1

/

of

6

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 19592-2019 English PDF

GB 19592-2019 English PDF

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 19592-2019

Historical versions: GB 19592-2019

Preview True-PDF (Reload/Scroll if blank)

GB 19592-2019: Detergent additive for motor gasoline

GB 19592-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 75.140

E 61

Replacing GB 19592-2004

Detergent Additive for Motor Gasoline

ISSUED ON: OCTOBER 14, 2019

IMPLEMENTED ON: MAY 1, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 7

4 Requirements and Test Methods ... 7

5 Inspection Rules ... 8

6 Marking, Packaging, Transportation and Storage ... 10

7 Safety ... 10

Appendix A (Normative) Base Fuel ... 11

Foreword

All the technical content in this Standard is mandatory.

This Standard was drafted in accordance with the rules in GB/T 1.1-2009.

This Standard serves as a replacement of GB 19592-2004 Detergent Additive for

Vehicle Gasoline. In comparison with GB 19592-2004, the main technical changes are

as follows:

---The scope of application is modified (see Chapter 1);

---Normative references are modified (see Chapter 2);

---The definition of base fuel is modified (see 3.1);

---The definition of detergent additive for motor gasoline is modified (see 3.2);

---The definition of intake system is deleted (see 3.3 in Version 2004);

---The definition of intake valve deposits is modified (see 3.3);

---The definition of total combustion deposits is modified (see 3.4);

---Table content in the previous version is modified into the content in 4.1 (see 4.1;

Table 1 in Version 2004);

---Pour point indicator is modified from “not higher than -15 °C” into “not higher

than -20 °C” (see Table 1);

---Flash point indicator is modified from “not lower than 45 °C” into “not lower than

60 °C” (see Table 1);

---The technical requirements of sulfur content and chlorine content are added

(see Table 1);

---The expression of technical requirements of anti-rust property is modified from

“not more than 5%” into “not more than moderate rust” (see Table 1);

---The expression of fuel nozzle cleanliness is deleted and modified into “nozzle

mass flow loss rate” (see Table 1);

---The requirements of deposit decline rate of intake system are deleted (see Table

1 in Version 2004);

---“Simulated intake valve deposit decline rate” is modified into “simulated intake

valve deposit mass”; “report” is modified into “not more than 2.0 mg”; test

method is modified into GB/T 37322-2019 (see Table 1);

Detergent Additive for Motor Gasoline

Warning: if appropriate precautions are not abided by, there might be dangers

in the production, storage, transportation and usage process of products that

belong to this Standard. This Standard does not intend to propose suggestions

to all the safety issues related with the products. Before putting this Standard

into effect, users shall undertake the responsibility of establishing appropriate

safety and preventive measures; confirming the applicability of relevant

stipulations and restrictions.

1 Scope

This Standard stipulates the terms and definitions, requirements, test methods,

inspection rules, marking, packaging, transportation, storage and safety of detergent

additive for motor gasoline.

This Standard is applicable to detergent additives used in motor gasoline and motor

ethanol gasoline.

2 Normative References

The following documents are indispensable to the application of this document. In

terms of references with a specified date, only versions with a specified date are

applicable to this document. In terms of references without a specified date, the latest

version (including all the modifications) is applicable to this document.

GB 190 Packing Symbol of Dangerous Goods;

GB/T 261 Determination of Flash Point - Pensky-Martens Closed Cup Method;

GB/T 511 Petroleum, Petroleum Products and Additives - Method for Determination of

Mechanical Admixtures;

GB/T 3535 Petroleum Products - Determination of Pour Point;

GB/T 4756 Method for Manual Sampling of Petroleum Liquids;

GB/T 11140 Standard Test Method for Sulfur in Petroleum Products by Wavelength

Dispersive X-ray Fluorescence Spectrometry;

GB 17930 Gasoline for Motor Vehicles;

GB/T 19230.1 Test Method for Evaluating Gasoline Detergent in Use - Part 1: Test

Method for Rust-preventing Characteristics of Gasoline Detergent;

3 Terms and Definitions

The following terms and definitions are applicable to this document.

3.1 Base Fuel

Base fuel refers to fuel that is used to inspect a certain property of additives in tests.

Base fuel has satisfying distinctiveness and does not include additives that may

improve the property being inspected.

3.2 Detergent Additive for Motor Gasoline

Detergent additive for motor gasoline refers to a matter that is added to motor gasoline

or motor ethanol gasoline to prevent the generation of deposits or separable deposits

in parts like engine inlet, intake valve and fuel spray nozzle, etc. Generally speaking,

detergent additive for motor gasoline is ashless organic matter that contains some

polymers.

3.3 Intake Valve Deposits; IVDs

Intake valve deposits refers to any matters that are generated by fuel, lubricating oil

and additives, or, inhaled from the outside, and deposit on the surface of intake valve.

3.4 Total Combustion Deposits; TCDs

Total combustion deposits refers to any matters that are generated by fuel, lubricating

oil and additives, or, inhaled from the outside, and deposit on the part of combustion

chamber (cylinder head and piston top).

4 Requirements and Test Methods

4.1 Chemical substances that may generate ash content cannot be manually added to

detergent additive for motor gasoline. Motor gasoline and motor ethanol gasoline,

which adds detergent additive in accordance with the recommended dosage, shall

comply with corresponding standards.

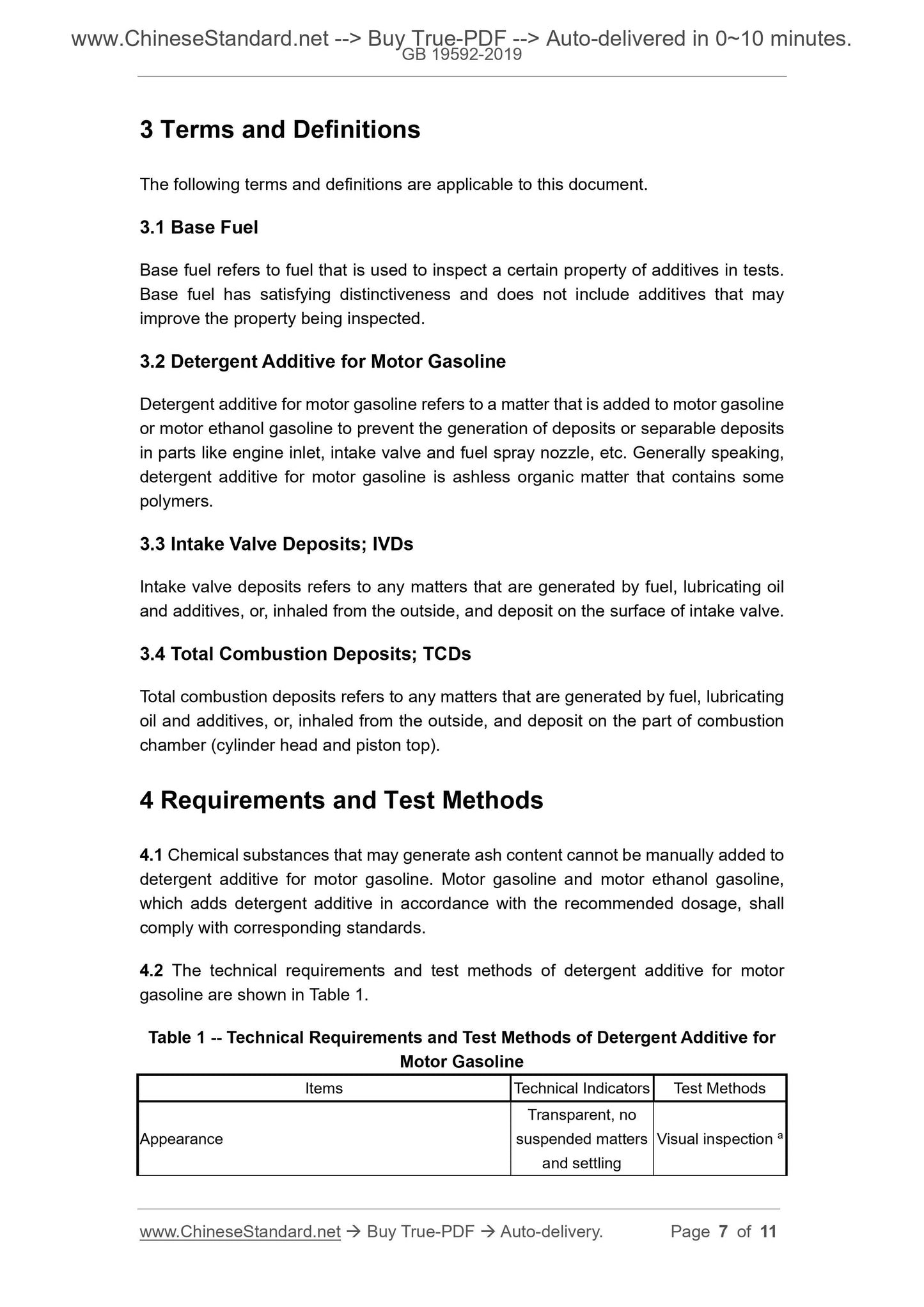

4.2 The technical requirements and test methods of detergent additive for motor

gasoline are shown in Table 1.

Table 1 -- Technical Requirements and Test Methods of Detergent Additive for

Motor Gasoline

Items Technical Indicators Test Methods

Appearance

Transparent, no

suspended matters

and settling

Visual inspection a

When there are no changes in raw materials and production process that might affect

product quality, exit-factory cyclic inspection items include: nozzle mass flow loss rate,

average intake valve deposit mass and total combustion deposit mass increasing rate.

The inspection cycle is one inspection in every three years of normal production.

5.1.2 Type inspection

Type inspection items include all the items stipulated in the technical requirements in

Table 1.

Under the following circumstances, type inspection shall be conducted:

a) When new products are put into production or products are receiving type

approval;

b) Where there are relatively significant changes in raw materials and production

process that might affect product quality;

c) When production is suspended for over two consecutive years, then, resumed.

5.2 Group Batch

Under the condition that raw materials and production process remain changeless,

every tin or kettle being produced shall be considered as one batch.

5.3 Sampling

Sampling shall comply with GB/T 4756. Sampling quantity shall be not less than 1 L;

reserve for inspection and as reserved sample.

5.4 Determination Rules

When the result of exit-factory inspection and the result of type inspection completely

comply with the stipulat...

Get QUOTATION in 1-minute: Click GB 19592-2019

Historical versions: GB 19592-2019

Preview True-PDF (Reload/Scroll if blank)

GB 19592-2019: Detergent additive for motor gasoline

GB 19592-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 75.140

E 61

Replacing GB 19592-2004

Detergent Additive for Motor Gasoline

ISSUED ON: OCTOBER 14, 2019

IMPLEMENTED ON: MAY 1, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 7

4 Requirements and Test Methods ... 7

5 Inspection Rules ... 8

6 Marking, Packaging, Transportation and Storage ... 10

7 Safety ... 10

Appendix A (Normative) Base Fuel ... 11

Foreword

All the technical content in this Standard is mandatory.

This Standard was drafted in accordance with the rules in GB/T 1.1-2009.

This Standard serves as a replacement of GB 19592-2004 Detergent Additive for

Vehicle Gasoline. In comparison with GB 19592-2004, the main technical changes are

as follows:

---The scope of application is modified (see Chapter 1);

---Normative references are modified (see Chapter 2);

---The definition of base fuel is modified (see 3.1);

---The definition of detergent additive for motor gasoline is modified (see 3.2);

---The definition of intake system is deleted (see 3.3 in Version 2004);

---The definition of intake valve deposits is modified (see 3.3);

---The definition of total combustion deposits is modified (see 3.4);

---Table content in the previous version is modified into the content in 4.1 (see 4.1;

Table 1 in Version 2004);

---Pour point indicator is modified from “not higher than -15 °C” into “not higher

than -20 °C” (see Table 1);

---Flash point indicator is modified from “not lower than 45 °C” into “not lower than

60 °C” (see Table 1);

---The technical requirements of sulfur content and chlorine content are added

(see Table 1);

---The expression of technical requirements of anti-rust property is modified from

“not more than 5%” into “not more than moderate rust” (see Table 1);

---The expression of fuel nozzle cleanliness is deleted and modified into “nozzle

mass flow loss rate” (see Table 1);

---The requirements of deposit decline rate of intake system are deleted (see Table

1 in Version 2004);

---“Simulated intake valve deposit decline rate” is modified into “simulated intake

valve deposit mass”; “report” is modified into “not more than 2.0 mg”; test

method is modified into GB/T 37322-2019 (see Table 1);

Detergent Additive for Motor Gasoline

Warning: if appropriate precautions are not abided by, there might be dangers

in the production, storage, transportation and usage process of products that

belong to this Standard. This Standard does not intend to propose suggestions

to all the safety issues related with the products. Before putting this Standard

into effect, users shall undertake the responsibility of establishing appropriate

safety and preventive measures; confirming the applicability of relevant

stipulations and restrictions.

1 Scope

This Standard stipulates the terms and definitions, requirements, test methods,

inspection rules, marking, packaging, transportation, storage and safety of detergent

additive for motor gasoline.

This Standard is applicable to detergent additives used in motor gasoline and motor

ethanol gasoline.

2 Normative References

The following documents are indispensable to the application of this document. In

terms of references with a specified date, only versions with a specified date are

applicable to this document. In terms of references without a specified date, the latest

version (including all the modifications) is applicable to this document.

GB 190 Packing Symbol of Dangerous Goods;

GB/T 261 Determination of Flash Point - Pensky-Martens Closed Cup Method;

GB/T 511 Petroleum, Petroleum Products and Additives - Method for Determination of

Mechanical Admixtures;

GB/T 3535 Petroleum Products - Determination of Pour Point;

GB/T 4756 Method for Manual Sampling of Petroleum Liquids;

GB/T 11140 Standard Test Method for Sulfur in Petroleum Products by Wavelength

Dispersive X-ray Fluorescence Spectrometry;

GB 17930 Gasoline for Motor Vehicles;

GB/T 19230.1 Test Method for Evaluating Gasoline Detergent in Use - Part 1: Test

Method for Rust-preventing Characteristics of Gasoline Detergent;

3 Terms and Definitions

The following terms and definitions are applicable to this document.

3.1 Base Fuel

Base fuel refers to fuel that is used to inspect a certain property of additives in tests.

Base fuel has satisfying distinctiveness and does not include additives that may

improve the property being inspected.

3.2 Detergent Additive for Motor Gasoline

Detergent additive for motor gasoline refers to a matter that is added to motor gasoline

or motor ethanol gasoline to prevent the generation of deposits or separable deposits

in parts like engine inlet, intake valve and fuel spray nozzle, etc. Generally speaking,

detergent additive for motor gasoline is ashless organic matter that contains some

polymers.

3.3 Intake Valve Deposits; IVDs

Intake valve deposits refers to any matters that are generated by fuel, lubricating oil

and additives, or, inhaled from the outside, and deposit on the surface of intake valve.

3.4 Total Combustion Deposits; TCDs

Total combustion deposits refers to any matters that are generated by fuel, lubricating

oil and additives, or, inhaled from the outside, and deposit on the part of combustion

chamber (cylinder head and piston top).

4 Requirements and Test Methods

4.1 Chemical substances that may generate ash content cannot be manually added to

detergent additive for motor gasoline. Motor gasoline and motor ethanol gasoline,

which adds detergent additive in accordance with the recommended dosage, shall

comply with corresponding standards.

4.2 The technical requirements and test methods of detergent additive for motor

gasoline are shown in Table 1.

Table 1 -- Technical Requirements and Test Methods of Detergent Additive for

Motor Gasoline

Items Technical Indicators Test Methods

Appearance

Transparent, no

suspended matters

and settling

Visual inspection a

When there are no changes in raw materials and production process that might affect

product quality, exit-factory cyclic inspection items include: nozzle mass flow loss rate,

average intake valve deposit mass and total combustion deposit mass increasing rate.

The inspection cycle is one inspection in every three years of normal production.

5.1.2 Type inspection

Type inspection items include all the items stipulated in the technical requirements in

Table 1.

Under the following circumstances, type inspection shall be conducted:

a) When new products are put into production or products are receiving type

approval;

b) Where there are relatively significant changes in raw materials and production

process that might affect product quality;

c) When production is suspended for over two consecutive years, then, resumed.

5.2 Group Batch

Under the condition that raw materials and production process remain changeless,

every tin or kettle being produced shall be considered as one batch.

5.3 Sampling

Sampling shall comply with GB/T 4756. Sampling quantity shall be not less than 1 L;

reserve for inspection and as reserved sample.

5.4 Determination Rules

When the result of exit-factory inspection and the result of type inspection completely

comply with the stipulat...

Share