1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 567.4-2012 English PDF (GB567.4-2012)

GB 567.4-2012 English PDF (GB567.4-2012)

Regular price

$145.00 USD

Regular price

Sale price

$145.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click GB 567.4-2012 (Self-service in 1-minute)

Historical versions (Master-website): GB 567.4-2012

Preview True-PDF (Reload/Scroll-down if blank)

GB 567.4-2012: [GB/T 567.4-2012] Bursting disc safety devices -- Part 4: Type test

GB 567.4-2012

Bursting disc safety devices - Part 4. Type test

ICS 13.240

J74

National Standards of People's Republic of China

Bursting disc safety device

Part 4. Test Type

Published 2012-05-11

2013-03-01 implementation

Administration of Quality Supervision, Inspection and Quarantine of People's Republic of China

Standardization Administration of China issued

Table of Contents

Preface Ⅰ

1 Scope 1

2 Normative References 1

Terms and definitions 1 3

4 Blast Test 2

5 Discharge of test 5

10 6 fatigue test

7 flow resistance Test 11

Measurement uncertainty 8 17

Appendix A (informative) test records and test results Table 19

Annex B (informative) Test Report 27

Foreword

Appendix A and Appendix B of this section are recommended, others are mandatory.

GB 567 "bursting disc safety device" is divided into four parts.

--- Part 1. General requirements;

--- Part 2. Applications, selection and installation;

--- Part 3. Classification and dimensions;

--- section 4. Type tests.

This is Part of 4 GB 567.

This section drafted in accordance with the rules GB/T 1.1-2009 given.

This part of the proposed and managed by the National Boiler and Pressure Vessel Standardization Technical Committee (SAC/TC262).

This part was drafted. Shenyang Special Equipment Inspection and Research Institute, Shanghai Gas Industry Association, China Special Equipment Inspection and Research Institute,

Shanghai Huayi Group Engineering Equipment Co., AQSIQ Special Equipment Safety Supervision Bureau, Shenyang Aerospace Xinguang Security Systems Limited

Division of Safety Equipment Co., Dalian, Chengdu AVIC Safety Systems Co., Ltd., Shanghai Hua Li Safety Equipment Co., Ltd.,

Gimhae Institute of Special Equipment Inspection and Technical.

This part of the main drafters. Zhang Zhiyi, Xu Zaiping, fresh Xu Song, Zhou Weiming, life than the south, following the high Xuan, Chen Zhaohui, Liu Duo, Han Fengjuan, Li Yue,

To Dong Liang, Yang Xiuxia, Wang Zhenggang, Xu VIP, Wei Yongbiao.

Bursting disc safety device

Part 4. Test Type

1 Scope

1.1 GB 567 This section specifies the test burst bursting disc safety type test apparatus of Leakage tests, fatigue tests, and the flow resistance test

Test principle and method, instrumentation and test equipment, test conditions and test preparation, test rules, test procedure, test data and test process

The results of the measurement uncertainty of the technical requirements.

1.2 applies to the following section bursting disc safety devices.

--- This section applies to the pressure vessel, the pressure closed pressure pipe or other equipment (hereinafter referred to as pressure equipment) to prevent an overpressure or

Excessive bursting disc safety device is now used in a vacuum;

--- bursting disc safety devices in this section applies bursting disc burst pressure is less than 500MPa, not less than 0.001MPa.

1.3 does not apply to the following bursting disc safety devices.

--- Operation during pressure surge may be generated, when the reaction rate reaches the detonation pressure equipment.

Bursting disc safety devices --- Defense military equipment with special requirements.

NOTE. Detonation. fast burning velocity material, reach 1000m/s or more, and usually produces the blasting fundamentally different phenomena, a phenomenon known as detonation.

2 Normative references

The following documents for the application of this document is essential. For dated references, only applies to the version dated paper

Pieces. For undated references, the latest edition (including any amendments) applies to this document.

GB 567.1 bursting disc safety devices - Part 1. General requirements

GB 567.2 Part 2 bursting disc safety devices. applications, selection and installation of

GB 567.3 bursting disc safety devices - Part 3. Classification and dimensions

GB/T 2624 throttle flow measurement tube is filled with plates, nozzles and venturi fluid flow measuring

GB/T 21188 with a critical flow Venturi nozzle Measurement of gas flow

3 Terms and Definitions

GB 567.1 ~ GB 567.3 Definition The following terms and definitions apply to this document.

3.1

Burst test burstpressuretesting

Bursting disc safety devices to verify operability, the test to determine the bursting pressure at a given temperature.

3.2

Discharge of test flowcapacitytesting

Determining operating characteristics of the bursting disc safety device, the discharge capacity of the assay at its respective pressure.

3.3

Theoretical Discharge of theoreticalrelieving (discharge) capacity

Over the nozzle bursting disc safety device according to the net flow area of the bleed amount calculation, expressed in mass per unit time or volume.

3.4

Measured Discharge of measuredrelieving (discharge) capacity

Measured at a pressure bleed vent bursting disc safety device volume, expressed in mass or volume of the bleed unit time.

3.5

Discharge coefficient coefficientofdischarge

Discharge of the measured and theoretical discharge volume ratio.

3.6

Flow resistance coefficient flowresistancefactor

Dimensionless term fluid loss through the bursting disc safety device head velocity (velocity squared divided by the gravitational acceleration 1/2) representation.

4 burst test

4.1 General requirements

Burst test should be completed on a dedicated burst test apparatus, but also in the vent volume flow resistance test of the test or tests, and Leakage of

Or flow resistance test performed simultaneously.

4.2 Test principles and methods

4.2.1 bursting disc safety device should be mounted on a burst test apparatus, the test apparatus and the volume should meet the test requirements.

4.2.2 at a predetermined pressure inside the boosting speed burst test of the test medium, until a bursting disc rupture, rupture disc recording and

Bursting pressure test device in an instant.

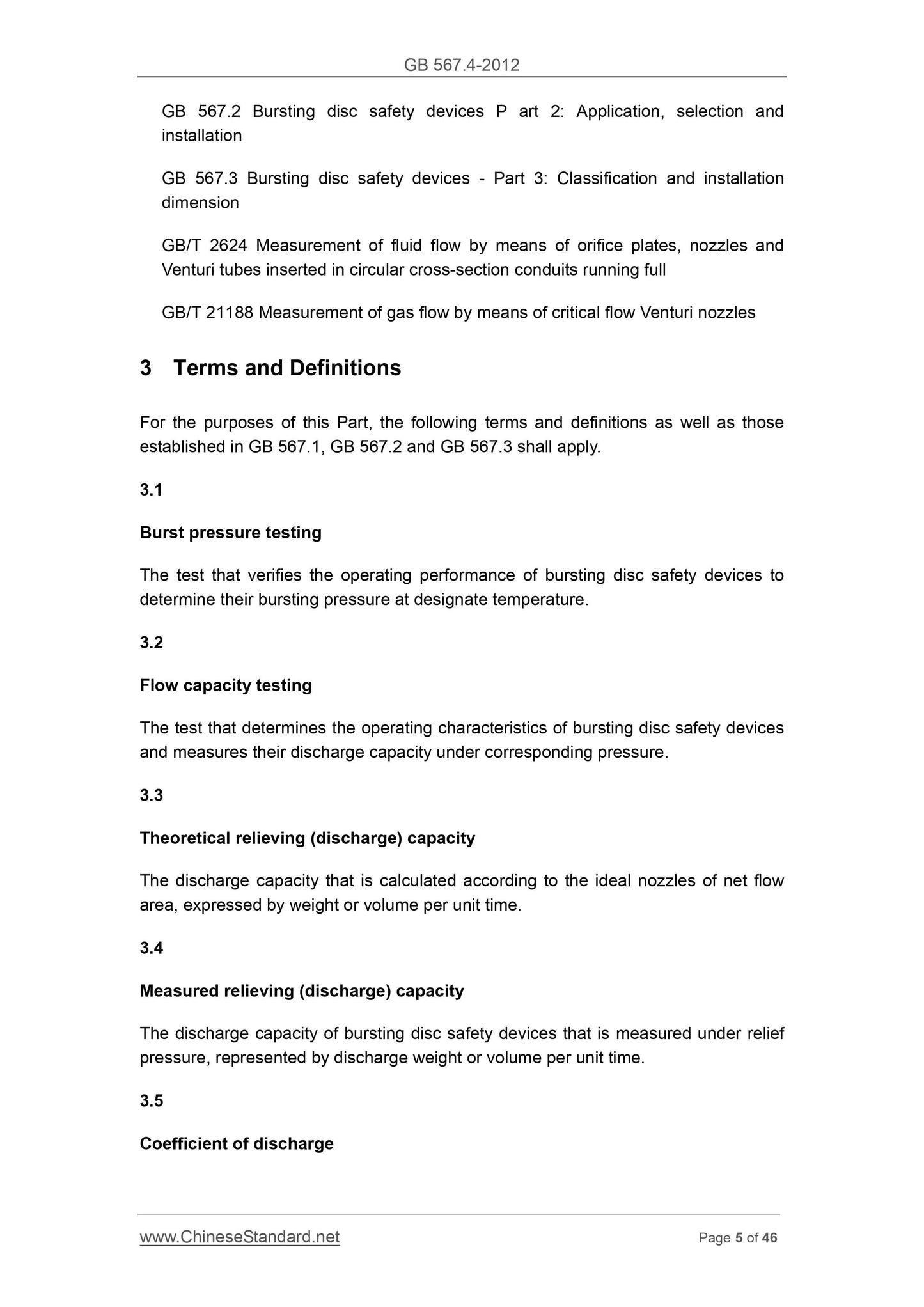

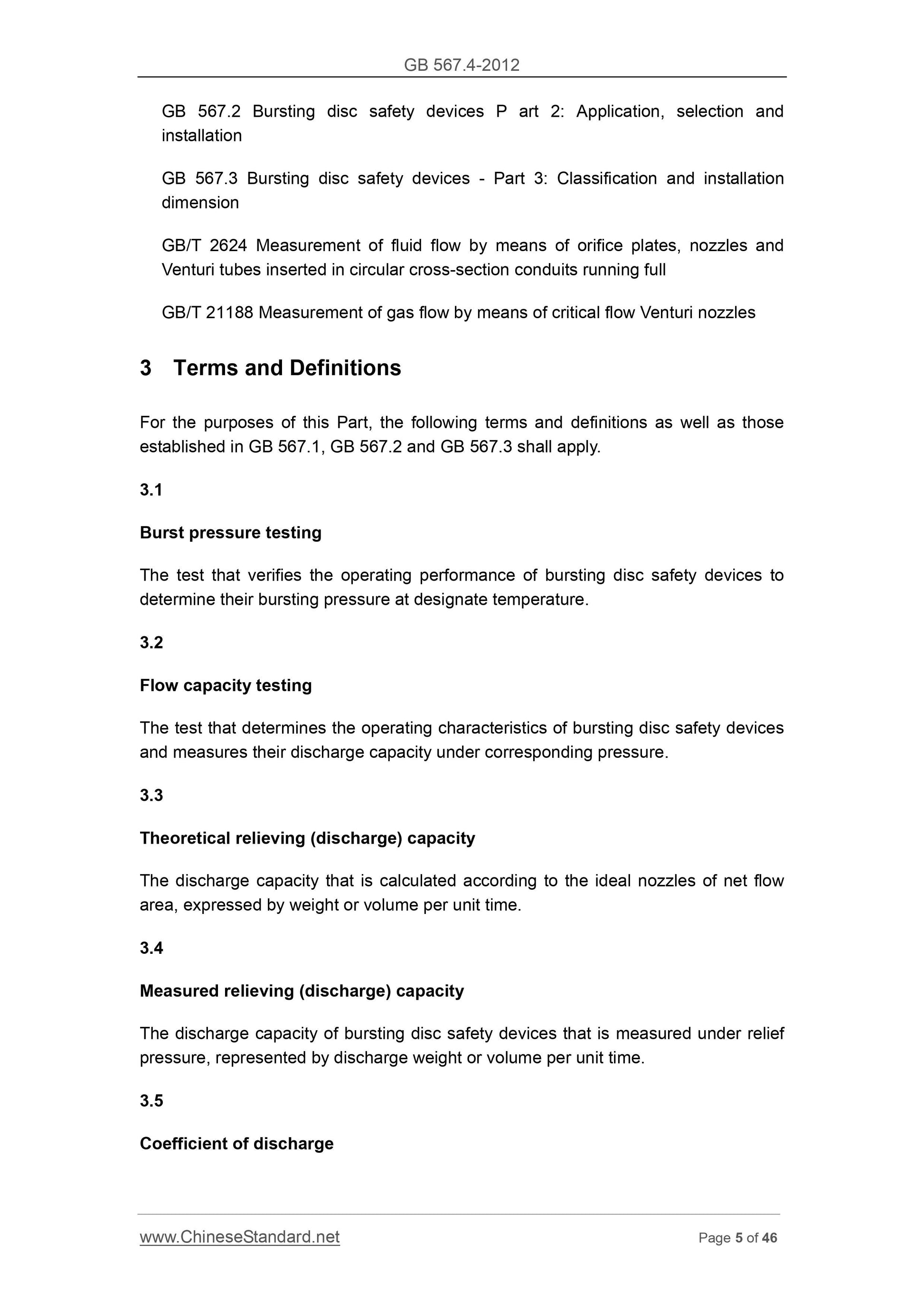

4.2.3 Test principle media burst test apparatus as shown in Figure 1 a gas bursting disc.

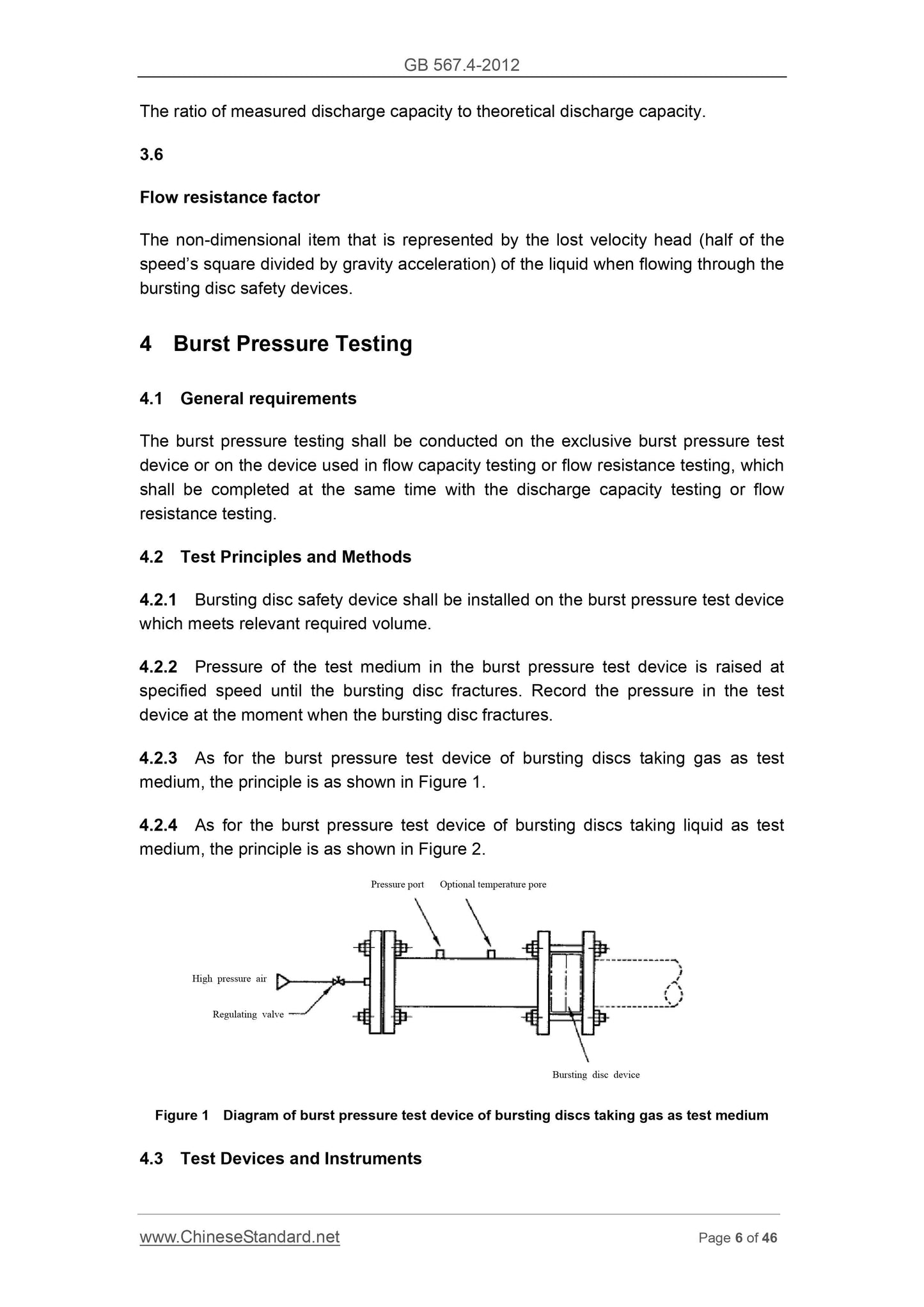

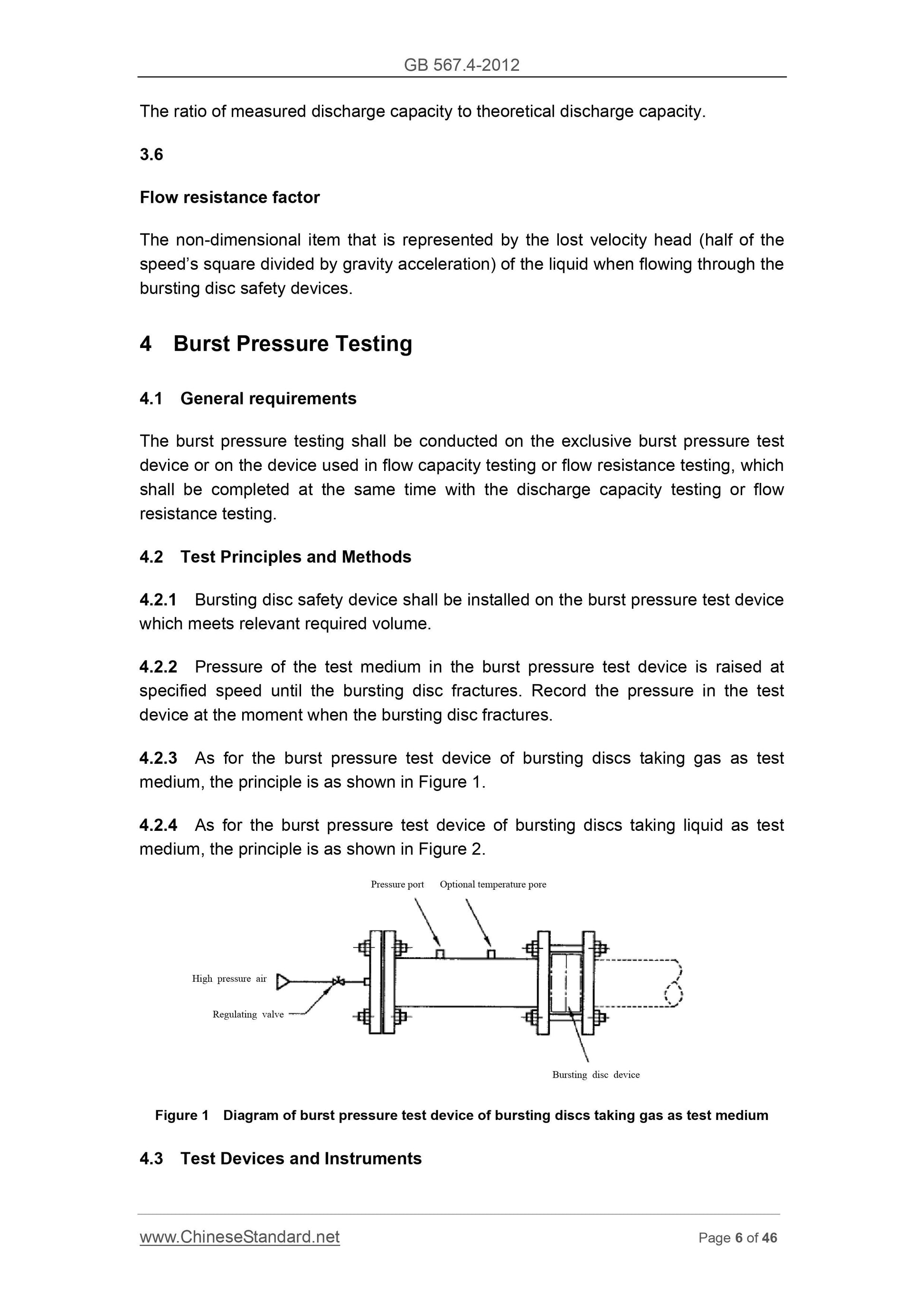

4.2.4 Test principle media burst test apparatus as shown in Figure 2 liquid bursting disc.

1 a schematic view of a gas testing apparatus of FIG bursting disc blasting medium

4.3 Test apparatus and instrumentation

4.3.1 Test device

Burst test apparatus should meet the following requirements.

a) male burst test apparatus, said test section of diameter not less than the bursting disc safety device is well known in diameter, and the volume should be large enough to ensure

Syndrome break open the rupture disc shape.

b) means connected to the burst test and bursting disc safety device should be strong, reliable, and should the clamper force uniform.

c) Test pressure burst test apparatus should be reliable control method capable of accurately measuring the static pressure test. Minimum speed boost

It should be stable to not greater than 0.001MPa/s.

d) the temperature should be adjusted burst test apparatus, and bursting disc should be a reliable method of measuring the surface temperature and corresponding instrumentation.

e) burst test device should be reliable and secure protection provided appropriate facilities.

FIG 2 a schematic view of the test apparatus using a liquid medium rupture disc bursting

4.3.2 Temperature Measurement

It should thermocouple, RTD, or other methods can accurately measure the temperature of the rupture disc bursting test sheet temperature measurement. temperature

Measuring instrument should have a resolution no less than 0.5 ℃. Shall include all leads and calibration transmitter or meter.

4.3.3 Pressure Measurement

Manometric pressure measurement test of the bursting disc as close as possible, and should be not less than 0.4 level of accuracy, the range of pressures tested

1.5 to 3 times the value of the pressure gauge or pressure transmitter.

4.4 Test conditions and test preparation

4.4.1 Test medium

The test medium should generally be compressed air, water or hydraulic oil, under high pressure of the test medium or high temperature conditions should be nitrogen gas, hydraulic oil

Or heat conducting oil.

4.4.2 Test preparation

Test preparation should meet the following requirements.

a) Check the burst test apparatus, the confirmation of the functioning. Measuring instruments, sensors and precision and scale parameters of the test piece matches;

b) preliminary test, the test apparatus can be achieved to ensure burst test requirements, and the operation with fully informed of this experiment

Body details;

c) a preliminary test should include complete the whole process of recording and practical tests necessary data, and instrumentation, and to calibrate the sensor.

4.5 Test Rules

4.5.1 Sampling

Test samples should be randomly selected by a bursting disc for mass production of the same batch of products, the number is four.

4.5.2 Number of test

Selected burst pressure test for three bursting disc apparatus from random sampling.

4.5.3 Test temperature

4.5.3.1 When the test temperature was normal bursting disc, the test temperature should be controlled (15-30) within the range ℃.

4.5.3.2 bursting disc test temperature is high or low temperature, the test temperature and the temperature of the calibration burst tolerance should be less than ± 5 ℃.

4.6 Test procedure

The test procedure is as follows.

a) the test piece according to the design requirements of the bursting disc preload means mounted on the test apparatus;

b) When the test piece after the need for explosion or leakage volume flow resistance tests, the bursting disc before importing volume should be large enough to allow blasting

The shape and degree of opening meet the requirements;

c) test pressure was slowly raised, and the observation of a pressure gauge indicating the consistency of the data display device with a pressure recording. When the pressure

90% to a minimum burst pressure of generally not more than the boosting speed control 3kPa/s or to facilitate accurate reading of pressure

Boosting lower speed value. For calibration bursting disc burst pressure is higher than 100MPa, the boosting speed can be controlled per second

Nominal burst pressure of not more than 0.1%;

d) Very temperature burst test, the temperature should rise (fall) to start boost near the blast temperature calibration, and controlling the rupture disc bursting when

Blasting temperature and calibration temperature tolerance of no greater than ± 5 ℃;

e) observe and record the burst pressure value, or use a computer, the recording apparatus automatically recording instrumentation burst pressure.

4.7 Data Processing

4.7.1 actual burst pressure rupture disc bursting pressure of its calibration error is within an allowable range of standard products, bonded burst test results

grid. For the same set of three test pieces and burst test were satisfactory burst test results of a particular model of this rupture disc is represented by the group qualified.

If the three are defective, the test results of a particular model burst rupture disc is represented by this group was rejected.

4.7.2 bursting disc type test results caused by other errors due to non-operation of the rupture disc reasons, can not increase the number of test pieces.

4.8 reinspection

4.8.1 Conclusion The test burst test piece not fully Eligible allow retest the same product was further extracted six.

4.8.2 burst test results retesting are within the scope permitted by the standard, the burst test piece representative of a particular model of rupture disc burst test product

Conclusions qualified.

4.8.3 If a conclusion is still unsatisfactory, on behalf of the test piece rupture disc bursting of a certain type of product for the conclusion burst test failed.

4.9 test records and test reports

Content 4.9.1 Test requirements for records in Appendix A.

4.9.2 Test report content requirements in Appendix B.

5 of Leakage test

5.1 General requirements

Discharge of the test should be performed simultaneously with the burst test on a dedicated Discharge of test apparatus may be completed after the burst test, again blasting

Safety sheet means Discharge Capacity Test.

5.2 Test principles and methods

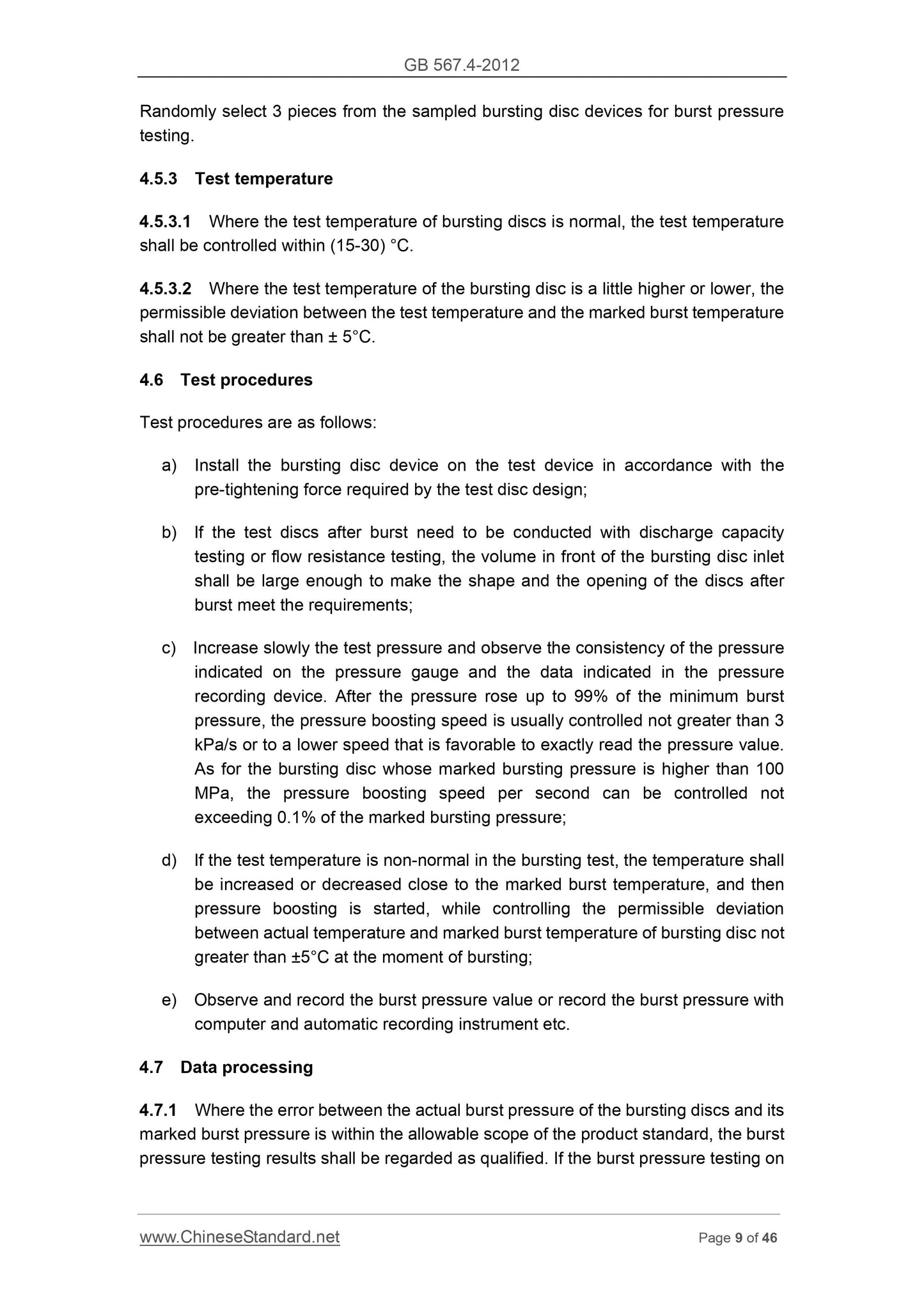

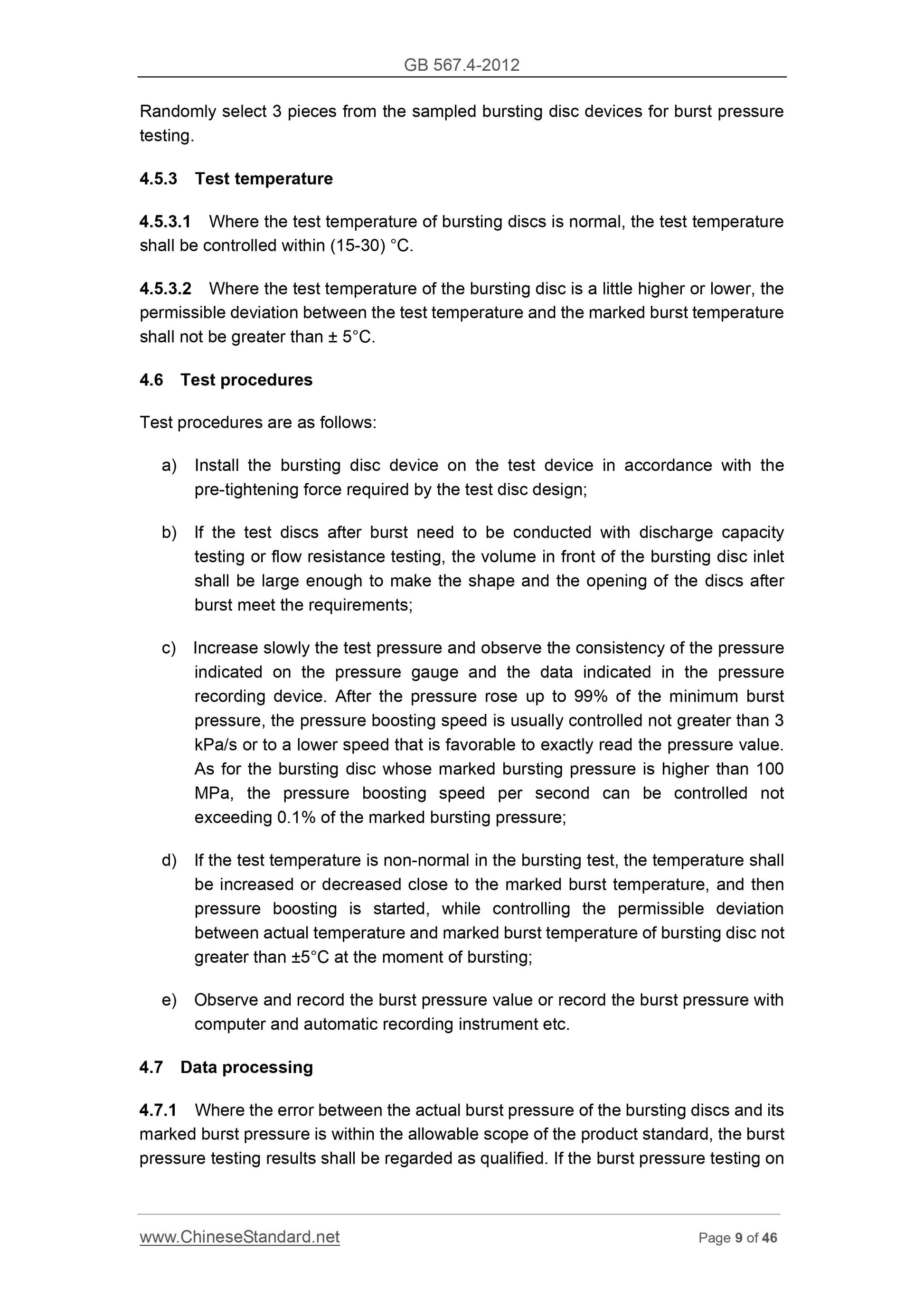

On dedicated testing device equipped with a flow meter or the test medium was collected and the weight of the apparatus, bursting disc safety devices installed to a predetermined

Emission test pressure medium to the pressure and flow rate stability, the pressure in the recording medium over time, temperature, flow and other parameters. With these parameters

Discharge of the calculation to obtain the actual bursting disc safety device. The principle of the test apparatus shown in Figure 3.

3 a schematic view of the test device of FIG vent volume

5.3 Test apparatus and instrumentation

5.3.1 Test device

Discharge of the test apparatus should meet the following requirements.

a) Discharge of the test apparatus should be sufficiently large volume, pressure can be maintained at a steady state bleed in order to accurately measure the assay medium

Bleed mass flow rate;

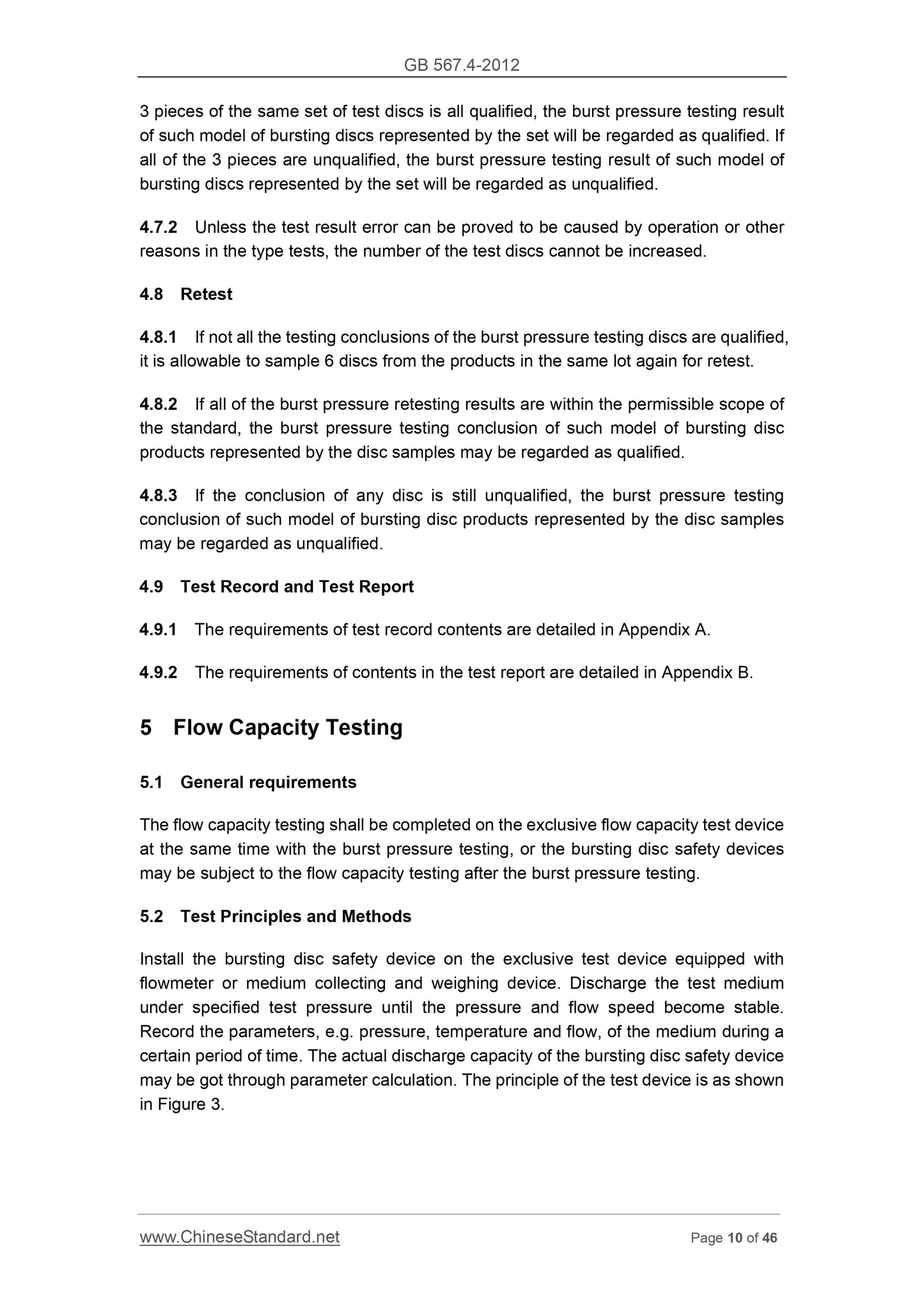

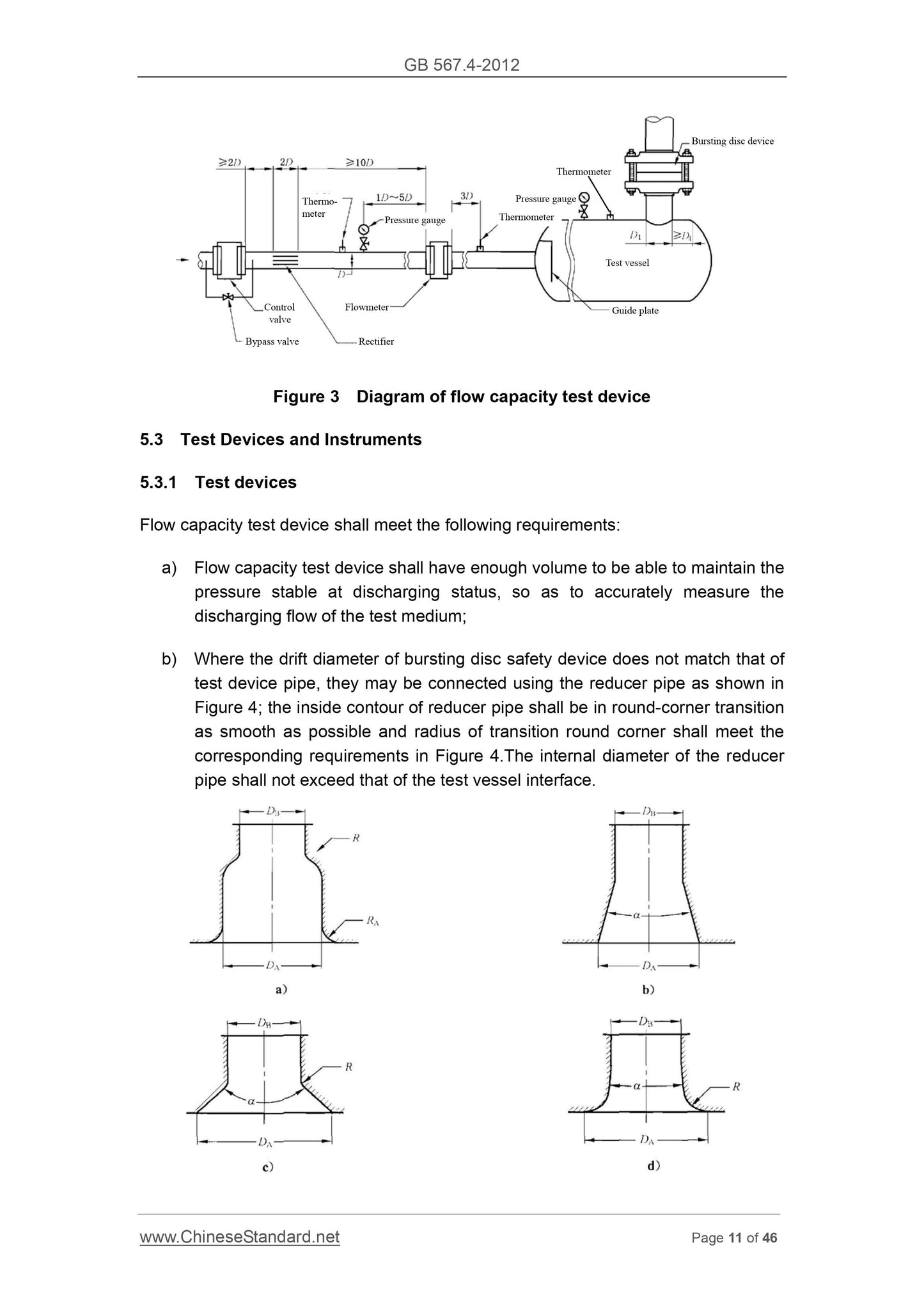

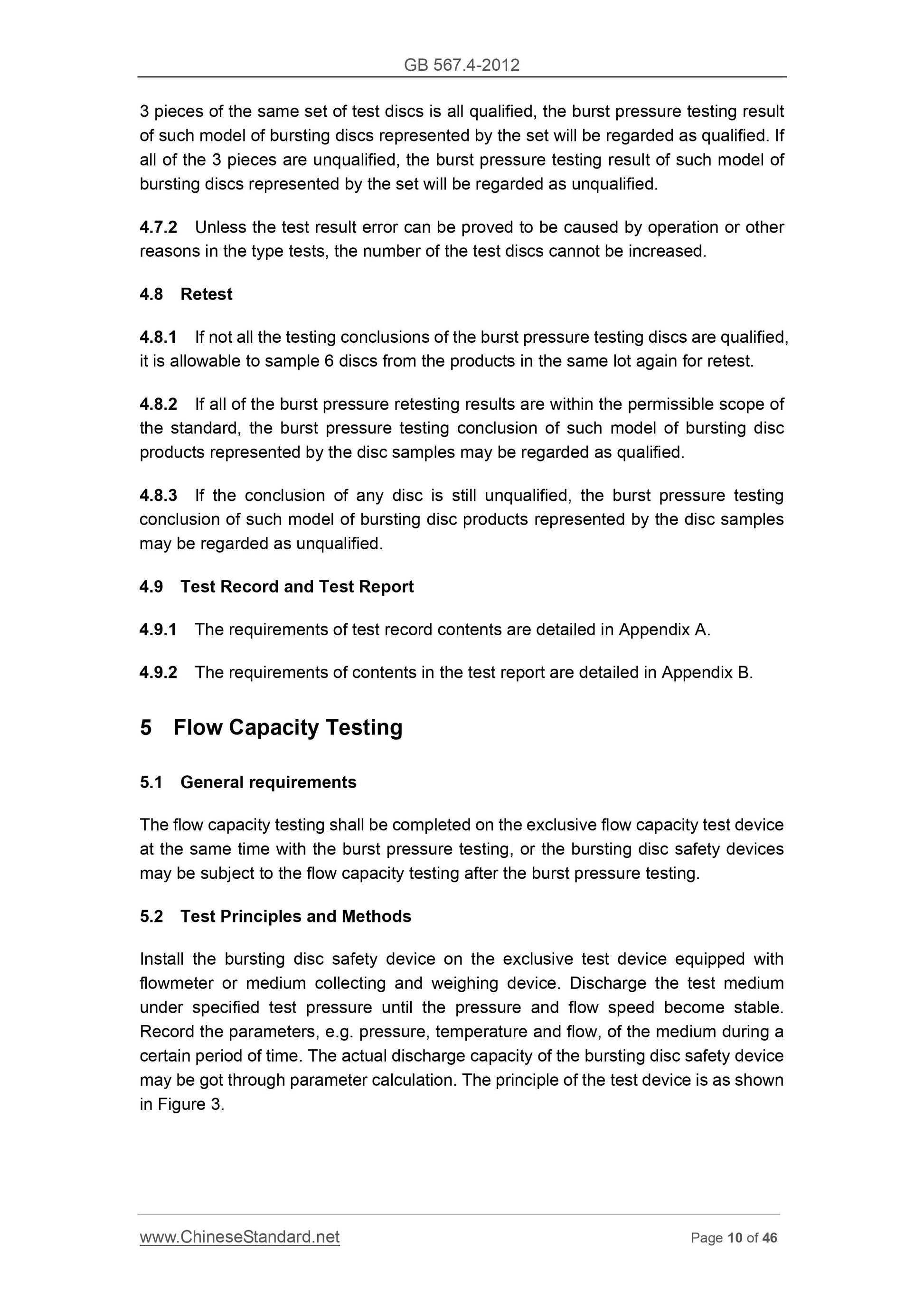

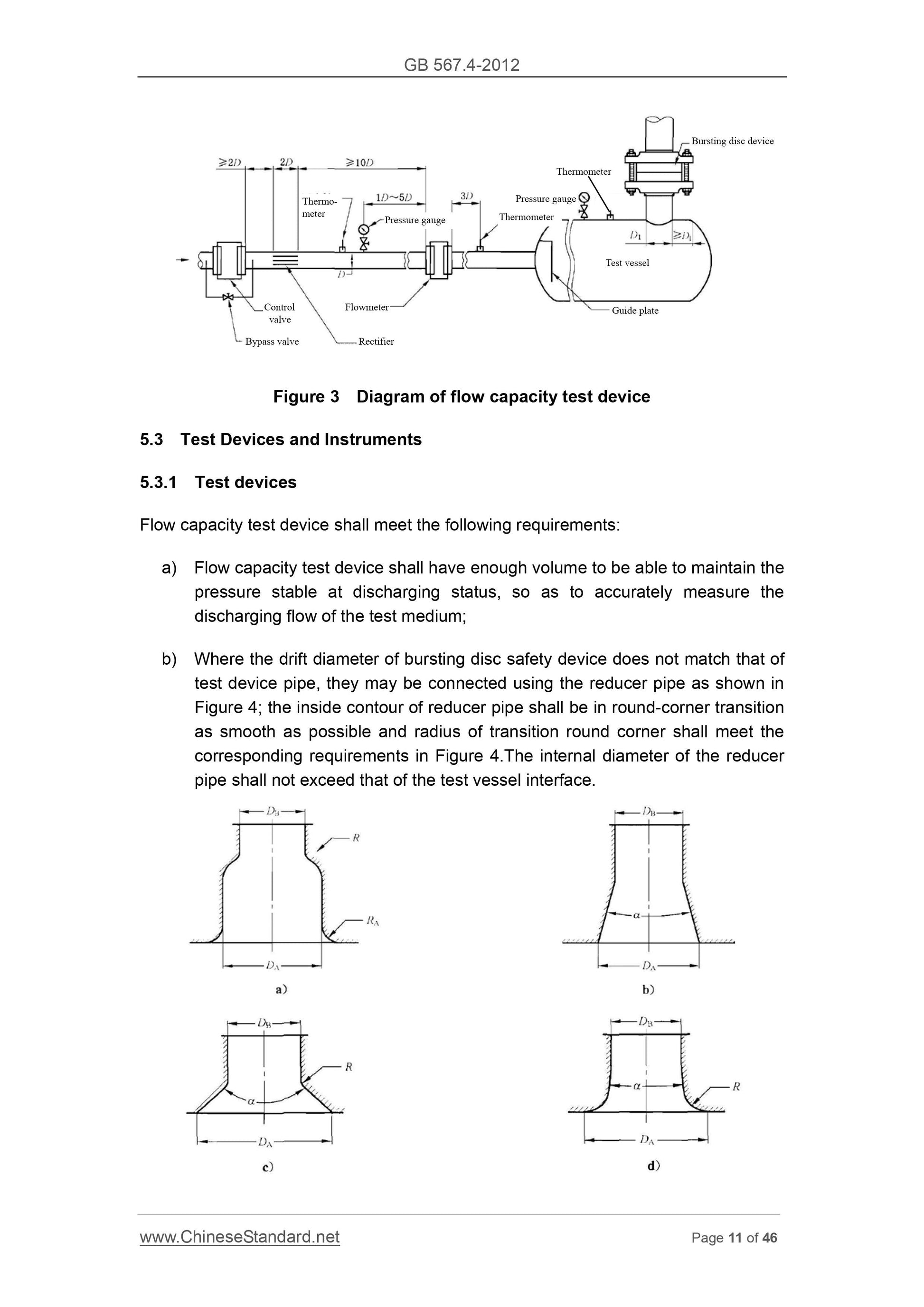

Within b) when the pipe diameter and the test apparatus bursting disc safety devices do not match, the choice of the adjustable tube as shown in FIG. 4 is connected, adjustable pipe

It should be as smooth rounded contour transition fillet radius should meet the corresponding requirements in FIG. 4. Reducing the inner diameter of the tube should not be

Than the inner diameter of the test container interface.

a) b)

4 a schematic view of the test apparatus and burst bursting disc safety device is connected reducer inner contour

c) d)

FIG. A). If DB≥0.75DA, the RA≥0.25DA, if DB < 0.75DA, the R≥0.25DA;

FIG b). If α≤30 ° and DB < 0.75DA, then all sharp edges down blunt edge;

FIG c). If α> 30 ° and DB < 0.75DA, the R≥0.25DA;

FIG d). If α≤30 ° and DB≥0.75DA, the R≥0.25DA.

FIG. 4 (Continued)

5.3.2 barometric pressure measurement

Use pressure gauge or absolute pressure sensor to measure atmospheric pressure. Calculation of Leakage during comprising, if the discharge pressure is not less than

0.15MPa, the test can be used to calculate the local average atmospheric pressure.

5.3.3 Pressure Measurement

Level with a precision of not less than 0.4, the test pressure range is 1.5 to 3 times the value of the pressure gauge or pressure tr...

Get Quotation: Click GB 567.4-2012 (Self-service in 1-minute)

Historical versions (Master-website): GB 567.4-2012

Preview True-PDF (Reload/Scroll-down if blank)

GB 567.4-2012: [GB/T 567.4-2012] Bursting disc safety devices -- Part 4: Type test

GB 567.4-2012

Bursting disc safety devices - Part 4. Type test

ICS 13.240

J74

National Standards of People's Republic of China

Bursting disc safety device

Part 4. Test Type

Published 2012-05-11

2013-03-01 implementation

Administration of Quality Supervision, Inspection and Quarantine of People's Republic of China

Standardization Administration of China issued

Table of Contents

Preface Ⅰ

1 Scope 1

2 Normative References 1

Terms and definitions 1 3

4 Blast Test 2

5 Discharge of test 5

10 6 fatigue test

7 flow resistance Test 11

Measurement uncertainty 8 17

Appendix A (informative) test records and test results Table 19

Annex B (informative) Test Report 27

Foreword

Appendix A and Appendix B of this section are recommended, others are mandatory.

GB 567 "bursting disc safety device" is divided into four parts.

--- Part 1. General requirements;

--- Part 2. Applications, selection and installation;

--- Part 3. Classification and dimensions;

--- section 4. Type tests.

This is Part of 4 GB 567.

This section drafted in accordance with the rules GB/T 1.1-2009 given.

This part of the proposed and managed by the National Boiler and Pressure Vessel Standardization Technical Committee (SAC/TC262).

This part was drafted. Shenyang Special Equipment Inspection and Research Institute, Shanghai Gas Industry Association, China Special Equipment Inspection and Research Institute,

Shanghai Huayi Group Engineering Equipment Co., AQSIQ Special Equipment Safety Supervision Bureau, Shenyang Aerospace Xinguang Security Systems Limited

Division of Safety Equipment Co., Dalian, Chengdu AVIC Safety Systems Co., Ltd., Shanghai Hua Li Safety Equipment Co., Ltd.,

Gimhae Institute of Special Equipment Inspection and Technical.

This part of the main drafters. Zhang Zhiyi, Xu Zaiping, fresh Xu Song, Zhou Weiming, life than the south, following the high Xuan, Chen Zhaohui, Liu Duo, Han Fengjuan, Li Yue,

To Dong Liang, Yang Xiuxia, Wang Zhenggang, Xu VIP, Wei Yongbiao.

Bursting disc safety device

Part 4. Test Type

1 Scope

1.1 GB 567 This section specifies the test burst bursting disc safety type test apparatus of Leakage tests, fatigue tests, and the flow resistance test

Test principle and method, instrumentation and test equipment, test conditions and test preparation, test rules, test procedure, test data and test process

The results of the measurement uncertainty of the technical requirements.

1.2 applies to the following section bursting disc safety devices.

--- This section applies to the pressure vessel, the pressure closed pressure pipe or other equipment (hereinafter referred to as pressure equipment) to prevent an overpressure or

Excessive bursting disc safety device is now used in a vacuum;

--- bursting disc safety devices in this section applies bursting disc burst pressure is less than 500MPa, not less than 0.001MPa.

1.3 does not apply to the following bursting disc safety devices.

--- Operation during pressure surge may be generated, when the reaction rate reaches the detonation pressure equipment.

Bursting disc safety devices --- Defense military equipment with special requirements.

NOTE. Detonation. fast burning velocity material, reach 1000m/s or more, and usually produces the blasting fundamentally different phenomena, a phenomenon known as detonation.

2 Normative references

The following documents for the application of this document is essential. For dated references, only applies to the version dated paper

Pieces. For undated references, the latest edition (including any amendments) applies to this document.

GB 567.1 bursting disc safety devices - Part 1. General requirements

GB 567.2 Part 2 bursting disc safety devices. applications, selection and installation of

GB 567.3 bursting disc safety devices - Part 3. Classification and dimensions

GB/T 2624 throttle flow measurement tube is filled with plates, nozzles and venturi fluid flow measuring

GB/T 21188 with a critical flow Venturi nozzle Measurement of gas flow

3 Terms and Definitions

GB 567.1 ~ GB 567.3 Definition The following terms and definitions apply to this document.

3.1

Burst test burstpressuretesting

Bursting disc safety devices to verify operability, the test to determine the bursting pressure at a given temperature.

3.2

Discharge of test flowcapacitytesting

Determining operating characteristics of the bursting disc safety device, the discharge capacity of the assay at its respective pressure.

3.3

Theoretical Discharge of theoreticalrelieving (discharge) capacity

Over the nozzle bursting disc safety device according to the net flow area of the bleed amount calculation, expressed in mass per unit time or volume.

3.4

Measured Discharge of measuredrelieving (discharge) capacity

Measured at a pressure bleed vent bursting disc safety device volume, expressed in mass or volume of the bleed unit time.

3.5

Discharge coefficient coefficientofdischarge

Discharge of the measured and theoretical discharge volume ratio.

3.6

Flow resistance coefficient flowresistancefactor

Dimensionless term fluid loss through the bursting disc safety device head velocity (velocity squared divided by the gravitational acceleration 1/2) representation.

4 burst test

4.1 General requirements

Burst test should be completed on a dedicated burst test apparatus, but also in the vent volume flow resistance test of the test or tests, and Leakage of

Or flow resistance test performed simultaneously.

4.2 Test principles and methods

4.2.1 bursting disc safety device should be mounted on a burst test apparatus, the test apparatus and the volume should meet the test requirements.

4.2.2 at a predetermined pressure inside the boosting speed burst test of the test medium, until a bursting disc rupture, rupture disc recording and

Bursting pressure test device in an instant.

4.2.3 Test principle media burst test apparatus as shown in Figure 1 a gas bursting disc.

4.2.4 Test principle media burst test apparatus as shown in Figure 2 liquid bursting disc.

1 a schematic view of a gas testing apparatus of FIG bursting disc blasting medium

4.3 Test apparatus and instrumentation

4.3.1 Test device

Burst test apparatus should meet the following requirements.

a) male burst test apparatus, said test section of diameter not less than the bursting disc safety device is well known in diameter, and the volume should be large enough to ensure

Syndrome break open the rupture disc shape.

b) means connected to the burst test and bursting disc safety device should be strong, reliable, and should the clamper force uniform.

c) Test pressure burst test apparatus should be reliable control method capable of accurately measuring the static pressure test. Minimum speed boost

It should be stable to not greater than 0.001MPa/s.

d) the temperature should be adjusted burst test apparatus, and bursting disc should be a reliable method of measuring the surface temperature and corresponding instrumentation.

e) burst test device should be reliable and secure protection provided appropriate facilities.

FIG 2 a schematic view of the test apparatus using a liquid medium rupture disc bursting

4.3.2 Temperature Measurement

It should thermocouple, RTD, or other methods can accurately measure the temperature of the rupture disc bursting test sheet temperature measurement. temperature

Measuring instrument should have a resolution no less than 0.5 ℃. Shall include all leads and calibration transmitter or meter.

4.3.3 Pressure Measurement

Manometric pressure measurement test of the bursting disc as close as possible, and should be not less than 0.4 level of accuracy, the range of pressures tested

1.5 to 3 times the value of the pressure gauge or pressure transmitter.

4.4 Test conditions and test preparation

4.4.1 Test medium

The test medium should generally be compressed air, water or hydraulic oil, under high pressure of the test medium or high temperature conditions should be nitrogen gas, hydraulic oil

Or heat conducting oil.

4.4.2 Test preparation

Test preparation should meet the following requirements.

a) Check the burst test apparatus, the confirmation of the functioning. Measuring instruments, sensors and precision and scale parameters of the test piece matches;

b) preliminary test, the test apparatus can be achieved to ensure burst test requirements, and the operation with fully informed of this experiment

Body details;

c) a preliminary test should include complete the whole process of recording and practical tests necessary data, and instrumentation, and to calibrate the sensor.

4.5 Test Rules

4.5.1 Sampling

Test samples should be randomly selected by a bursting disc for mass production of the same batch of products, the number is four.

4.5.2 Number of test

Selected burst pressure test for three bursting disc apparatus from random sampling.

4.5.3 Test temperature

4.5.3.1 When the test temperature was normal bursting disc, the test temperature should be controlled (15-30) within the range ℃.

4.5.3.2 bursting disc test temperature is high or low temperature, the test temperature and the temperature of the calibration burst tolerance should be less than ± 5 ℃.

4.6 Test procedure

The test procedure is as follows.

a) the test piece according to the design requirements of the bursting disc preload means mounted on the test apparatus;

b) When the test piece after the need for explosion or leakage volume flow resistance tests, the bursting disc before importing volume should be large enough to allow blasting

The shape and degree of opening meet the requirements;

c) test pressure was slowly raised, and the observation of a pressure gauge indicating the consistency of the data display device with a pressure recording. When the pressure

90% to a minimum burst pressure of generally not more than the boosting speed control 3kPa/s or to facilitate accurate reading of pressure

Boosting lower speed value. For calibration bursting disc burst pressure is higher than 100MPa, the boosting speed can be controlled per second

Nominal burst pressure of not more than 0.1%;

d) Very temperature burst test, the temperature should rise (fall) to start boost near the blast temperature calibration, and controlling the rupture disc bursting when

Blasting temperature and calibration temperature tolerance of no greater than ± 5 ℃;

e) observe and record the burst pressure value, or use a computer, the recording apparatus automatically recording instrumentation burst pressure.

4.7 Data Processing

4.7.1 actual burst pressure rupture disc bursting pressure of its calibration error is within an allowable range of standard products, bonded burst test results

grid. For the same set of three test pieces and burst test were satisfactory burst test results of a particular model of this rupture disc is represented by the group qualified.

If the three are defective, the test results of a particular model burst rupture disc is represented by this group was rejected.

4.7.2 bursting disc type test results caused by other errors due to non-operation of the rupture disc reasons, can not increase the number of test pieces.

4.8 reinspection

4.8.1 Conclusion The test burst test piece not fully Eligible allow retest the same product was further extracted six.

4.8.2 burst test results retesting are within the scope permitted by the standard, the burst test piece representative of a particular model of rupture disc burst test product

Conclusions qualified.

4.8.3 If a conclusion is still unsatisfactory, on behalf of the test piece rupture disc bursting of a certain type of product for the conclusion burst test failed.

4.9 test records and test reports

Content 4.9.1 Test requirements for records in Appendix A.

4.9.2 Test report content requirements in Appendix B.

5 of Leakage test

5.1 General requirements

Discharge of the test should be performed simultaneously with the burst test on a dedicated Discharge of test apparatus may be completed after the burst test, again blasting

Safety sheet means Discharge Capacity Test.

5.2 Test principles and methods

On dedicated testing device equipped with a flow meter or the test medium was collected and the weight of the apparatus, bursting disc safety devices installed to a predetermined

Emission test pressure medium to the pressure and flow rate stability, the pressure in the recording medium over time, temperature, flow and other parameters. With these parameters

Discharge of the calculation to obtain the actual bursting disc safety device. The principle of the test apparatus shown in Figure 3.

3 a schematic view of the test device of FIG vent volume

5.3 Test apparatus and instrumentation

5.3.1 Test device

Discharge of the test apparatus should meet the following requirements.

a) Discharge of the test apparatus should be sufficiently large volume, pressure can be maintained at a steady state bleed in order to accurately measure the assay medium

Bleed mass flow rate;

Within b) when the pipe diameter and the test apparatus bursting disc safety devices do not match, the choice of the adjustable tube as shown in FIG. 4 is connected, adjustable pipe

It should be as smooth rounded contour transition fillet radius should meet the corresponding requirements in FIG. 4. Reducing the inner diameter of the tube should not be

Than the inner diameter of the test container interface.

a) b)

4 a schematic view of the test apparatus and burst bursting disc safety device is connected reducer inner contour

c) d)

FIG. A). If DB≥0.75DA, the RA≥0.25DA, if DB < 0.75DA, the R≥0.25DA;

FIG b). If α≤30 ° and DB < 0.75DA, then all sharp edges down blunt edge;

FIG c). If α> 30 ° and DB < 0.75DA, the R≥0.25DA;

FIG d). If α≤30 ° and DB≥0.75DA, the R≥0.25DA.

FIG. 4 (Continued)

5.3.2 barometric pressure measurement

Use pressure gauge or absolute pressure sensor to measure atmospheric pressure. Calculation of Leakage during comprising, if the discharge pressure is not less than

0.15MPa, the test can be used to calculate the local average atmospheric pressure.

5.3.3 Pressure Measurement

Level with a precision of not less than 0.4, the test pressure range is 1.5 to 3 times the value of the pressure gauge or pressure tr...

Share