1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB/T 18941-2003 English PDF (GBT18941-2003)

GB/T 18941-2003 English PDF (GBT18941-2003)

Regular price

$125.00 USD

Regular price

Sale price

$125.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 18941-2003

Historical versions: GB/T 18941-2003

Preview True-PDF (Reload/Scroll if blank)

GB/T 18941-2003: Flexible cellular polymeric materials -- Determination of fatigue constant-load pounding

GB/T 18941-2003

Flexible cellular polymeric materials--Determination of fatigue by constant-load pounding

Determination of impact fatigue of polymer porous elastic material under constant load

ICS 83.100

G 44

idt ISO 3385. 1989

2003-01-10 released

2003-07-01 Implementation

Published by the People's Republic of China

General Administration of Quality Supervision, Inspection and Quarantine

Warning. Persons using this standard should be familiar with formal laboratory operating procedures. This standard is not intended to cover all safety issues that may arise due to the use of this standard.

It is the user's responsibility to develop appropriate safety and health systems and ensure compliance with national regulations.

1 Scope

This standard stipulates the methods for measuring the thickness reduction value and hardness reduction value of porous elastic materials used in interior decoration. This test method provides /

A method to evaluate the performance of the latex-type and polyamino-type porous elastic materials used for decoration. Measured thickness reduction

And the hardness reduction value is related to the possible loss in use, but it is not necessarily the same.

This standard applies to standard-size specimens taken from finished materials and also to molded parts.

2 Cited standards

The provisions contained in the following standards constitute the provisions of this standard by quotation in this standard. At the time of publication, the editions indicated were valid.

All standards will be revised, all parties using this standard should explore the possibility of using the latest version of the following standards.

GB/T 12825 Determination of hardness of porous elastic materials for polymers

3 Principle

The indenter, which is smaller than the sample, is repeatedly recessed into the sample, and the maximum load is reached in each impact cycle that maintains the specified range.

4 Instruments

Reciprocating impact testing machine with the following components.

4.1 The platform can fully support the sample.

4.2 Indenter, the indenter should be firmly installed on its guide rod, and its surface should be smooth but not polished. Through curved rollers or other suitable mechanical devices,

The testing machine should be able to reciprocate the table (4.1) or the indenter support carrying the sample, one to the other from the vertical direction (70 ± 5) times per minute

Impact at a rate, the impact amplitude should be adjustable.

4.3 The indenter bracket, when the bracket and the platform are close together, this concave force can be transmitted through it except for the impact point. At this time,

All the concave force is borne by the specimen, and the indenter should be freely supported by the support rod to prevent the specimen from being overloaded. Applying the entire force to the sample through the indenter

During this period, measures shall be taken at any impact point to use it to control the impact time, which shall not be greater than 25% of the duration of each impact cycle.

4.4 Force measuring device, which can measure the load applied to the sample through the indenter, a suitable method is to fix the platform on the load sensor.

5 Sample

5.1 Shape and size

The sample should be a right-angled hexahedron with a side length of 380 mm ± 20 mm and a thickness of 50 mm ± 2 mm, or it can be based on consultation between interested parties,

Test with components that do not meet the dimensions.

5.2 Specimens with orientation

If the porous structure of the product is oriented, both the supplier and the buyer shall agree on the orientation of the direction in which the test is conducted. In general, the direction of the test of the finished product should be the direction of the force under the conditions of use.

5.3 Number of samples

Three samples shall be used for testing.

5.4 Sample adjustment

Except that it can be verified that the difference between the measured compressive stress-strain properties and the performance values measured after 72 hours of manufacture is not greater than ± 10% after 16 hours or 48 hours of manufacture,

Specimens shall not be used for testing at least 72 hours after manufacture. If you have reached above the specified target at the selected time,

It is allowed to conduct the test 16 hours or 48 hours after manufacture.

During the test, the sample shall be adjusted for at least 16 h under one of the following conditions, and this time shall be calculated from the time of manufacture.

6 Test procedure

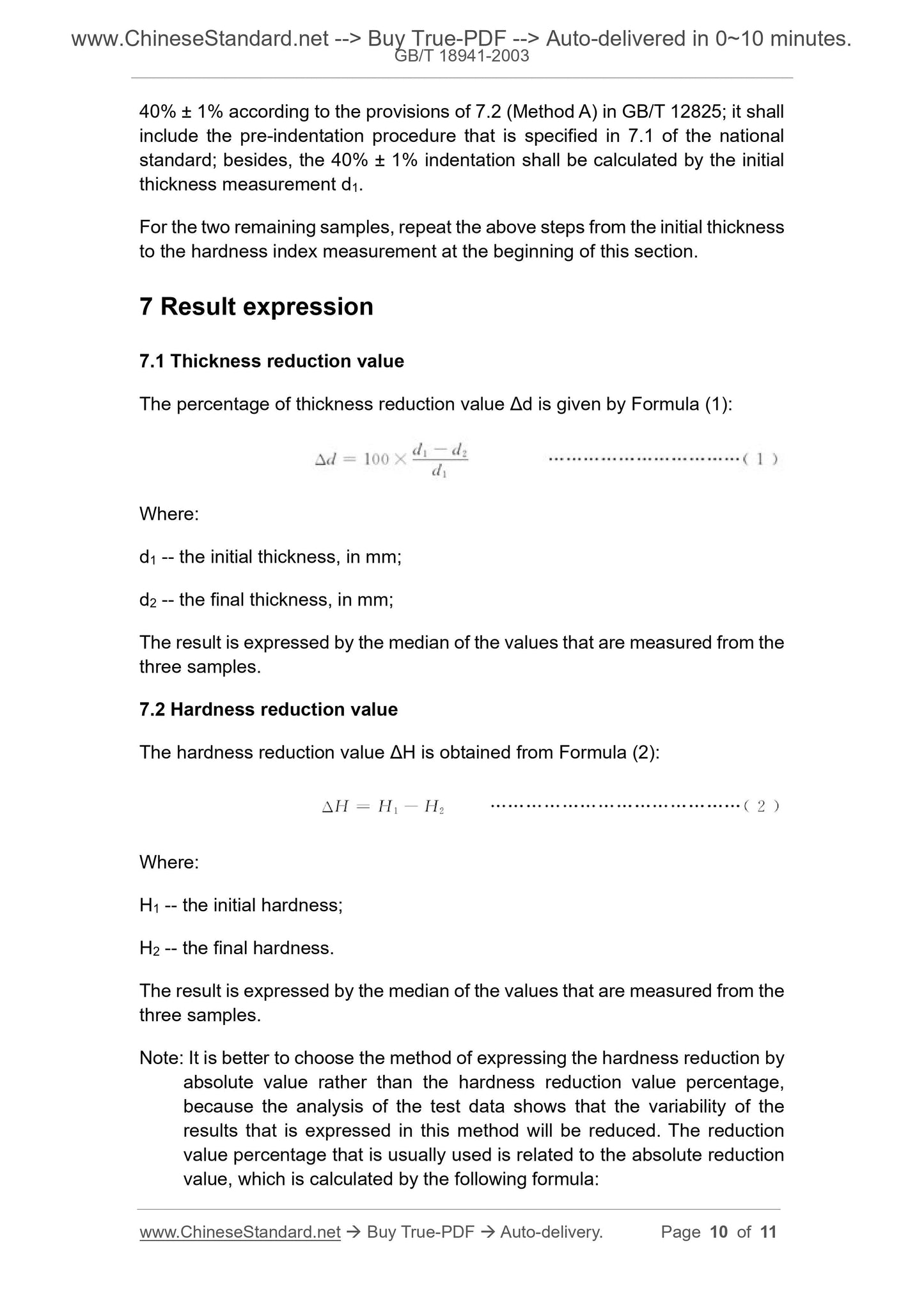

Measure the thickness and hardness index of any sample in accordance with GB/T 12825.

Place the sample in the center under the indenter, adjust the impact position to the thickness of the sample, and adjust the relative position of the indenter and the platform until it can be applied

For a specified load of 75 N ± 20 N, the mass of the indenter must be calibrated.

8 Test report

The test report shall include the following information.

a) National standards cited;

b) Types of test materials;

c) The adjustment method used;

d) If different from the standard sample, the shape and size of the test component;

e) If any, the main direction of the porous structure

f) The median thickness reduction percentage after impact;

g) The median value of hardness reduction after impact.

Get QUOTATION in 1-minute: Click GB/T 18941-2003

Historical versions: GB/T 18941-2003

Preview True-PDF (Reload/Scroll if blank)

GB/T 18941-2003: Flexible cellular polymeric materials -- Determination of fatigue constant-load pounding

GB/T 18941-2003

Flexible cellular polymeric materials--Determination of fatigue by constant-load pounding

Determination of impact fatigue of polymer porous elastic material under constant load

ICS 83.100

G 44

idt ISO 3385. 1989

2003-01-10 released

2003-07-01 Implementation

Published by the People's Republic of China

General Administration of Quality Supervision, Inspection and Quarantine

Warning. Persons using this standard should be familiar with formal laboratory operating procedures. This standard is not intended to cover all safety issues that may arise due to the use of this standard.

It is the user's responsibility to develop appropriate safety and health systems and ensure compliance with national regulations.

1 Scope

This standard stipulates the methods for measuring the thickness reduction value and hardness reduction value of porous elastic materials used in interior decoration. This test method provides /

A method to evaluate the performance of the latex-type and polyamino-type porous elastic materials used for decoration. Measured thickness reduction

And the hardness reduction value is related to the possible loss in use, but it is not necessarily the same.

This standard applies to standard-size specimens taken from finished materials and also to molded parts.

2 Cited standards

The provisions contained in the following standards constitute the provisions of this standard by quotation in this standard. At the time of publication, the editions indicated were valid.

All standards will be revised, all parties using this standard should explore the possibility of using the latest version of the following standards.

GB/T 12825 Determination of hardness of porous elastic materials for polymers

3 Principle

The indenter, which is smaller than the sample, is repeatedly recessed into the sample, and the maximum load is reached in each impact cycle that maintains the specified range.

4 Instruments

Reciprocating impact testing machine with the following components.

4.1 The platform can fully support the sample.

4.2 Indenter, the indenter should be firmly installed on its guide rod, and its surface should be smooth but not polished. Through curved rollers or other suitable mechanical devices,

The testing machine should be able to reciprocate the table (4.1) or the indenter support carrying the sample, one to the other from the vertical direction (70 ± 5) times per minute

Impact at a rate, the impact amplitude should be adjustable.

4.3 The indenter bracket, when the bracket and the platform are close together, this concave force can be transmitted through it except for the impact point. At this time,

All the concave force is borne by the specimen, and the indenter should be freely supported by the support rod to prevent the specimen from being overloaded. Applying the entire force to the sample through the indenter

During this period, measures shall be taken at any impact point to use it to control the impact time, which shall not be greater than 25% of the duration of each impact cycle.

4.4 Force measuring device, which can measure the load applied to the sample through the indenter, a suitable method is to fix the platform on the load sensor.

5 Sample

5.1 Shape and size

The sample should be a right-angled hexahedron with a side length of 380 mm ± 20 mm and a thickness of 50 mm ± 2 mm, or it can be based on consultation between interested parties,

Test with components that do not meet the dimensions.

5.2 Specimens with orientation

If the porous structure of the product is oriented, both the supplier and the buyer shall agree on the orientation of the direction in which the test is conducted. In general, the direction of the test of the finished product should be the direction of the force under the conditions of use.

5.3 Number of samples

Three samples shall be used for testing.

5.4 Sample adjustment

Except that it can be verified that the difference between the measured compressive stress-strain properties and the performance values measured after 72 hours of manufacture is not greater than ± 10% after 16 hours or 48 hours of manufacture,

Specimens shall not be used for testing at least 72 hours after manufacture. If you have reached above the specified target at the selected time,

It is allowed to conduct the test 16 hours or 48 hours after manufacture.

During the test, the sample shall be adjusted for at least 16 h under one of the following conditions, and this time shall be calculated from the time of manufacture.

6 Test procedure

Measure the thickness and hardness index of any sample in accordance with GB/T 12825.

Place the sample in the center under the indenter, adjust the impact position to the thickness of the sample, and adjust the relative position of the indenter and the platform until it can be applied

For a specified load of 75 N ± 20 N, the mass of the indenter must be calibrated.

8 Test report

The test report shall include the following information.

a) National standards cited;

b) Types of test materials;

c) The adjustment method used;

d) If different from the standard sample, the shape and size of the test component;

e) If any, the main direction of the porous structure

f) The median thickness reduction percentage after impact;

g) The median value of hardness reduction after impact.

Share