1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 11064.18-1989 English PDF (GB/T11064.18-1989)

GB/T 11064.18-1989 English PDF (GB/T11064.18-1989)

Regular price

$205.00

Regular price

Sale price

$205.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 11064.18-1989: Lithium carbonate--Determination of calcium, magnesium, copper, zinc, nickel, manganese and cadmium content--Ion exchange-flame atomic absorption spectrometric method

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 11064.18-1989 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 11064.18-1989

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 11064.18-1989 (GB 11064.18-1989)

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

GB/T 11064.18-1989

Lithium carbonate - Determination of calcium,

magnesium, copper, zinc, nickel, manganese and

cadmium contents - Ion exchange-flame atomic

absorption spectrometric method

APPROVED ON: JANUARY 28, 1989

IMPLEMENTED ON: FEBRUARY 01, 1990

Issued by: China Nonferrous Metal Industry Corporation

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Method summary ... 3

4 Reagents and materials ... 4

5 Instruments ... 7

6 Specimen ... 8

7 Analytical steps ... 8

8 Calculation and expression of analysis results... 10

9 Allowable deviation ... 11

Appendix A Instrument working conditions (Informative) ... 12

Additional information ... 12

Lithium carbonate - Determination of calcium,

magnesium, copper, zinc, nickel, manganese and

cadmium contents - Ion exchange-flame atomic

absorption spectrometric method

1 Scope

This standard specifies the determination method of calcium, magnesium,

copper, zinc, nickel, manganese and cadmium in lithium carbonate.

This standard applies to the determination of calcium, magnesium, copper, zinc,

nickel, manganese and cadmium content in phosphor-grade lithium carbonate,

as well as the individual determination of the content of one element.

Measurement range: calcium 0.00010% ~ 0.010%; magnesium, cadmium,

copper, zinc, nickel, manganese 0.00010% ~ 0.0060%.

2 Normative references

GB 1.4 Directives for the work of standardization - Rules for drafting

chemical analysis standards

GB 1467 General rules and regulations of the chemical analysis methods for

products of metallurgical industries

GB 7728 Chemical analysis of metallurgical products - General rule for flame

atomic absorption spectrometric methods

3 Method summary

The sample is decomposed by hydrochloric acid and adjusted to pH 8 ~ 9. Use

the potassium chelating resin t separate and enrich the trace precious impurity

elements calcium, magnesium, copper, nickel, manganese, zinc and cadmium.

The adsorbed impurity elements are respectively eluted by hydrochloric acid

(0.2 mol/L and 1.0 mol/L). At the wavelengths listed in atomic absorption

spectrometer Table 1, use an air-acetylene flame to measure each element

separately.

The standard solution shall have the same acidity as the elution solution.

4.12 Calcium standard solution:

4.12.1 Pipette 25.00 mL of calcium standard stock solution (4.11). Place it in a

250 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly. Each

1 mL of this solution contains 100 µg of calcium.

4.12.2 Pipette 10.00 mL of calcium standard stock solution (4.12.1). Place it in

a 100 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 10 µg of calcium.

4.13 Magnesium standard stock solution: Weigh 1.000 g pure metallic

magnesium (above 99.9%). Place it in a 300 mL beaker. Slowly add 34 mL of

hydrochloric acid (4.1) to dissolve it. Heat to boil. Cool to room temperature.

Transfer it into a 1000 mL volumetric flask. Use water to dilute it to the mark.

Mix it uniformly. Each 1 mL of this solution contains 1 mg of magnesium.

4.14 Magnesium standard solution:

4.14.1 Pipette 25.00 mL of magnesium standard stock solution (4.13). Put it in

a 250 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 100 µg of magnesium.

4.14.2 Pipette 10.00 mL of magnesium standard stock solution (4.14.1). Put it

in a 100 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 10 µg of magnesium.

4.15 Copper standard stock solution: Weigh 1.000 g of pure metallic copper

(above 99.9%) in a 300 mL beaker. Add 20 mL of nitric acid (1 + 1, superior

grade pure) to dissolve. Heat to evaporate it dry. Add 10.0 mL of sulfuric acid.

Heat carefully to evaporate to sulfuric acid fumes. Cool it. Add water and boil

until the salt is completely dissolved. Cool to room temperature. Transfer it into

a 1000 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 1 mg of copper.

4.16 Zinc standard stock solution: Weigh 1.000 g of pure metallic zinc (above

99.9%) in a 300 mL beaker. Add 25.0 mL of hydrochloric acid (1 + 1, superior

grade pure) to dissolve it. Heat to boil it. Cool it to room temperature. Transfer

it into a 1000 mL volumetric flask. Use water to dilute it to the mark. Mix it

uniformly. Each 1 mL of this solution contains 1 mg of zinc.

4.17 Nickel standard stock solution: Weigh 1.000 g of pure metallic nickel

(above 99.9%) in a 300 mL beaker. Add 15 mL of nitric acid (ρ1.42 g/mL,

superior grade pure). Heat at low temperature to completely dissolve it. Boil it.

Cool it to room temperature. Transfer it into a 1000 mL volumetric flask. Use

water to dilute it to the mark. Mix it uniformly. Each 1 mL of this solution contains

1 mg of nickel.

4.18 Manganese standard stock solution: Weigh 1.000 g of pure metallic

manganese (above 99.9%, use diluted sulfuric acid to wash off the oxide from

the surface of the manganese before weighing; then use water to wash off the

acid; bake it dry). Place it in a 300 mL beaker. Add 20 mL of hydrochloric acid

(1 + 1, superior grade pure). Heat to dissolve it. Cool it to room temperature.

Transfer it into a 1000 mL volumetric flask. Use water to dilute it to the mark.

Mix it uniformly. Each 1 mL of this solution contains 1 mg of manganese.

4.19 Cadmium standard stock solution: Weigh 1.000 g of pure metallic cadmium

(above 99.9%). Place it a 300 mL beaker. Add 25.0 mL of hydrochloric acid (4.1)

to dissolve it. Heat to boil it. Cool it to room temperature. Transfer it into a 1000

mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly. Each 1

mL of this solution contains 1 mg of cadmium.

4.20 Mixed standard solution:

4.20.1 Respectively pipette 25.00 mL of copper standard stock solution (4.15),

zinc standard stock solution (4.16), nickel standard stock solution (4.17),

manganese standard stock solution (4.18), cadmium standard stock solution

(4.19) in a 250 mL volumetric flask. Use water to dilute it to the mark. Mix it

uniformly. Each 1 mL of this solution contains 100 µg of copper, zinc, nickel,

manganese, cadmium.

4.20.2 Pipette 10.00 mL of mixed standard solution (4.21.1) in a 100 mL

volumetric flask. Use water to dilute it to the mark. Mix it uniformly. Each 1 mL

of this solution contains 10 µg of copper, zinc, nickel, manganese, cadmium.

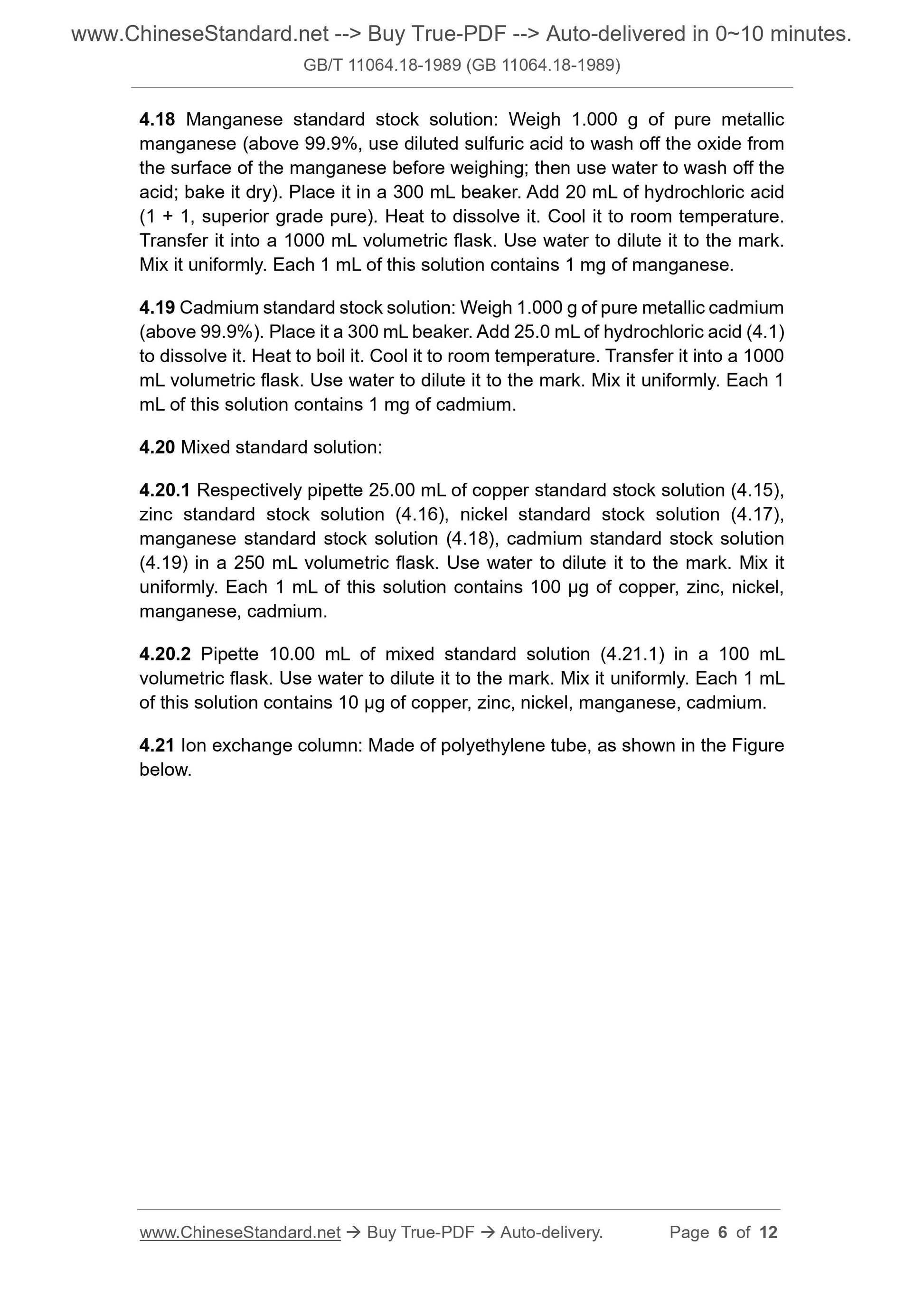

4.21 Ion exchange column: Made of polyethylene tube, as shown in the Figure

below.

7.3.1.1.

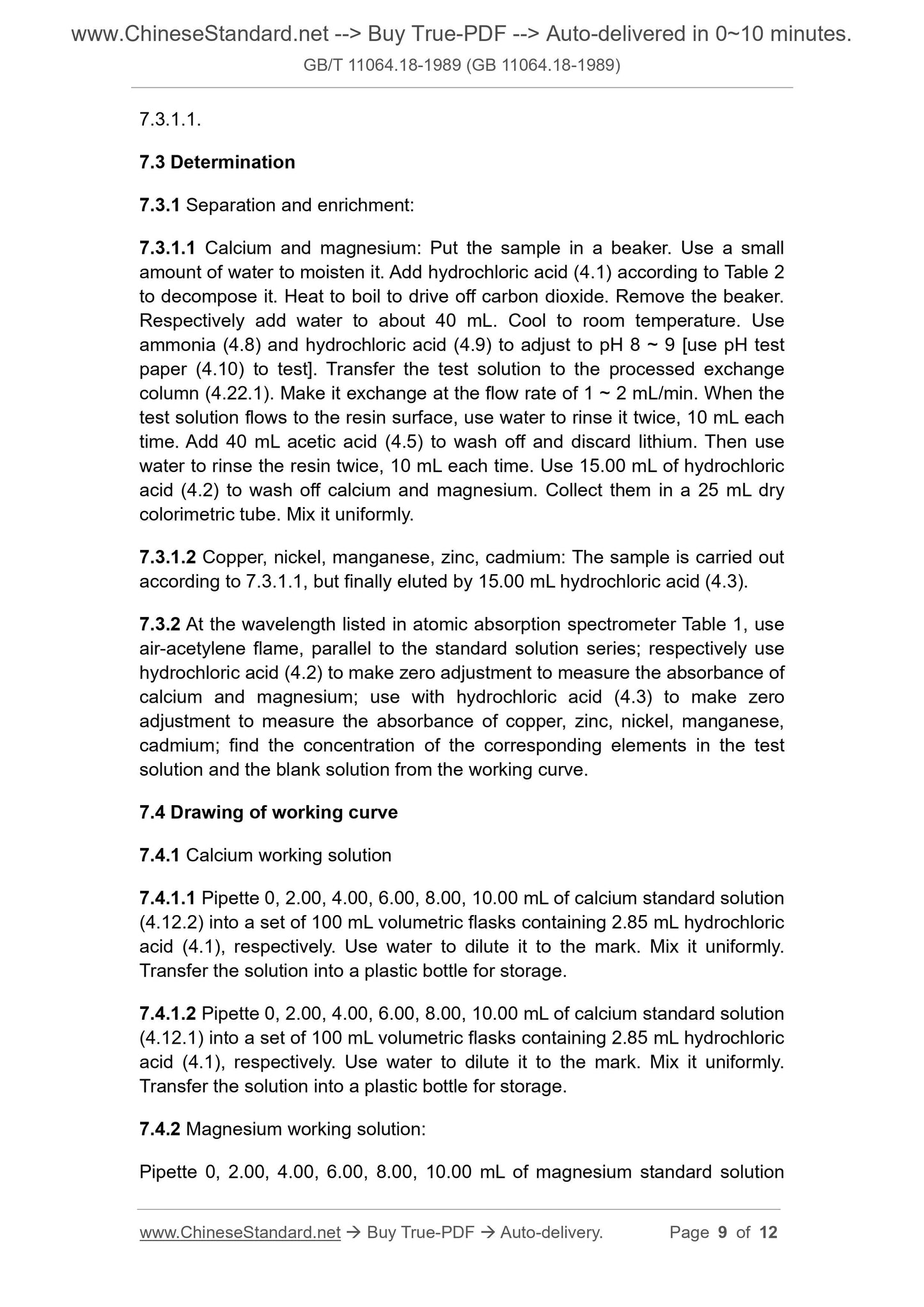

7.3 Determination

7.3.1 Separation and enrichment:

7.3.1.1 Calcium and magnesium: Put the sample in a beaker. Use a small

amount of water to moisten it. Add hydrochloric acid (4.1) according to Table 2

to decompose it. Heat to boil to drive off carbon dioxide. Remove the beaker.

Respectively add water to about 40 mL. Cool to room temperature. Use

ammonia (4.8) and hydrochloric acid (4.9) to adjust to pH 8 ~ 9 [use pH test

paper (4.10) to test]. Transfer the test solution to the processed exchange

column (4.22.1). Make it exchange at the flow rate of 1 ~ 2 mL/min. When the

test solution flows to the resin surface, use water to rinse it twice, 10 mL each

time. Add 40 mL acetic acid (4.5) to wash off and discard lithium. Then use

water to rinse the resin twice, 10 mL each time. Use 15.00 mL of hydrochloric

acid (4.2) to wash off calcium and magnesium. Collect them in a 25 mL dry

colorimetric tube. Mix it uniformly.

7.3.1.2 Copper, nickel, manganese, zinc, cadmium: The sample is carried out

according to 7.3.1.1, but finally eluted by 15.00 mL hydrochloric acid (4.3).

7.3.2 At the wavelength listed in atomic absorption spectrometer Table 1, use

air-acetylene flame, parallel to the standard solution series; respectively use

hydrochloric acid (4.2) to make zero adjustment to measure the absorbance of

calcium and magnesium; use with hydrochloric acid (4.3) to make zero

adjustment to measure the absorbance of copper, zinc, nickel, manganese,

cadmium; find the concentration of the corresponding elements in the test

solution and the blank solution from the working curve.

7.4 Drawing of working curve

7.4.1 Calcium working solution

7.4.1.1 Pipette 0, 2.00, 4.00, 6.00, 8.00, 10.00 mL of calcium standard solution

(4.12.2) into a set of 100 mL volumetric flasks containing 2.85 mL hydrochloric

acid (4.1), respectively. Use water to dilute it to the mark. Mix it uniformly.

Transfer the solution into a plastic bottle for storage.

7.4.1.2 Pipette 0, 2.00, 4.00, 6.00, 8.00, 10.00 mL of calcium standard solution

(4.12.1) into a set of 100 mL volumetric flasks containing 2.85 mL hydrochloric

acid (4.1), respectively. Use water to dilute it to the mark. Mix it uniformly.

Transfer the solution into a plastic bottle for storage.

7.4.2 Magnesium working solution:

Pipette 0, 2.00, 4.00, 6.00, 8.00, 10.00 mL of magnesium standard solution

GB/T 11064.18-1989 (GB 11064.18-1989)

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

GB/T 11064.18-1989

Lithium carbonate - Determination of calcium,

magnesium, copper, zinc, nickel, manganese and

cadmium contents - Ion exchange-flame atomic

absorption spectrometric method

APPROVED ON: JANUARY 28, 1989

IMPLEMENTED ON: FEBRUARY 01, 1990

Issued by: China Nonferrous Metal Industry Corporation

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Method summary ... 3

4 Reagents and materials ... 4

5 Instruments ... 7

6 Specimen ... 8

7 Analytical steps ... 8

8 Calculation and expression of analysis results... 10

9 Allowable deviation ... 11

Appendix A Instrument working conditions (Informative) ... 12

Additional information ... 12

Lithium carbonate - Determination of calcium,

magnesium, copper, zinc, nickel, manganese and

cadmium contents - Ion exchange-flame atomic

absorption spectrometric method

1 Scope

This standard specifies the determination method of calcium, magnesium,

copper, zinc, nickel, manganese and cadmium in lithium carbonate.

This standard applies to the determination of calcium, magnesium, copper, zinc,

nickel, manganese and cadmium content in phosphor-grade lithium carbonate,

as well as the individual determination of the content of one element.

Measurement range: calcium 0.00010% ~ 0.010%; magnesium, cadmium,

copper, zinc, nickel, manganese 0.00010% ~ 0.0060%.

2 Normative references

GB 1.4 Directives for the work of standardization - Rules for drafting

chemical analysis standards

GB 1467 General rules and regulations of the chemical analysis methods for

products of metallurgical industries

GB 7728 Chemical analysis of metallurgical products - General rule for flame

atomic absorption spectrometric methods

3 Method summary

The sample is decomposed by hydrochloric acid and adjusted to pH 8 ~ 9. Use

the potassium chelating resin t separate and enrich the trace precious impurity

elements calcium, magnesium, copper, nickel, manganese, zinc and cadmium.

The adsorbed impurity elements are respectively eluted by hydrochloric acid

(0.2 mol/L and 1.0 mol/L). At the wavelengths listed in atomic absorption

spectrometer Table 1, use an air-acetylene flame to measure each element

separately.

The standard solution shall have the same acidity as the elution solution.

4.12 Calcium standard solution:

4.12.1 Pipette 25.00 mL of calcium standard stock solution (4.11). Place it in a

250 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly. Each

1 mL of this solution contains 100 µg of calcium.

4.12.2 Pipette 10.00 mL of calcium standard stock solution (4.12.1). Place it in

a 100 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 10 µg of calcium.

4.13 Magnesium standard stock solution: Weigh 1.000 g pure metallic

magnesium (above 99.9%). Place it in a 300 mL beaker. Slowly add 34 mL of

hydrochloric acid (4.1) to dissolve it. Heat to boil. Cool to room temperature.

Transfer it into a 1000 mL volumetric flask. Use water to dilute it to the mark.

Mix it uniformly. Each 1 mL of this solution contains 1 mg of magnesium.

4.14 Magnesium standard solution:

4.14.1 Pipette 25.00 mL of magnesium standard stock solution (4.13). Put it in

a 250 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 100 µg of magnesium.

4.14.2 Pipette 10.00 mL of magnesium standard stock solution (4.14.1). Put it

in a 100 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 10 µg of magnesium.

4.15 Copper standard stock solution: Weigh 1.000 g of pure metallic copper

(above 99.9%) in a 300 mL beaker. Add 20 mL of nitric acid (1 + 1, superior

grade pure) to dissolve. Heat to evaporate it dry. Add 10.0 mL of sulfuric acid.

Heat carefully to evaporate to sulfuric acid fumes. Cool it. Add water and boil

until the salt is completely dissolved. Cool to room temperature. Transfer it into

a 1000 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 1 mg of copper.

4.16 Zinc standard stock solution: Weigh 1.000 g of pure metallic zinc (above

99.9%) in a 300 mL beaker. Add 25.0 mL of hydrochloric acid (1 + 1, superior

grade pure) to dissolve it. Heat to boil it. Cool it to room temperature. Transfer

it into a 1000 mL volumetric flask. Use water to dilute it to the mark. Mix it

uniformly. Each 1 mL of this solution contains 1 mg of zinc.

4.17 Nickel standard stock solution: Weigh 1.000 g of pure metallic nickel

(above 99.9%) in a 300 mL beaker. Add 15 mL of nitric acid (ρ1.42 g/mL,

superior grade pure). Heat at low temperature to completely dissolve it. Boil it.

Cool it to room temperature. Transfer it into a 1000 mL volumetric f...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 11064.18-1989 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 11064.18-1989

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 11064.18-1989 (GB 11064.18-1989)

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

GB/T 11064.18-1989

Lithium carbonate - Determination of calcium,

magnesium, copper, zinc, nickel, manganese and

cadmium contents - Ion exchange-flame atomic

absorption spectrometric method

APPROVED ON: JANUARY 28, 1989

IMPLEMENTED ON: FEBRUARY 01, 1990

Issued by: China Nonferrous Metal Industry Corporation

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Method summary ... 3

4 Reagents and materials ... 4

5 Instruments ... 7

6 Specimen ... 8

7 Analytical steps ... 8

8 Calculation and expression of analysis results... 10

9 Allowable deviation ... 11

Appendix A Instrument working conditions (Informative) ... 12

Additional information ... 12

Lithium carbonate - Determination of calcium,

magnesium, copper, zinc, nickel, manganese and

cadmium contents - Ion exchange-flame atomic

absorption spectrometric method

1 Scope

This standard specifies the determination method of calcium, magnesium,

copper, zinc, nickel, manganese and cadmium in lithium carbonate.

This standard applies to the determination of calcium, magnesium, copper, zinc,

nickel, manganese and cadmium content in phosphor-grade lithium carbonate,

as well as the individual determination of the content of one element.

Measurement range: calcium 0.00010% ~ 0.010%; magnesium, cadmium,

copper, zinc, nickel, manganese 0.00010% ~ 0.0060%.

2 Normative references

GB 1.4 Directives for the work of standardization - Rules for drafting

chemical analysis standards

GB 1467 General rules and regulations of the chemical analysis methods for

products of metallurgical industries

GB 7728 Chemical analysis of metallurgical products - General rule for flame

atomic absorption spectrometric methods

3 Method summary

The sample is decomposed by hydrochloric acid and adjusted to pH 8 ~ 9. Use

the potassium chelating resin t separate and enrich the trace precious impurity

elements calcium, magnesium, copper, nickel, manganese, zinc and cadmium.

The adsorbed impurity elements are respectively eluted by hydrochloric acid

(0.2 mol/L and 1.0 mol/L). At the wavelengths listed in atomic absorption

spectrometer Table 1, use an air-acetylene flame to measure each element

separately.

The standard solution shall have the same acidity as the elution solution.

4.12 Calcium standard solution:

4.12.1 Pipette 25.00 mL of calcium standard stock solution (4.11). Place it in a

250 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly. Each

1 mL of this solution contains 100 µg of calcium.

4.12.2 Pipette 10.00 mL of calcium standard stock solution (4.12.1). Place it in

a 100 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 10 µg of calcium.

4.13 Magnesium standard stock solution: Weigh 1.000 g pure metallic

magnesium (above 99.9%). Place it in a 300 mL beaker. Slowly add 34 mL of

hydrochloric acid (4.1) to dissolve it. Heat to boil. Cool to room temperature.

Transfer it into a 1000 mL volumetric flask. Use water to dilute it to the mark.

Mix it uniformly. Each 1 mL of this solution contains 1 mg of magnesium.

4.14 Magnesium standard solution:

4.14.1 Pipette 25.00 mL of magnesium standard stock solution (4.13). Put it in

a 250 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 100 µg of magnesium.

4.14.2 Pipette 10.00 mL of magnesium standard stock solution (4.14.1). Put it

in a 100 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 10 µg of magnesium.

4.15 Copper standard stock solution: Weigh 1.000 g of pure metallic copper

(above 99.9%) in a 300 mL beaker. Add 20 mL of nitric acid (1 + 1, superior

grade pure) to dissolve. Heat to evaporate it dry. Add 10.0 mL of sulfuric acid.

Heat carefully to evaporate to sulfuric acid fumes. Cool it. Add water and boil

until the salt is completely dissolved. Cool to room temperature. Transfer it into

a 1000 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 1 mg of copper.

4.16 Zinc standard stock solution: Weigh 1.000 g of pure metallic zinc (above

99.9%) in a 300 mL beaker. Add 25.0 mL of hydrochloric acid (1 + 1, superior

grade pure) to dissolve it. Heat to boil it. Cool it to room temperature. Transfer

it into a 1000 mL volumetric flask. Use water to dilute it to the mark. Mix it

uniformly. Each 1 mL of this solution contains 1 mg of zinc.

4.17 Nickel standard stock solution: Weigh 1.000 g of pure metallic nickel

(above 99.9%) in a 300 mL beaker. Add 15 mL of nitric acid (ρ1.42 g/mL,

superior grade pure). Heat at low temperature to completely dissolve it. Boil it.

Cool it to room temperature. Transfer it into a 1000 mL volumetric flask. Use

water to dilute it to the mark. Mix it uniformly. Each 1 mL of this solution contains

1 mg of nickel.

4.18 Manganese standard stock solution: Weigh 1.000 g of pure metallic

manganese (above 99.9%, use diluted sulfuric acid to wash off the oxide from

the surface of the manganese before weighing; then use water to wash off the

acid; bake it dry). Place it in a 300 mL beaker. Add 20 mL of hydrochloric acid

(1 + 1, superior grade pure). Heat to dissolve it. Cool it to room temperature.

Transfer it into a 1000 mL volumetric flask. Use water to dilute it to the mark.

Mix it uniformly. Each 1 mL of this solution contains 1 mg of manganese.

4.19 Cadmium standard stock solution: Weigh 1.000 g of pure metallic cadmium

(above 99.9%). Place it a 300 mL beaker. Add 25.0 mL of hydrochloric acid (4.1)

to dissolve it. Heat to boil it. Cool it to room temperature. Transfer it into a 1000

mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly. Each 1

mL of this solution contains 1 mg of cadmium.

4.20 Mixed standard solution:

4.20.1 Respectively pipette 25.00 mL of copper standard stock solution (4.15),

zinc standard stock solution (4.16), nickel standard stock solution (4.17),

manganese standard stock solution (4.18), cadmium standard stock solution

(4.19) in a 250 mL volumetric flask. Use water to dilute it to the mark. Mix it

uniformly. Each 1 mL of this solution contains 100 µg of copper, zinc, nickel,

manganese, cadmium.

4.20.2 Pipette 10.00 mL of mixed standard solution (4.21.1) in a 100 mL

volumetric flask. Use water to dilute it to the mark. Mix it uniformly. Each 1 mL

of this solution contains 10 µg of copper, zinc, nickel, manganese, cadmium.

4.21 Ion exchange column: Made of polyethylene tube, as shown in the Figure

below.

7.3.1.1.

7.3 Determination

7.3.1 Separation and enrichment:

7.3.1.1 Calcium and magnesium: Put the sample in a beaker. Use a small

amount of water to moisten it. Add hydrochloric acid (4.1) according to Table 2

to decompose it. Heat to boil to drive off carbon dioxide. Remove the beaker.

Respectively add water to about 40 mL. Cool to room temperature. Use

ammonia (4.8) and hydrochloric acid (4.9) to adjust to pH 8 ~ 9 [use pH test

paper (4.10) to test]. Transfer the test solution to the processed exchange

column (4.22.1). Make it exchange at the flow rate of 1 ~ 2 mL/min. When the

test solution flows to the resin surface, use water to rinse it twice, 10 mL each

time. Add 40 mL acetic acid (4.5) to wash off and discard lithium. Then use

water to rinse the resin twice, 10 mL each time. Use 15.00 mL of hydrochloric

acid (4.2) to wash off calcium and magnesium. Collect them in a 25 mL dry

colorimetric tube. Mix it uniformly.

7.3.1.2 Copper, nickel, manganese, zinc, cadmium: The sample is carried out

according to 7.3.1.1, but finally eluted by 15.00 mL hydrochloric acid (4.3).

7.3.2 At the wavelength listed in atomic absorption spectrometer Table 1, use

air-acetylene flame, parallel to the standard solution series; respectively use

hydrochloric acid (4.2) to make zero adjustment to measure the absorbance of

calcium and magnesium; use with hydrochloric acid (4.3) to make zero

adjustment to measure the absorbance of copper, zinc, nickel, manganese,

cadmium; find the concentration of the corresponding elements in the test

solution and the blank solution from the working curve.

7.4 Drawing of working curve

7.4.1 Calcium working solution

7.4.1.1 Pipette 0, 2.00, 4.00, 6.00, 8.00, 10.00 mL of calcium standard solution

(4.12.2) into a set of 100 mL volumetric flasks containing 2.85 mL hydrochloric

acid (4.1), respectively. Use water to dilute it to the mark. Mix it uniformly.

Transfer the solution into a plastic bottle for storage.

7.4.1.2 Pipette 0, 2.00, 4.00, 6.00, 8.00, 10.00 mL of calcium standard solution

(4.12.1) into a set of 100 mL volumetric flasks containing 2.85 mL hydrochloric

acid (4.1), respectively. Use water to dilute it to the mark. Mix it uniformly.

Transfer the solution into a plastic bottle for storage.

7.4.2 Magnesium working solution:

Pipette 0, 2.00, 4.00, 6.00, 8.00, 10.00 mL of magnesium standard solution

GB/T 11064.18-1989 (GB 11064.18-1989)

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

GB/T 11064.18-1989

Lithium carbonate - Determination of calcium,

magnesium, copper, zinc, nickel, manganese and

cadmium contents - Ion exchange-flame atomic

absorption spectrometric method

APPROVED ON: JANUARY 28, 1989

IMPLEMENTED ON: FEBRUARY 01, 1990

Issued by: China Nonferrous Metal Industry Corporation

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Method summary ... 3

4 Reagents and materials ... 4

5 Instruments ... 7

6 Specimen ... 8

7 Analytical steps ... 8

8 Calculation and expression of analysis results... 10

9 Allowable deviation ... 11

Appendix A Instrument working conditions (Informative) ... 12

Additional information ... 12

Lithium carbonate - Determination of calcium,

magnesium, copper, zinc, nickel, manganese and

cadmium contents - Ion exchange-flame atomic

absorption spectrometric method

1 Scope

This standard specifies the determination method of calcium, magnesium,

copper, zinc, nickel, manganese and cadmium in lithium carbonate.

This standard applies to the determination of calcium, magnesium, copper, zinc,

nickel, manganese and cadmium content in phosphor-grade lithium carbonate,

as well as the individual determination of the content of one element.

Measurement range: calcium 0.00010% ~ 0.010%; magnesium, cadmium,

copper, zinc, nickel, manganese 0.00010% ~ 0.0060%.

2 Normative references

GB 1.4 Directives for the work of standardization - Rules for drafting

chemical analysis standards

GB 1467 General rules and regulations of the chemical analysis methods for

products of metallurgical industries

GB 7728 Chemical analysis of metallurgical products - General rule for flame

atomic absorption spectrometric methods

3 Method summary

The sample is decomposed by hydrochloric acid and adjusted to pH 8 ~ 9. Use

the potassium chelating resin t separate and enrich the trace precious impurity

elements calcium, magnesium, copper, nickel, manganese, zinc and cadmium.

The adsorbed impurity elements are respectively eluted by hydrochloric acid

(0.2 mol/L and 1.0 mol/L). At the wavelengths listed in atomic absorption

spectrometer Table 1, use an air-acetylene flame to measure each element

separately.

The standard solution shall have the same acidity as the elution solution.

4.12 Calcium standard solution:

4.12.1 Pipette 25.00 mL of calcium standard stock solution (4.11). Place it in a

250 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly. Each

1 mL of this solution contains 100 µg of calcium.

4.12.2 Pipette 10.00 mL of calcium standard stock solution (4.12.1). Place it in

a 100 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 10 µg of calcium.

4.13 Magnesium standard stock solution: Weigh 1.000 g pure metallic

magnesium (above 99.9%). Place it in a 300 mL beaker. Slowly add 34 mL of

hydrochloric acid (4.1) to dissolve it. Heat to boil. Cool to room temperature.

Transfer it into a 1000 mL volumetric flask. Use water to dilute it to the mark.

Mix it uniformly. Each 1 mL of this solution contains 1 mg of magnesium.

4.14 Magnesium standard solution:

4.14.1 Pipette 25.00 mL of magnesium standard stock solution (4.13). Put it in

a 250 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 100 µg of magnesium.

4.14.2 Pipette 10.00 mL of magnesium standard stock solution (4.14.1). Put it

in a 100 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 10 µg of magnesium.

4.15 Copper standard stock solution: Weigh 1.000 g of pure metallic copper

(above 99.9%) in a 300 mL beaker. Add 20 mL of nitric acid (1 + 1, superior

grade pure) to dissolve. Heat to evaporate it dry. Add 10.0 mL of sulfuric acid.

Heat carefully to evaporate to sulfuric acid fumes. Cool it. Add water and boil

until the salt is completely dissolved. Cool to room temperature. Transfer it into

a 1000 mL volumetric flask. Use water to dilute it to the mark. Mix it uniformly.

Each 1 mL of this solution contains 1 mg of copper.

4.16 Zinc standard stock solution: Weigh 1.000 g of pure metallic zinc (above

99.9%) in a 300 mL beaker. Add 25.0 mL of hydrochloric acid (1 + 1, superior

grade pure) to dissolve it. Heat to boil it. Cool it to room temperature. Transfer

it into a 1000 mL volumetric flask. Use water to dilute it to the mark. Mix it

uniformly. Each 1 mL of this solution contains 1 mg of zinc.

4.17 Nickel standard stock solution: Weigh 1.000 g of pure metallic nickel

(above 99.9%) in a 300 mL beaker. Add 15 mL of nitric acid (ρ1.42 g/mL,

superior grade pure). Heat at low temperature to completely dissolve it. Boil it.

Cool it to room temperature. Transfer it into a 1000 mL volumetric f...

Share