1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 50683-2011 English PDF (GB50683-2011)

GB 50683-2011 English PDF (GB50683-2011)

Regular price

$145.00 USD

Regular price

Sale price

$145.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 50683-2011

Historical versions: GB 50683-2011

Preview True-PDF (Reload/Scroll if blank)

GB 50683-2011: Code for acceptance of field equipment, industrial pipe welding construction quality

GB 50683-2011

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

UDC

P GB 50683-2011

Code for Acceptance of Field Equipment,

Industrial Pipe Welding Construction Quality

ISSUED ON: FEBRUARY 18, 2011

IMPLEMENTED ON: MAY 1, 2012

Jointly issued by: Ministry of Housing and Urban-Rural Development of

the People's Republic of China;

General Administration of Quality Supervision,

Inspection and Quarantine of the People's Republic of

China.

Table of Contents

Foreword ... 4

1 General Provisions ... 7

2 Terms ... 8

3 Basic Requirements ... 9

3.1 Division for Acceptance of Construction Quality ... 9

3.2 Acceptance of Construction Quality ... 9

3.3 Procedure and Organization for Acceptance of Construction Quality ... 10

4 Materials ... 11

5 Preparation Before Welding ... 13

6 Welding ... 19

7 Heat Treatment After Welding ... 21

8 Examination of Welded Seam Quality ... 24

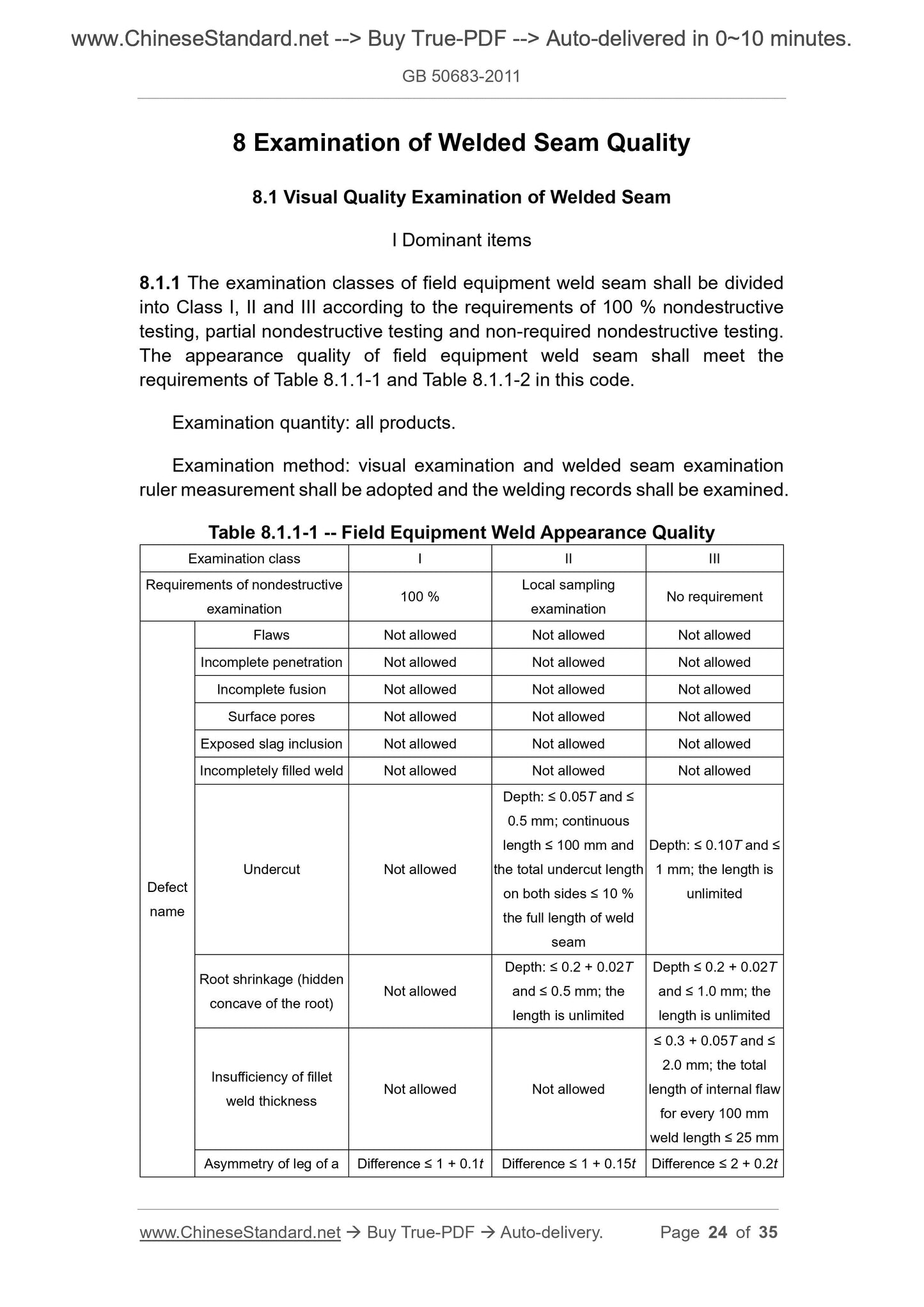

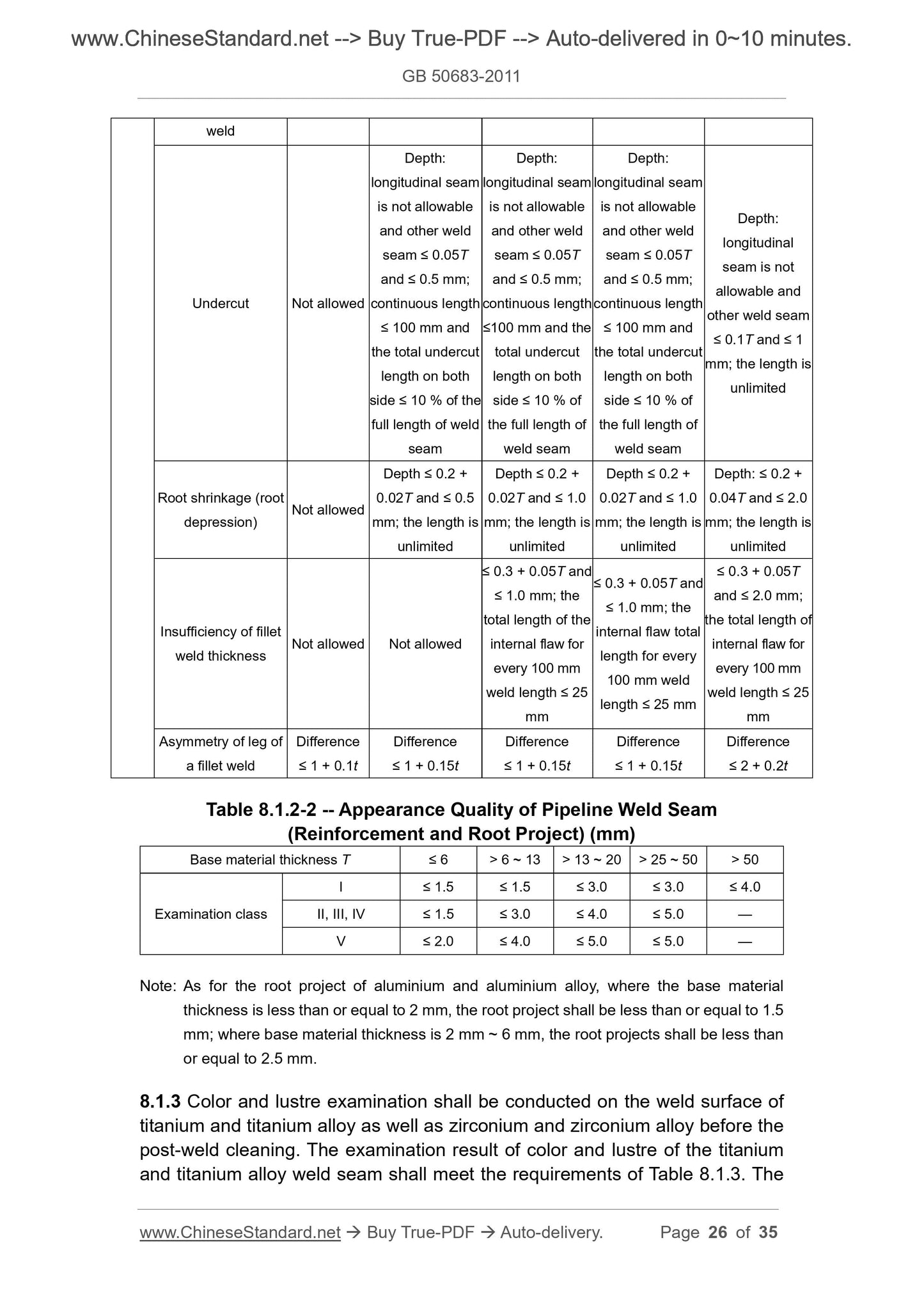

8.1 Visual Quality Examination of Welded Seam ... 24

8.2 Nondestructive Detection of Welded Seam Surface ... 28

8.3 Radiographic Examination and Ultrasonic Flaw Detection for Welded Seam ... 29

8.4 Other Examination ... 30

Appendix A -- Record for Quality Acceptance of Sub-item Project ... 32

Explanation of Wording in This Code ... 34

List of Quoted Standards ... 35

1 General Provisions

1.0.1 This code was formulated in order to unify the acceptance of welding

quality acceptance of field equipment and industrial pipelines and strengthen

the engineering quality management.

1.0.2 This code is applicable to the construction quality acceptance of the

welding engineering of the metallic materials such as carbon steel, alloy steel,

aluminium and aluminium alloy, copper and copper alloy, nickel and nickel alloy,

titanium and titanium alloy as well as zirconium and zirconium alloy.

1.0.3 The codes shall be applied together with “Code for Construction of Field

Equipment, Industrial Pipe Welding Engineering” GB 50236.

1.0.4 The requirements for the construction quality acceptance of engineering

technical document and contract agreement document shall not be less than

those specified in this code.

1.0.5 Except meeting this code, the acceptance of welding engineering

construction quality shall also meet the requirements of the current relevant

national standards.

2 Terms

2.0.1 100 % examination

The entire examination of a specific item in a specified examination batch

2.0.2 Random sampling examination

The examination is conducted on a specific item by a certain proportion of

random sampling.

2.0.3 Local sampling examination

A specific part of examination is conducted for a specific item on every piece in

a specific examination batch.

3 Basic Requirements

3.1 Division for Acceptance of Construction Quality

3.1.1 The welding engineering quality acceptance of field equipment and

industrial pipelines shall be conducted on the division into the sub-item project.

3.1.2 The sub-item project of field equipment welding engineering shall be

divided according to the piece of field equipment and the sub-item project of

industrial pipeline welding engineering shall be divided into according to the

pipeline grades and materials.

3.2 Acceptance of Construction Quality

3.2.1 The quality acceptance of sub-item project shall meet the following

requirements:

1 The dominant items shall meet the requirements of this code.

2 The measured value of every item sampling examination for general

items shall fall into the range of the permissible variation as specified in this

code.

3.2.2 The welding engineering quality acceptance document and record shall

include the following content:

1 The welding engineering construction technology documents, construction

records and reports and shall meet the requirements of the current national

standard “Code for Construction of Field Equipment, Industrial Pipe Welding

Engineering” GB 50236.

2 The quality acceptance records, content and form of sub-item project

quality acceptance records shall meet the requirements of Appendix A of this

code.

3.2.3 Where the welding engineering does not meet the requirements of this

code, it shall be processed according to the following requirements:

1 The acceptance shall be re-conducted for the sub-divisional work after

rework or repair.

2 The sub-item project capable of reaching the design requirement in the

examination and verification of qualified examination organizations shall be

accepted.

3 The sub-item project that cannot reach the design requirement in the

4 Materials

Dominant items

4.0.1 Before the application of base metal, the examination and acceptance shall

be conducted according to the requirements of design document; the material,

specification and appearance quality shall meet the requirements of the product

standard and design document of base metal. The material marker shall be

clear and complete and shall be traced back to the product quality certification.

Examination quantity: all products

Examination method: quality proof documents shall be examined, visual

examination and measurement examination shall be conduced and spectrogram

examination may be conducted if necessary.

4.0.2 Before the application of the welding materials, the visual quality, quality

proof documents, external packing and packing mark shall be examined.

Corresponding tests or reexamination shall be carried out where there is any

doubt. The quality shall conform to the design document and meet the following

requirements:

1 The welding materials shall be provided with intact packing as well as

clear and complete marking on the package.

2 Quality proof documents shall meet requirements of the relevant current

national product standards and technical conditions of order.

3 The surface of the welding materials shall not be damp and contaminated,

shall be free from the electrode coating damage or defects influencing welding

quality and the solder wire surface shall be smooth and neat. The identification

mark of the welding materials shall be clear and firm and conform to the real

products.

Examination quantity: all.

Examination method: quality proof documents shall be examined, visual

examination shall be conducted and the examination acceptance record or

reexamination reports of welding materials shall be examined.

4.0.3 The welding material shall be baked according to the specification before

application and shall be kept dry in application process and the baking

conditions shall meet the requirements of welding materials directions and

relevant technical document.

Before the application, de-oiling, derusting and cleaning processes shall be

5 Preparation Before Welding

I Dominant items

5.0.1 Where nondestructive testing is required for the groove face in the design

document, magnetic particle testing or penetrant testing shall be conducted.

Groove face quality shall not be lower than Class I as specified in the current

professional standard “Nondestructive Testing of Pressure Equipment” JB/T 4730.

Examination quantity: it shall meet the requirements of the design

document.

Examination method: the magnetic particle testing reports or penetrant

testing reports shall be examined.

5.0.2 As for the weld seam specified for weld preheating, the preheating

temperature in the weldment preheating zone shall be examined before the

welding and shall meet the requirements of design document and welding

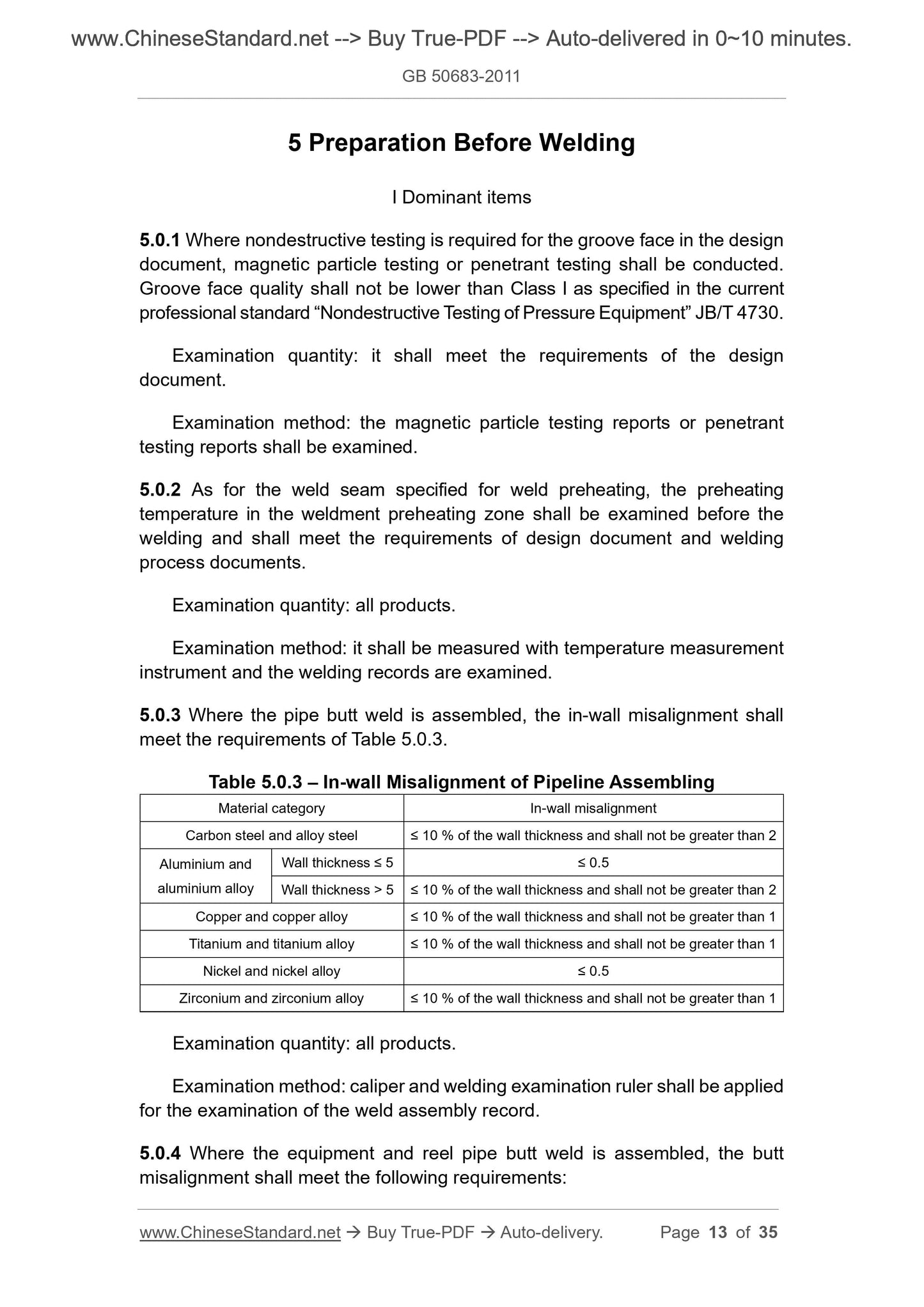

proce...

Get QUOTATION in 1-minute: Click GB 50683-2011

Historical versions: GB 50683-2011

Preview True-PDF (Reload/Scroll if blank)

GB 50683-2011: Code for acceptance of field equipment, industrial pipe welding construction quality

GB 50683-2011

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

UDC

P GB 50683-2011

Code for Acceptance of Field Equipment,

Industrial Pipe Welding Construction Quality

ISSUED ON: FEBRUARY 18, 2011

IMPLEMENTED ON: MAY 1, 2012

Jointly issued by: Ministry of Housing and Urban-Rural Development of

the People's Republic of China;

General Administration of Quality Supervision,

Inspection and Quarantine of the People's Republic of

China.

Table of Contents

Foreword ... 4

1 General Provisions ... 7

2 Terms ... 8

3 Basic Requirements ... 9

3.1 Division for Acceptance of Construction Quality ... 9

3.2 Acceptance of Construction Quality ... 9

3.3 Procedure and Organization for Acceptance of Construction Quality ... 10

4 Materials ... 11

5 Preparation Before Welding ... 13

6 Welding ... 19

7 Heat Treatment After Welding ... 21

8 Examination of Welded Seam Quality ... 24

8.1 Visual Quality Examination of Welded Seam ... 24

8.2 Nondestructive Detection of Welded Seam Surface ... 28

8.3 Radiographic Examination and Ultrasonic Flaw Detection for Welded Seam ... 29

8.4 Other Examination ... 30

Appendix A -- Record for Quality Acceptance of Sub-item Project ... 32

Explanation of Wording in This Code ... 34

List of Quoted Standards ... 35

1 General Provisions

1.0.1 This code was formulated in order to unify the acceptance of welding

quality acceptance of field equipment and industrial pipelines and strengthen

the engineering quality management.

1.0.2 This code is applicable to the construction quality acceptance of the

welding engineering of the metallic materials such as carbon steel, alloy steel,

aluminium and aluminium alloy, copper and copper alloy, nickel and nickel alloy,

titanium and titanium alloy as well as zirconium and zirconium alloy.

1.0.3 The codes shall be applied together with “Code for Construction of Field

Equipment, Industrial Pipe Welding Engineering” GB 50236.

1.0.4 The requirements for the construction quality acceptance of engineering

technical document and contract agreement document shall not be less than

those specified in this code.

1.0.5 Except meeting this code, the acceptance of welding engineering

construction quality shall also meet the requirements of the current relevant

national standards.

2 Terms

2.0.1 100 % examination

The entire examination of a specific item in a specified examination batch

2.0.2 Random sampling examination

The examination is conducted on a specific item by a certain proportion of

random sampling.

2.0.3 Local sampling examination

A specific part of examination is conducted for a specific item on every piece in

a specific examination batch.

3 Basic Requirements

3.1 Division for Acceptance of Construction Quality

3.1.1 The welding engineering quality acceptance of field equipment and

industrial pipelines shall be conducted on the division into the sub-item project.

3.1.2 The sub-item project of field equipment welding engineering shall be

divided according to the piece of field equipment and the sub-item project of

industrial pipeline welding engineering shall be divided into according to the

pipeline grades and materials.

3.2 Acceptance of Construction Quality

3.2.1 The quality acceptance of sub-item project shall meet the following

requirements:

1 The dominant items shall meet the requirements of this code.

2 The measured value of every item sampling examination for general

items shall fall into the range of the permissible variation as specified in this

code.

3.2.2 The welding engineering quality acceptance document and record shall

include the following content:

1 The welding engineering construction technology documents, construction

records and reports and shall meet the requirements of the current national

standard “Code for Construction of Field Equipment, Industrial Pipe Welding

Engineering” GB 50236.

2 The quality acceptance records, content and form of sub-item project

quality acceptance records shall meet the requirements of Appendix A of this

code.

3.2.3 Where the welding engineering does not meet the requirements of this

code, it shall be processed according to the following requirements:

1 The acceptance shall be re-conducted for the sub-divisional work after

rework or repair.

2 The sub-item project capable of reaching the design requirement in the

examination and verification of qualified examination organizations shall be

accepted.

3 The sub-item project that cannot reach the design requirement in the

4 Materials

Dominant items

4.0.1 Before the application of base metal, the examination and acceptance shall

be conducted according to the requirements of design document; the material,

specification and appearance quality shall meet the requirements of the product

standard and design document of base metal. The material marker shall be

clear and complete and shall be traced back to the product quality certification.

Examination quantity: all products

Examination method: quality proof documents shall be examined, visual

examination and measurement examination shall be conduced and spectrogram

examination may be conducted if necessary.

4.0.2 Before the application of the welding materials, the visual quality, quality

proof documents, external packing and packing mark shall be examined.

Corresponding tests or reexamination shall be carried out where there is any

doubt. The quality shall conform to the design document and meet the following

requirements:

1 The welding materials shall be provided with intact packing as well as

clear and complete marking on the package.

2 Quality proof documents shall meet requirements of the relevant current

national product standards and technical conditions of order.

3 The surface of the welding materials shall not be damp and contaminated,

shall be free from the electrode coating damage or defects influencing welding

quality and the solder wire surface shall be smooth and neat. The identification

mark of the welding materials shall be clear and firm and conform to the real

products.

Examination quantity: all.

Examination method: quality proof documents shall be examined, visual

examination shall be conducted and the examination acceptance record or

reexamination reports of welding materials shall be examined.

4.0.3 The welding material shall be baked according to the specification before

application and shall be kept dry in application process and the baking

conditions shall meet the requirements of welding materials directions and

relevant technical document.

Before the application, de-oiling, derusting and cleaning processes shall be

5 Preparation Before Welding

I Dominant items

5.0.1 Where nondestructive testing is required for the groove face in the design

document, magnetic particle testing or penetrant testing shall be conducted.

Groove face quality shall not be lower than Class I as specified in the current

professional standard “Nondestructive Testing of Pressure Equipment” JB/T 4730.

Examination quantity: it shall meet the requirements of the design

document.

Examination method: the magnetic particle testing reports or penetrant

testing reports shall be examined.

5.0.2 As for the weld seam specified for weld preheating, the preheating

temperature in the weldment preheating zone shall be examined before the

welding and shall meet the requirements of design document and welding

proce...

Share