1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 18175-2000 English PDF (GB/T18175-2000)

GB/T 18175-2000 English PDF (GB/T18175-2000)

Regular price

$105.00

Regular price

Sale price

$105.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 18175-2000: Determination of corrosion inhibition performance of water treatment agents - Rotation specimen method

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 18175-2000 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 18175-2000

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 18175-2000

ICS 71.100.80

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Determination of corrosion inhibition performance of

water treatment agents - Rotation specimen method

ISSUED ON. JULY 03, 2000

IMPLEMENTED ON. MARCH 01, 2001

Issued by.

General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Method summary ... 4

4 Reagents and materials ... 5

5 Instruments and apparatus ... 5

6 Test conditions ... 6

7 Test procedures ... 7

8 Result expression and calculation ... 8

9 Allowable difference ... 9

10 Test report ... 9

Appendix A (Normative) ... 10

Appendix B (Normative) ... 11

Foreword

This Standard non-equivalently adopts ASTM G31-1995 Laboratory Metal Materials Impregnation and

Corrosion Test Standard.

This Standard is different from ASTM G31-1995, because it specifies using the rotation specimen

method to determine the corrosion inhibition performance of water treatment agents for metal

materials.

Since the date of implementation of this Standard, it will replace HG/T 2159-1991 Determination of

Corrosion Inhibition Performance of Water Treatment Agents-Rotation Specimen Method.

Appendix A of this Standard is the standard appendix.

Appendix B of this Standard is suggestive appendix.

This Standard is proposed by the Ministry of Chemical Industry of the People’s Republic of China.

This Standard is under the jurisdiction of the Branch of Water Treatment Agents of the National

Chemical Standardization Technology Committee.

This Standard is drafted by organization. Guangming Chemical Industry Research and Design

Institute.

The main drafters of this Standard. Li Chengguo, Guo Ximin, Guo Fengxiang, Cai Qiang, Li Yuanyuan,

Cai Kangyu, and Jiang Chunhua.

Determination of corrosion inhibition performance of water

treatment agents - Rotation specimen method

1 Scope

This Standard specifies the laboratory method of using the rotation specimen method to determine the

corrosion inhibition performance of water treatment agents.

This Standard applies to the determination of corrosion inhibition performance of water treatment

agents.

2 Normative references

The following standards contain provisions which, through reference in this text, become part of this

Standard. At the time of publication of this Standard, all editions indicated are valid. All standards are

subject to revision. Parties who enter into agreements based on this Standard are encouraged to

investigate the possibility of applying the most recent editions of the standards indicated below.

GB/T 603-1988 Chemical reagents - Preparation of chemical reagents and products used in the test

method

GB/T 6682-1992 Analysis of water specifications and test methods of laboratory (neq ISO

3696.1986)

GB/T 15724.1-1995 Laboratory glassware - beaker

HG/T 3523-1985 Technical conditions on standard corrosion specimens for chemical treatment of

cooling water.

3 Method summary

The rotation specimen corrosive test method is conducted under the given laboratory conditions,

calculates the corrosion rate and inhibition rate to evaluate the corrosion inhibition performance of

water treatment agents by using the quality loss of test specimen.

7.8 USE brush to clean the test specimen, then SOAK into acid pickling solution (4.5) for 3-5 minutes.

TAKE out, after quickly washing with tap water, then immediately IMMERSE into NaOH (4.4) solution

for 30s. TAKE out, WASH with distilled water, USE filer paper to clean and dry, SOAK into the absolute

ethyl alcohol for about 3 minutes, PLACE onto the clean filter paper, PLACE in the dryer for over 4

hours, and WEIGH it (accurate to 0.0002g).

Do the pickling blank test of the specimen at the same time.

7.9 Do blank test without adding water treatment agents.

7.10 CONDUCT appearance observation and RECORD the data for the specimen after pickling.

8 Result expression and calculation

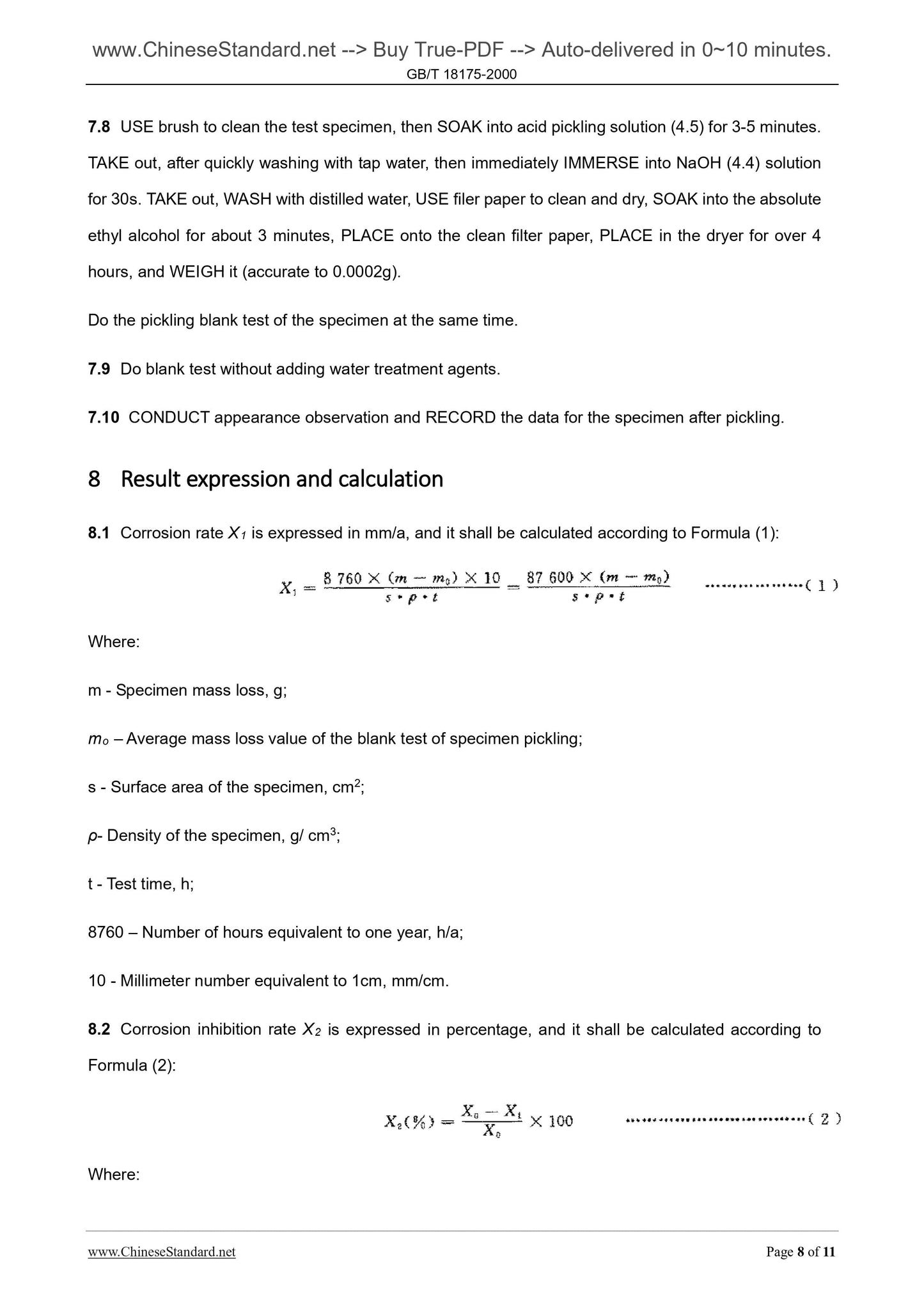

8.1 Corrosion rate X1 is expressed in mm/a, and it shall be calculated according to Formula (1).

Where.

m - Specimen mass loss, g;

mo – Average mass loss value of the blank test of specimen pickling;

s - Surface area of the specimen, cm2;

ρ- Density of the specimen, g/ cm3;

t - Test time, h;

8760 – Number of hours equivalent to one year, h/a;

10 - Millimeter number equivalent to 1cm, mm/cm.

8.2 Corrosion inhibition rate X2 is expressed in percentage, and it shall be calculated according to

Formula (2).

Where.

Appendix A

(Normative)

Recommended standard preparation water

A1 Reagents and materials

A1.1 Anhydrous calcium chloride.

A1.2 Magnesium sulfate monohydrate.

A1.3 Sodium hydrogen carbonate.

A1.4 Sodium chloride.

A2 Preparation of standard preparation water

WEIGH 7.35g of calcium chloride dihydrate (A1.1), 4.93g of magnesium sulfate heptahydrate (A1.2)

and 6.58g of NaCl (A1.4), DISSOLVE them into 7L of water, MIX well after complete dissolution.

WEIGH another 1.68g of sodium bicarbonate (A1.3) and DISSOLVE it into 1L of water, MIX well after

complete dissolution. TRANSFER the solution to above solution, USE water to dilute to 10.0L, MIX

well.

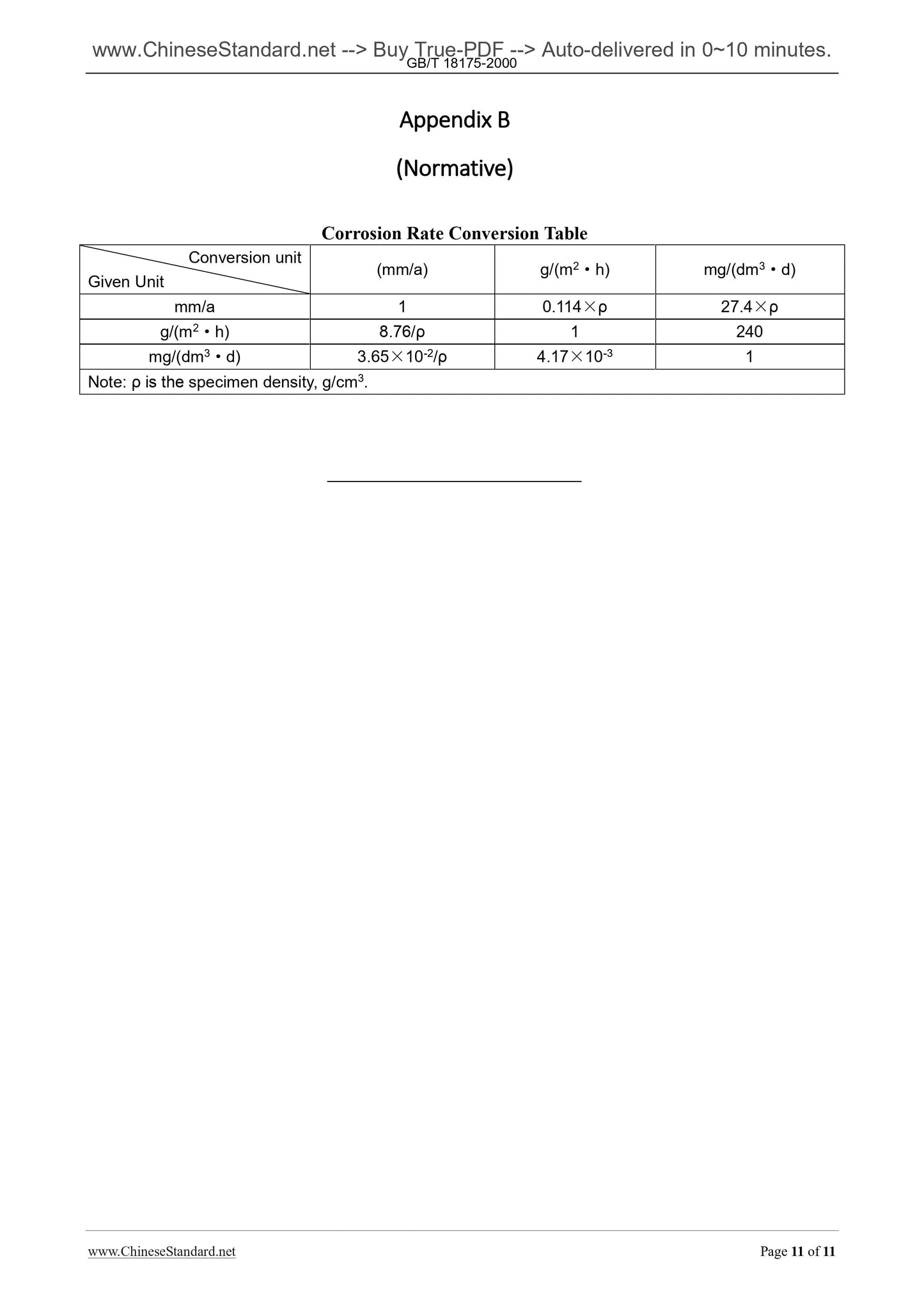

Appendix B

(Normative)

Corrosion Rate Conversion Table

Conversion unit

Given Unit

(mm/a) g/(m2·h) mg/(dm3·d)

mm/a 1 0.114×ρ 27.4×ρ

g/(m2·h) 8.76/ρ 1 240

mg/(dm3·d) 3.65×10-2/ρ 4.17×10-3 1

Note. ρ is the specimen density, g/cm3.

GB/T 18175-2000

ICS 71.100.80

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Determination of corrosion inhibition performance of

water treatment agents - Rotation specimen method

ISSUED ON. JULY 03, 2000

IMPLEMENTED ON. MARCH 01, 2001

Issued by.

General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Method summary ... 4

4 Reagents and materials ... 5

5 Instruments and apparatus ... 5

6 Test conditions ... 6

7 Test procedures ... 7

8 Result expression and calculation ... 8

9 Allowable difference ... 9

10 Test report ... 9

Appendix A (Normative) ... 10

Appendix B (Normative) ... 11

Foreword

This Standard non-equivalently adopts ASTM G31-1995 Laboratory Metal Materials Impregnation and

Corrosion Test Standard.

This Standard is different from ASTM G31-1995, because it specifies using the rotation specimen

method to determine the corrosion inhibition performance of water treatment agents for metal

materials.

Since the date of implementation of this Standard, it will replace HG/T 2159-1991 Determination of

Corrosion Inhibition Performance of Water Treatment Agents-Rotation Specimen Method.

Appendix A of this Standard is the standard appendix.

Appendix B of this Standard is suggestive appendix.

This Standard is proposed by the Ministry of Chemical Industry of the People’s Republic of China.

This Standard is under the jurisdiction of the Branch of Water Treatment Agents of the National

Chemical Standardization Technology Committee.

This Standard is drafted by organization. Guangming Chemical Industry Research and Design

Institute.

The main drafters of this Standard. Li Chengguo, Guo Ximin, Guo Fengxiang, Cai Qiang, Li Yuanyuan,

Cai Kangyu, and Jiang Chunhua.

Determination of corrosion inhibition performance of water

treatment agents - Rotation specimen method

1 Scope

This Standard specifies the laboratory method of using the rotation specimen method to determine the

corrosion inhibition performance of water treatment agents.

This Standard applies to the determination of corrosion inhibition performance of water treatment

agents.

2 Normative references

The following standards contain provisions which, through reference in this text, become part of this

Standard. At the time of publication of this Standard, all editions indicated are valid. All standards are

subject to revision. Parties who enter into agreements based on this Standard are encouraged to

investigate the possibility of applying the most recent editions of the standards indicated below.

GB/T 603-1988 Chemical reagents - Preparation of chemical reagents and products used in the test

method

GB/T 6682-1992 Analysis of water specifications and test methods of laboratory (neq ISO

3696.1986)

GB/T 15724.1-1995 Laboratory glassware - beaker

HG/T 3523-1985 Technical conditions on standard corrosion specimens for chemical treatment of

cooling water.

3 Method summary

The rotation specimen corrosive test method is conducted under the given laboratory conditions,

calculates the corrosion rate and inhibition rate to evaluate the corrosion inhibition performance of

water treatment agents by using the quality loss of test specimen.

7.8 USE brush to clean the test specimen, then SOAK into acid pickling solution (4.5) for 3-5 minutes.

TAKE out, after quickly washing with tap water, then immediately IMMERSE into NaOH (4.4) solution

for 30s. TAKE out, WASH with distilled water, USE filer paper to clean and dry, SOAK into the absolute

ethyl alcohol for about 3 minutes, PLACE onto the clean filter paper, PLACE in the dryer for over 4

hours, and WEIGH it (accurate to 0.0002g).

Do the pickling blank test of the specimen at the same time.

7.9 Do blank test without adding water treatment agents.

7.10 CONDUCT appearance observation and RECORD the data for the specimen after pickling.

8 Result expression and calculation

8.1 Corrosion rate X1 is expressed in mm/a, and it shall be calculated according to Formula (1).

Where.

m - Specimen mass loss, g;

mo – Average mass loss value of the blank test of specimen pickling;

s - Surface area of the specimen, cm2;

ρ- Density of the specimen, g/ cm3;

t - Test time, h;

8760 – Number of hours equivalent to one year, h/a;

10 - Millimeter number equivalent to 1cm, mm/cm.

8.2 Corrosion inhibition rate X2 is expressed in percentage, and it shall be calculated according to

Formula (2).

Where.

Appendix A

(Normative)

Recommended standard preparation water

A1 Reagents and materials

A1.1 Anhydrous calcium chloride.

A1.2 Magnesium sulfate monohydrate.

A1.3 Sodium hydrogen carbonate.

A1.4 Sodium chloride.

A2 Preparation of standard preparation water

WEIGH 7.35g of calcium chloride dihydrate (A1.1), 4.93g of magnesium sulfate heptahydrate (A1.2)

and 6.58g of NaCl (A1.4), DISSOLVE them into 7L of water, MIX well after complete dissolution.

WEIGH another 1.68g of sodium bicarbonate (A1.3) and DISSOLVE it into 1L of water, MIX well after

complete dissolution. TRANSFER the solution to above solution, USE water to dilute to 10.0L, MIX

well.

Appendix B

(Normative)

Corrosion Rate Conversion Table

Conversion unit

Given Unit

(mm/a) g/(m2·h) mg/(dm3·d)

mm/a 1 0.114×ρ 27.4×ρ

g/(m2·h) 8.76/ρ 1 240

mg/(dm3·d) 3.65×10-2/ρ 4.17×10-3 1

Note. ρ is the specimen density, g/cm3.

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 18175-2000 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 18175-2000

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 18175-2000

ICS 71.100.80

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Determination of corrosion inhibition performance of

water treatment agents - Rotation specimen method

ISSUED ON. JULY 03, 2000

IMPLEMENTED ON. MARCH 01, 2001

Issued by.

General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Method summary ... 4

4 Reagents and materials ... 5

5 Instruments and apparatus ... 5

6 Test conditions ... 6

7 Test procedures ... 7

8 Result expression and calculation ... 8

9 Allowable difference ... 9

10 Test report ... 9

Appendix A (Normative) ... 10

Appendix B (Normative) ... 11

Foreword

This Standard non-equivalently adopts ASTM G31-1995 Laboratory Metal Materials Impregnation and

Corrosion Test Standard.

This Standard is different from ASTM G31-1995, because it specifies using the rotation specimen

method to determine the corrosion inhibition performance of water treatment agents for metal

materials.

Since the date of implementation of this Standard, it will replace HG/T 2159-1991 Determination of

Corrosion Inhibition Performance of Water Treatment Agents-Rotation Specimen Method.

Appendix A of this Standard is the standard appendix.

Appendix B of this Standard is suggestive appendix.

This Standard is proposed by the Ministry of Chemical Industry of the People’s Republic of China.

This Standard is under the jurisdiction of the Branch of Water Treatment Agents of the National

Chemical Standardization Technology Committee.

This Standard is drafted by organization. Guangming Chemical Industry Research and Design

Institute.

The main drafters of this Standard. Li Chengguo, Guo Ximin, Guo Fengxiang, Cai Qiang, Li Yuanyuan,

Cai Kangyu, and Jiang Chunhua.

Determination of corrosion inhibition performance of water

treatment agents - Rotation specimen method

1 Scope

This Standard specifies the laboratory method of using the rotation specimen method to determine the

corrosion inhibition performance of water treatment agents.

This Standard applies to the determination of corrosion inhibition performance of water treatment

agents.

2 Normative references

The following standards contain provisions which, through reference in this text, become part of this

Standard. At the time of publication of this Standard, all editions indicated are valid. All standards are

subject to revision. Parties who enter into agreements based on this Standard are encouraged to

investigate the possibility of applying the most recent editions of the standards indicated below.

GB/T 603-1988 Chemical reagents - Preparation of chemical reagents and products used in the test

method

GB/T 6682-1992 Analysis of water specifications and test methods of laboratory (neq ISO

3696.1986)

GB/T 15724.1-1995 Laboratory glassware - beaker

HG/T 3523-1985 Technical conditions on standard corrosion specimens for chemical treatment of

cooling water.

3 Method summary

The rotation specimen corrosive test method is conducted under the given laboratory conditions,

calculates the corrosion rate and inhibition rate to evaluate the corrosion inhibition performance of

water treatment agents by using the quality loss of test specimen.

7.8 USE brush to clean the test specimen, then SOAK into acid pickling solution (4.5) for 3-5 minutes.

TAKE out, after quickly washing with tap water, then immediately IMMERSE into NaOH (4.4) solution

for 30s. TAKE out, WASH with distilled water, USE filer paper to clean and dry, SOAK into the absolute

ethyl alcohol for about 3 minutes, PLACE onto the clean filter paper, PLACE in the dryer for over 4

hours, and WEIGH it (accurate to 0.0002g).

Do the pickling blank test of the specimen at the same time.

7.9 Do blank test without adding water treatment agents.

7.10 CONDUCT appearance observation and RECORD the data for the specimen after pickling.

8 Result expression and calculation

8.1 Corrosion rate X1 is expressed in mm/a, and it shall be calculated according to Formula (1).

Where.

m - Specimen mass loss, g;

mo – Average mass loss value of the blank test of specimen pickling;

s - Surface area of the specimen, cm2;

ρ- Density of the specimen, g/ cm3;

t - Test time, h;

8760 – Number of hours equivalent to one year, h/a;

10 - Millimeter number equivalent to 1cm, mm/cm.

8.2 Corrosion inhibition rate X2 is expressed in percentage, and it shall be calculated according to

Formula (2).

Where.

Appendix A

(Normative)

Recommended standard preparation water

A1 Reagents and materials

A1.1 Anhydrous calcium chloride.

A1.2 Magnesium sulfate monohydrate.

A1.3 Sodium hydrogen carbonate.

A1.4 Sodium chloride.

A2 Preparation of standard preparation water

WEIGH 7.35g of calcium chloride dihydrate (A1.1), 4.93g of magnesium sulfate heptahydrate (A1.2)

and 6.58g of NaCl (A1.4), DISSOLVE them into 7L of water, MIX well after complete dissolution.

WEIGH another 1.68g of sodium bicarbonate (A1.3) and DISSOLVE it into 1L of water, MIX well after

complete dissolution. TRANSFER the solution to above solution, USE water to dilute to 10.0L, MIX

well.

Appendix B

(Normative)

Corrosion Rate Conversion Table

Conversion unit

Given Unit

(mm/a) g/(m2·h) mg/(dm3·d)

mm/a 1 0.114×ρ 27.4×ρ

g/(m2·h) 8.76/ρ 1 240

mg/(dm3·d) 3.65×10-2/ρ 4.17×10-3 1

Note. ρ is the specimen density, g/cm3.

GB/T 18175-2000

ICS 71.100.80

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Determination of corrosion inhibition performance of

water treatment agents - Rotation specimen method

ISSUED ON. JULY 03, 2000

IMPLEMENTED ON. MARCH 01, 2001

Issued by.

General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Method summary ... 4

4 Reagents and materials ... 5

5 Instruments and apparatus ... 5

6 Test conditions ... 6

7 Test procedures ... 7

8 Result expression and calculation ... 8

9 Allowable difference ... 9

10 Test report ... 9

Appendix A (Normative) ... 10

Appendix B (Normative) ... 11

Foreword

This Standard non-equivalently adopts ASTM G31-1995 Laboratory Metal Materials Impregnation and

Corrosion Test Standard.

This Standard is different from ASTM G31-1995, because it specifies using the rotation specimen

method to determine the corrosion inhibition performance of water treatment agents for metal

materials.

Since the date of implementation of this Standard, it will replace HG/T 2159-1991 Determination of

Corrosion Inhibition Performance of Water Treatment Agents-Rotation Specimen Method.

Appendix A of this Standard is the standard appendix.

Appendix B of this Standard is suggestive appendix.

This Standard is proposed by the Ministry of Chemical Industry of the People’s Republic of China.

This Standard is under the jurisdiction of the Branch of Water Treatment Agents of the National

Chemical Standardization Technology Committee.

This Standard is drafted by organization. Guangming Chemical Industry Research and Design

Institute.

The main drafters of this Standard. Li Chengguo, Guo Ximin, Guo Fengxiang, Cai Qiang, Li Yuanyuan,

Cai Kangyu, and Jiang Chunhua.

Determination of corrosion inhibition performance of water

treatment agents - Rotation specimen method

1 Scope

This Standard specifies the laboratory method of using the rotation specimen method to determine the

corrosion inhibition performance of water treatment agents.

This Standard applies to the determination of corrosion inhibition performance of water treatment

agents.

2 Normative references

The following standards contain provisions which, through reference in this text, become part of this

Standard. At the time of publication of this Standard, all editions indicated are valid. All standards are

subject to revision. Parties who enter into agreements based on this Standard are encouraged to

investigate the possibility of applying the most recent editions of the standards indicated below.

GB/T 603-1988 Chemical reagents - Preparation of chemical reagents and products used in the test

method

GB/T 6682-1992 Analysis of water specifications and test methods of laboratory (neq ISO

3696.1986)

GB/T 15724.1-1995 Laboratory glassware - beaker

HG/T 3523-1985 Technical conditions on standard corrosion specimens for chemical treatment of

cooling water.

3 Method summary

The rotation specimen corrosive test method is conducted under the given laboratory conditions,

calculates the corrosion rate and inhibition rate to evaluate the corrosion inhibition performance of

water treatment agents by using the quality loss of test specimen.

7.8 USE brush to clean the test specimen, then SOAK into acid pickling solution (4.5) for 3-5 minutes.

TAKE out, after quickly washing with tap water, then immediately IMMERSE into NaOH (4.4) solution

for 30s. TAKE out, WASH with distilled water, USE filer paper to clean and dry, SOAK into the absolute

ethyl alcohol for about 3 minutes, PLACE onto the clean filter paper, PLACE in the dryer for over 4

hours, and WEIGH it (accurate to 0.0002g).

Do the pickling blank test of the specimen at the same time.

7.9 Do blank test without adding water treatment agents.

7.10 CONDUCT appearance observation and RECORD the data for the specimen after pickling.

8 Result expression and calculation

8.1 Corrosion rate X1 is expressed in mm/a, and it shall be calculated according to Formula (1).

Where.

m - Specimen mass loss, g;

mo – Average mass loss value of the blank test of specimen pickling;

s - Surface area of the specimen, cm2;

ρ- Density of the specimen, g/ cm3;

t - Test time, h;

8760 – Number of hours equivalent to one year, h/a;

10 - Millimeter number equivalent to 1cm, mm/cm.

8.2 Corrosion inhibition rate X2 is expressed in percentage, and it shall be calculated according to

Formula (2).

Where.

Appendix A

(Normative)

Recommended standard preparation water

A1 Reagents and materials

A1.1 Anhydrous calcium chloride.

A1.2 Magnesium sulfate monohydrate.

A1.3 Sodium hydrogen carbonate.

A1.4 Sodium chloride.

A2 Preparation of standard preparation water

WEIGH 7.35g of calcium chloride dihydrate (A1.1), 4.93g of magnesium sulfate heptahydrate (A1.2)

and 6.58g of NaCl (A1.4), DISSOLVE them into 7L of water, MIX well after complete dissolution.

WEIGH another 1.68g of sodium bicarbonate (A1.3) and DISSOLVE it into 1L of water, MIX well after

complete dissolution. TRANSFER the solution to above solution, USE water to dilute to 10.0L, MIX

well.

Appendix B

(Normative)

Corrosion Rate Conversion Table

Conversion unit

Given Unit

(mm/a) g/(m2·h) mg/(dm3·d)

mm/a 1 0.114×ρ 27.4×ρ

g/(m2·h) 8.76/ρ 1 240

mg/(dm3·d) 3.65×10-2/ρ 4.17×10-3 1

Note. ρ is the specimen density, g/cm3.

Share