1

/

of

7

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 5009.91-2017 English PDF

GB 5009.91-2017 English PDF

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 5009.91-2017

Historical versions: GB 5009.91-2017

Preview True-PDF (Reload/Scroll if blank)

GB 5009.91-2017: Food safety national standard -- Determination of potassium and sodium in food

GB 5009.91-2017

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

National food safety standard

Determination of potassium and sodium in foods

ISSUED ON. APRIL 06, 2017

IMPLEMENTED ON. OCTOBER 06, 2017

Issued by. National Health and Family Planning Commission of the PRC;

State Food and Drug Administration

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of contents

Foreword ... 3

1 Scope ... 4

2 Principle... 4

3 Reagents and materials ... 4

4 Instruments and equipment ... 6

5 Analytical procedures ... 6

6 Expression of analytical results ... 9

7 Precision... 9

8 Others ... 9

9 Principles ... 10

10 Reagents and materials... 10

11 Instruments and equipment ... 11

12 Analytical procedures ... 12

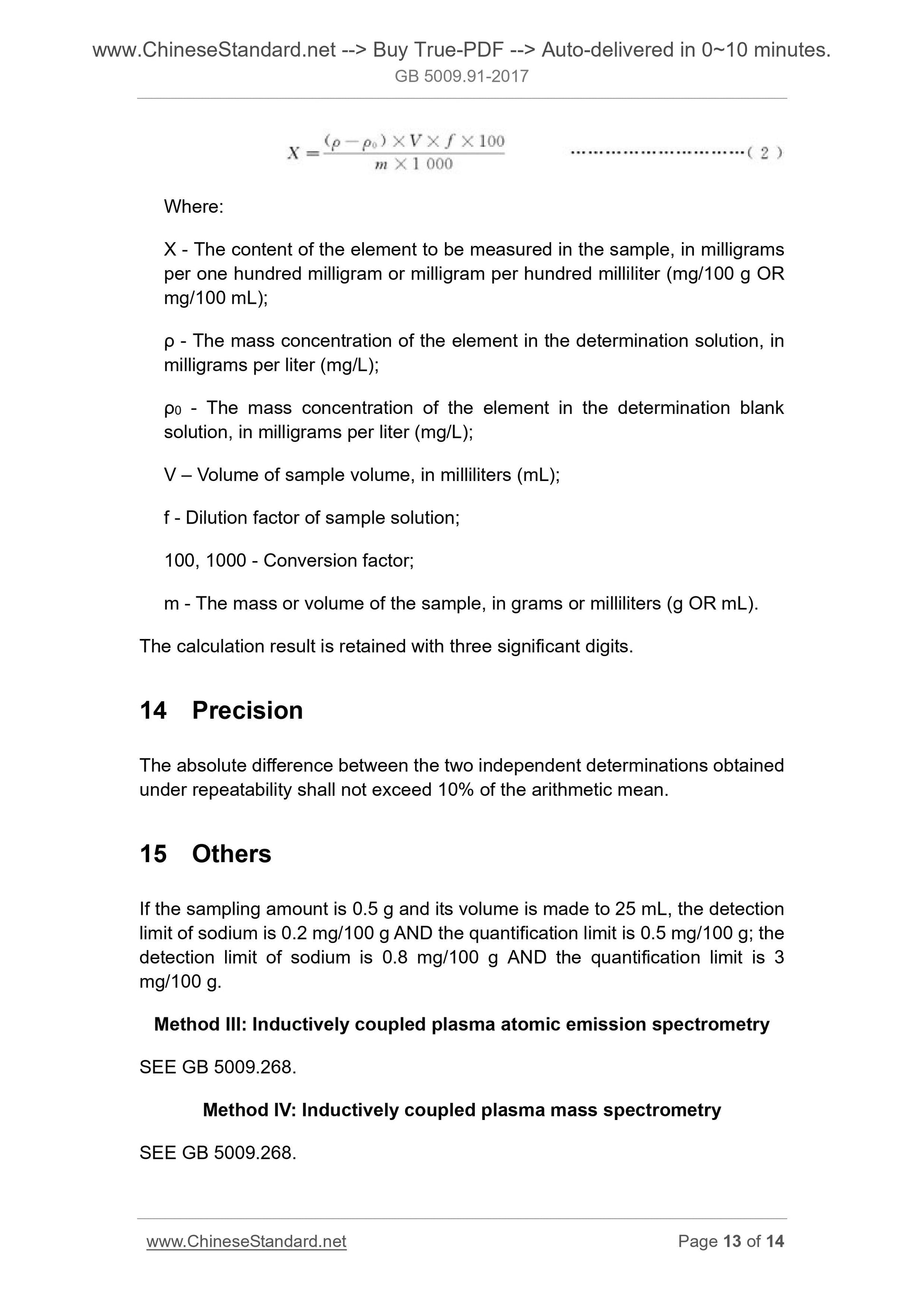

13 Expression of analytical results ... 12

14 Precision ... 13

15 Others ... 13

Appendix A Sample determination reference condition ... 14

Foreword

This standard replaces the potassium and sodium determination part in GB/T

5009.91-2003 “Determination of potassium and sodium in foods”, GB/T

15402-1994 “Fruits, vegetables and derived products – determination of

sodium and potassium”, NY 82.18-1988 “Determination of potassium and

sodium in fruit juice”, GB 5413.21-2010 “National food safety standard –

Determination of calcium, iron, zinc, sodium, potassium, magnesium, copper

and manganese in foods for infants and young children, milk and milk

products”, GB/T 18932.11-2002 “Method for determination of potassium,

phosphorus, iron, calcium, zinc, aluminum, sodium, magnesium, boron,

manganese, copper, barium, titanium, vanadium, nickel, cobalt and chromium

in honey - Inductively coupled plasma atomic emission spectrometry (ICP-AES

method”, GB/T 18932.12-2002 “Method for determination of potassium,

sodium, calcium, magnesium, zinc, iron, copper, manganese, chromium, lead

and cadmium contents in honey - Atomic absorption spectrometry”, AND NY/T

1653-2008 “Determination for mineral elements in vegetables, fruits, and

derived products by ICP-AES method”.

As compared with the above standards, the main changes are as follows.

- CHANGE the standard name into “National food safety standard -

Determination of potassium and sodium in foods”;

- MODIFY the flame atomic absorption spectrometry method as the first

method, the flame atomic emission spectrometry method as the second

method, the inductively coupled plasma emission spectroscopy method

as the third method, AND the inductively coupled plasma mass

spectrometry as the fourth method;

- MODIFY some part of the sample preparation;

- MODIFY some part of the sample digestion;

- INCREASE the method detection limit and quantitative limit;

- ADD appendix.

National food safety standard

Determination of potassium and sodium in foods

1 Scope

This standard specifies four methods for the determination of potassium and

sodium in food. the flame atomic absorption spectrometry, the flame atomic

emission spectrometry, the inductively coupled plasma emission spectroscopy,

AND the inductively coupled plasma mass spectrometry.

This standard applies to the determination of potassium and sodium in food.

Method I. Flame atomic absorption spectrometry

2 Principle

After digestion, the sample is injected into the atomic absorption spectrometer.

After the flame atomization, the potassium and sodium respectively absorb the

766.5 nm and 589.0 nm resonance line. AND within a concentration range, its

absorption value is proportional to the contents of potassium and sodium, AND

it is quantified through comparison with standard series.

3 Reagents and materials

Unless otherwise specified, the reagents used in this method are excellent

grade pure, AND the water is level II water as specified in GB/T 6682.

3.1 Reagents

3.1.1 Nitric acid (HNO3).

3.1.2 Perchloric acid (HClO4).

3.1.3 Cesium chloride (CsCl).

3.2 Reagent preparation

3.2.1 Mixed acid [perchloric acid + nitric acid (1 + 9)]. TAKE 100 mL of

perchloric acid; slowly ADD it into 900 mL of nitric acid; MIX it uniformly.

3.2.2 Nitric acid solution (1 + 99). TAKE 10 mL of nitric acid; slowly ADD it into

990 mL of water; MIX it uniformly.

3.2.3 Cesium chloride solution (50 g/L). DISSOLVE 5.0 g of cesium chloride in

water; USE water to dilute it to 100 mL.

3.3 Standard substance

3.3.1 Potassium chloride standard substance (KCl). its purity is greater than

99.99%.

3.3.2 Sodium chloride standard substance (NaCl). its purity is greater than

99.99%.

3.4 Preparation of standard solution

3.4.1 Potassium and sodium standard stock solution (1000 mg/L). PLACE the

potassium chloride or sodium chloride in the oven at 110 °C ~ 120 °C to dry it

for 2 h. Accurately WEIGH 1.9068 g of potassium chloride or 2.5421 g of

sodium chloride; respectively DISSOLVE it into water; TRANSFER it into a

1000 mL volumetric flask; DILUTE it to the mark; MIX it uniformly; STORE it in

a polyethylene bottle; PRESERVE it at 4 °C; or otherwise USE the standard

solution which had been certified and awarded with the standard substance

certificate by the state.

3.4.2 Potassium and sodium standard working solution (100 mg/L). accurately

PIPETTE 10.0 mL of potassium or sodium standard stock solution in a 100 mL

volumetric flask; USE water to dilute it to the mark; STORE it in a polyethylene

bottle; PRESERVE it at 4 °C.

3.4.3 Potassium and sodium standard series working solution. accurately

PIPETTE 0 mL, 0.1 mL, 0.5 mL, 1.0 mL, 2.0 mL, and 4.0 mL of potassium

standard working solution in 100 mL volumetric flask; ADD 4 mL of cesium

chloride solution; USE water to make its volume reach to the mark; MIX it

uniformly. The concentration of potassium in this standard series working

solution is 0 mg/L, 0.100 mg/L, 0.500 mg/L, 1.00 mg/L, 2.00 mg/L, and 4.00

mg/L, respectively; AND it may, in accordance with the potassium

concentration in the actual sample solution, appropriately adjust the

concentration range of the standard solution. Accurately PIPETTE 0 mL, 0.5

mL, 1.0 mL, 2.0 mL, 3.0 mL, and 4.0 mL of sodium standard working solution in

100 mL volumetric flask; ADD 4 mL of cesium chloride solution; USE water to

make its volume reach to the mark; MIX it uniformly. The concentration of

sodium in the standard series working solution is 0 mg/L, 0.500 mg/L, 1.00

mg/L, 2.00 mg/L, 3.00 mg/L, and 4.00 mg/L, respectively; AND it may, in

WEIGH 0.5 g ~ 5 g (accurate to 0.001 g) of sample in the glass OR Teflon

pressure digestion tank; as for the samples containing ethanol or carbon

dioxide, PLACE it on the heating plate to heat it at low temperature to remove

ethanol or carbon dioxide; ADD 10 mL of mixed acid; COVER and PLACE it for

1 h or overnight; PLACE it in the adjustable temperature control electric

heating plate or furnace for digestion; if it changes into dark brown, COOL it

down and ADD the mixed acid, until white smoke is generated AND the

digestion solution is in colorless transparent OR in light yellow; COOL it down;

USE water to make its volume reach to 25 mL or 50 mL; MIX it uniformly to

prepare for use; and meanwhile MAKE blank test.

5.2.4 Dry digestion method

WEIGH 0.5 g ~ 5 g (accurate to 0.001 g) of sample in the crucible; MAKE it

subject to carbonization in the electric furnace at small fire to make it

smokeless; PLACE it into the 525 °C ± 25 °C muffle furnace for ashing for 5 ...

Get QUOTATION in 1-minute: Click GB 5009.91-2017

Historical versions: GB 5009.91-2017

Preview True-PDF (Reload/Scroll if blank)

GB 5009.91-2017: Food safety national standard -- Determination of potassium and sodium in food

GB 5009.91-2017

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

National food safety standard

Determination of potassium and sodium in foods

ISSUED ON. APRIL 06, 2017

IMPLEMENTED ON. OCTOBER 06, 2017

Issued by. National Health and Family Planning Commission of the PRC;

State Food and Drug Administration

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of contents

Foreword ... 3

1 Scope ... 4

2 Principle... 4

3 Reagents and materials ... 4

4 Instruments and equipment ... 6

5 Analytical procedures ... 6

6 Expression of analytical results ... 9

7 Precision... 9

8 Others ... 9

9 Principles ... 10

10 Reagents and materials... 10

11 Instruments and equipment ... 11

12 Analytical procedures ... 12

13 Expression of analytical results ... 12

14 Precision ... 13

15 Others ... 13

Appendix A Sample determination reference condition ... 14

Foreword

This standard replaces the potassium and sodium determination part in GB/T

5009.91-2003 “Determination of potassium and sodium in foods”, GB/T

15402-1994 “Fruits, vegetables and derived products – determination of

sodium and potassium”, NY 82.18-1988 “Determination of potassium and

sodium in fruit juice”, GB 5413.21-2010 “National food safety standard –

Determination of calcium, iron, zinc, sodium, potassium, magnesium, copper

and manganese in foods for infants and young children, milk and milk

products”, GB/T 18932.11-2002 “Method for determination of potassium,

phosphorus, iron, calcium, zinc, aluminum, sodium, magnesium, boron,

manganese, copper, barium, titanium, vanadium, nickel, cobalt and chromium

in honey - Inductively coupled plasma atomic emission spectrometry (ICP-AES

method”, GB/T 18932.12-2002 “Method for determination of potassium,

sodium, calcium, magnesium, zinc, iron, copper, manganese, chromium, lead

and cadmium contents in honey - Atomic absorption spectrometry”, AND NY/T

1653-2008 “Determination for mineral elements in vegetables, fruits, and

derived products by ICP-AES method”.

As compared with the above standards, the main changes are as follows.

- CHANGE the standard name into “National food safety standard -

Determination of potassium and sodium in foods”;

- MODIFY the flame atomic absorption spectrometry method as the first

method, the flame atomic emission spectrometry method as the second

method, the inductively coupled plasma emission spectroscopy method

as the third method, AND the inductively coupled plasma mass

spectrometry as the fourth method;

- MODIFY some part of the sample preparation;

- MODIFY some part of the sample digestion;

- INCREASE the method detection limit and quantitative limit;

- ADD appendix.

National food safety standard

Determination of potassium and sodium in foods

1 Scope

This standard specifies four methods for the determination of potassium and

sodium in food. the flame atomic absorption spectrometry, the flame atomic

emission spectrometry, the inductively coupled plasma emission spectroscopy,

AND the inductively coupled plasma mass spectrometry.

This standard applies to the determination of potassium and sodium in food.

Method I. Flame atomic absorption spectrometry

2 Principle

After digestion, the sample is injected into the atomic absorption spectrometer.

After the flame atomization, the potassium and sodium respectively absorb the

766.5 nm and 589.0 nm resonance line. AND within a concentration range, its

absorption value is proportional to the contents of potassium and sodium, AND

it is quantified through comparison with standard series.

3 Reagents and materials

Unless otherwise specified, the reagents used in this method are excellent

grade pure, AND the water is level II water as specified in GB/T 6682.

3.1 Reagents

3.1.1 Nitric acid (HNO3).

3.1.2 Perchloric acid (HClO4).

3.1.3 Cesium chloride (CsCl).

3.2 Reagent preparation

3.2.1 Mixed acid [perchloric acid + nitric acid (1 + 9)]. TAKE 100 mL of

perchloric acid; slowly ADD it into 900 mL of nitric acid; MIX it uniformly.

3.2.2 Nitric acid solution (1 + 99). TAKE 10 mL of nitric acid; slowly ADD it into

990 mL of water; MIX it uniformly.

3.2.3 Cesium chloride solution (50 g/L). DISSOLVE 5.0 g of cesium chloride in

water; USE water to dilute it to 100 mL.

3.3 Standard substance

3.3.1 Potassium chloride standard substance (KCl). its purity is greater than

99.99%.

3.3.2 Sodium chloride standard substance (NaCl). its purity is greater than

99.99%.

3.4 Preparation of standard solution

3.4.1 Potassium and sodium standard stock solution (1000 mg/L). PLACE the

potassium chloride or sodium chloride in the oven at 110 °C ~ 120 °C to dry it

for 2 h. Accurately WEIGH 1.9068 g of potassium chloride or 2.5421 g of

sodium chloride; respectively DISSOLVE it into water; TRANSFER it into a

1000 mL volumetric flask; DILUTE it to the mark; MIX it uniformly; STORE it in

a polyethylene bottle; PRESERVE it at 4 °C; or otherwise USE the standard

solution which had been certified and awarded with the standard substance

certificate by the state.

3.4.2 Potassium and sodium standard working solution (100 mg/L). accurately

PIPETTE 10.0 mL of potassium or sodium standard stock solution in a 100 mL

volumetric flask; USE water to dilute it to the mark; STORE it in a polyethylene

bottle; PRESERVE it at 4 °C.

3.4.3 Potassium and sodium standard series working solution. accurately

PIPETTE 0 mL, 0.1 mL, 0.5 mL, 1.0 mL, 2.0 mL, and 4.0 mL of potassium

standard working solution in 100 mL volumetric flask; ADD 4 mL of cesium

chloride solution; USE water to make its volume reach to the mark; MIX it

uniformly. The concentration of potassium in this standard series working

solution is 0 mg/L, 0.100 mg/L, 0.500 mg/L, 1.00 mg/L, 2.00 mg/L, and 4.00

mg/L, respectively; AND it may, in accordance with the potassium

concentration in the actual sample solution, appropriately adjust the

concentration range of the standard solution. Accurately PIPETTE 0 mL, 0.5

mL, 1.0 mL, 2.0 mL, 3.0 mL, and 4.0 mL of sodium standard working solution in

100 mL volumetric flask; ADD 4 mL of cesium chloride solution; USE water to

make its volume reach to the mark; MIX it uniformly. The concentration of

sodium in the standard series working solution is 0 mg/L, 0.500 mg/L, 1.00

mg/L, 2.00 mg/L, 3.00 mg/L, and 4.00 mg/L, respectively; AND it may, in

WEIGH 0.5 g ~ 5 g (accurate to 0.001 g) of sample in the glass OR Teflon

pressure digestion tank; as for the samples containing ethanol or carbon

dioxide, PLACE it on the heating plate to heat it at low temperature to remove

ethanol or carbon dioxide; ADD 10 mL of mixed acid; COVER and PLACE it for

1 h or overnight; PLACE it in the adjustable temperature control electric

heating plate or furnace for digestion; if it changes into dark brown, COOL it

down and ADD the mixed acid, until white smoke is generated AND the

digestion solution is in colorless transparent OR in light yellow; COOL it down;

USE water to make its volume reach to 25 mL or 50 mL; MIX it uniformly to

prepare for use; and meanwhile MAKE blank test.

5.2.4 Dry digestion method

WEIGH 0.5 g ~ 5 g (accurate to 0.001 g) of sample in the crucible; MAKE it

subject to carbonization in the electric furnace at small fire to make it

smokeless; PLACE it into the 525 °C ± 25 °C muffle furnace for ashing for 5 ...

Share