1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 1239.2-2009 English PDF (GB/T1239.2-2009)

GB/T 1239.2-2009 English PDF (GB/T1239.2-2009)

Regular price

$105.00 USD

Regular price

Sale price

$105.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 1239.2-2009

Historical versions: GB/T 1239.2-2009

Preview True-PDF (Reload/Scroll if blank)

GB/T 1239.2-2009: Cold coiled helical springs technical specifications -- Part 2: Compressions spring

GB/T 1239.2-2009

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 21.160

J 26

Replacing GB/T 1239.2-1989

Cold coiled helical springs technical specifications -

Part 2: Compressions spring

ISSUED ON: MARCH 16, 2009

IMPLEMENTED ON: NOVEMBER 01, 2009

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Structure type ... 6

5 Technical requirements ... 6

6 Test methods ... 11

7 Inspection rules ... 14

8 Marking, packaging, transportation, storage ... 15

Annex A (informative) Legend ... 17

Cold coiled helical springs technical specifications -

Part 2: Compressions spring

1 Scope

This Part of GB/T 1239 specifies technical requirements, test methods,

inspection rules and packaging, marking, transportation and storage

requirements for helical compression spring of cold rolled round section cylinder.

This Part is applicable to helical compression spring of cold rolled round section

cylinder (hereinafter referred to as the spring). The cross-sectional diameter of

the spring material is greater than or equal to 0.5 mm.

This Part is inapplicable to the spring of special requirements.

2 Normative references

The following documents contain the provisions which, through reference in this

Part, become the provisions of this Part of GB/T 1239. For dated references,

their subsequent amendments (excluding corrigendum) or revisions do not

apply to this Standard. However, the parties who enter into agreement based

on this Standard are encouraged to investigate whether the latest versions of

these documents are applicable. For undated reference documents, the latest

versions apply to this Standard.

GB/T 1805, Nomenclature of springs

GB/T 4357-1989, Carbon spring steel wires (neq JIS G3521:1984)

GB/T 16947, Helical spring fatigue testing standard

GB/T 18983, Oil - Hardened and tempered steel wire for mechanical springs

(GB/T 18983-2003, ISO/FDIS 8458-3:1992, MOD)

GB/T 21652, Copper and copper alloy wire

JB/T 7367, Magnetic particle inspection for helical compression springs

JB/T 7944, Coiled helical compression springs - Sampling inspection

JB/T 10802, Specification for shot peening of springs

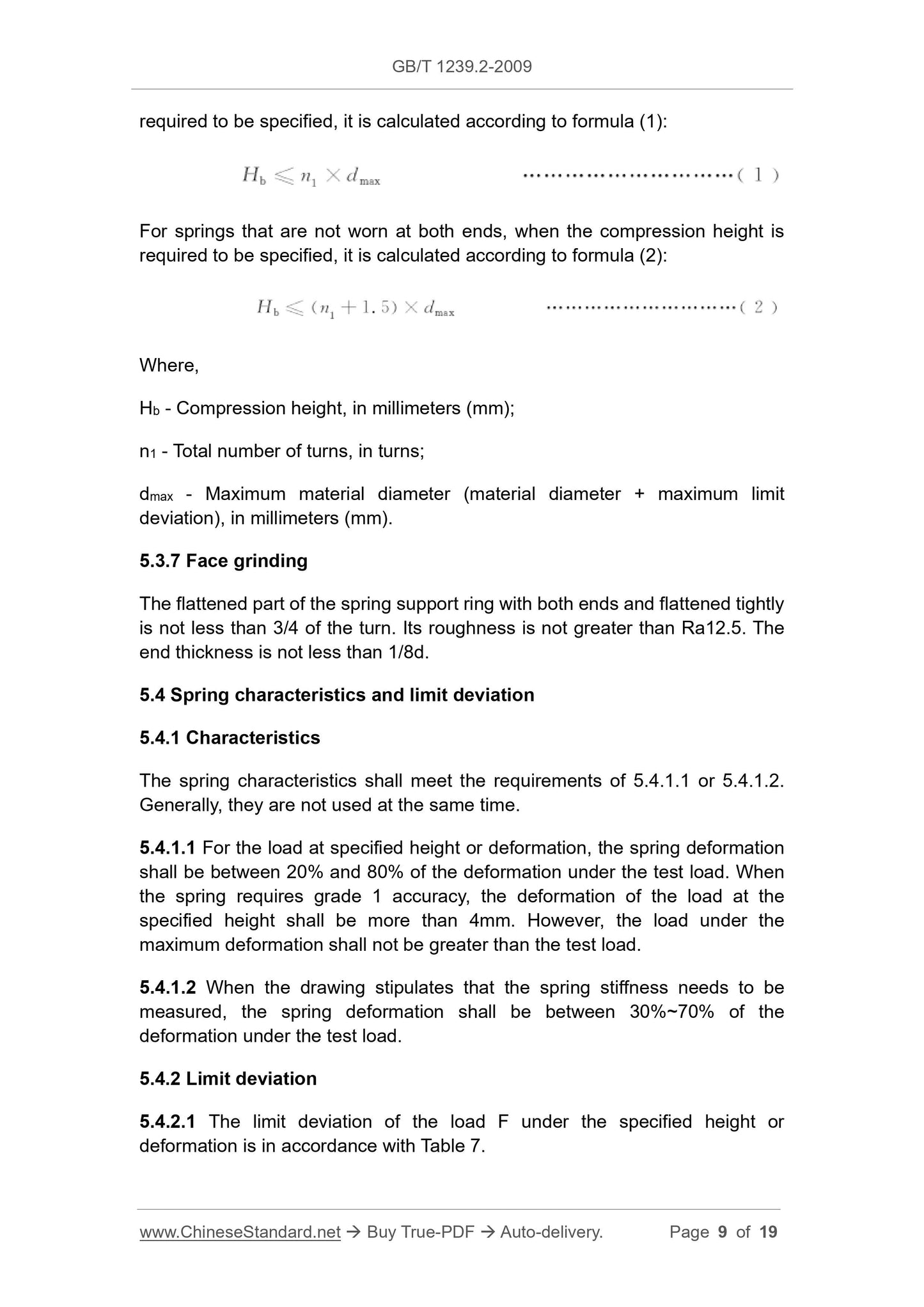

required to be specified, it is calculated according to formula (1):

For springs that are not worn at both ends, when the compression height is

required to be specified, it is calculated according to formula (2):

Where,

Hb - Compression height, in millimeters (mm);

n1 - Total number of turns, in turns;

dmax - Maximum material diameter (material diameter + maximum limit

deviation), in millimeters (mm).

5.3.7 Face grinding

The flattened part of the spring support ring with both ends and flattened tightly

is not less than 3/4 of the turn. Its roughness is not greater than Ra12.5. The

end thickness is not less than 1/8d.

5.4 Spring characteristics and limit deviation

5.4.1 Characteristics

The spring characteristics shall meet the requirements of 5.4.1.1 or 5.4.1.2.

Generally, they are not used at the same time.

5.4.1.1 For the load at specified height or deformation, the spring deformation

shall be between 20% and 80% of the deformation under the test load. When

the spring requires grade 1 accuracy, the deformation of the load at the

specified height shall be more than 4mm. However, the load under the

maximum deformation shall not be greater than the test load.

5.4.1.2 When the drawing stipulates that the spring stiffness needs to be

measured, the spring deformation shall be between 30%~70% of the

deformation under the test load.

5.4.2 Limit deviation

5.4.2.1 The limit deviation of the load F under the specified height or

deformation is in accordance with Table 7.

The surface treatment of the spring shall be indicated in the product drawing.

The surface treatment medium and method shall comply with the corresponding

environmental protection regulations. However, surface treatments that may

cause hydrogen embrittlement shall be avoided as far as possible for the spring.

5.10 Other requirements

According to needs, the following requirements can be specified for the spring

in the product drawing:

a) Shot peening;

b) Nondestructive inspection;

c) Fatigue test;

d) Heating and pressure treatment.

See Annex A for the spring legend. When there are special technical

requirements, it shall be stipulated by agreement between the supplier and the

purchaser.

6 Test methods

6.1 Permanent deformation

Compress the spring with the test load three times. Measure the change of free

height after the second and third compression. When the test load is greater

than the compression load, the compression load is regarded as the test load.

6.2 Spring characteristics

The spring characteristics are measured on a spring testing machine with an

accuracy of not less than ±1%. Measure the load or stiffness as specified in the

drawing. When measuring the load under the specified deformation amount,

the preload amount shall be negotiated between the supplier and the purchaser.

The spring characteristics are measured after preloading the spring once. The

preload height is the height corresponding to the test load or the compression

height. The maximum compression load shall not exceed 1.5 times the

theoretical compression load.

The test load is calculated by formula (3). The test stress is shown in Table 9.

between the supplier and the purchaser.

6.8 Surface quality

Use visual inspection or use a 5x magnifying glass to inspect the surface of the

spring.

6.9 Surface treatment

The surface treatment of the spring shall be carried out in accordance with

relevant standards or technical agreements.

6.10 Other requirements

The shot peening of the spring is carried out in accordance with the regulations

of JB/T 10802.

The magnetic particle inspection of the spring shall be carried out in accordance

with JB/T 7367.

The fatigue test of the spring shall be carried out in accordance with GB/T

16947.

Other special requirements such as spring treatment, heating and pressure,

shall be implemented in accordance with product drawings and relevant

standards.

7 Inspection rules

7.1 Sampling inspection

The product acceptance sampling inspection shall be in accordance with the

provisions of JB/T 7944, or it may be negotiated by both the supplier and the

purchaser.

7.2 Product inspection items

a) Spring characteristics;

b) Outer diameter or inner diameter;

c) Free height;

d) Total number of turns;

e) Verticality or straightness;

Get QUOTATION in 1-minute: Click GB/T 1239.2-2009

Historical versions: GB/T 1239.2-2009

Preview True-PDF (Reload/Scroll if blank)

GB/T 1239.2-2009: Cold coiled helical springs technical specifications -- Part 2: Compressions spring

GB/T 1239.2-2009

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 21.160

J 26

Replacing GB/T 1239.2-1989

Cold coiled helical springs technical specifications -

Part 2: Compressions spring

ISSUED ON: MARCH 16, 2009

IMPLEMENTED ON: NOVEMBER 01, 2009

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Structure type ... 6

5 Technical requirements ... 6

6 Test methods ... 11

7 Inspection rules ... 14

8 Marking, packaging, transportation, storage ... 15

Annex A (informative) Legend ... 17

Cold coiled helical springs technical specifications -

Part 2: Compressions spring

1 Scope

This Part of GB/T 1239 specifies technical requirements, test methods,

inspection rules and packaging, marking, transportation and storage

requirements for helical compression spring of cold rolled round section cylinder.

This Part is applicable to helical compression spring of cold rolled round section

cylinder (hereinafter referred to as the spring). The cross-sectional diameter of

the spring material is greater than or equal to 0.5 mm.

This Part is inapplicable to the spring of special requirements.

2 Normative references

The following documents contain the provisions which, through reference in this

Part, become the provisions of this Part of GB/T 1239. For dated references,

their subsequent amendments (excluding corrigendum) or revisions do not

apply to this Standard. However, the parties who enter into agreement based

on this Standard are encouraged to investigate whether the latest versions of

these documents are applicable. For undated reference documents, the latest

versions apply to this Standard.

GB/T 1805, Nomenclature of springs

GB/T 4357-1989, Carbon spring steel wires (neq JIS G3521:1984)

GB/T 16947, Helical spring fatigue testing standard

GB/T 18983, Oil - Hardened and tempered steel wire for mechanical springs

(GB/T 18983-2003, ISO/FDIS 8458-3:1992, MOD)

GB/T 21652, Copper and copper alloy wire

JB/T 7367, Magnetic particle inspection for helical compression springs

JB/T 7944, Coiled helical compression springs - Sampling inspection

JB/T 10802, Specification for shot peening of springs

required to be specified, it is calculated according to formula (1):

For springs that are not worn at both ends, when the compression height is

required to be specified, it is calculated according to formula (2):

Where,

Hb - Compression height, in millimeters (mm);

n1 - Total number of turns, in turns;

dmax - Maximum material diameter (material diameter + maximum limit

deviation), in millimeters (mm).

5.3.7 Face grinding

The flattened part of the spring support ring with both ends and flattened tightly

is not less than 3/4 of the turn. Its roughness is not greater than Ra12.5. The

end thickness is not less than 1/8d.

5.4 Spring characteristics and limit deviation

5.4.1 Characteristics

The spring characteristics shall meet the requirements of 5.4.1.1 or 5.4.1.2.

Generally, they are not used at the same time.

5.4.1.1 For the load at specified height or deformation, the spring deformation

shall be between 20% and 80% of the deformation under the test load. When

the spring requires grade 1 accuracy, the deformation of the load at the

specified height shall be more than 4mm. However, the load under the

maximum deformation shall not be greater than the test load.

5.4.1.2 When the drawing stipulates that the spring stiffness needs to be

measured, the spring deformation shall be between 30%~70% of the

deformation under the test load.

5.4.2 Limit deviation

5.4.2.1 The limit deviation of the load F under the specified height or

deformation is in accordance with Table 7.

The surface treatment of the spring shall be indicated in the product drawing.

The surface treatment medium and method shall comply with the corresponding

environmental protection regulations. However, surface treatments that may

cause hydrogen embrittlement shall be avoided as far as possible for the spring.

5.10 Other requirements

According to needs, the following requirements can be specified for the spring

in the product drawing:

a) Shot peening;

b) Nondestructive inspection;

c) Fatigue test;

d) Heating and pressure treatment.

See Annex A for the spring legend. When there are special technical

requirements, it shall be stipulated by agreement between the supplier and the

purchaser.

6 Test methods

6.1 Permanent deformation

Compress the spring with the test load three times. Measure the change of free

height after the second and third compression. When the test load is greater

than the compression load, the compression load is regarded as the test load.

6.2 Spring characteristics

The spring characteristics are measured on a spring testing machine with an

accuracy of not less than ±1%. Measure the load or stiffness as specified in the

drawing. When measuring the load under the specified deformation amount,

the preload amount shall be negotiated between the supplier and the purchaser.

The spring characteristics are measured after preloading the spring once. The

preload height is the height corresponding to the test load or the compression

height. The maximum compression load shall not exceed 1.5 times the

theoretical compression load.

The test load is calculated by formula (3). The test stress is shown in Table 9.

between the supplier and the purchaser.

6.8 Surface quality

Use visual inspection or use a 5x magnifying glass to inspect the surface of the

spring.

6.9 Surface treatment

The surface treatment of the spring shall be carried out in accordance with

relevant standards or technical agreements.

6.10 Other requirements

The shot peening of the spring is carried out in accordance with the regulations

of JB/T 10802.

The magnetic particle inspection of the spring shall be carried out in accordance

with JB/T 7367.

The fatigue test of the spring shall be carried out in accordance with GB/T

16947.

Other special requirements such as spring treatment, heating and pressure,

shall be implemented in accordance with product drawings and relevant

standards.

7 Inspection rules

7.1 Sampling inspection

The product acceptance sampling inspection shall be in accordance with the

provisions of JB/T 7944, or it may be negotiated by both the supplier and the

purchaser.

7.2 Product inspection items

a) Spring characteristics;

b) Outer diameter or inner diameter;

c) Free height;

d) Total number of turns;

e) Verticality or straightness;

Share