1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 12673-2019 English PDF (GB/T12673-2019)

GB/T 12673-2019 English PDF (GB/T12673-2019)

Regular price

$455.00

Regular price

Sale price

$455.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 12673-2019: Motor vehicle main dimensions measurement method

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 12673-2019 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 12673-2019

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 12673-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.020

T 04

Replacing GB/T 12673-1990

Motor vehicle main dimensions measurement method

ISSUED ON: OCTOBER 18, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Measurement preparation ... 17

5 Dimension codes ... 19

6 Determination of the zero plane and the base point ... 21

7 Dimension codes, name and measurement methods of internal dimensions

... 24

8 Dimension codes, name and measurement methods of external dimensions

... 47

9 Dimension codes, name and measurement methods of luggage

compartment/ cargo dimension ... 55

Appendix A (Informative) Driver and passenger head contour and positioning

... 66

Appendix B (Normative) H-point travel path ... 72

Appendix C (Normative) Structural diagram of seat type determination method

and L48, L51 measurement method ... 74

Appendix D (Informative) Figures ... 76

Motor vehicle main dimensions measurement method

1 Scope

This Standard specifies motor vehicle main dimensions measurement method.

The external dimensions and luggage/ cargo dimensions measurement

methods that are specified in this Standard are applicable to M and N vehicles;

other vehicles can implement by reference.

The internal dimensions measurement methods that are specified in this

Standard are applicable to M1 vehicles; other vehicles can implement by

reference.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB 1589, Limits of dimensions, axle load and masses for motor vehicles,

trailers and combination vehicles

GB/T 3730.2, Road vehicle – Masses - Vocabulary and codes

GB/T 3730.3-1992, Motor vehicles and towed vehicles - Dimensions of

vehicles - Terms and definitions

GB/T 19514, Passenger cars - Luggage compartments - Method of

measuring reference volume

GB/T 29120-2012, Procedure for H-point and R-point determination

3 Terms and definitions

Terms and definitions determined by GB 1589, GB/T 3730.2, GB/T 3730.3-1992,

GB/T 29120-2012, and the following ones are applicable to this document. For

ease of use, some of the terms and definitions in GB/T 29120-2012 are

repeated below.

3.1 Vehicle coordinate system

In HPM, the seat is located at the ride base point that is specified by the

manufacturer. When HPM uses the appropriate leg length, measure the H-point

at the hinge center of its torso line and thigh bar centerline. In HPM-II, the seat

is located at the ride base point that is specified by the manufacturer. When

HPM-II adopts a proper posture, measure the H-point at the hinge center point

of its seat plate assembly and back plate assembly.

[GB/T 29120-2012, Definition 3.3.2]

3.2.3 R-point

The designed H-point position that is set by the manufacturer, which is

specifically designated as the R-point or SgRP and meets all the following

requirements:

a) the basic base point that is used to establish passenger adjustment tools

and dimensions;

b) simulate the hinge center position of the human torso and thigh;

c) have a coordinate that is established relative to the structure of the

designed vehicle;

d) establish the rear end of each designated seating position or the H-point

of the normal driving and seating positions that are designated by the

manufacturer, which takes into account all the adjustment states of the

seat, including horizontal, vertical and tilt, but does not include seat

movement that is used for abnormal driving or seating purposes.

3.2.4 H-point travel path

All possible positions of H-point under all adjustment states (including horizontal,

vertical and tilt) of the specified seating position.

[GB/T 29120-2012, Definition 3.9]

3.2.5 Three-dimensional H-point machine; HPM

The device that is used to measure the actual H-point and the actual torso angle

on a vehicle.

[GB/T 29120-2012, Definition 3.1]

3.2.6 Three-dimensional H-point machine-II; HPM-II

The new SAE (Society of Automotive Engineers) H-point machine that is used

to more accurately determine the actual H-point, actual torso angle and other

parameter values on a vehicle. The main change of HPM-II is the improved

3.3.3 Thigh line

In the Y-plane, the line that connects the K-point to the H-point on the H-point

measurement machine, as shown in Figure 2.

3.3.4 Torso line

In HPM, the centerline of the probe stick when the head-space probe sticks

back to the HPM back plane.

In HPM-II, the straight line that passes through the H-point and the chest sliding

hinge axis, as shown in Figure 2.

Note: In HPM, the torso line crosses the H-point and is parallel to the flat part

of the back plate that determines the torso angle.

[GB/T 29120-2012, Definition 3.4]

3.3.5 Ankle point

The hinge point of the footwear and the leg on the H-point measurement

machine, as shown in Figure 2.

3.3.6 Heel of shoe; HOS

When the passenger's seat is located at the R-point, the intersection OF the

right side of the H-point measurement machine AND the pressed floor covering

or other support surface of the heel, as shown in Figure 2.

3.3.7 Ball of foot; BOF

On the bottom of shoe, the point on the lateral centerline of the shoe that is 203

mm away from HOS, as shown in Figure 3.

Figure 4 -- Short-coupled seating interference and FRP positions

3.3.15 Steering wheel center

When the front wheels are straight forward, the intersection of the upper surface

of the steering wheel rim and the centerline of the steering column.

3.3.16 Center line of occupant

Y-coordinate plane for each designated seating position R-point.

Note: For single-seat, it generally refers to the center plane of the seat. For

bench seat, the center line of occupant is specified by the manufacturer.

3.4 Seat layout types

3.4.1 Long-coupled seating

When the front row of seats is in the designed position and the H-point

measurement machine is located on the left outer seat in the rear row, the two

consecutive two rows of seats (from the first row to second row, or from the

second row to third row, etc.) whose continuous distance in the X-axis direction

from the front row of seats is sufficient to place the H-point measurement

machine whose ankle angle is greater than 130°.

3.4.2 Standard-coupled seating

When the front row of seats is in the designed position and the H-point

measurement machine is located on the left outer seat in the rear row, the two

consecutive two rows of seats (from the first row to second row, or from the

second row to third row, etc.) whose continuous distance in the X-axis direction

from the front row of seats is sufficient to place the H-point measurement

machine whose ankle angle is not greater than 130°.

3.4.3 Short-coupled seating

When the front row of seats is in the designed position and the H-point

measurement machine is located on the left outer seat in the rear row, the

consecutive two rows of seats that interfere with the front-seat trim or seat

structure when the shoe or leg model of the H-point measurement machine is

at the minimum limiting position in the X-axis direction.

Note: As shown in Figure 4: at least one of the occupant's effective legroom

(L51), the occupant leg clearance (L58) or the minimum knee clearance

(L48) will be affected by the short-coupled seating.

3.5 Body design terms

4.2.4 Unless otherwise specified, when the motor vehicle is equipped with

adjustable or movable parts, it shall be measured in the following prescribed

state:

a) The cargo fence shall be closed;

b) The doors, engine hood, luggage compartment cover and vent cover are

all closed;

c) The radio antenna shall be retracted;

d) It excludes the car license plate, but includes the car license plate holder

(frame);

e) If the steering wheel is adjustable, it shall be adjusted to the position that

is specified by the manufacturer; if it is not specified by the manufacturer,

it shall be adjusted to the middle position of the adjustable range;

f) The vehicle pedal shall be in the free position; for adjustable pedal, it shall

be adjusted to the maximum or forward position that is specified by the

manufacturer;

g) The vehicle seats shall be adjusted as follows:

1) For height-adjustable headrests, unless otherwise specified, it shall be

adjusted to the highest position;

2) If the seat is adjustable horizontally and vertically, it shall be adjusted

to the R-point or the position that is specified by the manufacturer;

3) If the backrest is adjustable, it shall be adjusted to the fully retracted

position;

4) If the cushion angle is adjustable, it shall be adjusted to the angle that

is specified by the manufacturer;

5) If the seat back angle is adjustable, the first row of seats shall be

adjusted to 22° or the angle that is specified by the manufacturer; the

second and third rows of seats shall be adjusted to 25° or the angle that

is specified by the manufacturer;

h) If other parts are adjustable, they shall be adjusted to the position that is

specified by the manufacturer.

4.3 Measurement benchmark

4.3.1 Unless otherwise specified, the length shall be measured on a straight

line parallel to the X-axis direction; the width shall be measured on a straight

line parallel to the Y-axis direction; the height shall be measured on a straight

line parallel to the Z-axis direction.

4.3.2 If the sides of the vehicle are symmetrical, measure only the left or right

side.

4.3.3 Unless otherwise specified, the internal dimensions of the vehicle shall be

measured on the center line of occupant. When the H-point measurement

machine is used for measurement, it should use HPM-II, and the leg length

should be adjusted to the position of the 95th percentile. In order to make the

measurements consistent, it should use the formula for the H-point travel path

of the seat that is given in Appendix B.

4.3.4 For the determination methods of the long-coupled, standard-coupled and

short-coupled seating types, see Appendix C. During the measurement of long-

coupled and standard-coupled seating, the H-point measurement machine is

recommended to use the 95th percentile; other types can be specified by the

manufacturer.

4.4 Precision requirements of measurement tools

During the measurement, direct or indirect measurement machines can be

used for measurement. The unit and precision of measurement tools are shown

in Table 1.

Table 1 -- Unit and precision of the measurement tools

Measurement tool Unit Precision

Length measurement tool mm ±1 mm

Width measurement tool mm ±1 mm

Height measurement tool mm ±1 mm

Angle measurement tool ° ±1°

5 Dimension codes

5.1 Dimension codes and definition

The capital letters in Table 2 indicate the measured dimension classification

code.

Table 2 -- Dimension codes and definition

Dimension codes Definition

L Length dimension or X-coordinate

W Width dimension or Y-coordinate

H Height dimension or Z-coordinate

A Angle

SL Seat length dimension

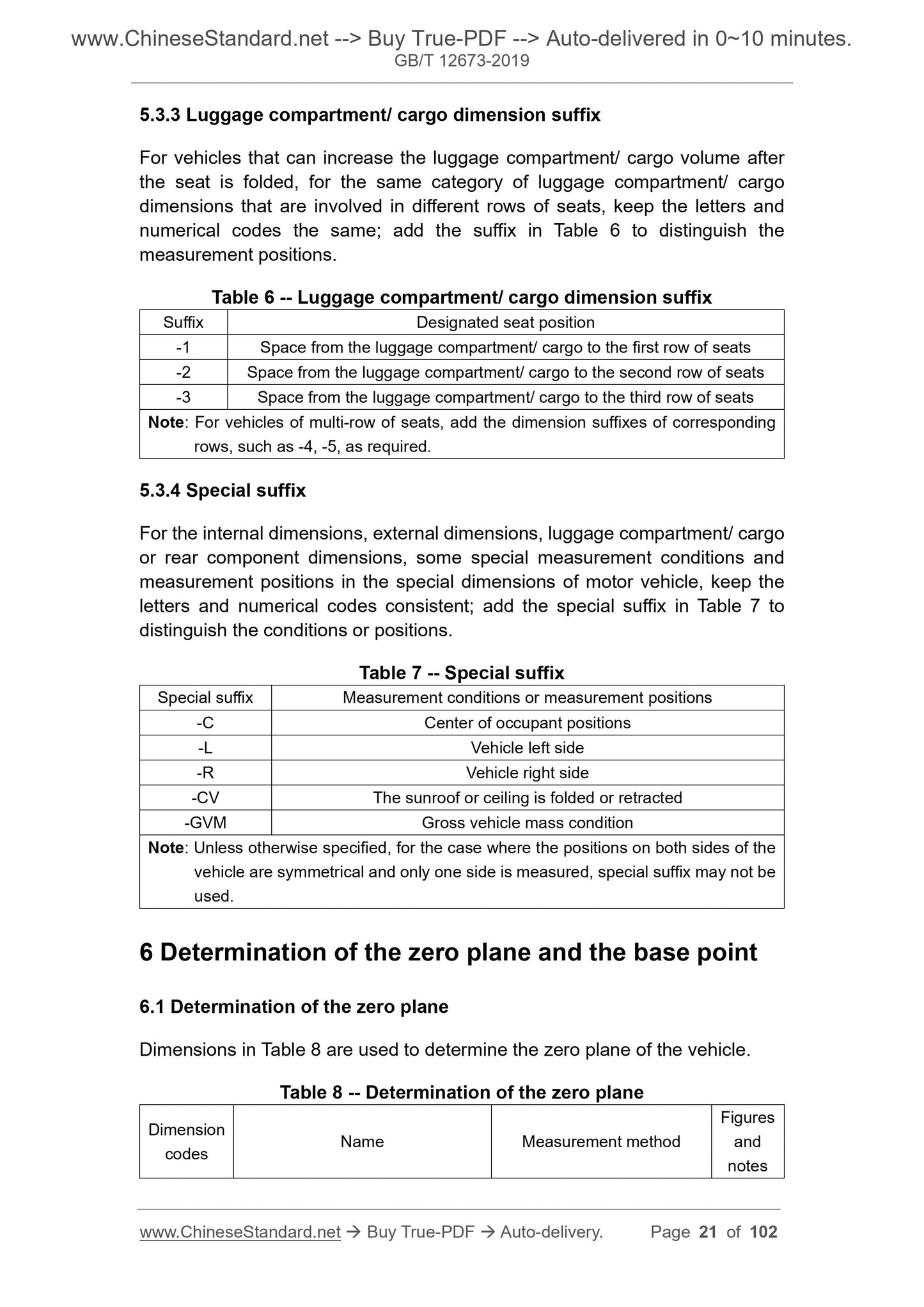

5.3.3 Luggage compartment/ cargo dimension suffix

For vehicles that can increase the luggage compartment/ cargo volume after

the seat is folded, for the same category of luggage compartment/ cargo

dimensions that are involved in different rows of seats, keep the letters and

numerical codes the same; add the suffix in Table 6 to distinguish the

measurement positions.

Table 6 -- Luggage compartment/ cargo dimension suffix

Suffix Designated seat position

-1 Space from the luggage compartment/ cargo to the first row of seats

-2 Space from the luggage compartment/ cargo to the second row of seats

-3 Space from the luggage compartment/ cargo to the third row of seats

Note: For vehicles of multi-row of seats, add the dimension suffixes of corresponding

rows, such as -4, -5, as required.

5.3.4 Special suffix

For the internal dimensions, external dimensions, luggage compartment/ cargo

or rear component dimensions, some special measurement conditions and

measurement positions in the special dimensions of motor vehicle, keep the

letters and numerical codes consistent; add the special suffix in Table 7 to

distinguish the conditions or positions.

Table 7 -- Special suffix

Special suffix Measurement conditions or measurement positions

-C Center of occupant positions

-L Vehicle left side

-R Vehicle right side

-CV The sunroof or ceiling is folded or retracted

-GVM Gross vehicle mass condition

Note: Unless otherwise specified, for the case where the positions on both sides of the

vehicle are symmetrical and only one side is measured, special suffix may not be

used.

6 Determination of the zero plane and the base point

6.1 Determination of the zero plane

Dimensions in Table 8 are used to determine the zero plane of the vehicle.

Table 8 -- Determination of the zero plane

Dimension

codes Name Measurement method

Figures

and

notes

GB/T 12673-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.020

T 04

Replacing GB/T 12673-1990

Motor vehicle main dimensions measurement method

ISSUED ON: OCTOBER 18, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Measurement preparation ... 17

5 Dimension codes ... 19

6 Determination of the zero plane and the base point ... 21

7 Dimension codes, name and measurement methods of int...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 12673-2019 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 12673-2019

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 12673-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.020

T 04

Replacing GB/T 12673-1990

Motor vehicle main dimensions measurement method

ISSUED ON: OCTOBER 18, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Measurement preparation ... 17

5 Dimension codes ... 19

6 Determination of the zero plane and the base point ... 21

7 Dimension codes, name and measurement methods of internal dimensions

... 24

8 Dimension codes, name and measurement methods of external dimensions

... 47

9 Dimension codes, name and measurement methods of luggage

compartment/ cargo dimension ... 55

Appendix A (Informative) Driver and passenger head contour and positioning

... 66

Appendix B (Normative) H-point travel path ... 72

Appendix C (Normative) Structural diagram of seat type determination method

and L48, L51 measurement method ... 74

Appendix D (Informative) Figures ... 76

Motor vehicle main dimensions measurement method

1 Scope

This Standard specifies motor vehicle main dimensions measurement method.

The external dimensions and luggage/ cargo dimensions measurement

methods that are specified in this Standard are applicable to M and N vehicles;

other vehicles can implement by reference.

The internal dimensions measurement methods that are specified in this

Standard are applicable to M1 vehicles; other vehicles can implement by

reference.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB 1589, Limits of dimensions, axle load and masses for motor vehicles,

trailers and combination vehicles

GB/T 3730.2, Road vehicle – Masses - Vocabulary and codes

GB/T 3730.3-1992, Motor vehicles and towed vehicles - Dimensions of

vehicles - Terms and definitions

GB/T 19514, Passenger cars - Luggage compartments - Method of

measuring reference volume

GB/T 29120-2012, Procedure for H-point and R-point determination

3 Terms and definitions

Terms and definitions determined by GB 1589, GB/T 3730.2, GB/T 3730.3-1992,

GB/T 29120-2012, and the following ones are applicable to this document. For

ease of use, some of the terms and definitions in GB/T 29120-2012 are

repeated below.

3.1 Vehicle coordinate system

In HPM, the seat is located at the ride base point that is specified by the

manufacturer. When HPM uses the appropriate leg length, measure the H-point

at the hinge center of its torso line and thigh bar centerline. In HPM-II, the seat

is located at the ride base point that is specified by the manufacturer. When

HPM-II adopts a proper posture, measure the H-point at the hinge center point

of its seat plate assembly and back plate assembly.

[GB/T 29120-2012, Definition 3.3.2]

3.2.3 R-point

The designed H-point position that is set by the manufacturer, which is

specifically designated as the R-point or SgRP and meets all the following

requirements:

a) the basic base point that is used to establish passenger adjustment tools

and dimensions;

b) simulate the hinge center position of the human torso and thigh;

c) have a coordinate that is established relative to the structure of the

designed vehicle;

d) establish the rear end of each designated seating position or the H-point

of the normal driving and seating positions that are designated by the

manufacturer, which takes into account all the adjustment states of the

seat, including horizontal, vertical and tilt, but does not include seat

movement that is used for abnormal driving or seating purposes.

3.2.4 H-point travel path

All possible positions of H-point under all adjustment states (including horizontal,

vertical and tilt) of the specified seating position.

[GB/T 29120-2012, Definition 3.9]

3.2.5 Three-dimensional H-point machine; HPM

The device that is used to measure the actual H-point and the actual torso angle

on a vehicle.

[GB/T 29120-2012, Definition 3.1]

3.2.6 Three-dimensional H-point machine-II; HPM-II

The new SAE (Society of Automotive Engineers) H-point machine that is used

to more accurately determine the actual H-point, actual torso angle and other

parameter values on a vehicle. The main change of HPM-II is the improved

3.3.3 Thigh line

In the Y-plane, the line that connects the K-point to the H-point on the H-point

measurement machine, as shown in Figure 2.

3.3.4 Torso line

In HPM, the centerline of the probe stick when the head-space probe sticks

back to the HPM back plane.

In HPM-II, the straight line that passes through the H-point and the chest sliding

hinge axis, as shown in Figure 2.

Note: In HPM, the torso line crosses the H-point and is parallel to the flat part

of the back plate that determines the torso angle.

[GB/T 29120-2012, Definition 3.4]

3.3.5 Ankle point

The hinge point of the footwear and the leg on the H-point measurement

machine, as shown in Figure 2.

3.3.6 Heel of shoe; HOS

When the passenger's seat is located at the R-point, the intersection OF the

right side of the H-point measurement machine AND the pressed floor covering

or other support surface of the heel, as shown in Figure 2.

3.3.7 Ball of foot; BOF

On the bottom of shoe, the point on the lateral centerline of the shoe that is 203

mm away from HOS, as shown in Figure 3.

Figure 4 -- Short-coupled seating interference and FRP positions

3.3.15 Steering wheel center

When the front wheels are straight forward, the intersection of the upper surface

of the steering wheel rim and the centerline of the steering column.

3.3.16 Center line of occupant

Y-coordinate plane for each designated seating position R-point.

Note: For single-seat, it generally refers to the center plane of the seat. For

bench seat, the center line of occupant is specified by the manufacturer.

3.4 Seat layout types

3.4.1 Long-coupled seating

When the front row of seats is in the designed position and the H-point

measurement machine is located on the left outer seat in the rear row, the two

consecutive two rows of seats (from the first row to second row, or from the

second row to third row, etc.) whose continuous distance in the X-axis direction

from the front row of seats is sufficient to place the H-point measurement

machine whose ankle angle is greater than 130°.

3.4.2 Standard-coupled seating

When the front row of seats is in the designed position and the H-point

measurement machine is located on the left outer seat in the rear row, the two

consecutive two rows of seats (from the first row to second row, or from the

second row to third row, etc.) whose continuous distance in the X-axis direction

from the front row of seats is sufficient to place the H-point measurement

machine whose ankle angle is not greater than 130°.

3.4.3 Short-coupled seating

When the front row of seats is in the designed position and the H-point

measurement machine is located on the left outer seat in the rear row, the

consecutive two rows of seats that interfere with the front-seat trim or seat

structure when the shoe or leg model of the H-point measurement machine is

at the minimum limiting position in the X-axis direction.

Note: As shown in Figure 4: at least one of the occupant's effective legroom

(L51), the occupant leg clearance (L58) or the minimum knee clearance

(L48) will be affected by the short-coupled seating.

3.5 Body design terms

4.2.4 Unless otherwise specified, when the motor vehicle is equipped with

adjustable or movable parts, it shall be measured in the following prescribed

state:

a) The cargo fence shall be closed;

b) The doors, engine hood, luggage compartment cover and vent cover are

all closed;

c) The radio antenna shall be retracted;

d) It excludes the car license plate, but includes the car license plate holder

(frame);

e) If the steering wheel is adjustable, it shall be adjusted to the position that

is specified by the manufacturer; if it is not specified by the manufacturer,

it shall be adjusted to the middle position of the adjustable range;

f) The vehicle pedal shall be in the free position; for adjustable pedal, it shall

be adjusted to the maximum or forward position that is specified by the

manufacturer;

g) The vehicle seats shall be adjusted as follows:

1) For height-adjustable headrests, unless otherwise specified, it shall be

adjusted to the highest position;

2) If the seat is adjustable horizontally and vertically, it shall be adjusted

to the R-point or the position that is specified by the manufacturer;

3) If the backrest is adjustable, it shall be adjusted to the fully retracted

position;

4) If the cushion angle is adjustable, it shall be adjusted to the angle that

is specified by the manufacturer;

5) If the seat back angle is adjustable, the first row of seats shall be

adjusted to 22° or the angle that is specified by the manufacturer; the

second and third rows of seats shall be adjusted to 25° or the angle that

is specified by the manufacturer;

h) If other parts are adjustable, they shall be adjusted to the position that is

specified by the manufacturer.

4.3 Measurement benchmark

4.3.1 Unless otherwise specified, the length shall be measured on a straight

line parallel to the X-axis direction; the width shall be measured on a straight

line parallel to the Y-axis direction; the height shall be measured on a straight

line parallel to the Z-axis direction.

4.3.2 If the sides of the vehicle are symmetrical, measure only the left or right

side.

4.3.3 Unless otherwise specified, the internal dimensions of the vehicle shall be

measured on the center line of occupant. When the H-point measurement

machine is used for measurement, it should use HPM-II, and the leg length

should be adjusted to the position of the 95th percentile. In order to make the

measurements consistent, it should use the formula for the H-point travel path

of the seat that is given in Appendix B.

4.3.4 For the determination methods of the long-coupled, standard-coupled and

short-coupled seating types, see Appendix C. During the measurement of long-

coupled and standard-coupled seating, the H-point measurement machine is

recommended to use the 95th percentile; other types can be specified by the

manufacturer.

4.4 Precision requirements of measurement tools

During the measurement, direct or indirect measurement machines can be

used for measurement. The unit and precision of measurement tools are shown

in Table 1.

Table 1 -- Unit and precision of the measurement tools

Measurement tool Unit Precision

Length measurement tool mm ±1 mm

Width measurement tool mm ±1 mm

Height measurement tool mm ±1 mm

Angle measurement tool ° ±1°

5 Dimension codes

5.1 Dimension codes and definition

The capital letters in Table 2 indicate the measured dimension classification

code.

Table 2 -- Dimension codes and definition

Dimension codes Definition

L Length dimension or X-coordinate

W Width dimension or Y-coordinate

H Height dimension or Z-coordinate

A Angle

SL Seat length dimension

5.3.3 Luggage compartment/ cargo dimension suffix

For vehicles that can increase the luggage compartment/ cargo volume after

the seat is folded, for the same category of luggage compartment/ cargo

dimensions that are involved in different rows of seats, keep the letters and

numerical codes the same; add the suffix in Table 6 to distinguish the

measurement positions.

Table 6 -- Luggage compartment/ cargo dimension suffix

Suffix Designated seat position

-1 Space from the luggage compartment/ cargo to the first row of seats

-2 Space from the luggage compartment/ cargo to the second row of seats

-3 Space from the luggage compartment/ cargo to the third row of seats

Note: For vehicles of multi-row of seats, add the dimension suffixes of corresponding

rows, such as -4, -5, as required.

5.3.4 Special suffix

For the internal dimensions, external dimensions, luggage compartment/ cargo

or rear component dimensions, some special measurement conditions and

measurement positions in the special dimensions of motor vehicle, keep the

letters and numerical codes consistent; add the special suffix in Table 7 to

distinguish the conditions or positions.

Table 7 -- Special suffix

Special suffix Measurement conditions or measurement positions

-C Center of occupant positions

-L Vehicle left side

-R Vehicle right side

-CV The sunroof or ceiling is folded or retracted

-GVM Gross vehicle mass condition

Note: Unless otherwise specified, for the case where the positions on both sides of the

vehicle are symmetrical and only one side is measured, special suffix may not be

used.

6 Determination of the zero plane and the base point

6.1 Determination of the zero plane

Dimensions in Table 8 are used to determine the zero plane of the vehicle.

Table 8 -- Determination of the zero plane

Dimension

codes Name Measurement method

Figures

and

notes

GB/T 12673-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.020

T 04

Replacing GB/T 12673-1990

Motor vehicle main dimensions measurement method

ISSUED ON: OCTOBER 18, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Measurement preparation ... 17

5 Dimension codes ... 19

6 Determination of the zero plane and the base point ... 21

7 Dimension codes, name and measurement methods of int...

Share