1

/

of

8

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 15260-2016 English PDF (GBT15260-2016)

GB/T 15260-2016 English PDF (GBT15260-2016)

Regular price

$140.00 USD

Regular price

Sale price

$140.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 15260-2016

Historical versions: GB/T 15260-2016

Preview True-PDF (Reload/Scroll if blank)

GB/T 15260-2016: Corrosion of metals and alloys -- Test methods for intergranular corrosion of nickel alloys

GB/T 15260-2016

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.060

H 25

Replacing GB/T 15260-1994

Corrosion of metals and alloys - Test methods

for intergranular corrosion of nickel alloys

ISSUED ON. AUGUST 29, 2016

IMPLEMENTED ON. JULY 1, 2017

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 General ... 5

4 Method A. ferric sulfate (III) - sulfuric acid test ... 10

5 Method B. copper - copper sulfate - 16 % sulfuric acid test ... 13

6 Method C. hydrochloric acid test ... 15

7 Method D. nitric acid test ... 16

Foreword

This Standard is drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 15260-1994 “Test methods for intergranular corrosion of

nickel alloys”; compared with GB/T 15260-1994, main technical changes are as follows.

- ADD the sampling requirements;

- MODIFY the general title of the clause in the original standard from “Sample

preparation” TO “Sampling and preparation”; SPECIFY the dimension of the

recommended sample according to different methods;

- MODIFY the schematic diagram of the test device in the original standard;

- MODIFY the “glass bracket” in the original standard TO “sample bracket”; RETAIN

the schematic diagram of bracket in the original standard; RECOMMEND two

kinds of glass bracket;

- DELETE the “boiling debris” in the original standard; ADD the relevant content to

the test solution of Method A;

- MODIFY the “heating device” in the original standard;

- DELETE subclause 8.4 of Method A in the original standard;

- ADD the test duration and density constant of the recommended alloy in Method

A;

- ADD the method for inspecting the effect of steam escape on the acid

concentration and the criteria for re-testing in Method A;

- MODIFY the normal annealed material in Method A in the original standard TO the

solid solution material;

- ADD the relevant clauses of the test report.

This Standard is proposed by China Iron and Steel Industry Association.

This Standard is under the jurisdiction of National Technical Committee on Steel of

Standardization Administration of China (SAC/TC 183).

Drafting organizations of this Standard. Pangang Group Jiangyou Changcheng

Special Steel Co., Ltd., Metallurgical Industry Information Standards Institute, Zhejiang

JIULI Hi-Tech Metals Co., Ltd., Iron and Steel Research Institute.

Main drafters of this Standard. Wu Jie, Hu Jin, Hou Jie, Chu Yanli, Zhou Pingjiang,

Corrosion of metals and alloys - Test methods for

intergranular corrosion of nickel alloys

1 Scope

This Standard specifies the samples, test equipment, scope of application, test solution,

test procedures, evaluation of test results and test report of test methods for

intergranular corrosion of nickel alloys (iron nickel base, nickel base). This Standard

includes the following four test methods.

a) Method A. ferric sulfate (III) - sulfuric acid test;

b) Method B. copper - copper sulfate - 16 % sulfuric acid test;

c) Method C. hydrochloric acid test;

d) Method D. nitric acid test.

This Standard applies to nickel alloys used in corrosive environments. The choice of

the four methods, the sensitization treatment system of the alloy and the criteria for the

results are negotiated by the supply and demand parties of the alloy.

2 Normative references

The following documents are indispensable for the application of this document. For

dated references, the only dated edition applies to this document. For undated

references, the latest edition (including all modifications) applies to this document.

GB/T 622 Chemical reagent - Hydrochloric acid

GB/T 625 Chemical reagent - Sulfuric acid

GB/T 626 Chemical reagent - Nitric acid

GB/T 665 Chemical reagent - Copper sulfate pentahydrate

3 General

3.1 Sampling and preparation

3.1.1 For the recommended sample of Method A, C and D, the total area is 500 mm2

~ 2000 mm2, the ratio of the area of the sample to the area of the two faces shall not

be more than 20 %. The welding samples shall include welds, heat affected zones and

base metals, both of which are not more than 13 mm.

3.1.2 The dimension of the recommended bending sample of Method B. the length is

80 mm ~ 100 mm, the width is 20 mm, the thickness is 3 mm ~ 4 mm (samples with a

width or a thickness less than the recommended dimension shall be taken according

to the actual dimension). Pipes with an outside diameter of not more than 40 mm shall

be taken at 25 mm in length. In Method B, it shall take the original surface as the outer

surface of bending.

3.1.3 The sample shall be taken in the direction of the forging, and the surface shall

be as close as possible to the surface of the material in use. If necessary, the surface

of the sample is allowed to be machined, and the surface roughness is generally Ra ≤

0.80 μm.

3.1.4 When cutting the sample, it shall remove the deformed metal by grinding or

machining before the test. The sample shall be prevented from overheating during

machining.

3.1.5 The sample shall be degreased by non-chlorinated solvents, rinsed and dried

before the test.

3.2 Sensitization treatment of samples

3.2.1 For samples require sensitization treatment before the test, the surface needs to

be cleaned before the sensitization treatment, to remove carbon-containing lubricants,

grease, etc. To obtain a clean surface, mild surface grinding or pickling shall be carried

out, followed by washing with non-chlorinated solvents, rinsing and drying.

3.2.2 The sensitization system shall be negotiated by both supply and demand parties.

3.2.3 The sensitization treatment shall be carried out before the sample is finished.

3.2.4 For samples that do not require sensitization treatment, the test shall be carried

out in a state where the final conditions of use are simulated. For alloy materials that

need to be welded or heat-treated, they shall be treated as much as possible with the

same treatment as the material being manufactured or used.

3.2.5 Before the test, remove the scale of the sensitized sample by grinding.

3.3 Test equipment

3.3.1 Test devices

Figure 1 and Figure 2 are two recommended test devices. Figure 1 is a ground flask

with a capacity of 1 L and Soxhlet or Aster's condenser with at least four condensed

The precision of the analysis balance shall not be less than 0.001 g.

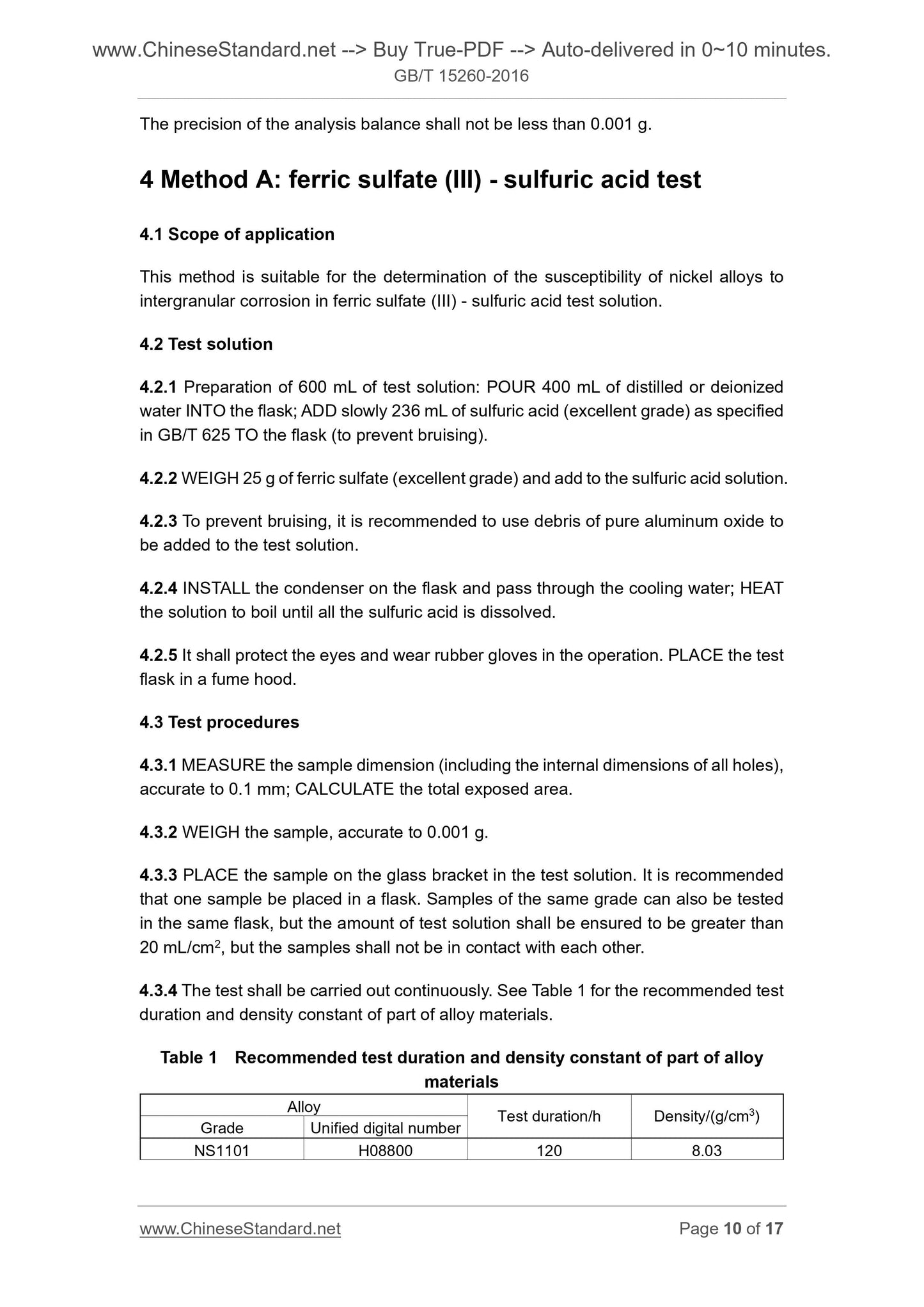

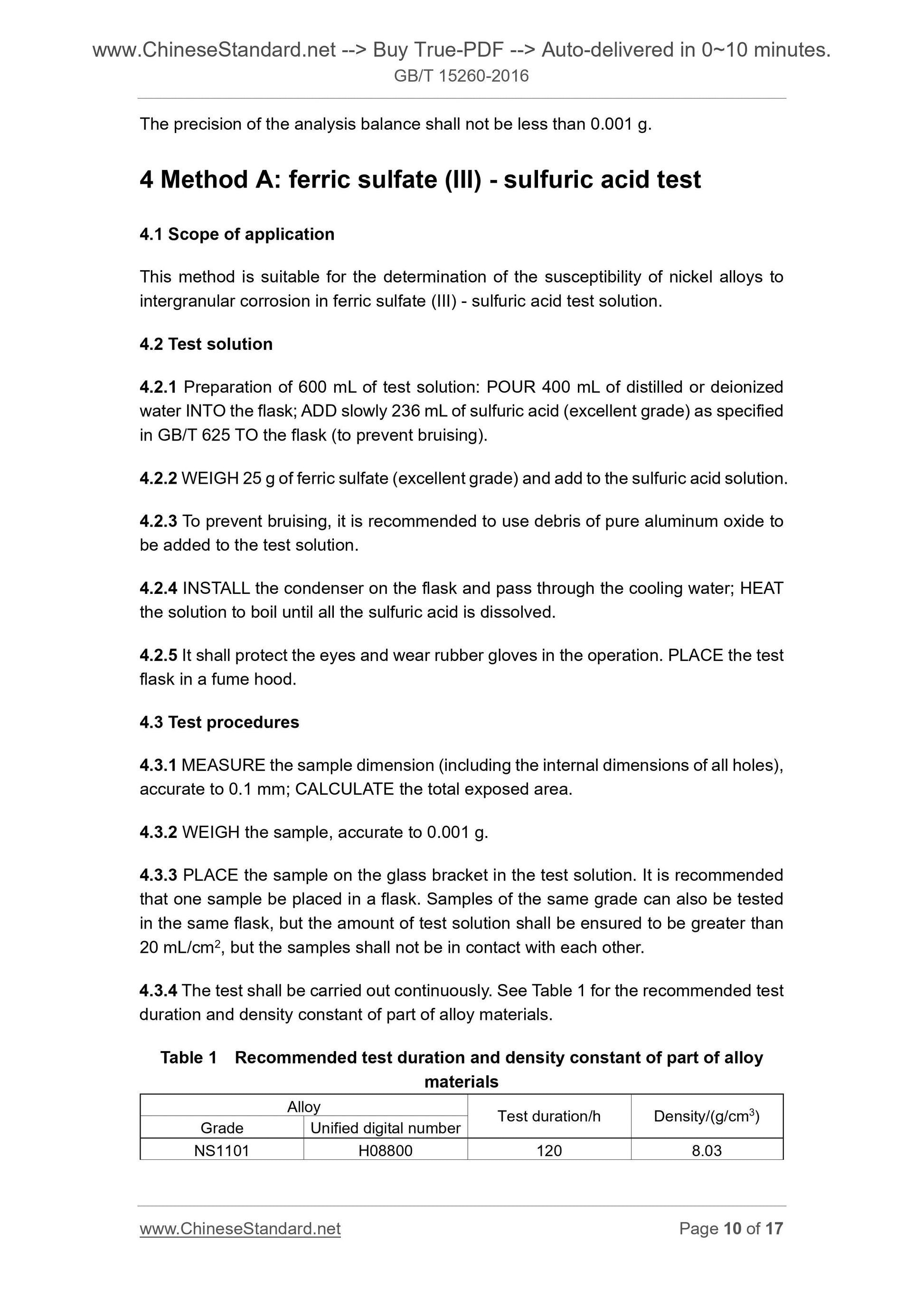

4 Method A. ferric sulfate (III) - sulfuric acid test

4.1 Scope of application

This method is suitable for the determination of the susceptibility of nickel alloys to

intergranular corrosion in ferric sulfate (III) - sulfuric acid test solution.

4.2 Test solution

4.2.1 Preparation of 600 mL of test solution. POUR 400 mL of distilled or deionized

water INTO the flask; ADD slowly 236 mL of sulfuric acid (excellent grade) as specified

in GB/T 625 TO the flask (to prevent bruising).

4.2.2 WEIGH 25 g of ferric sulfate (excellent grade) and add to the sulfuric acid solution.

4.2.3 To prevent bruising, it is recommended to use debris of pure aluminum oxide to

be added to the test solution.

4.2.4 INSTALL the condenser on the flask and pass through the cooling water; HEAT

the solution to boil until all the sulfuric acid is dissolved.

4.2.5 It shall protect the eyes and wear rubber gloves in the ope...

Get QUOTATION in 1-minute: Click GB/T 15260-2016

Historical versions: GB/T 15260-2016

Preview True-PDF (Reload/Scroll if blank)

GB/T 15260-2016: Corrosion of metals and alloys -- Test methods for intergranular corrosion of nickel alloys

GB/T 15260-2016

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.060

H 25

Replacing GB/T 15260-1994

Corrosion of metals and alloys - Test methods

for intergranular corrosion of nickel alloys

ISSUED ON. AUGUST 29, 2016

IMPLEMENTED ON. JULY 1, 2017

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 General ... 5

4 Method A. ferric sulfate (III) - sulfuric acid test ... 10

5 Method B. copper - copper sulfate - 16 % sulfuric acid test ... 13

6 Method C. hydrochloric acid test ... 15

7 Method D. nitric acid test ... 16

Foreword

This Standard is drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 15260-1994 “Test methods for intergranular corrosion of

nickel alloys”; compared with GB/T 15260-1994, main technical changes are as follows.

- ADD the sampling requirements;

- MODIFY the general title of the clause in the original standard from “Sample

preparation” TO “Sampling and preparation”; SPECIFY the dimension of the

recommended sample according to different methods;

- MODIFY the schematic diagram of the test device in the original standard;

- MODIFY the “glass bracket” in the original standard TO “sample bracket”; RETAIN

the schematic diagram of bracket in the original standard; RECOMMEND two

kinds of glass bracket;

- DELETE the “boiling debris” in the original standard; ADD the relevant content to

the test solution of Method A;

- MODIFY the “heating device” in the original standard;

- DELETE subclause 8.4 of Method A in the original standard;

- ADD the test duration and density constant of the recommended alloy in Method

A;

- ADD the method for inspecting the effect of steam escape on the acid

concentration and the criteria for re-testing in Method A;

- MODIFY the normal annealed material in Method A in the original standard TO the

solid solution material;

- ADD the relevant clauses of the test report.

This Standard is proposed by China Iron and Steel Industry Association.

This Standard is under the jurisdiction of National Technical Committee on Steel of

Standardization Administration of China (SAC/TC 183).

Drafting organizations of this Standard. Pangang Group Jiangyou Changcheng

Special Steel Co., Ltd., Metallurgical Industry Information Standards Institute, Zhejiang

JIULI Hi-Tech Metals Co., Ltd., Iron and Steel Research Institute.

Main drafters of this Standard. Wu Jie, Hu Jin, Hou Jie, Chu Yanli, Zhou Pingjiang,

Corrosion of metals and alloys - Test methods for

intergranular corrosion of nickel alloys

1 Scope

This Standard specifies the samples, test equipment, scope of application, test solution,

test procedures, evaluation of test results and test report of test methods for

intergranular corrosion of nickel alloys (iron nickel base, nickel base). This Standard

includes the following four test methods.

a) Method A. ferric sulfate (III) - sulfuric acid test;

b) Method B. copper - copper sulfate - 16 % sulfuric acid test;

c) Method C. hydrochloric acid test;

d) Method D. nitric acid test.

This Standard applies to nickel alloys used in corrosive environments. The choice of

the four methods, the sensitization treatment system of the alloy and the criteria for the

results are negotiated by the supply and demand parties of the alloy.

2 Normative references

The following documents are indispensable for the application of this document. For

dated references, the only dated edition applies to this document. For undated

references, the latest edition (including all modifications) applies to this document.

GB/T 622 Chemical reagent - Hydrochloric acid

GB/T 625 Chemical reagent - Sulfuric acid

GB/T 626 Chemical reagent - Nitric acid

GB/T 665 Chemical reagent - Copper sulfate pentahydrate

3 General

3.1 Sampling and preparation

3.1.1 For the recommended sample of Method A, C and D, the total area is 500 mm2

~ 2000 mm2, the ratio of the area of the sample to the area of the two faces shall not

be more than 20 %. The welding samples shall include welds, heat affected zones and

base metals, both of which are not more than 13 mm.

3.1.2 The dimension of the recommended bending sample of Method B. the length is

80 mm ~ 100 mm, the width is 20 mm, the thickness is 3 mm ~ 4 mm (samples with a

width or a thickness less than the recommended dimension shall be taken according

to the actual dimension). Pipes with an outside diameter of not more than 40 mm shall

be taken at 25 mm in length. In Method B, it shall take the original surface as the outer

surface of bending.

3.1.3 The sample shall be taken in the direction of the forging, and the surface shall

be as close as possible to the surface of the material in use. If necessary, the surface

of the sample is allowed to be machined, and the surface roughness is generally Ra ≤

0.80 μm.

3.1.4 When cutting the sample, it shall remove the deformed metal by grinding or

machining before the test. The sample shall be prevented from overheating during

machining.

3.1.5 The sample shall be degreased by non-chlorinated solvents, rinsed and dried

before the test.

3.2 Sensitization treatment of samples

3.2.1 For samples require sensitization treatment before the test, the surface needs to

be cleaned before the sensitization treatment, to remove carbon-containing lubricants,

grease, etc. To obtain a clean surface, mild surface grinding or pickling shall be carried

out, followed by washing with non-chlorinated solvents, rinsing and drying.

3.2.2 The sensitization system shall be negotiated by both supply and demand parties.

3.2.3 The sensitization treatment shall be carried out before the sample is finished.

3.2.4 For samples that do not require sensitization treatment, the test shall be carried

out in a state where the final conditions of use are simulated. For alloy materials that

need to be welded or heat-treated, they shall be treated as much as possible with the

same treatment as the material being manufactured or used.

3.2.5 Before the test, remove the scale of the sensitized sample by grinding.

3.3 Test equipment

3.3.1 Test devices

Figure 1 and Figure 2 are two recommended test devices. Figure 1 is a ground flask

with a capacity of 1 L and Soxhlet or Aster's condenser with at least four condensed

The precision of the analysis balance shall not be less than 0.001 g.

4 Method A. ferric sulfate (III) - sulfuric acid test

4.1 Scope of application

This method is suitable for the determination of the susceptibility of nickel alloys to

intergranular corrosion in ferric sulfate (III) - sulfuric acid test solution.

4.2 Test solution

4.2.1 Preparation of 600 mL of test solution. POUR 400 mL of distilled or deionized

water INTO the flask; ADD slowly 236 mL of sulfuric acid (excellent grade) as specified

in GB/T 625 TO the flask (to prevent bruising).

4.2.2 WEIGH 25 g of ferric sulfate (excellent grade) and add to the sulfuric acid solution.

4.2.3 To prevent bruising, it is recommended to use debris of pure aluminum oxide to

be added to the test solution.

4.2.4 INSTALL the condenser on the flask and pass through the cooling water; HEAT

the solution to boil until all the sulfuric acid is dissolved.

4.2.5 It shall protect the eyes and wear rubber gloves in the ope...

Share