1

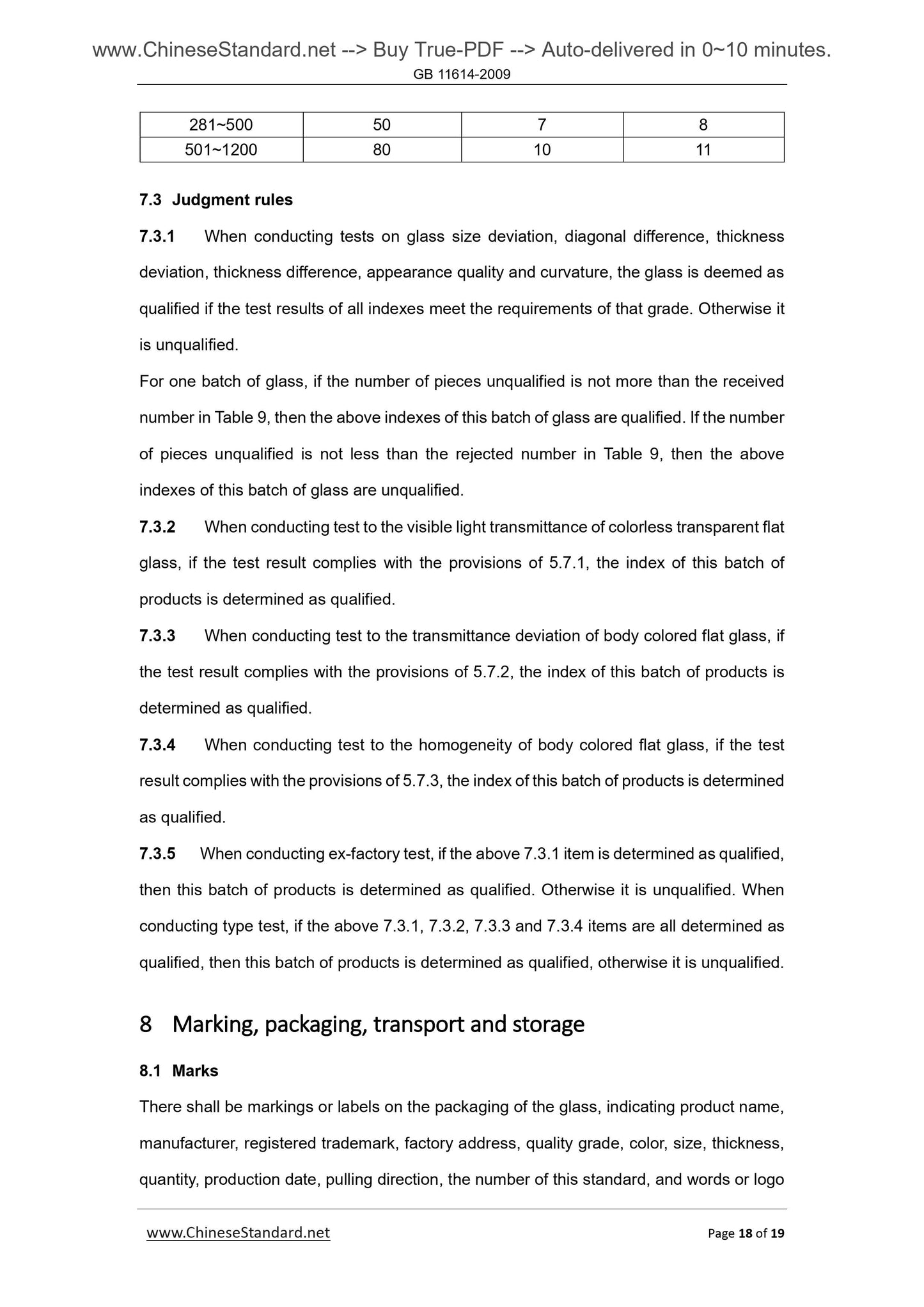

/

of

10

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 11614-2009 English PDF (GB11614-2009)

GB 11614-2009 English PDF (GB11614-2009)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.Newer version: (Replacing this standard) GB 11614-2022

Get QUOTATION in 1-minute: Click GB 11614-2009

Historical versions: GB 11614-2009

Preview True-PDF (Reload/Scroll if blank)

GB 11614-2009: Flat glass

GB 11614-2009

GB

ICS 81.040.20

Q 33

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Replacing GB 4871-1995, GB 11614-1999, GB/T 18701-2002

Flat glass

平板玻璃

ISSUED ON. MARCH 28, 2009

IMPLEMENTED ON. MARCH 1, 2010

Issued by.

General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration Committee of the People’s

Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Classifications ... 6

5 Requirements ... 7

6 Test Methods ... 12

7 Inspection rules ... 17

8 Marking, packaging, transport and storage ... 18

Foreword

Provisions in Chapters 5.2 - 5.6 of this standard are mandatory, the rest are

recommendatory.

This standard shall replace GB 4871-1995 Common Flat Glass, GB 11614-1999 Float

Glass, and GB/T 18701-2002 Colored Glass.

This standard, in comparison with GB 11614-1999, has the major changes as follows.

― Change the classification method from “by use” to “by appearance quality” (3.1 of

1999 version, 4.2 of this version);

― Add “Terms and Definitions” (Chapter 3 of this version);

― Add the provisions on the thickness difference of 12mm or above (4.2 of 1999 version,

5.4 of this version);

― In the appearance quality part, use the term “spot faults” to replace “bubbles” and

“impurities”. And increase the requirements. Add the provisions that the number of

spot faults within a 100mm-diameter circle shall not be more than 3 (4.3, 4.4.and 4.5

of 1999 version, 5.5 of this version);

― Add "inspection and classification" and "sampling" clauses (Chapter 6 of 1999

version, Chapter 7 of this version).

This standard, in comparison with GB/T 18701-200, has the major changes as follows.

― Delete “the colored glass is classified according to hue” (3.3 of 2002 version);

― Delete the requirements of visible light transmittance of the colored glass (4.3 of 2002

version);

― Delete the requirements of color shading of the same glass (2002 version 3.4).

This standard was proposed by China Building Material Council.

This standard shall be centralized by the National Architectural Glass Standardization

Technical Committee (SAC/TC 255).

Drafting organization of this standard. Qinhuangdao Glass Industry Research and Design

Institute.

Participating drafting organizations of this standard. Luoyang Glass Company Limited, Jin

Jing Technology Co., Ltd., Qinhuangdao Yaohua Glass Co., Ltd., Jiangsu Farun Group Co.,

Ltd., Zhejiang Glass Co., Ltd., Weihai Blue Star Glass Holding Co., Ltd., Xinyi Glass

Holdings Limited, TG Changjiang Glass Co., Ltd., and China Building Materials Academy.

The main drafters of this standard. Wang Yulan, Liu Zhifu, Wu Qingtao, Zhang Baiheng,

Lu Wanshun, Liu Huanzhang, Wu Nan, Tian Chunxiang, Shi Xinyong, Lv Jin, and Li Bo.

The previous versions replaced by this standard are as follows.

― GB 1871-1985, GB 4871-1995;

― GB 11614-1989, GB 11614-1999;

― GB/T 18701-2002.

Plate Glass

1 Scope

This standard specifies the terms and definitions, classifications, requirements, test

methods, inspection rules, markings, packing, transportation, and storage of the colorless

transparent flat glass and colored flat glass.

This standard is applicable to the sodium calcium silicon plate glass produced by all kinds

of process.

This standard does not apply to patterned glass and wired glass.

2 Normative references

The articles contained in the following documents have become part of this standard when

they are quoted herein. For the dated documents so quoted, all the modifications

(excluding corrections) or revisions made thereafter shall not be applicable to this standard.

For the undated documents so quoted, the latest versions shall be applicable to this

standard.

GB/T 1216 External micrometer

GB/T 2680 Determination of light transmittance, solar direct transmittance, total solar

energy transmittance and ultraviolet transmittance for glass in building and

related glazing factors

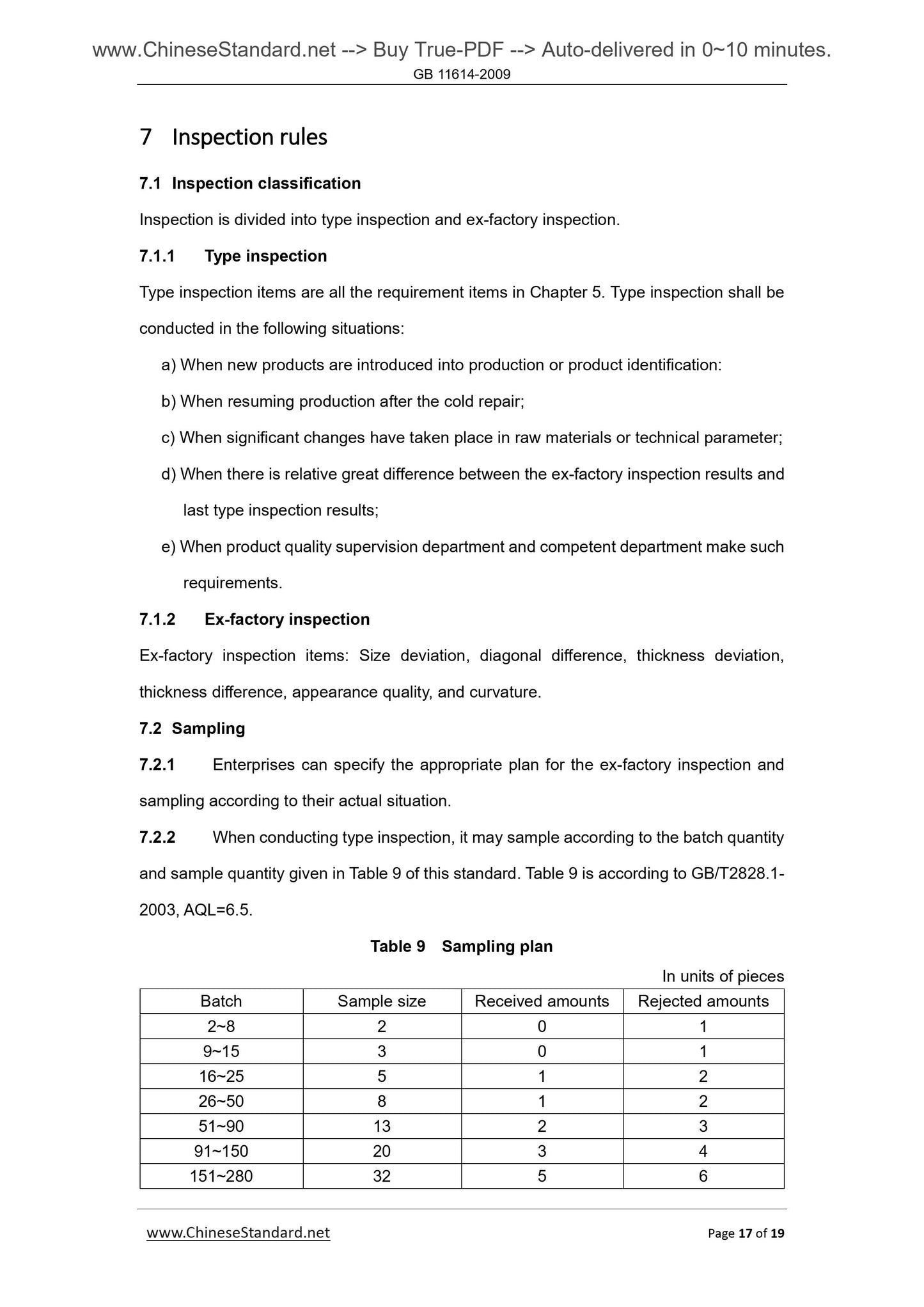

GB/T 2828.1-2003 Sampling procedures for inspection by attributea-Part1. Sampling

schemes indexed by acceptance quality limit(AQL) for lot-by-lot inspection

GB/T 8170 Rules of rounding off for numerical values and expression and judgement of

limiting values

GB/T 9056 Metal ruler

GB/T 11942 Colorimetric methods for colour building materials

GB/T 15764 Standard terminology of flat glass

JB/T 2369 Reading Microscope

JB/T 8788 Feeler gauges

QB/T 2443-1999 Steel measuring tapes

3 Terms and definitions

For the purpose of this standard, the following terms and definitions AND those defined in

GB/T 15764 apply.

3.1

Optical distortion

The distortion occurs when observing objects through the glass from a certain angle. Its

deformation degree is represented by the angle of incidence (commonly known as the

zebra angle).

3.2

Spot faults

The general term for defects such as bubbles, inclusions and spots.

3.3

Edge defects

Convex or concave parts of the glass plate cross section, including defects such as burst

edge, edge unevenness, short corner, and beveled edge.

3.4

Thickness difference

The difference between the maximum and minimum values of the thickness of the same

glass.

4 Classifications

4.1 According to the color attributes, it can be divided into colorless transparent flat glass

and colored flat glass.

4.2 According to the appearance quality, it can be divided into qualified product, first-class

product, and superior product.

4.3 According to nominal thickness, it can be divided into.

2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm, 22mm, and 25mm.

Use a metal ruler conforming to the requirements of GB/T 9056 with a division value of 1

mm OR a steel tape meeting the requirements of QB/T2443-1999 with the precision of

Grade 1 to measure the respective distances of the two parallel edges at the centers of the

length and the width. The difference between the measured value and the nominal

dimension is the dimension deviation.

6.2 Diagonal deviation

Use a steel tape meeting the requirements of QB/T2443-1999 with the precision of Grade

1 to measure the lengths of the two diagonals of the glass plate of which the absolute value

of the difference is the diagonal difference.

6.3 Thickness deviation

Use an outside-micrometer meeting the requirements of GB/T1216 with a division value of

0.01 mm to measure 5 points vertical to the pulling direction of the glass plate. Take one

point respectively [Translator. total 5 points] at inward 15 mm from the edge. Between the

2 points, divide the rest 3 points [Translator. The original Chinese text of this sentence is

ambiguous in grammar]. The difference between the measured value and the nominal

dimension is the thickness deviation.

6.4 Thickness difference

In the same way as 6.3, measure the thickness of five different points of a piece of glass

plate. And calculate the difference between the maximum value and minimum value.

6.5 Appearance quality

6.5.1 Point defects

Use a reading microscope complying with JB/T2369 with scale division of 0.01 mm to

measure the maximum size of the spot fault.

6.5.2 Spot faults concentration

Use a metal ruler meeting the requirements of GB/T9056 with a division value of 1 mm to

measure the shortest distance between two spot faults and count the number of spot faults

with a regulated si...

Get QUOTATION in 1-minute: Click GB 11614-2009

Historical versions: GB 11614-2009

Preview True-PDF (Reload/Scroll if blank)

GB 11614-2009: Flat glass

GB 11614-2009

GB

ICS 81.040.20

Q 33

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Replacing GB 4871-1995, GB 11614-1999, GB/T 18701-2002

Flat glass

平板玻璃

ISSUED ON. MARCH 28, 2009

IMPLEMENTED ON. MARCH 1, 2010

Issued by.

General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration Committee of the People’s

Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Classifications ... 6

5 Requirements ... 7

6 Test Methods ... 12

7 Inspection rules ... 17

8 Marking, packaging, transport and storage ... 18

Foreword

Provisions in Chapters 5.2 - 5.6 of this standard are mandatory, the rest are

recommendatory.

This standard shall replace GB 4871-1995 Common Flat Glass, GB 11614-1999 Float

Glass, and GB/T 18701-2002 Colored Glass.

This standard, in comparison with GB 11614-1999, has the major changes as follows.

― Change the classification method from “by use” to “by appearance quality” (3.1 of

1999 version, 4.2 of this version);

― Add “Terms and Definitions” (Chapter 3 of this version);

― Add the provisions on the thickness difference of 12mm or above (4.2 of 1999 version,

5.4 of this version);

― In the appearance quality part, use the term “spot faults” to replace “bubbles” and

“impurities”. And increase the requirements. Add the provisions that the number of

spot faults within a 100mm-diameter circle shall not be more than 3 (4.3, 4.4.and 4.5

of 1999 version, 5.5 of this version);

― Add "inspection and classification" and "sampling" clauses (Chapter 6 of 1999

version, Chapter 7 of this version).

This standard, in comparison with GB/T 18701-200, has the major changes as follows.

― Delete “the colored glass is classified according to hue” (3.3 of 2002 version);

― Delete the requirements of visible light transmittance of the colored glass (4.3 of 2002

version);

― Delete the requirements of color shading of the same glass (2002 version 3.4).

This standard was proposed by China Building Material Council.

This standard shall be centralized by the National Architectural Glass Standardization

Technical Committee (SAC/TC 255).

Drafting organization of this standard. Qinhuangdao Glass Industry Research and Design

Institute.

Participating drafting organizations of this standard. Luoyang Glass Company Limited, Jin

Jing Technology Co., Ltd., Qinhuangdao Yaohua Glass Co., Ltd., Jiangsu Farun Group Co.,

Ltd., Zhejiang Glass Co., Ltd., Weihai Blue Star Glass Holding Co., Ltd., Xinyi Glass

Holdings Limited, TG Changjiang Glass Co., Ltd., and China Building Materials Academy.

The main drafters of this standard. Wang Yulan, Liu Zhifu, Wu Qingtao, Zhang Baiheng,

Lu Wanshun, Liu Huanzhang, Wu Nan, Tian Chunxiang, Shi Xinyong, Lv Jin, and Li Bo.

The previous versions replaced by this standard are as follows.

― GB 1871-1985, GB 4871-1995;

― GB 11614-1989, GB 11614-1999;

― GB/T 18701-2002.

Plate Glass

1 Scope

This standard specifies the terms and definitions, classifications, requirements, test

methods, inspection rules, markings, packing, transportation, and storage of the colorless

transparent flat glass and colored flat glass.

This standard is applicable to the sodium calcium silicon plate glass produced by all kinds

of process.

This standard does not apply to patterned glass and wired glass.

2 Normative references

The articles contained in the following documents have become part of this standard when

they are quoted herein. For the dated documents so quoted, all the modifications

(excluding corrections) or revisions made thereafter shall not be applicable to this standard.

For the undated documents so quoted, the latest versions shall be applicable to this

standard.

GB/T 1216 External micrometer

GB/T 2680 Determination of light transmittance, solar direct transmittance, total solar

energy transmittance and ultraviolet transmittance for glass in building and

related glazing factors

GB/T 2828.1-2003 Sampling procedures for inspection by attributea-Part1. Sampling

schemes indexed by acceptance quality limit(AQL) for lot-by-lot inspection

GB/T 8170 Rules of rounding off for numerical values and expression and judgement of

limiting values

GB/T 9056 Metal ruler

GB/T 11942 Colorimetric methods for colour building materials

GB/T 15764 Standard terminology of flat glass

JB/T 2369 Reading Microscope

JB/T 8788 Feeler gauges

QB/T 2443-1999 Steel measuring tapes

3 Terms and definitions

For the purpose of this standard, the following terms and definitions AND those defined in

GB/T 15764 apply.

3.1

Optical distortion

The distortion occurs when observing objects through the glass from a certain angle. Its

deformation degree is represented by the angle of incidence (commonly known as the

zebra angle).

3.2

Spot faults

The general term for defects such as bubbles, inclusions and spots.

3.3

Edge defects

Convex or concave parts of the glass plate cross section, including defects such as burst

edge, edge unevenness, short corner, and beveled edge.

3.4

Thickness difference

The difference between the maximum and minimum values of the thickness of the same

glass.

4 Classifications

4.1 According to the color attributes, it can be divided into colorless transparent flat glass

and colored flat glass.

4.2 According to the appearance quality, it can be divided into qualified product, first-class

product, and superior product.

4.3 According to nominal thickness, it can be divided into.

2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm, 22mm, and 25mm.

Use a metal ruler conforming to the requirements of GB/T 9056 with a division value of 1

mm OR a steel tape meeting the requirements of QB/T2443-1999 with the precision of

Grade 1 to measure the respective distances of the two parallel edges at the centers of the

length and the width. The difference between the measured value and the nominal

dimension is the dimension deviation.

6.2 Diagonal deviation

Use a steel tape meeting the requirements of QB/T2443-1999 with the precision of Grade

1 to measure the lengths of the two diagonals of the glass plate of which the absolute value

of the difference is the diagonal difference.

6.3 Thickness deviation

Use an outside-micrometer meeting the requirements of GB/T1216 with a division value of

0.01 mm to measure 5 points vertical to the pulling direction of the glass plate. Take one

point respectively [Translator. total 5 points] at inward 15 mm from the edge. Between the

2 points, divide the rest 3 points [Translator. The original Chinese text of this sentence is

ambiguous in grammar]. The difference between the measured value and the nominal

dimension is the thickness deviation.

6.4 Thickness difference

In the same way as 6.3, measure the thickness of five different points of a piece of glass

plate. And calculate the difference between the maximum value and minimum value.

6.5 Appearance quality

6.5.1 Point defects

Use a reading microscope complying with JB/T2369 with scale division of 0.01 mm to

measure the maximum size of the spot fault.

6.5.2 Spot faults concentration

Use a metal ruler meeting the requirements of GB/T9056 with a division value of 1 mm to

measure the shortest distance between two spot faults and count the number of spot faults

with a regulated si...

Share