1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 19335-2003 English PDF (GB19335-2003)

GB 19335-2003 English PDF (GB19335-2003)

Regular price

$125.00 USD

Regular price

Sale price

$125.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.Newer version: (Replacing this standard) GB/T 19335-2022

Get QUOTATION in 1-minute: Click GB 19335-2003

Historical versions: GB 19335-2003

Preview True-PDF (Reload/Scroll if blank)

GB 19335-2003: Blood flow products for single use -- General specification

GB/T 19335-2003

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.20

C 31

Blood flow products for single use –

General specification

ISSUED ON. OCTOBER 20, 2003

IMPLEMENTED ON. APRIL 01, 2004

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of PRC.

Table of contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Requirements ... 5

4 Packaging, labelling ... 8

Appendix A (Normative) Particulate content test method ... 9

Appendix B (Normative) Injection part self-sealing test method ... 10

Appendix C (Normative) Test method for blood and blood components filter

efficiency ... 11

Appendix D (Normative) Test method for air filter’s filtration rate ... 14

Appendix E (Normative) Chemical properties test solution preparation ... 15

Appendix F (Normative) Ethylene oxide residue analysis method ... 16

Foreword

The technical contents of this Standard mainly make reference to ISO

1135-4.1998 “Transfusion equipment for medical use – Part 4. Transfusion

sets for single use” as well as the international standards on relevant products.

This Standard was formulated based on YY 0311-1998 “Blood flow products

for single use – General specification”. This Standard replaces YY 0311-1998.

The Appendix A, Appendix B, Appendix C, Appendix D, Appendix E and

Appendix F of this Standard are normative.

This Standard was proposed by China Food and Drug Administration.

This Standard shall be under the jurisdiction of the National Technical

Committee for Medical Transfusion Equipment.

The drafting organizations of this Standard. State Drug Administration Jinan

Medical Device Quality Supervision and Inspection Center.

The main drafters of this Standard. Pan Huaxian, Luo Hongyu, Wang Xin, Wu

Ping, Sun Guangyu.

Blood flow products for single use –

General specification

1 Scope

This Standard specifies the general technical conditions for the blood flow

products for single use.

This Standard applies to the blood path AND its connected subsidiary pipelines

which are mainly made from PVC, including the products composed of fluid

path AND pressure monitoring pipeline, etc. (abbreviated as blood path).

The relevant provisions of this Standard take precedence over this Standard.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this Standard;

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 1962 Conical fittings with a 6% (Luer) taper for syringes, needles and

certain other medical equipment

GB/T 14233.1-1998 Test methods for infusion transfusion injection

equipment for medical use – Part 1. Chemical analysis methods

GB/T 14233.2 Test methods for infusion transfusion injection equipment for

medical use – Part 2. Biological test methods

GB 15593 Plasticized polyvinyl chloride (PVC) compounds for transfusion

(infusion) equipment

GB 15811 Sterile hypodermic needles for single use

GB/T 16886.1 Biological evaluation of medical devices – Part 1. Evaluation

and testing

3.2.6 Color code

When the blood path is divided into arterial blood path and venous blood path,

within 100mm from the pipeline end, it shall have apparent color identifications.

It is preferable for the arterial blood path to use red color, AND the venous

blood path to use blue color.

3.2.7 6% Luer taper

The 6% Luer taper between blood paths shall comply with the requirements of

GB/T 1962.

3.2.8 Blood filter

The mesh of the blood AND blood component filters along the blood path shall

be uniform, AND the effective filtration area shall be not less than 10cm2.

When conducting test in accordance with Appendix C, the filtration rate shall

be not less than 80%.

3.2.9 Switch

3.2.9.1 As for the blood path switch selection, GIVE priority to non-contact tube

clamp or flow regulator. Its performance shall be reliable.

3.2.9.2 The blood-contacted blood path change-over switch (such as single

valve three way switch, double valve four way switch, and triple valve five way

switch, etc.) shall have clear switching state indication. Its performance shall

be reliable.

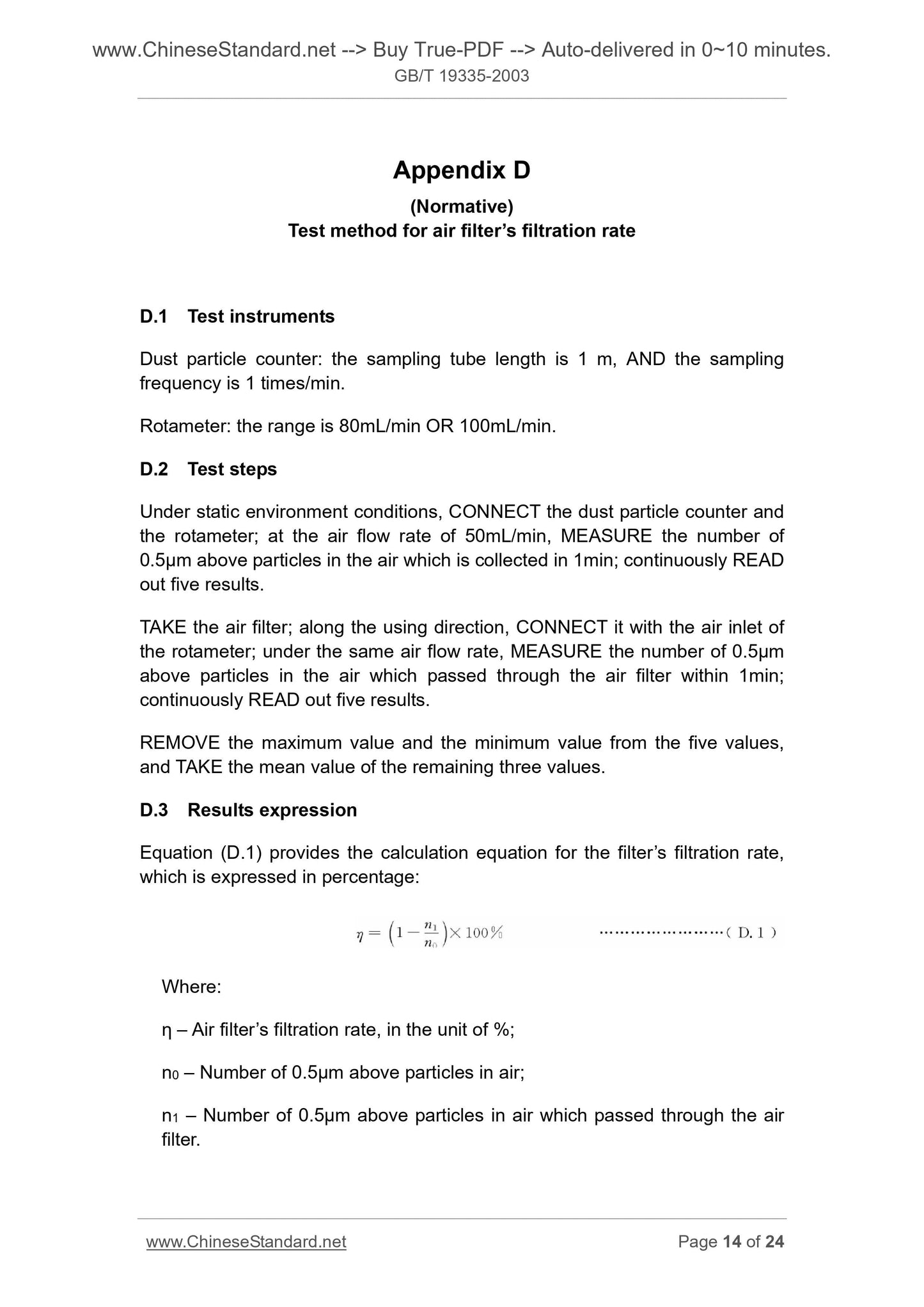

3.2.10 Air filter

If there is admission line along the blood path, then it shall have air filter which

can prevent outside microorganisms and dust from entering into the blood path.

When conducting test in accordance with Appendix D, the air filter’s filtration

rate for 0.5μm above particles in air shall be not less than 90%.

3.2.11 Appearance

The hose along the blood path shall be plasticized uniformly, have no kinks,

AND its transparency shall guarantee that using normal vision or corrected

vision can find the bubbles from the blood path.

3.3 Chemical properties

The test solution prepared in accordance with Appendix E shall comply with

the requirements of 3.3.1 to 3.3.6.

Appendix A

(Normative)

Particulate content test method

A.1 Principle

This method is, by flushing the blood path internal liquid passage surface AND

collecting the particles from the passage surface flushing solution, to count the

particle amount, in order to evaluate such contamination.

A.2 Test instrument

A.2.1 Dedicated particle counter. it has a stirring system AND one sampling

volume is 100mL; it can simultaneously conduct counting for the particles of

15μm ~ 25μm OR greater than 25μm.

A.2.2 Flushing liquid. it shall comply with the particle counter requirements,

AND pass the new 0.45μm microporous membrane for filtration.

A.3 Step

Note. The test shall avoid environmental pollution.

A.3.1 Eluent preparation

Using the flushing liquid at the proportion of 1mL per square centimeter

internal surface area, RINSE the blood path internal surface. This method shall

be designed that, each unit area inside of the pipeline directly or indirectly

contacting the blood or blood component shall be able to subject to the same

volume of flushing liquid (if along the blood path there is vessel shaped part,

then this blood path section shall be correspondingly added of the flushing

liquid of this vessel volume). The effluent is collected into a clean vessel, which

is the eluent.

A.3.2 Particle inspection

PIPETTE 200mL of eluent into the sample cup of the particle counter; USE the

particle counter to count the particle in the 100mL of eluent.

A.4 Results expression

USE the counted value of the counter to divide 100 to obtain the particle

content, in the unit of piece per millilitre. USE blank solution to correct it.

Appendix B

(Normative)

Injection part self-sealing test method

PLACE the injection part level AND unstressed; FILL water into the blood path

and AVOID inclusion of bubbles; LEAD in the pressure 20kPa (200 mbar)

above the atmospheric pressure; USE 0.6mm outer diameter needle which

complies with GB 15811 to pierce the puncture area of the injection part; after

piercing in for 15s, PULL out the needle and quickly make the pierced location

dry. OBSERVE it for 1 min to see whether there is leakage.

NOTE. If there are injection parts of other design types, they shall, in accordance

with the instructions p...

Get QUOTATION in 1-minute: Click GB 19335-2003

Historical versions: GB 19335-2003

Preview True-PDF (Reload/Scroll if blank)

GB 19335-2003: Blood flow products for single use -- General specification

GB/T 19335-2003

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.20

C 31

Blood flow products for single use –

General specification

ISSUED ON. OCTOBER 20, 2003

IMPLEMENTED ON. APRIL 01, 2004

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of PRC.

Table of contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Requirements ... 5

4 Packaging, labelling ... 8

Appendix A (Normative) Particulate content test method ... 9

Appendix B (Normative) Injection part self-sealing test method ... 10

Appendix C (Normative) Test method for blood and blood components filter

efficiency ... 11

Appendix D (Normative) Test method for air filter’s filtration rate ... 14

Appendix E (Normative) Chemical properties test solution preparation ... 15

Appendix F (Normative) Ethylene oxide residue analysis method ... 16

Foreword

The technical contents of this Standard mainly make reference to ISO

1135-4.1998 “Transfusion equipment for medical use – Part 4. Transfusion

sets for single use” as well as the international standards on relevant products.

This Standard was formulated based on YY 0311-1998 “Blood flow products

for single use – General specification”. This Standard replaces YY 0311-1998.

The Appendix A, Appendix B, Appendix C, Appendix D, Appendix E and

Appendix F of this Standard are normative.

This Standard was proposed by China Food and Drug Administration.

This Standard shall be under the jurisdiction of the National Technical

Committee for Medical Transfusion Equipment.

The drafting organizations of this Standard. State Drug Administration Jinan

Medical Device Quality Supervision and Inspection Center.

The main drafters of this Standard. Pan Huaxian, Luo Hongyu, Wang Xin, Wu

Ping, Sun Guangyu.

Blood flow products for single use –

General specification

1 Scope

This Standard specifies the general technical conditions for the blood flow

products for single use.

This Standard applies to the blood path AND its connected subsidiary pipelines

which are mainly made from PVC, including the products composed of fluid

path AND pressure monitoring pipeline, etc. (abbreviated as blood path).

The relevant provisions of this Standard take precedence over this Standard.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this Standard;

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 1962 Conical fittings with a 6% (Luer) taper for syringes, needles and

certain other medical equipment

GB/T 14233.1-1998 Test methods for infusion transfusion injection

equipment for medical use – Part 1. Chemical analysis methods

GB/T 14233.2 Test methods for infusion transfusion injection equipment for

medical use – Part 2. Biological test methods

GB 15593 Plasticized polyvinyl chloride (PVC) compounds for transfusion

(infusion) equipment

GB 15811 Sterile hypodermic needles for single use

GB/T 16886.1 Biological evaluation of medical devices – Part 1. Evaluation

and testing

3.2.6 Color code

When the blood path is divided into arterial blood path and venous blood path,

within 100mm from the pipeline end, it shall have apparent color identifications.

It is preferable for the arterial blood path to use red color, AND the venous

blood path to use blue color.

3.2.7 6% Luer taper

The 6% Luer taper between blood paths shall comply with the requirements of

GB/T 1962.

3.2.8 Blood filter

The mesh of the blood AND blood component filters along the blood path shall

be uniform, AND the effective filtration area shall be not less than 10cm2.

When conducting test in accordance with Appendix C, the filtration rate shall

be not less than 80%.

3.2.9 Switch

3.2.9.1 As for the blood path switch selection, GIVE priority to non-contact tube

clamp or flow regulator. Its performance shall be reliable.

3.2.9.2 The blood-contacted blood path change-over switch (such as single

valve three way switch, double valve four way switch, and triple valve five way

switch, etc.) shall have clear switching state indication. Its performance shall

be reliable.

3.2.10 Air filter

If there is admission line along the blood path, then it shall have air filter which

can prevent outside microorganisms and dust from entering into the blood path.

When conducting test in accordance with Appendix D, the air filter’s filtration

rate for 0.5μm above particles in air shall be not less than 90%.

3.2.11 Appearance

The hose along the blood path shall be plasticized uniformly, have no kinks,

AND its transparency shall guarantee that using normal vision or corrected

vision can find the bubbles from the blood path.

3.3 Chemical properties

The test solution prepared in accordance with Appendix E shall comply with

the requirements of 3.3.1 to 3.3.6.

Appendix A

(Normative)

Particulate content test method

A.1 Principle

This method is, by flushing the blood path internal liquid passage surface AND

collecting the particles from the passage surface flushing solution, to count the

particle amount, in order to evaluate such contamination.

A.2 Test instrument

A.2.1 Dedicated particle counter. it has a stirring system AND one sampling

volume is 100mL; it can simultaneously conduct counting for the particles of

15μm ~ 25μm OR greater than 25μm.

A.2.2 Flushing liquid. it shall comply with the particle counter requirements,

AND pass the new 0.45μm microporous membrane for filtration.

A.3 Step

Note. The test shall avoid environmental pollution.

A.3.1 Eluent preparation

Using the flushing liquid at the proportion of 1mL per square centimeter

internal surface area, RINSE the blood path internal surface. This method shall

be designed that, each unit area inside of the pipeline directly or indirectly

contacting the blood or blood component shall be able to subject to the same

volume of flushing liquid (if along the blood path there is vessel shaped part,

then this blood path section shall be correspondingly added of the flushing

liquid of this vessel volume). The effluent is collected into a clean vessel, which

is the eluent.

A.3.2 Particle inspection

PIPETTE 200mL of eluent into the sample cup of the particle counter; USE the

particle counter to count the particle in the 100mL of eluent.

A.4 Results expression

USE the counted value of the counter to divide 100 to obtain the particle

content, in the unit of piece per millilitre. USE blank solution to correct it.

Appendix B

(Normative)

Injection part self-sealing test method

PLACE the injection part level AND unstressed; FILL water into the blood path

and AVOID inclusion of bubbles; LEAD in the pressure 20kPa (200 mbar)

above the atmospheric pressure; USE 0.6mm outer diameter needle which

complies with GB 15811 to pierce the puncture area of the injection part; after

piercing in for 15s, PULL out the needle and quickly make the pierced location

dry. OBSERVE it for 1 min to see whether there is leakage.

NOTE. If there are injection parts of other design types, they shall, in accordance

with the instructions p...

Share