1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 14849.1-2020 English PDF (GB/T14849.1-2020)

GB/T 14849.1-2020 English PDF (GB/T14849.1-2020)

Regular price

$155.00

Regular price

Sale price

$155.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 14849.1-2020: Methods for chemical analysis of silicon metal - Part 1: Determination of iron content

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 14849.1-2020 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 14849.1-2020

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 14849.1-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.30

H 17

Replacing GB/T 14849.1-2007

Methods for chemical analysis of silicon metal - Part

1: Determination of iron content

ISSUED ON: MARCH 06, 2020

IMPLEMENTED ON: FEBRUARY 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 1,10-phenanthroline spectrophotometry ... 5

4 Flame atomic absorption spectrometry ... 9

5 Quality assurance and control ... 13

6 Test report ... 13

Foreword

GB/T 14849 “Methods for chemical analysis of industrial silicon” consists of the

following 11 parts:

- Part 1: Determination of iron content;

- Part 2: Determination of aluminum content - Chrome azurol S

spectrophotometric method;

- Part 3: Determination of calcium content;

- Part 4: Determination of elements content Inductively coupled plasma

atomic emission spectrometric method;

- Part 5: Determination of elements content—Analysis using an X-ray

fluorescence method;

- Part 6: Determination of carbon-Infrared absorption method;

- Part 7: Determination of phosphorus content - Phosphorus molybdenum

blue spectrophotometry;

- Part 8: Determination of copper content - Atomic absorption spectrometric

method;

- Part 9: Determination of titanium content - Diantipyryl methane

spectrophotometry;

- Part 10: Determination of mercury content - Atomic fluorescence

spectrometric method;

- Part 11: Determination of chromium content - Diphenylcarbazide

spectrophotometric method.

This Part is Part 1 of GB/T 14849.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 14849.1-2007 “Methods for chemical analysis of silicon

metal - Part 1: Determination of iron content - 1,10-Phenanthrolion

spectrophotometric method”. Compared with GB/T 14849.1-2007, in addition to

editorial modifications, the main technical changes are as follows:

- added warning;

- modified range of determination from 0.10%~0.65% to 0.050%~0.75% (see

Methods for chemical analysis of silicon metal - Part

1: Determination of iron content

Warning - The personnel using this Part shall have practical experience

in formal laboratory work. This Part does not point out all possible

security issues. The user is responsible for taking appropriate safety and

health measures and ensuring compliance with the conditions stipulated

by relevant national laws and regulations.

1 Scope

This Part of GB/T 14849 specifies the method for determination of iron content

in silicon metal.

This Part is applicable to determination of iron content in silicon metal. The

range for determination is: 0.050%~0.75%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 8170, Rules of rounding off for numerical values and expression and

judgement of limiting values

3 1,10-phenanthroline spectrophotometry

3.1 Method summary

Use hydrofluoric acid and nitric acid to dissolve the specimen. Add perchloric

acid to evaporate till smoke appears to remove silicon and fluorine. Use

hydrochloric acid to dissolve the residue. Use hydroxylamine hydrochloride to

reduce Fe(III) to Fe(II). In pH3~pH5 sodium acetate buffer medium, Fe(II) ion

and 1,10-phenanthroline form a red complex. At 510nm wavelength, measure

the absorbance of the solution. Calculate the mass fraction of iron.

3.2 Reagents and materials

Unless otherwise specified, in the analysis, it shall only use the confirmed

analytically-pure reagent AND distilled water or deionized water or equivalent-

pure water.

3.2.1 Hydrofluoric acid (ρ=1.14g/mL).

3.2.2 Perchloric acid (ρ=1.67g/mL).

3.2.3 Nitric acid (1+1).

3.2.4 Hydrochloric acid (1+1).

3.2.5 Hydroxylamine hydrochloride solution (10g/L): Weigh 2.0g of

hydroxylamine hydrochloride. Place in a 100mL beaker. Add a small amount of

water and stir to dissolve completely. Use water to dilute to 200mL. Mix well.

3.2.6 1,10-phenanthroline solution (5g/L): Weigh 2.5g of 1,10-phenanthroline.

Place in a 100mL beaker. Add 2mL of hydrochloric acid (3.2.4), 20mL of water.

Stir and dissolve completely. Use water to dilute to 500mL. Mix well.

3.2.7 Acetic acid-sodium acetate buffer solution: Weigh 272g of sodium acetate

trihydrate. Place in a 1L beaker. Add 500mL of water. Stir and dissolve

completely. Filter in a 1000mL volumetric flask. Add 240mL of glacial acetic acid

(ρ=1.05g/mL). Use water to dilute to the scale. Mix well.

3.2.8 Mixed color developing solution: Mix hydroxylamine hydrochloride

solution (3.2.5), 1,10-phenanthroline solution (3.2.6) and acetic acid-sodium

acetate buffer solution (3.2.7) according to the volume of (1+1+2). Use within

one week.

3.2.9 Iron standard stock solution: Weigh 0.2860g of ferric oxide that has been

burned at 600°C for 1h and placed in a dryer to cool to room temperature

(benchmark reagent, ≥99.995%). Place in a beaker. Add 30mL of

hydrochloric acid (3.2.4). Heat at a low temperature to dissolve. Cool to room

temperature. Transfer to a 1000mL volumetric flask. Use water to dilute to the

scale. Mix well. 1mL of this solution contains 200μg of iron.

3.2.10 Iron standard solution: Pipette 25.00mL of iron standard stock solution

(3.2.9) into a 100mL volumetric flask. Use water to dilute to the scale. Mix well.

1mL of this solution contains 50μg of iron.

3.3 Instruments

3.3.1 Spectrophotometer.

3.3.2 Teflon beaker, 250mL.

- When the mass fraction of iron is >0.15%~0.75%, transfer the test solution

(3.5.4.1) into a 100mL volumetric flask. Use water to dilute to the scale. Mix

well. Pipette 20.00mL of test solution. Place in a 100mL volumetric flask.

Add 2.5mL of hydrochloric acid (3.2.4). Use water to dilute to about 50mL.

Add 5mL of mixed color developing solution (3.2.8). Use water to dilute to

the scale. Mix well. Leave it for 15min. The dilution factor (R1) of this solution

is 5.

3.5.4.3 Transfer part of the color solution (3.5.4.2) into the cuvette (3.3.4). Take

the blank solution (3.5.3) of the test material as reference. At a wavelength of

510nm, determine the absorbance of the solution. Find the iron mass (m1) from

the working curve.

3.5.5 Drawing of working curve

3.5.5.1 Pipette 0mL, 1.00mL, 2.00mL, 4.00mL, 6.00mL, 8.00mL, 10.00mL of

iron standard solution (3.2.10). Respectively put them in a set of 100mL

volumetric flasks. Add 2.5mL of hydrochloric acid (3.2.4). Use water to dilute to

about 50mL. Add 5mL of mixed color developing solution (3.2.8). Use water to

dilute to the scale. Mix well. Leave it for 15min.

3.5.5.2 Transfer part of the color developing solution (3.5.5.1) into the cuvette

(3.3.4). Take reagent blank solution as reference. At a wavelength of 510nm,

measure its absorbance. Use the mass of iron as the abscissa and absorbance

as the ordinate to draw the working curve.

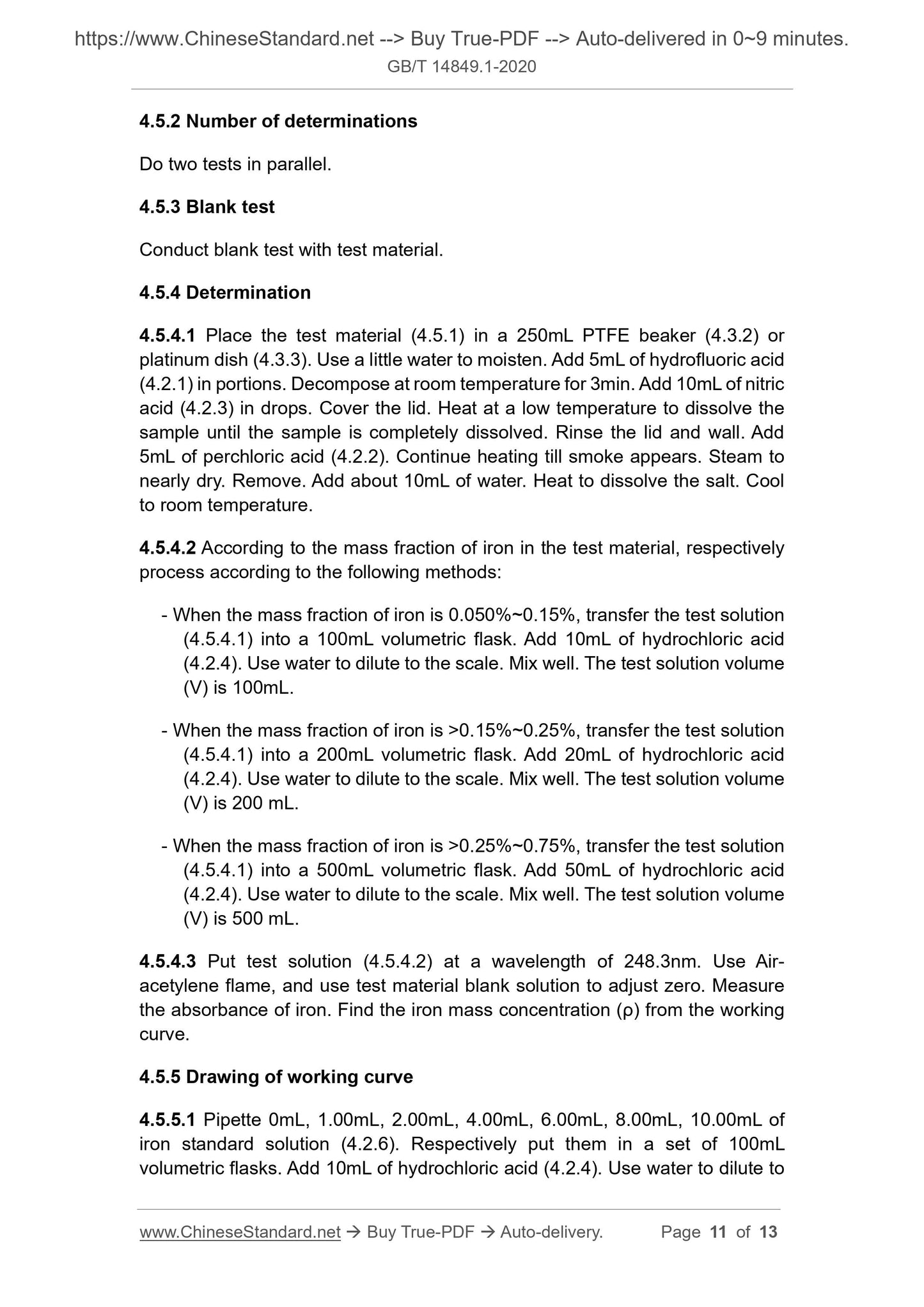

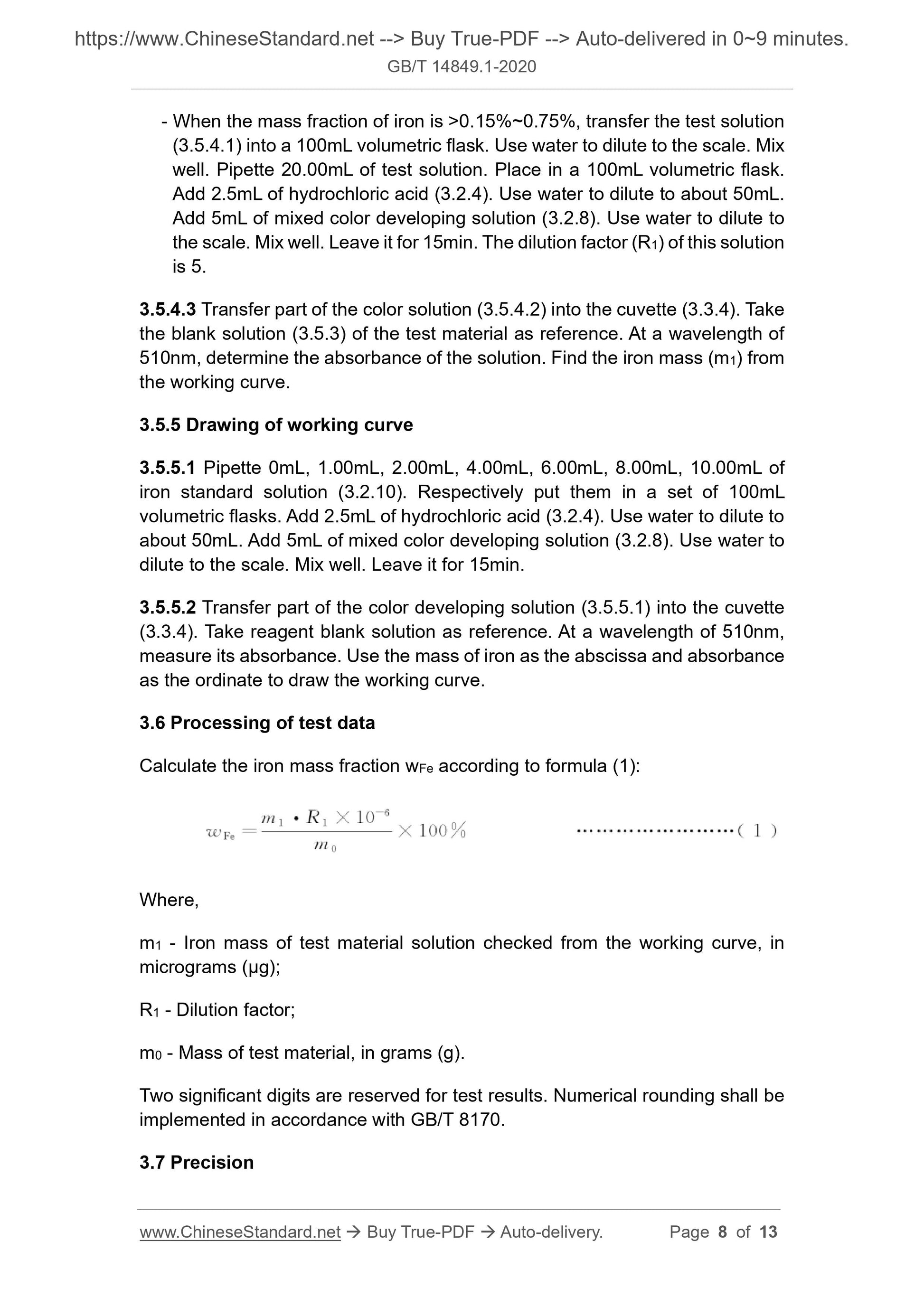

3.6 Processing of test data

Calculate the iron mass fraction wFe according to formula (1):

Where,

m1 - Iron mass of test material solution checked from the working curve, in

micrograms (μg);

R1 - Dilution factor;

m0 - Mass of test material, in grams (g).

Two significant digits are reserved for test results. Numerical rounding shall be

implemented in accordance with GB/T 8170.

3.7 Precision

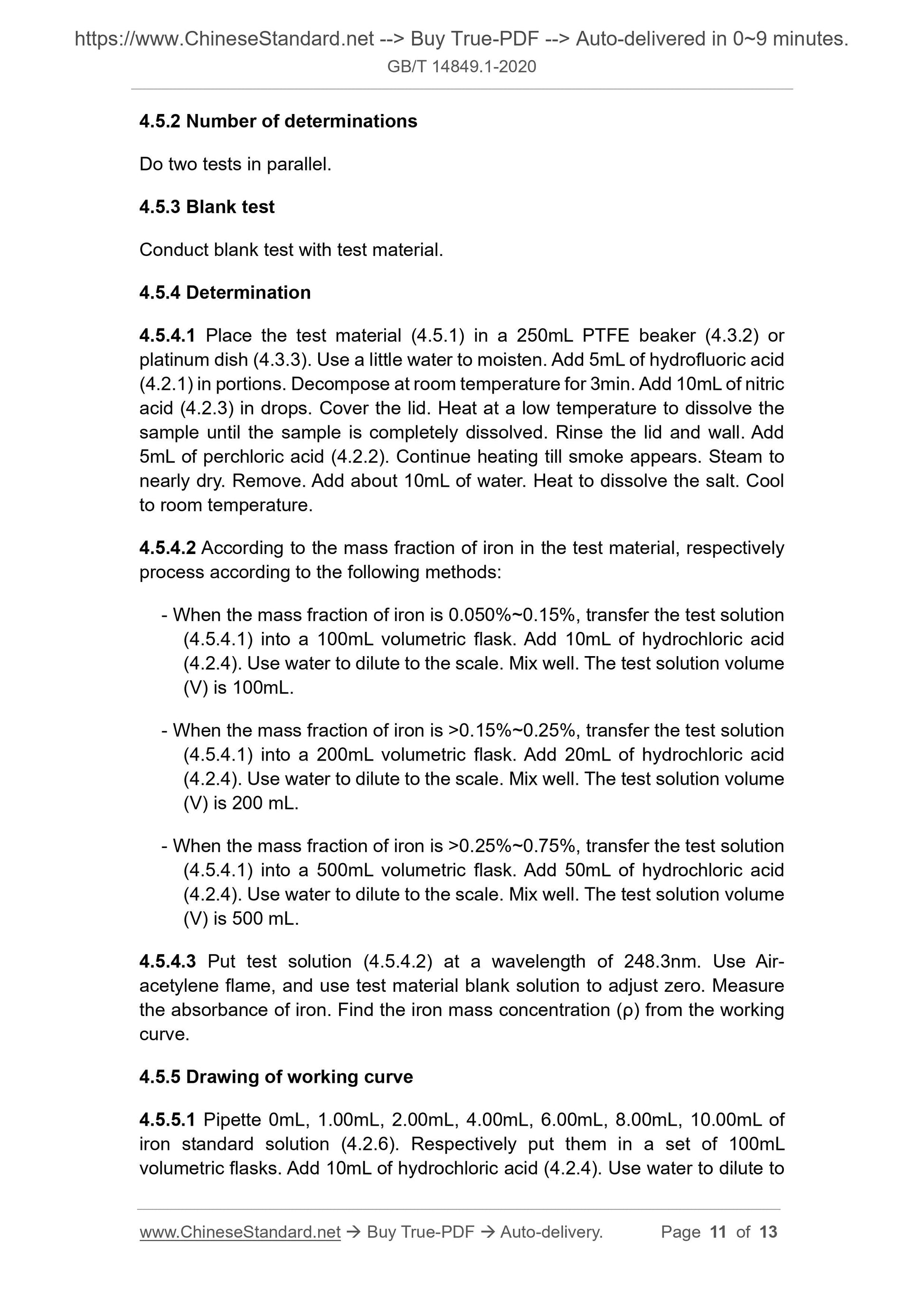

4.5.2 Number of determinations

Do two tests in parallel.

4.5.3 Blank test

Conduct blank test with test material.

4.5.4 Determination

4.5.4.1 Place the test material (4.5.1) in a 250mL PTFE beaker (4.3.2) or

platinum dish (4.3.3). Use a little water to moisten. Add 5mL of hydrofluoric acid

(4.2.1) in portions. Decompose at room temperature for 3min. Add 10mL of nitric

acid (4.2.3) in drops. Cover the lid. Heat at a low temperature to dissolve the

sample until the sample is completely dissolved. Rinse the lid and wall. Add

5mL of perchloric acid (4.2.2). Continue heating till smoke appears. Steam to

nearly dry. Remove. Add about 10mL of water. Heat to dissolve the salt. Cool

to room temperature.

4.5.4.2 According to the mass fraction of iron in the test material, respectively

process according to the following methods:

- When the mass fraction of iron is 0.050%~0.15%, transfer the test solution

(4.5.4.1) into a 100mL volumetric flask. Add 10mL of hydrochloric acid

(4.2.4). Use water to dilute to the scale. Mix well. The test solution volume

(V) is 100mL.

- When the mass fraction of iron is >0.15%~0.25%, transfer the test solution

(4.5.4.1) into a 200mL volumetric flask. Add 20mL of hydrochloric acid

(4.2.4). Use water to dilute to the scale. Mix well. The test solution volume

(V) is 200 mL.

- When the mass fraction of iron is >0.25%~0.75%, transfer the test solution

(4.5.4.1) into a 500mL volumetric flask. Add 50mL of hydrochloric acid

(4.2.4). Use water to dilute to the scale. Mix well. The test solution volume

(V) is 500 mL.

4.5.4.3 Put test solution (4.5.4.2) at a wavelength of 248.3nm. Use Air-

acetylene flame, and use test material blank solution to adjust zero. Measure

the absorbance of iron. Find the iron mass concentration (ρ) from the working

curve.

4.5.5 Drawing of working curve

4.5.5.1 Pipette 0mL, 1.00mL, 2.00mL, 4.00mL, 6.00mL, 8.00mL, 10.00mL of

iron standard solution (4.2.6). Respectively put them in a set of 100mL

volumetric flasks. Add 10mL of hydrochloric acid (4.2.4). Use water to dilute to

GB/T 14849.1-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.30

H 17

Replacing GB/T 14849.1-2007

Methods for chemical analysis of silicon metal - Part

1: Determination of iron content

ISSUED ON: MARCH 06, 2020

IMPLEMENTED ON: FEBRUARY 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 1,10-phenanthroline spectrophotometry ... 5

4 Flame atomic absorption spectrometry ... 9

5 Quality assurance and control ... 13

6 Test report ... 13

Foreword

GB/T 14849 “Methods for chemical analysis of industrial silicon” consists of the

following 11 parts:

- Part 1: Determination of iron content;

- Part 2: Determination of aluminum content - Chrome azurol S

spectrophotometric method;

- Part 3: Determination of calcium content;

- Part 4: Determination of elements content Inductively coupled plasma

atomic emission spectrometric method;

- Part 5: Determination of elements content—Analysis using an X-ray

fluorescence method;

- Part 6: Determination of carbon-Infrared absorption method;

- Part 7: Determination of phosphorus content - Phosphorus molybdenum

blue spectrophotometry;

- Part 8: Determination of copper content - Atomic absorption spectrometric

method;

- Part 9: Determination of titanium content - Diantipyryl methane

spectrophotometry;

- Part 10: Determination of mercury content - Atomic fluorescence

spectrometric method;

- Part 11: Determination of chromium content - Diphenylcarbazide

spectrophotometric method.

This Part is Part 1 of GB/T 14849.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 14849.1-2007 “Methods for chemical analysis of silicon

metal - Part 1: Determination of iron content - 1,10-Phenanthrolion

spectrophotometric method”. Compared with GB/T 14849.1-2007, in addition to

editorial modifications, the main technical changes are as follows:

- added warning;

- modified range of determination from 0.10%~0.65% to 0.050%~0.75% (see

Methods for chemical analysis of silicon metal - Part

1: Determination of iron content

Warning - The personnel using this Part shall have practical experience

in formal laboratory work. This Part does not point out all possible

security issues. The user is responsible for taking appropriate safety and

health measures and ensuring compliance with the conditions stipulated

by relevant national laws and regulations.

1 Scope

This Part of GB/T 14849 specifies the method for determination of iron content

in silicon metal.

This Part is applicable to determination of iron content in silicon metal. The

range for determination is: 0.050%~0.75%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 8170, Rules of rounding off for numerical values and expression and

judgement of limiting values

3 1,10-phenanthroline spectrophotometry

3.1 Method summary

Use hydrofluoric acid and nitric acid to dissolve the specimen. Add perchloric

acid to evaporate till smoke appears to remove silicon and fluorine. Use

hydrochloric acid to dissolve the residue. Use hydroxylamine hydrochloride to

reduce Fe(III) to Fe(II). In pH3~pH5 sodium acetate buffer medium, Fe(II) ion

and 1,10-phenanthroline form a red complex. At 510nm wavelength, measure

the absorbance of the solution. Calculate the mass fraction of iron.

3.2 Reagents and materials

Unless otherwise specified, in the analysis, it shall only use the confirmed

analytically-pure reagent AND distilled water or deionized water or equivalent-

pure water.

3.2.1 Hydrofluoric acid (ρ=1.14g/mL).

3.2.2 Perchloric acid (ρ=1.67g/mL).

3.2.3 Nitric acid (1+1).

3.2.4 Hydrochloric acid (1+1).

3.2.5 Hydroxylamine hydrochloride solution (10g/L): Weigh 2.0g of

hydroxylamine hydrochloride. Place in a 100mL beaker. Add a small amount of

water and stir to dissolve completely. Use water to dilute to 200mL. Mix well.

3.2.6 1,10-ph...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 14849.1-2020 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 14849.1-2020

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 14849.1-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.30

H 17

Replacing GB/T 14849.1-2007

Methods for chemical analysis of silicon metal - Part

1: Determination of iron content

ISSUED ON: MARCH 06, 2020

IMPLEMENTED ON: FEBRUARY 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 1,10-phenanthroline spectrophotometry ... 5

4 Flame atomic absorption spectrometry ... 9

5 Quality assurance and control ... 13

6 Test report ... 13

Foreword

GB/T 14849 “Methods for chemical analysis of industrial silicon” consists of the

following 11 parts:

- Part 1: Determination of iron content;

- Part 2: Determination of aluminum content - Chrome azurol S

spectrophotometric method;

- Part 3: Determination of calcium content;

- Part 4: Determination of elements content Inductively coupled plasma

atomic emission spectrometric method;

- Part 5: Determination of elements content—Analysis using an X-ray

fluorescence method;

- Part 6: Determination of carbon-Infrared absorption method;

- Part 7: Determination of phosphorus content - Phosphorus molybdenum

blue spectrophotometry;

- Part 8: Determination of copper content - Atomic absorption spectrometric

method;

- Part 9: Determination of titanium content - Diantipyryl methane

spectrophotometry;

- Part 10: Determination of mercury content - Atomic fluorescence

spectrometric method;

- Part 11: Determination of chromium content - Diphenylcarbazide

spectrophotometric method.

This Part is Part 1 of GB/T 14849.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 14849.1-2007 “Methods for chemical analysis of silicon

metal - Part 1: Determination of iron content - 1,10-Phenanthrolion

spectrophotometric method”. Compared with GB/T 14849.1-2007, in addition to

editorial modifications, the main technical changes are as follows:

- added warning;

- modified range of determination from 0.10%~0.65% to 0.050%~0.75% (see

Methods for chemical analysis of silicon metal - Part

1: Determination of iron content

Warning - The personnel using this Part shall have practical experience

in formal laboratory work. This Part does not point out all possible

security issues. The user is responsible for taking appropriate safety and

health measures and ensuring compliance with the conditions stipulated

by relevant national laws and regulations.

1 Scope

This Part of GB/T 14849 specifies the method for determination of iron content

in silicon metal.

This Part is applicable to determination of iron content in silicon metal. The

range for determination is: 0.050%~0.75%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 8170, Rules of rounding off for numerical values and expression and

judgement of limiting values

3 1,10-phenanthroline spectrophotometry

3.1 Method summary

Use hydrofluoric acid and nitric acid to dissolve the specimen. Add perchloric

acid to evaporate till smoke appears to remove silicon and fluorine. Use

hydrochloric acid to dissolve the residue. Use hydroxylamine hydrochloride to

reduce Fe(III) to Fe(II). In pH3~pH5 sodium acetate buffer medium, Fe(II) ion

and 1,10-phenanthroline form a red complex. At 510nm wavelength, measure

the absorbance of the solution. Calculate the mass fraction of iron.

3.2 Reagents and materials

Unless otherwise specified, in the analysis, it shall only use the confirmed

analytically-pure reagent AND distilled water or deionized water or equivalent-

pure water.

3.2.1 Hydrofluoric acid (ρ=1.14g/mL).

3.2.2 Perchloric acid (ρ=1.67g/mL).

3.2.3 Nitric acid (1+1).

3.2.4 Hydrochloric acid (1+1).

3.2.5 Hydroxylamine hydrochloride solution (10g/L): Weigh 2.0g of

hydroxylamine hydrochloride. Place in a 100mL beaker. Add a small amount of

water and stir to dissolve completely. Use water to dilute to 200mL. Mix well.

3.2.6 1,10-phenanthroline solution (5g/L): Weigh 2.5g of 1,10-phenanthroline.

Place in a 100mL beaker. Add 2mL of hydrochloric acid (3.2.4), 20mL of water.

Stir and dissolve completely. Use water to dilute to 500mL. Mix well.

3.2.7 Acetic acid-sodium acetate buffer solution: Weigh 272g of sodium acetate

trihydrate. Place in a 1L beaker. Add 500mL of water. Stir and dissolve

completely. Filter in a 1000mL volumetric flask. Add 240mL of glacial acetic acid

(ρ=1.05g/mL). Use water to dilute to the scale. Mix well.

3.2.8 Mixed color developing solution: Mix hydroxylamine hydrochloride

solution (3.2.5), 1,10-phenanthroline solution (3.2.6) and acetic acid-sodium

acetate buffer solution (3.2.7) according to the volume of (1+1+2). Use within

one week.

3.2.9 Iron standard stock solution: Weigh 0.2860g of ferric oxide that has been

burned at 600°C for 1h and placed in a dryer to cool to room temperature

(benchmark reagent, ≥99.995%). Place in a beaker. Add 30mL of

hydrochloric acid (3.2.4). Heat at a low temperature to dissolve. Cool to room

temperature. Transfer to a 1000mL volumetric flask. Use water to dilute to the

scale. Mix well. 1mL of this solution contains 200μg of iron.

3.2.10 Iron standard solution: Pipette 25.00mL of iron standard stock solution

(3.2.9) into a 100mL volumetric flask. Use water to dilute to the scale. Mix well.

1mL of this solution contains 50μg of iron.

3.3 Instruments

3.3.1 Spectrophotometer.

3.3.2 Teflon beaker, 250mL.

- When the mass fraction of iron is >0.15%~0.75%, transfer the test solution

(3.5.4.1) into a 100mL volumetric flask. Use water to dilute to the scale. Mix

well. Pipette 20.00mL of test solution. Place in a 100mL volumetric flask.

Add 2.5mL of hydrochloric acid (3.2.4). Use water to dilute to about 50mL.

Add 5mL of mixed color developing solution (3.2.8). Use water to dilute to

the scale. Mix well. Leave it for 15min. The dilution factor (R1) of this solution

is 5.

3.5.4.3 Transfer part of the color solution (3.5.4.2) into the cuvette (3.3.4). Take

the blank solution (3.5.3) of the test material as reference. At a wavelength of

510nm, determine the absorbance of the solution. Find the iron mass (m1) from

the working curve.

3.5.5 Drawing of working curve

3.5.5.1 Pipette 0mL, 1.00mL, 2.00mL, 4.00mL, 6.00mL, 8.00mL, 10.00mL of

iron standard solution (3.2.10). Respectively put them in a set of 100mL

volumetric flasks. Add 2.5mL of hydrochloric acid (3.2.4). Use water to dilute to

about 50mL. Add 5mL of mixed color developing solution (3.2.8). Use water to

dilute to the scale. Mix well. Leave it for 15min.

3.5.5.2 Transfer part of the color developing solution (3.5.5.1) into the cuvette

(3.3.4). Take reagent blank solution as reference. At a wavelength of 510nm,

measure its absorbance. Use the mass of iron as the abscissa and absorbance

as the ordinate to draw the working curve.

3.6 Processing of test data

Calculate the iron mass fraction wFe according to formula (1):

Where,

m1 - Iron mass of test material solution checked from the working curve, in

micrograms (μg);

R1 - Dilution factor;

m0 - Mass of test material, in grams (g).

Two significant digits are reserved for test results. Numerical rounding shall be

implemented in accordance with GB/T 8170.

3.7 Precision

4.5.2 Number of determinations

Do two tests in parallel.

4.5.3 Blank test

Conduct blank test with test material.

4.5.4 Determination

4.5.4.1 Place the test material (4.5.1) in a 250mL PTFE beaker (4.3.2) or

platinum dish (4.3.3). Use a little water to moisten. Add 5mL of hydrofluoric acid

(4.2.1) in portions. Decompose at room temperature for 3min. Add 10mL of nitric

acid (4.2.3) in drops. Cover the lid. Heat at a low temperature to dissolve the

sample until the sample is completely dissolved. Rinse the lid and wall. Add

5mL of perchloric acid (4.2.2). Continue heating till smoke appears. Steam to

nearly dry. Remove. Add about 10mL of water. Heat to dissolve the salt. Cool

to room temperature.

4.5.4.2 According to the mass fraction of iron in the test material, respectively

process according to the following methods:

- When the mass fraction of iron is 0.050%~0.15%, transfer the test solution

(4.5.4.1) into a 100mL volumetric flask. Add 10mL of hydrochloric acid

(4.2.4). Use water to dilute to the scale. Mix well. The test solution volume

(V) is 100mL.

- When the mass fraction of iron is >0.15%~0.25%, transfer the test solution

(4.5.4.1) into a 200mL volumetric flask. Add 20mL of hydrochloric acid

(4.2.4). Use water to dilute to the scale. Mix well. The test solution volume

(V) is 200 mL.

- When the mass fraction of iron is >0.25%~0.75%, transfer the test solution

(4.5.4.1) into a 500mL volumetric flask. Add 50mL of hydrochloric acid

(4.2.4). Use water to dilute to the scale. Mix well. The test solution volume

(V) is 500 mL.

4.5.4.3 Put test solution (4.5.4.2) at a wavelength of 248.3nm. Use Air-

acetylene flame, and use test material blank solution to adjust zero. Measure

the absorbance of iron. Find the iron mass concentration (ρ) from the working

curve.

4.5.5 Drawing of working curve

4.5.5.1 Pipette 0mL, 1.00mL, 2.00mL, 4.00mL, 6.00mL, 8.00mL, 10.00mL of

iron standard solution (4.2.6). Respectively put them in a set of 100mL

volumetric flasks. Add 10mL of hydrochloric acid (4.2.4). Use water to dilute to

GB/T 14849.1-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.30

H 17

Replacing GB/T 14849.1-2007

Methods for chemical analysis of silicon metal - Part

1: Determination of iron content

ISSUED ON: MARCH 06, 2020

IMPLEMENTED ON: FEBRUARY 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 1,10-phenanthroline spectrophotometry ... 5

4 Flame atomic absorption spectrometry ... 9

5 Quality assurance and control ... 13

6 Test report ... 13

Foreword

GB/T 14849 “Methods for chemical analysis of industrial silicon” consists of the

following 11 parts:

- Part 1: Determination of iron content;

- Part 2: Determination of aluminum content - Chrome azurol S

spectrophotometric method;

- Part 3: Determination of calcium content;

- Part 4: Determination of elements content Inductively coupled plasma

atomic emission spectrometric method;

- Part 5: Determination of elements content—Analysis using an X-ray

fluorescence method;

- Part 6: Determination of carbon-Infrared absorption method;

- Part 7: Determination of phosphorus content - Phosphorus molybdenum

blue spectrophotometry;

- Part 8: Determination of copper content - Atomic absorption spectrometric

method;

- Part 9: Determination of titanium content - Diantipyryl methane

spectrophotometry;

- Part 10: Determination of mercury content - Atomic fluorescence

spectrometric method;

- Part 11: Determination of chromium content - Diphenylcarbazide

spectrophotometric method.

This Part is Part 1 of GB/T 14849.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 14849.1-2007 “Methods for chemical analysis of silicon

metal - Part 1: Determination of iron content - 1,10-Phenanthrolion

spectrophotometric method”. Compared with GB/T 14849.1-2007, in addition to

editorial modifications, the main technical changes are as follows:

- added warning;

- modified range of determination from 0.10%~0.65% to 0.050%~0.75% (see

Methods for chemical analysis of silicon metal - Part

1: Determination of iron content

Warning - The personnel using this Part shall have practical experience

in formal laboratory work. This Part does not point out all possible

security issues. The user is responsible for taking appropriate safety and

health measures and ensuring compliance with the conditions stipulated

by relevant national laws and regulations.

1 Scope

This Part of GB/T 14849 specifies the method for determination of iron content

in silicon metal.

This Part is applicable to determination of iron content in silicon metal. The

range for determination is: 0.050%~0.75%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 8170, Rules of rounding off for numerical values and expression and

judgement of limiting values

3 1,10-phenanthroline spectrophotometry

3.1 Method summary

Use hydrofluoric acid and nitric acid to dissolve the specimen. Add perchloric

acid to evaporate till smoke appears to remove silicon and fluorine. Use

hydrochloric acid to dissolve the residue. Use hydroxylamine hydrochloride to

reduce Fe(III) to Fe(II). In pH3~pH5 sodium acetate buffer medium, Fe(II) ion

and 1,10-phenanthroline form a red complex. At 510nm wavelength, measure

the absorbance of the solution. Calculate the mass fraction of iron.

3.2 Reagents and materials

Unless otherwise specified, in the analysis, it shall only use the confirmed

analytically-pure reagent AND distilled water or deionized water or equivalent-

pure water.

3.2.1 Hydrofluoric acid (ρ=1.14g/mL).

3.2.2 Perchloric acid (ρ=1.67g/mL).

3.2.3 Nitric acid (1+1).

3.2.4 Hydrochloric acid (1+1).

3.2.5 Hydroxylamine hydrochloride solution (10g/L): Weigh 2.0g of

hydroxylamine hydrochloride. Place in a 100mL beaker. Add a small amount of

water and stir to dissolve completely. Use water to dilute to 200mL. Mix well.

3.2.6 1,10-ph...

Share