenon that is generated very differently from the common burning and explosion

when the burning rate of the material is quickly, above 1 000m/s, is known as detonation.

2 Normative References

The following documents are indispensable for the application of this standard. For

dated references, only the dated edition is applicable to this document. For undated

references, the latest editions of the normative documents (including all the

amendments) are applicable to this document.

GB 567.1 Bursting disc safety devices - Part 1 Basic requirements

GB 567.2 Bursting disc safety devices P art 2. Application, selection and

installation

GB 567.3 Bursting disc safety devices - Part 3. Classification and installation

dimension

GB/T 2624 Measurement of fluid flow by means of orifice plates, nozzles and

Venturi tubes inserted in circular cross-section conduits running full

GB/T 21188 Measurement of gas flow by means of critical flow Venturi nozzles

3 Terms and Definitions

For the purposes of this Part, the following terms and definitions as well as those

established in GB 567.1, GB 567.2 and GB 567.3 shall apply.

3.1

Burst pressure testing

The test that verifies the operating performance of bursting disc safety devices to

determine their bursting pressure at designate temperature.

3.2

Flow capacity testing

The test that determines the operating characteristics of bursting disc safety devices

and measures their discharge capacity under corresponding pressure.

3.3

Theoretical relieving (discharge) capacity

The discharge capacity that is calculated according to the ideal nozzles of net flow

area, expressed by weight or volume per unit time.

3.4

Measured relieving (discharge) capacity

The discharge capacity of bursting disc safety devices that is measured under relief

pressure, represented by discharge weight or volume per unit time.

3.5

Coefficient of discharge

4.3.2 Temperature measurement

Thermocouple, thermal resistance or other devices that are able to accurately

measure the bursting disc temperature shall be adopted to measure the test

temperature of the bursting disc. The resolution of the temperature measuring

instruments shall not be below 0.5°C. All the leading wires and transmitters or

instruments shall be covered when calibrated.

4.3.3 Pressure measurement

The pressure measurement point shall be as close as possible to the tested bursting

disc. Pressure gauge or pressure transmitter whose accuracy grade is not below 0.4

and measuring range is 1.5~3 times of the test pressure value shall be adopted.

4.4 Test conditions and test preparation

4.4.1 Test medium

In general, the test medium shall be compressed air, water or hydraulic oil. However,

the test medium under high pressure or high temperature shall be nitrogen, hydraulic

oil or heat-transfer oil.

4.4.2 Test preparation

Test preparation shall meet the following requirements.

a) Check and make sure the burst pressure test device is in normal condition.

The accuracy and measuring range of the measuring instruments and sensors

are in coinciding with the parameters of the test disc;

b) Conduct preliminary test to ensure that the burst pressure test device be able

to reach the test requirements and make the operation personnel get fully

aware of the concrete test details;

c) All the process of the actual test shall be covered in the preliminary test and

the necessary data shall be recorded and the instruments and sensors shall

be calibrated.

4.5 Test rules

4.5.1 Sampling

Sampling of bursting discs for test shall be selected at random from the same lot in

the lot production; the number of samples shall be 4.

4.5.2 Test number

Randomly select 3 pieces from the sampled bursting disc devices for burst pressure

testing.

4.5.3 Test temperature

4.5.3.1 Where the test temperature of bursting discs is normal, the test temperature

shall be controlled within (15-30) °C.

4.5.3.2 Where the test temperature of the bursting disc is a little higher or lower, the

permissible...

Share