1

/

of

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

CQC-C1601-2016 English PDF (CQC-C1601-2016)

CQC-C1601-2016 English PDF (CQC-C1601-2016)

Regular price

$790.00 USD

Regular price

Sale price

$790.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click CQC-C1601-2016

Historical versions: CQC-C1601-2016

Preview True-PDF (Reload/Scroll if blank)

CQC-C1601-2016: China Compulsory Certification Implementation Detailed-Rules - Telecommunication terminal equipment

CQC-C1601-2016

Serial No.: CQC-C1601-2016

Implementation Detailed-Rules for

China Compulsory Certification

Telecommunication terminal equipment

ISSUED ON: AUGUST 1, 2016

IMPLEMENTED ON: AUGUST 1, 2016

China Quality Certification Centre

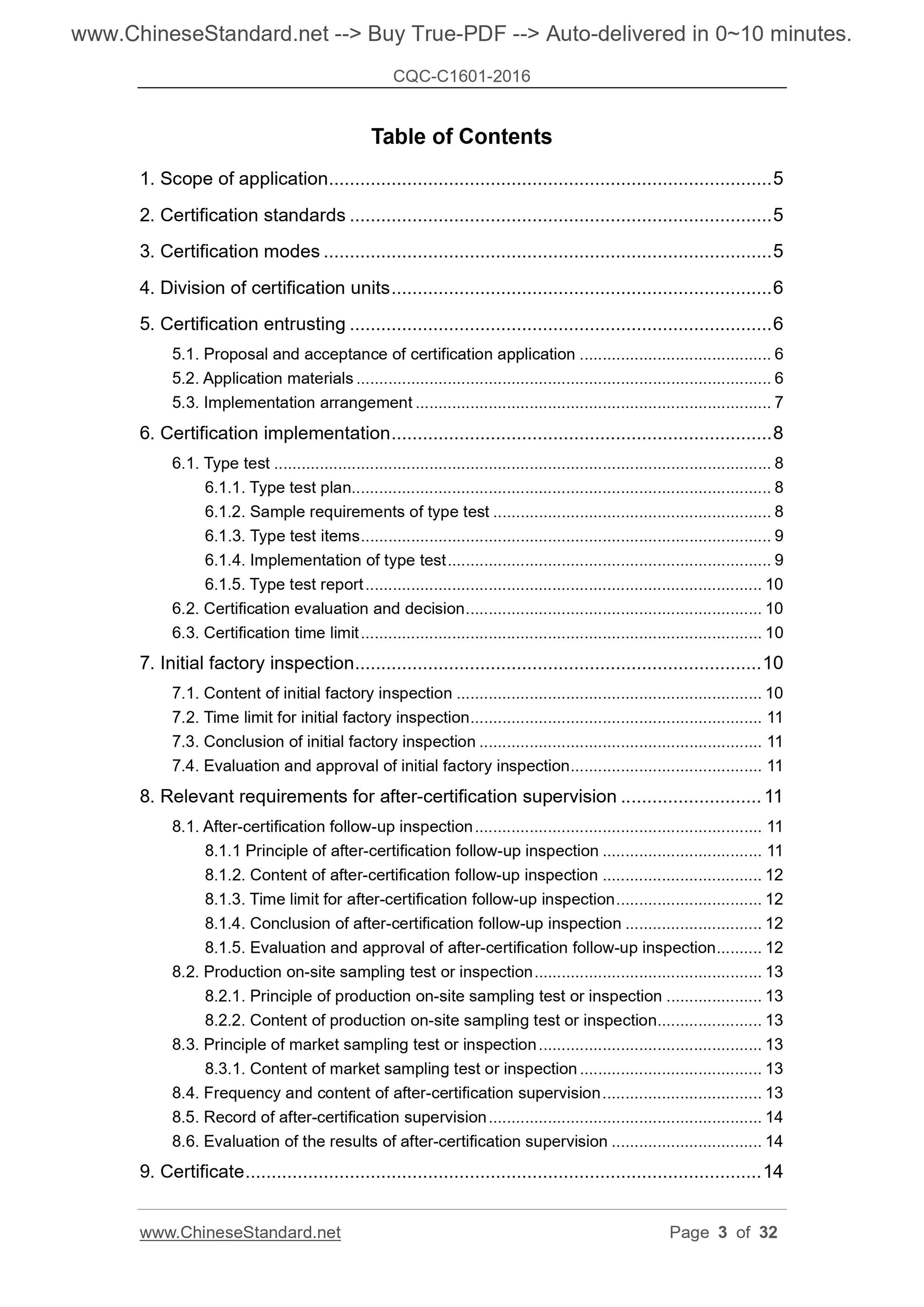

Table of Contents

1. Scope of application ... 5

2. Certification standards ... 5

3. Certification modes ... 5

4. Division of certification units ... 6

5. Certification entrusting ... 6

5.1. Proposal and acceptance of certification application ... 6

5.2. Application materials ... 6

5.3. Implementation arrangement ... 7

6. Certification implementation ... 8

6.1. Type test ... 8

6.1.1. Type test plan... 8

6.1.2. Sample requirements of type test ... 8

6.1.3. Type test items ... 9

6.1.4. Implementation of type test ... 9

6.1.5. Type test report ... 10

6.2. Certification evaluation and decision ... 10

6.3. Certification time limit ... 10

7. Initial factory inspection ... 10

7.1. Content of initial factory inspection ... 10

7.2. Time limit for initial factory inspection ... 11

7.3. Conclusion of initial factory inspection ... 11

7.4. Evaluation and approval of initial factory inspection ... 11

8. Relevant requirements for after-certification supervision ... 11

8.1. After-certification follow-up inspection ... 11

8.1.1 Principle of after-certification follow-up inspection ... 11

8.1.2. Content of after-certification follow-up inspection ... 12

8.1.3. Time limit for after-certification follow-up inspection ... 12

8.1.4. Conclusion of after-certification follow-up inspection ... 12

8.1.5. Evaluation and approval of after-certification follow-up inspection ... 12

8.2. Production on-site sampling test or inspection ... 13

8.2.1. Principle of production on-site sampling test or inspection ... 13

8.2.2. Content of production on-site sampling test or inspection ... 13

8.3. Principle of market sampling test or inspection ... 13

8.3.1. Content of market sampling test or inspection ... 13

8.4. Frequency and content of after-certification supervision ... 13

8.5. Record of after-certification supervision ... 14

8.6. Evaluation of the results of after-certification supervision ... 14

9. Certificate ... 14

9.1. Maintenance of the certificate ... 14

9.2. Change record of products covered by the certificate ... 14

9.2.1. Change request ... 14

9.2.2. Evaluation and approval of change ... 15

9.2.3. Principle of change record ... 15

9.3. Extension of products covered by the certificate ... 15

9.4. Cancellation, suspension, and withdrawal of the certificate ... 15

9.5. Use of the certificate ... 15

10. Certification mark ... 15

11. Charging basis and requirements ... 15

12. Certification responsibility ... 15

13. Principles for classification of manufacturing enterprises ... 15

Attached Table 1 -- ... 19

Attached Table 2 -- ... 24

Attached Table 3 -- ... 29

Attachment 4 ... 31

1. Scope of application

“Implementation Detailed-Rules for telecommunication terminal equipment” (hereinafter

referred to as Implementation Detailed-Rules) is compiled based on the requirements of

“China Compulsory Certification Implementation Rules - Telecommunication terminal

equipment” (CNCA-C16-01:2014) (hereinafter referred to as Implementation-Rules). As

supportive document for the Implementation-Rules, this Detailed-Rules is used together

with the Implementation-Rules.

The applicable product scope, certification basis and all other contents of this

Implementation Detailed-Rules shall comply with relevant provisions of

Implementation-Rules. It shall also be adjusted according to the Notices such as defined

directory and directory adjustment that are issued by Certification and Accreditation

Administration of the PRC (hereafter referred to as CNCA).

In accordance with the provisions of Certification Implementation-Rules, following the

principles of maintaining the effectiveness of product certification, improving quality of

product, serving certification companies, and controlling risk of certification, CQC

formulates and issues this certification Implementation Detailed-Rules. Through

establishing the classification management requirements of manufacturing enterprises,

and combining the classification of manufacturing enterprises, this Detailed-Rules

determines the implementation requirements for China Compulsory Certification of

telecommunication terminal equipment.

2. Certification standards

IMPLEMENT in accordance with Clause 2 of the Implementation-Rules.

3. Certification modes

The optional certification modes for telecommunication terminal equipment are:

Mode 1:

Class I or Class II equipment: Type test + after-certification supervision

Equipment other than Class I or Class II: Type test + after-certification follow-up

inspection

The above after-certification supervision refers to one of three methods:

after-certification follow-up inspection, production on-site sampling test or inspection,

and market sampling test or inspection.

Mode 2:

CQC and / or laboratory with relevant application materials and technical materials,

including but not limited to:

(1) Certification application;

(2) Registration certificates (such as business license, organization code certificate,

etc.) of the CLIENT, manufacturer, and manufacturing enterprise (when

necessary);

(3) Self-assessment report / declaration of the factory's quality assurance capability of

the manufacturing enterprise (when necessary);

(4) Factory inspection questionnaire (when necessary);

(5) Relevant agreements or contracts (such as ODM agreements, OEM agreements,

authorization letters, etc.) signed between CLIENT, manufacturer, and

manufacturing enterprise (when necessary);

(6) Product description information, mainly including: model description, technical

parameters, critical components and / or material list, electrical schematic diagram,

difference description of products of different specifications contained in the same

certification unit, etc. (when necessary);

(7) Chinese instruction manual, Chinese nameplate and warning mark (when

necessary);

(8) Appointment letter of certification technical director and the CQC assessment

certification and other materials (if any and necessary);

(9) For the application change, the supporting documents of the relevant change items

(such as the name change of enterprise, the re-division of administrative region,

etc.) (when necessary);

(10) Other required documents.

5.3. Implementation arrangement

After CQC accepts the certification application, based on the classification management

requirements of the manufacturing enterprise and the relevant product information

submitted by the enterprise, etc., it will formulate a certification scheme and notify the

CLIENT. The certification scheme usually includes the following:

(1) List of application materials to be submitted;

(2) Sample delivery requirements for type test;

(3) Laboratory information;

items shall be reduced as much as possible.

The requirements for the list of critical components and materials shall be implemented in

accordance with the resolutions of the technical expert group of the CNCA. For specific

requirements, refer to the attached Table 1 and Table 2.

The classification and change filing instructions of critical components and materials

(hereinafter referred to as critical parts) are as follows:

The proc...

Get QUOTATION in 1-minute: Click CQC-C1601-2016

Historical versions: CQC-C1601-2016

Preview True-PDF (Reload/Scroll if blank)

CQC-C1601-2016: China Compulsory Certification Implementation Detailed-Rules - Telecommunication terminal equipment

CQC-C1601-2016

Serial No.: CQC-C1601-2016

Implementation Detailed-Rules for

China Compulsory Certification

Telecommunication terminal equipment

ISSUED ON: AUGUST 1, 2016

IMPLEMENTED ON: AUGUST 1, 2016

China Quality Certification Centre

Table of Contents

1. Scope of application ... 5

2. Certification standards ... 5

3. Certification modes ... 5

4. Division of certification units ... 6

5. Certification entrusting ... 6

5.1. Proposal and acceptance of certification application ... 6

5.2. Application materials ... 6

5.3. Implementation arrangement ... 7

6. Certification implementation ... 8

6.1. Type test ... 8

6.1.1. Type test plan... 8

6.1.2. Sample requirements of type test ... 8

6.1.3. Type test items ... 9

6.1.4. Implementation of type test ... 9

6.1.5. Type test report ... 10

6.2. Certification evaluation and decision ... 10

6.3. Certification time limit ... 10

7. Initial factory inspection ... 10

7.1. Content of initial factory inspection ... 10

7.2. Time limit for initial factory inspection ... 11

7.3. Conclusion of initial factory inspection ... 11

7.4. Evaluation and approval of initial factory inspection ... 11

8. Relevant requirements for after-certification supervision ... 11

8.1. After-certification follow-up inspection ... 11

8.1.1 Principle of after-certification follow-up inspection ... 11

8.1.2. Content of after-certification follow-up inspection ... 12

8.1.3. Time limit for after-certification follow-up inspection ... 12

8.1.4. Conclusion of after-certification follow-up inspection ... 12

8.1.5. Evaluation and approval of after-certification follow-up inspection ... 12

8.2. Production on-site sampling test or inspection ... 13

8.2.1. Principle of production on-site sampling test or inspection ... 13

8.2.2. Content of production on-site sampling test or inspection ... 13

8.3. Principle of market sampling test or inspection ... 13

8.3.1. Content of market sampling test or inspection ... 13

8.4. Frequency and content of after-certification supervision ... 13

8.5. Record of after-certification supervision ... 14

8.6. Evaluation of the results of after-certification supervision ... 14

9. Certificate ... 14

9.1. Maintenance of the certificate ... 14

9.2. Change record of products covered by the certificate ... 14

9.2.1. Change request ... 14

9.2.2. Evaluation and approval of change ... 15

9.2.3. Principle of change record ... 15

9.3. Extension of products covered by the certificate ... 15

9.4. Cancellation, suspension, and withdrawal of the certificate ... 15

9.5. Use of the certificate ... 15

10. Certification mark ... 15

11. Charging basis and requirements ... 15

12. Certification responsibility ... 15

13. Principles for classification of manufacturing enterprises ... 15

Attached Table 1 -- ... 19

Attached Table 2 -- ... 24

Attached Table 3 -- ... 29

Attachment 4 ... 31

1. Scope of application

“Implementation Detailed-Rules for telecommunication terminal equipment” (hereinafter

referred to as Implementation Detailed-Rules) is compiled based on the requirements of

“China Compulsory Certification Implementation Rules - Telecommunication terminal

equipment” (CNCA-C16-01:2014) (hereinafter referred to as Implementation-Rules). As

supportive document for the Implementation-Rules, this Detailed-Rules is used together

with the Implementation-Rules.

The applicable product scope, certification basis and all other contents of this

Implementation Detailed-Rules shall comply with relevant provisions of

Implementation-Rules. It shall also be adjusted according to the Notices such as defined

directory and directory adjustment that are issued by Certification and Accreditation

Administration of the PRC (hereafter referred to as CNCA).

In accordance with the provisions of Certification Implementation-Rules, following the

principles of maintaining the effectiveness of product certification, improving quality of

product, serving certification companies, and controlling risk of certification, CQC

formulates and issues this certification Implementation Detailed-Rules. Through

establishing the classification management requirements of manufacturing enterprises,

and combining the classification of manufacturing enterprises, this Detailed-Rules

determines the implementation requirements for China Compulsory Certification of

telecommunication terminal equipment.

2. Certification standards

IMPLEMENT in accordance with Clause 2 of the Implementation-Rules.

3. Certification modes

The optional certification modes for telecommunication terminal equipment are:

Mode 1:

Class I or Class II equipment: Type test + after-certification supervision

Equipment other than Class I or Class II: Type test + after-certification follow-up

inspection

The above after-certification supervision refers to one of three methods:

after-certification follow-up inspection, production on-site sampling test or inspection,

and market sampling test or inspection.

Mode 2:

CQC and / or laboratory with relevant application materials and technical materials,

including but not limited to:

(1) Certification application;

(2) Registration certificates (such as business license, organization code certificate,

etc.) of the CLIENT, manufacturer, and manufacturing enterprise (when

necessary);

(3) Self-assessment report / declaration of the factory's quality assurance capability of

the manufacturing enterprise (when necessary);

(4) Factory inspection questionnaire (when necessary);

(5) Relevant agreements or contracts (such as ODM agreements, OEM agreements,

authorization letters, etc.) signed between CLIENT, manufacturer, and

manufacturing enterprise (when necessary);

(6) Product description information, mainly including: model description, technical

parameters, critical components and / or material list, electrical schematic diagram,

difference description of products of different specifications contained in the same

certification unit, etc. (when necessary);

(7) Chinese instruction manual, Chinese nameplate and warning mark (when

necessary);

(8) Appointment letter of certification technical director and the CQC assessment

certification and other materials (if any and necessary);

(9) For the application change, the supporting documents of the relevant change items

(such as the name change of enterprise, the re-division of administrative region,

etc.) (when necessary);

(10) Other required documents.

5.3. Implementation arrangement

After CQC accepts the certification application, based on the classification management

requirements of the manufacturing enterprise and the relevant product information

submitted by the enterprise, etc., it will formulate a certification scheme and notify the

CLIENT. The certification scheme usually includes the following:

(1) List of application materials to be submitted;

(2) Sample delivery requirements for type test;

(3) Laboratory information;

items shall be reduced as much as possible.

The requirements for the list of critical components and materials shall be implemented in

accordance with the resolutions of the technical expert group of the CNCA. For specific

requirements, refer to the attached Table 1 and Table 2.

The classification and change filing instructions of critical components and materials

(hereinafter referred to as critical parts) are as follows:

The proc...

Share