1

/

of

7

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB/T 18984-2016 English PDF (GB/T18984-2016)

GB/T 18984-2016 English PDF (GB/T18984-2016)

Regular price

$140.00 USD

Regular price

Sale price

$140.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click GB/T 18984-2016 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 18984-2016

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 18984-2016: Seamless steel tubes for low-temperature-service piping

GB/T 18984-2016

Seamless steel tubes for low-temperature-service piping

ICS 77.140.75

H48

National Standards of People's Republic of China

Replacing GB/T 18984-2003

Low temperature seamless steel pipes

Published 2016-12-30

2017-09-01 implementation

Administration of Quality Supervision, Inspection and Quarantine of People's Republic of China

Standardization Administration of China issued

Foreword

This standard was drafted in accordance with rules GB/T 1.1-2009 given.

Instead of the standard GB/T 18984-2003 "cryogenic seamless steel pipe", compared with the GB/T 18984-2003, Technical change

Of the following.

--- modify the normative references;

--- modify the pipe ordering specifications;

--- modified pipe size tolerance;

--- modify the cut length tolerance;

--- modify the predetermined curvature;

--- increased 06Ni9DG grades;

--- modified steel phosphorus, sulfur content requirements;

--- modified steel smelting method;

--- modify the delivery status of steel;

--- modified flattening test applicable specifications and requirements determined;

--- modify the low magnification inspection requirements;

--- modified nonmetallic inclusions testing requirements;

--- modify the non-destructive inspection requirements;

--- revised set of rules approved.

The standard proposed by China Iron and Steel Association.

This standard by the National Steel Standardization Technical Committee (SAC/TC183).

This standard was drafted. Pangang Group Chengdu Steel and Vanadium Co., Ltd., Hengyang Valin Steel Tube Co., Ltd., Metallurgical Industry Information Standards Institute.

The main drafters. to Haitao, Wu Hong, Huang Pingjia, Zhao Bin, Dong Li, who Yonggang, Zhang San.

This standard supersedes the previous editions are.

--- GB/T 18984-2003.

Low temperature seamless steel pipes

1 Scope

This standard specifies the seamless steel pipes of low classification code, order contents, size, shape, weight, technical requirements, test methods,

Inspection rules, packaging, marking and certification.

This standard applies to -45 ℃ ~ -196 ℃ level stage cryogenic pressure vessel and the low temperature heat exchanger pipes seamless steel pipes.

2 Normative references

The following documents for the application of this document is essential. For dated references, only applies to the version dated paper

this. For undated references, the latest edition (including any amendments) applies to this document.

Chemical composition of the finished GB/T 222 steel tolerance

GB /Determination of soluble silicon steel and total silicon content T 223.5 reduced silicon molybdate salt spectrophotometric

GB/T 223.9 chromium alloy steel and the aluminum content was measured Azure S Spectrophotometry

GB/T 223.14 steel and tantalum alloys - spectrophotometric determination reagent vanadium content Cuiqu

GB/T 223.16 steel and alloys - Determination of Ti amount chromotropic acid

Determination of nickel content GB/T 223.25 steel and alloys - dimethylglyoxime gravimetric method

GB/T 223.26 thiocyanate salt spectrophotometric determination of molybdenum content alloy steel and

GB/T 223.40 Determination of the contents of alloy steel and niobium sulphochlorophenol S Spectrophotometry

GB/T 223.59 phosphorus content of steel and alloy measured by bismuth phosphomolybdate blue spectrophotometric method and antimony phosphomolybdate blue spectrophotometric method

GB/T 223.63 steel and alloys - sodium periodate (K) for Determination of the amount of

Determination of sulfur content potassium iodate titration method after GB/T 223.68 and alloy steel pipe furnace combustion

GB/T 223.69 after the carbon content and alloy steel measuring tube furnace combustion gas volumetric method

GB/T 226 steel macrostructure defects and Etch Test Method

Rt Test Method. Part 1 Test GB/T 228.1 metal material tensile

GB/T 229 summer metallic materials than methods pendulum impact test

GB/T 241 Test Method metal hydraulic tube

GB/T 242 Test Method for expanding a metal tube opening

GB/T 244 Test Method for bending a metal pipe

GB/T 246 Test Method flattening the metal tube

GB/T 1979-fold structural steels and defect FIG.

Acceptance of GB/T 2102 steel, packaging, marking and certification

Sampling and sample preparation Test positions GB/T 2975 Mechanical properties of steel and steel products

GB/T 4336 carbon steel and low alloy steel for spark discharge atomic emission spectrometric method (conventional method)

GB/T 5777-2008 seamless steel ultrasonic testing method

GB/T 7735-2016 seamless and welded (except submerged arc) steel imperfections automatic eddy current testing

10561-2005 nonmetallic inclusions in steel content GB/T measurement standard rating FIG microscopic test method

Full-circumferential GB/T 12606-2016 seamless and welded (except submerged arc) ferromagnetic steel longitudinal and/or transverse imperfections automatic MFL

Detect

GB/T 17395 seamless steel pipe size, shape, weight and tolerance

GB/T 20066 Steel and iron chemical composition of the sample and the measurement sample preparation methods

GB/T 20123 total carbon and sulfur content of steel an induction furnace combustion infrared absorption method (conventional method)

GB/T 31925 walled seamless ultrasonic inspection methods

3 Classification and designation

3.1 Standard manufacturing seamless steel pipe by way divided into two categories and their code as follows.

a) hot rolling (expanded) steel, code for WH;

b) cold drawn (rolled) steel, code of WC.

After the letter 3.2 standard steel grades listed in "DG" is the first in capital letters are "low temperature" "pipe" pinyin.

4 ordering content

According to the standard steel pipe order contract or order shall include, but not limited to, the following.

a) the product name;

b) standard number;

c) steel grades;

d) Order number (or the total weight of the total length);

e) Dimensions;

f) the production method;

g) Special requirements.

5 size, shape and weight

5.1 diameter and wall thickness

5.1.1 well pipe nominal diameter (D) and the nominal wall thickness (S) shall comply with GB/T 17395's. According to the demand side, the supply and demand sides Association

Supplier, can supply pipe size than a predetermined GB/T 17395.

5.1.2 pipe diameter and wall thickness tolerance shall be as specified in Table 1. According to the demand side, the supply and demand sides negotiated, rules to produce Table 1

Outside tolerances given pipe size.

Table 1 pipe diameter and wall thickness tolerance in mm

5.2 length

5.2.1 usual length

Pipe length is generally 4000mm ~ 12000mm.

By agreement between the manufacturer and specified in the contract, the delivery can be shorter than the length of 4000mm but not less than short-foot steel pipe 3000mm, but

Their number should not exceed the total amount of steel batch delivery by 5%.

5.2.2 Length and double length

5.2.2.1 According to the demand side, the supply and demand sides negotiated, and in the contract, the pipe can be cut to length or double length delivery. Steel pipe set

Scale length and the total length of the double length should be within the range of usual length.

5.2.2.2 steel cut length tolerance shall be as follows.

a) length ≤6000mm, 0mm ~ 10mm;

b) a length> 6000mm, 0mm ~ 15mm.

5.2.2.3 Each double length should leave a notch below a predetermined margin.

When a) D≤159mm, cutout balance 5mm ~ 10mm;

b) D> When 159mm, slit balance 10mm ~ 15mm.

5.3 curvature

Bending the steel pipe should not exceed the following provisions.

a) S≤15mm, the curvature is not greater than 1.5mm/m;

b) S> 15mm ~ When 30mm, curvature is not greater than 2.0mm/m;

c) S> 30mm, or D≥351mm, curvature is not greater than 3.0mm/m.

5.4 tip shape

Pipe and pipe end faces at both ends should be perpendicular to the axis, the cutout burrs should be removed.

5.5 roundness and uneven thickness

According to the demand side, the supply and demand sides negotiated and specified in the contract, roundness and wall thickness of the pipe shall not exceed the outside diameter is not public

80% of the difference between the wall thickness and tolerances.

5.6 Weight

5.6.1 steel delivery by actual weight, also according to theoretical weight delivery. Theoretical calculation of the weight of steel required to GB/T 17395 (the steel

A density of 7.85kg/dm3).

5.6.2 Weight Tolerance

According to the demand side, the supply and demand sides negotiated and specified in the contract, allowing the deviation of the actual weight and the theoretical weight of the delivery pipe should

Comply with the following provisions.

a) a single steel tube. ± 10%;

b) minimum batch of steel 10t. ± 7.5%.

6 Technical Requirements

Grades and chemical composition of the steel 6.1

6.1.1 steel grades and chemical composition (melting analysis) should meet the requirements of Table 2, the acceptance by melting steel component. According to the buyer requirements, by

Supply and demand of both parties, and indicate in the contract, other steel grades can be used.

Table 2 Steel grade and chemical composition of the

6.1.2 demand side, product analysis, should be specified in the contract. The chemical composition of the finished steel tolerance should be consistent GB/T 222

Provisions.

6.1.3 steel content of residual elements shall be as follows. Cr≤0.25%, Cu≤0.20%, Ni≤0.40%, Mo≤0.08%.

6.2 Manufacturing Methods

6.2.1 outer arc furnace steel should be used by adding refining and outer vacuum refining process, or added oxygen converter refining and vacuum refining process. root

According to the demand side, the supply and demand sides negotiated and specified in the contract, but also use other methods of smelting.

6.2.2 rolled steel should be used (expanded) or a method for producing cold drawn (rolled).

6.3 Delivery status

6.3.1 addition 06Ni9DG steel, steel should be normalized, normalized or quenched and tempered and tempering state delivery. When the finish rolling temperature is not lower than the phase

Become critical temperature (Ar3), and passes through the steel pipe is air-cooled, shall be considered steel is the result of normalizing.

6.3.2 06Ni9DG steel should be quenched and tempered or normalized and tempered state secondary delivery.

6.4 Mechanical Properties

6.4.1 Mechanical Properties of longitudinal steel to comply with Table 3. Tensile test specimens shall conform to the model of Appendix A.

Table 3 Mechanical Properties of longitudinal steel

Lower yield strength or proof strength

A percentage elongation

a pipe outer diameter smaller than 20mm, a predetermined value in this table is not applicable percentage elongation, percentage elongation whose value is determined by agreement between the manufacturer.

When b is smaller than the wall thickness of 8mm steel, a tensile test sample No. 2, the wall thickness is reduced by a predetermined minimum value in this table should its percentage elongation of 1mm

Subtracting a minimum percentage elongation of 1.5%, in numerical integer rounding rule be rounded.

6.4.2 cryogenic pipe longitudinal Charpy V-notch impact absorption energy shall be as specified in Table 4. The impact test temperature shall comply with the following regulations

Set. 16MnDG, 10MnDG and 09DG was -45 ℃, 09Mn2VDG of -70 ℃, 06Ni3MoDG of -100 ℃, 06Ni9DG

As -196 ℃.

Table 4 Steel low temperature impact absorption energy of the longitudinal

Sample size (width × height) /

(Mm × mm)

Impact absorption energy a, bKV2/J

A group (3) the average of at least two of the individual values of a minimum value

10 × 10 ≥21 (40) ≥21 (40) ≥15 (28)

10 × 7.5 ≥18 (35) ≥18 (35) ≥13 (25)

10 × 5 ≥14 (26) ≥14 (26) ≥10 (18)

10 × 2.5 ≥7 (13) ≥7 (13) ≥5 (9)

It can not be used for a 10mm × 2.5mm steel sample size of impact, the impact absorbing energy is determined by the supply and negotiated.

B is a number in parentheses is the impact energy absorbing pipe 06Ni9DG.

6.5 Hydraulic

6.5.1 steel pipe hydraulic test should be carried out by the root. Pressure test according to formula (1) is calculated, the maximum test pressure of 10MPa. At a test pressure,

Regulator not be less than 5s, pipe leakage is not allowed.

P = 2SR/D (1)

Where.

P --- test pressure in megapascals (MPa);

S --- said well pipe wall thickness in millimeters (mm);

D --- male outer diameter of said pipe in millimeters (mm);

--- R and lt allowable stress, as specified in Table 3 at 60% of the yield strength in megapascals (MPa).

6.5.2 only for magnetic flux leakage inspection using eddy current inspection or testing instead of hydraulic. When a magnetic flux leakage inspection, an outer surface of the comparative sample tube longitudinal notch grooves

Shall comply with GB/T 12606-2016 F4 in the acceptance level; when the eddy current testing, comparative sample tube artificial defects should meet

Predetermined GB/T 7735-2016 E4H or E4 in the acceptance level.

6.6 Process Performance

6.6.1 crushed

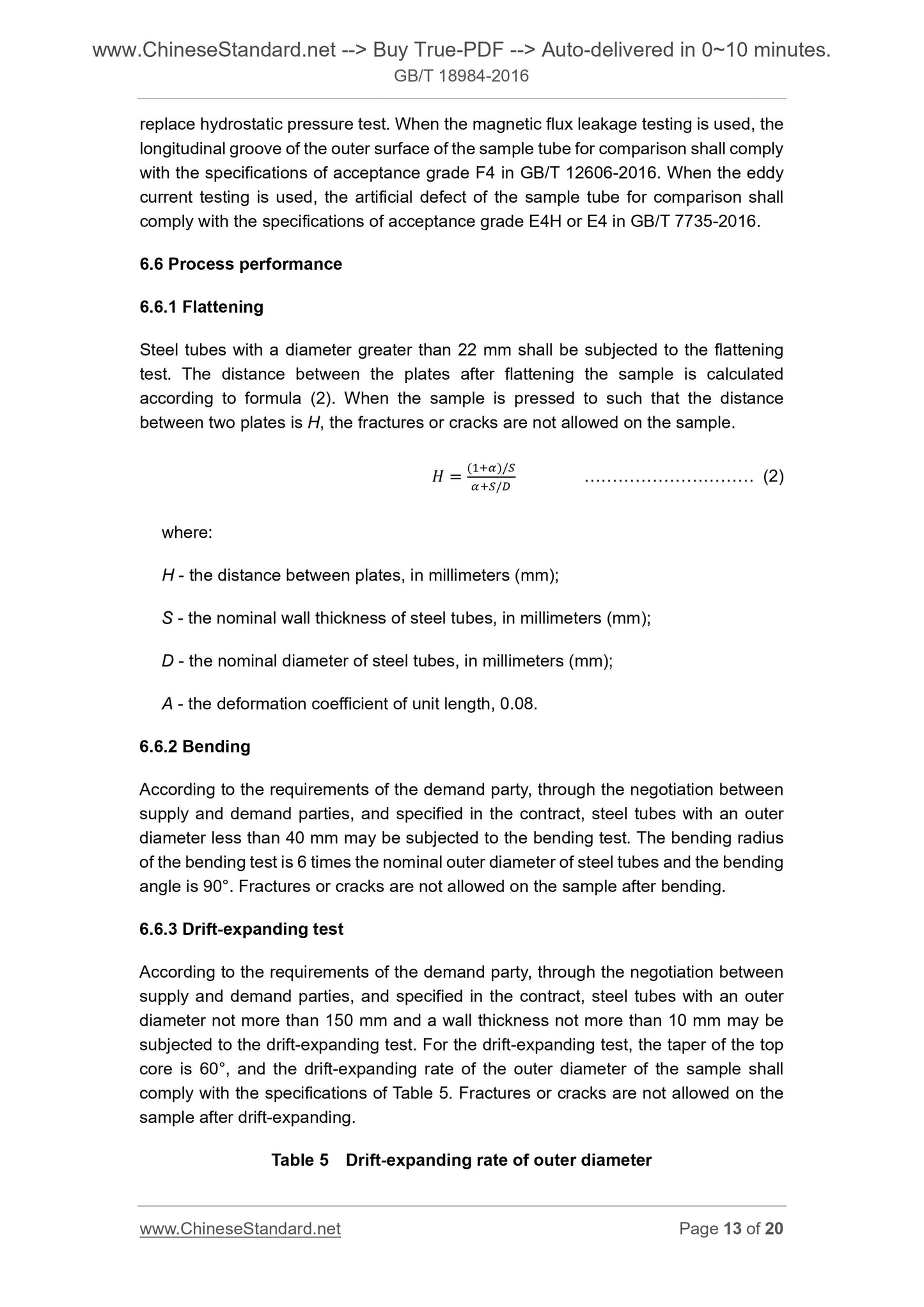

Outer diameter larger than 22mm pipe flattening test should be done. Distance H calculated according to the formula (2) between the sample plate was flattened. Pressed to two sample

When the inter-plate is H, cracks or gaps are not allowed on the sample distance.

H --- distance between plates, in millimeters (mm);

S --- said well pipe wall thickness in millimeters (mm);

D --- male outer diameter of said pipe in millimeters (mm);

--- deformation coefficient per unit length [alpha], was 0.08.

6.6.2 bent

According to the buyer requirements, the agreement between manufacturer, and in the contract, the outer diameter of less than 40mm steel bending test may be performed. bending

Bend radius test was six times the nominal outer diameter of the steel pipe, the bending angle is 90 °, the sample after bending crack or cracks are not allowed.

6.6.3 flaring test

According to the buyer requirements, the agreement between manufacturer, and in the contract, the outer diameter no greater than 150mm and a wall thickness of not more than 10mm steel

Test tube may be flared. Mandrel Test flaring taper of 60 °, the outer diameter of the flaring of the specimen shall be as specified in Table 5, the sample that is not flared

Permitting le...

Get Quotation: Click GB/T 18984-2016 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 18984-2016

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 18984-2016: Seamless steel tubes for low-temperature-service piping

GB/T 18984-2016

Seamless steel tubes for low-temperature-service piping

ICS 77.140.75

H48

National Standards of People's Republic of China

Replacing GB/T 18984-2003

Low temperature seamless steel pipes

Published 2016-12-30

2017-09-01 implementation

Administration of Quality Supervision, Inspection and Quarantine of People's Republic of China

Standardization Administration of China issued

Foreword

This standard was drafted in accordance with rules GB/T 1.1-2009 given.

Instead of the standard GB/T 18984-2003 "cryogenic seamless steel pipe", compared with the GB/T 18984-2003, Technical change

Of the following.

--- modify the normative references;

--- modify the pipe ordering specifications;

--- modified pipe size tolerance;

--- modify the cut length tolerance;

--- modify the predetermined curvature;

--- increased 06Ni9DG grades;

--- modified steel phosphorus, sulfur content requirements;

--- modified steel smelting method;

--- modify the delivery status of steel;

--- modified flattening test applicable specifications and requirements determined;

--- modify the low magnification inspection requirements;

--- modified nonmetallic inclusions testing requirements;

--- modify the non-destructive inspection requirements;

--- revised set of rules approved.

The standard proposed by China Iron and Steel Association.

This standard by the National Steel Standardization Technical Committee (SAC/TC183).

This standard was drafted. Pangang Group Chengdu Steel and Vanadium Co., Ltd., Hengyang Valin Steel Tube Co., Ltd., Metallurgical Industry Information Standards Institute.

The main drafters. to Haitao, Wu Hong, Huang Pingjia, Zhao Bin, Dong Li, who Yonggang, Zhang San.

This standard supersedes the previous editions are.

--- GB/T 18984-2003.

Low temperature seamless steel pipes

1 Scope

This standard specifies the seamless steel pipes of low classification code, order contents, size, shape, weight, technical requirements, test methods,

Inspection rules, packaging, marking and certification.

This standard applies to -45 ℃ ~ -196 ℃ level stage cryogenic pressure vessel and the low temperature heat exchanger pipes seamless steel pipes.

2 Normative references

The following documents for the application of this document is essential. For dated references, only applies to the version dated paper

this. For undated references, the latest edition (including any amendments) applies to this document.

Chemical composition of the finished GB/T 222 steel tolerance

GB /Determination of soluble silicon steel and total silicon content T 223.5 reduced silicon molybdate salt spectrophotometric

GB/T 223.9 chromium alloy steel and the aluminum content was measured Azure S Spectrophotometry

GB/T 223.14 steel and tantalum alloys - spectrophotometric determination reagent vanadium content Cuiqu

GB/T 223.16 steel and alloys - Determination of Ti amount chromotropic acid

Determination of nickel content GB/T 223.25 steel and alloys - dimethylglyoxime gravimetric method

GB/T 223.26 thiocyanate salt spectrophotometric determination of molybdenum content alloy steel and

GB/T 223.40 Determination of the contents of alloy steel and niobium sulphochlorophenol S Spectrophotometry

GB/T 223.59 phosphorus content of steel and alloy measured by bismuth phosphomolybdate blue spectrophotometric method and antimony phosphomolybdate blue spectrophotometric method

GB/T 223.63 steel and alloys - sodium periodate (K) for Determination of the amount of

Determination of sulfur content potassium iodate titration method after GB/T 223.68 and alloy steel pipe furnace combustion

GB/T 223.69 after the carbon content and alloy steel measuring tube furnace combustion gas volumetric method

GB/T 226 steel macrostructure defects and Etch Test Method

Rt Test Method. Part 1 Test GB/T 228.1 metal material tensile

GB/T 229 summer metallic materials than methods pendulum impact test

GB/T 241 Test Method metal hydraulic tube

GB/T 242 Test Method for expanding a metal tube opening

GB/T 244 Test Method for bending a metal pipe

GB/T 246 Test Method flattening the metal tube

GB/T 1979-fold structural steels and defect FIG.

Acceptance of GB/T 2102 steel, packaging, marking and certification

Sampling and sample preparation Test positions GB/T 2975 Mechanical properties of steel and steel products

GB/T 4336 carbon steel and low alloy steel for spark discharge atomic emission spectrometric method (conventional method)

GB/T 5777-2008 seamless steel ultrasonic testing method

GB/T 7735-2016 seamless and welded (except submerged arc) steel imperfections automatic eddy current testing

10561-2005 nonmetallic inclusions in steel content GB/T measurement standard rating FIG microscopic test method

Full-circumferential GB/T 12606-2016 seamless and welded (except submerged arc) ferromagnetic steel longitudinal and/or transverse imperfections automatic MFL

Detect

GB/T 17395 seamless steel pipe size, shape, weight and tolerance

GB/T 20066 Steel and iron chemical composition of the sample and the measurement sample preparation methods

GB/T 20123 total carbon and sulfur content of steel an induction furnace combustion infrared absorption method (conventional method)

GB/T 31925 walled seamless ultrasonic inspection methods

3 Classification and designation

3.1 Standard manufacturing seamless steel pipe by way divided into two categories and their code as follows.

a) hot rolling (expanded) steel, code for WH;

b) cold drawn (rolled) steel, code of WC.

After the letter 3.2 standard steel grades listed in "DG" is the first in capital letters are "low temperature" "pipe" pinyin.

4 ordering content

According to the standard steel pipe order contract or order shall include, but not limited to, the following.

a) the product name;

b) standard number;

c) steel grades;

d) Order number (or the total weight of the total length);

e) Dimensions;

f) the production method;

g) Special requirements.

5 size, shape and weight

5.1 diameter and wall thickness

5.1.1 well pipe nominal diameter (D) and the nominal wall thickness (S) shall comply with GB/T 17395's. According to the demand side, the supply and demand sides Association

Supplier, can supply pipe size than a predetermined GB/T 17395.

5.1.2 pipe diameter and wall thickness tolerance shall be as specified in Table 1. According to the demand side, the supply and demand sides negotiated, rules to produce Table 1

Outside tolerances given pipe size.

Table 1 pipe diameter and wall thickness tolerance in mm

5.2 length

5.2.1 usual length

Pipe length is generally 4000mm ~ 12000mm.

By agreement between the manufacturer and specified in the contract, the delivery can be shorter than the length of 4000mm but not less than short-foot steel pipe 3000mm, but

Their number should not exceed the total amount of steel batch delivery by 5%.

5.2.2 Length and double length

5.2.2.1 According to the demand side, the supply and demand sides negotiated, and in the contract, the pipe can be cut to length or double length delivery. Steel pipe set

Scale length and the total length of the double length should be within the range of usual length.

5.2.2.2 steel cut length tolerance shall be as follows.

a) length ≤6000mm, 0mm ~ 10mm;

b) a length> 6000mm, 0mm ~ 15mm.

5.2.2.3 Each double length should leave a notch below a predetermined margin.

When a) D≤159mm, cutout balance 5mm ~ 10mm;

b) D> When 159mm, slit balance 10mm ~ 15mm.

5.3 curvature

Bending the steel pipe should not exceed the following provisions.

a) S≤15mm, the curvature is not greater than 1.5mm/m;

b) S> 15mm ~ When 30mm, curvature is not greater than 2.0mm/m;

c) S> 30mm, or D≥351mm, curvature is not greater than 3.0mm/m.

5.4 tip shape

Pipe and pipe end faces at both ends should be perpendicular to the axis, the cutout burrs should be removed.

5.5 roundness and uneven thickness

According to the demand side, the supply and demand sides negotiated and specified in the contract, roundness and wall thickness of the pipe shall not exceed the outside diameter is not public

80% of the difference between the wall thickness and tolerances.

5.6 Weight

5.6.1 steel delivery by actual weight, also according to theoretical weight delivery. Theoretical calculation of the weight of steel required to GB/T 17395 (the steel

A density of 7.85kg/dm3).

5.6.2 Weight Tolerance

According to the demand side, the supply and demand sides negotiated and specified in the contract, allowing the deviation of the actual weight and the theoretical weight of the delivery pipe should

Comply with the following provisions.

a) a single steel tube. ± 10%;

b) minimum batch of steel 10t. ± 7.5%.

6 Technical Requirements

Grades and chemical composition of the steel 6.1

6.1.1 steel grades and chemical composition (melting analysis) should meet the requirements of Table 2, the acceptance by melting steel component. According to the buyer requirements, by

Supply and demand of both parties, and indicate in the contract, other steel grades can be used.

Table 2 Steel grade and chemical composition of the

6.1.2 demand side, product analysis, should be specified in the contract. The chemical composition of the finished steel tolerance should be consistent GB/T 222

Provisions.

6.1.3 steel content of residual elements shall be as follows. Cr≤0.25%, Cu≤0.20%, Ni≤0.40%, Mo≤0.08%.

6.2 Manufacturing Methods

6.2.1 outer arc furnace steel should be used by adding refining and outer vacuum refining process, or added oxygen converter refining and vacuum refining process. root

According to the demand side, the supply and demand sides negotiated and specified in the contract, but also use other methods of smelting.

6.2.2 rolled steel should be used (expanded) or a method for producing cold drawn (rolled).

6.3 Delivery status

6.3.1 addition 06Ni9DG steel, steel should be normalized, normalized or quenched and tempered and tempering state delivery. When the finish rolling temperature is not lower than the phase

Become critical temperature (Ar3), and passes through the steel pipe is air-cooled, shall be considered steel is the result of normalizing.

6.3.2 06Ni9DG steel should be quenched and tempered or normalized and tempered state secondary delivery.

6.4 Mechanical Properties

6.4.1 Mechanical Properties of longitudinal steel to comply with Table 3. Tensile test specimens shall conform to the model of Appendix A.

Table 3 Mechanical Properties of longitudinal steel

Lower yield strength or proof strength

A percentage elongation

a pipe outer diameter smaller than 20mm, a predetermined value in this table is not applicable percentage elongation, percentage elongation whose value is determined by agreement between the manufacturer.

When b is smaller than the wall thickness of 8mm steel, a tensile test sample No. 2, the wall thickness is reduced by a predetermined minimum value in this table should its percentage elongation of 1mm

Subtracting a minimum percentage elongation of 1.5%, in numerical integer rounding rule be rounded.

6.4.2 cryogenic pipe longitudinal Charpy V-notch impact absorption energy shall be as specified in Table 4. The impact test temperature shall comply with the following regulations

Set. 16MnDG, 10MnDG and 09DG was -45 ℃, 09Mn2VDG of -70 ℃, 06Ni3MoDG of -100 ℃, 06Ni9DG

As -196 ℃.

Table 4 Steel low temperature impact absorption energy of the longitudinal

Sample size (width × height) /

(Mm × mm)

Impact absorption energy a, bKV2/J

A group (3) the average of at least two of the individual values of a minimum value

10 × 10 ≥21 (40) ≥21 (40) ≥15 (28)

10 × 7.5 ≥18 (35) ≥18 (35) ≥13 (25)

10 × 5 ≥14 (26) ≥14 (26) ≥10 (18)

10 × 2.5 ≥7 (13) ≥7 (13) ≥5 (9)

It can not be used for a 10mm × 2.5mm steel sample size of impact, the impact absorbing energy is determined by the supply and negotiated.

B is a number in parentheses is the impact energy absorbing pipe 06Ni9DG.

6.5 Hydraulic

6.5.1 steel pipe hydraulic test should be carried out by the root. Pressure test according to formula (1) is calculated, the maximum test pressure of 10MPa. At a test pressure,

Regulator not be less than 5s, pipe leakage is not allowed.

P = 2SR/D (1)

Where.

P --- test pressure in megapascals (MPa);

S --- said well pipe wall thickness in millimeters (mm);

D --- male outer diameter of said pipe in millimeters (mm);

--- R and lt allowable stress, as specified in Table 3 at 60% of the yield strength in megapascals (MPa).

6.5.2 only for magnetic flux leakage inspection using eddy current inspection or testing instead of hydraulic. When a magnetic flux leakage inspection, an outer surface of the comparative sample tube longitudinal notch grooves

Shall comply with GB/T 12606-2016 F4 in the acceptance level; when the eddy current testing, comparative sample tube artificial defects should meet

Predetermined GB/T 7735-2016 E4H or E4 in the acceptance level.

6.6 Process Performance

6.6.1 crushed

Outer diameter larger than 22mm pipe flattening test should be done. Distance H calculated according to the formula (2) between the sample plate was flattened. Pressed to two sample

When the inter-plate is H, cracks or gaps are not allowed on the sample distance.

H --- distance between plates, in millimeters (mm);

S --- said well pipe wall thickness in millimeters (mm);

D --- male outer diameter of said pipe in millimeters (mm);

--- deformation coefficient per unit length [alpha], was 0.08.

6.6.2 bent

According to the buyer requirements, the agreement between manufacturer, and in the contract, the outer diameter of less than 40mm steel bending test may be performed. bending

Bend radius test was six times the nominal outer diameter of the steel pipe, the bending angle is 90 °, the sample after bending crack or cracks are not allowed.

6.6.3 flaring test

According to the buyer requirements, the agreement between manufacturer, and in the contract, the outer diameter no greater than 150mm and a wall thickness of not more than 10mm steel

Test tube may be flared. Mandrel Test flaring taper of 60 °, the outer diameter of the flaring of the specimen shall be as specified in Table 5, the sample that is not flared

Permitting le...

Share