1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 19348.1-2014 English PDF (GB/T19348.1-2014)

GB/T 19348.1-2014 English PDF (GB/T19348.1-2014)

Regular price

$125.00

Regular price

Sale price

$125.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 19348.1-2014: Non-destructive testing -- Industrial radiographic film -- Part 1: Classification of film systems for industrial radiography

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 19348.1-2014 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 19348.1-2014

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 19348.1-2014

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 37.040.25; 19.100

J 04

Replacing GB/T 19348.1-2003

Non-destructive Testing – Industrial Radiographic

Film – Part 1. Classification of Film Systems for

Industrial Radiography

(ISO 11699-1. 2008, MOD)

ISSUED ON. JUNE 24, 2014

IMPLEMENTED ON. DECEMBER 31, 2014

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Application Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 5

4 Sampling and Storage ... 7

5 Test Method ... 8

6 Limiting Values for Classification ... 13

Bibliography ... 15

Foreword

GB/T 19348, Non-destructive Testing – Industrial Radiographic Film, is divided into two

parts.

-- Part 1. Classification of Film Systems for Industrial Radiography

-- Part 2. Control of Film Processing by Means of Reference Values

This Part is the 1st part of GB/T 19348.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 19348.1, Non-destructive Testing – Industrial Radiographic

Film - Part 1. Classification of Film Systems for Industrial Radiography. Compared with

GB/T 19348.1-2003, the main technical changes of this Part, except editorial changes,

are as follows.

-- adds normative references (see Article 2);

-- modifies part of test methods (see Article 5; Article 4 of Edition 2003); and

-- modifies limiting values for classification.

This Part was redrafted by modifying and adopting ISO 11699-1.2008, Non-destructive

Testing – Industrial Radiographic Film – Part 1. Classification of Film Systems for

Industrial Radiography.

The main technical differences and their reasons between this Part and ISO 11699-

1.2008 are as follows.

-- for normative references, some adjustments with technical differences are made

in this Part, in order to suit the technical conditions of China. The details of

adjustments are mainly reflected in Article 2 “Normative References”, including.

uses Chinese standard GB/T 19348.2 to replace ISO 11699-2 (Article 1 and

5.2); and

uses Chinese standard GB/T 27025 to replace ISO/IEC 17025 (see 5.5).

This Part was proposed by and shall be under the jurisdiction of the National Technical

Committee 56 on Non-destructive Testing of Standardization Administration of China

(SAC/TC 56).

The drafting organizations of this Part. Shanghai Taisi Testing Technology Co., Ltd.,

Shanghai Electric Nuclear Power Group Co., Ltd., Shanghai Research Institute of

Materials, COMAC Shanghai Aircraft Design and Research Institute, Shanghai Key

Laboratory for Application and Evaluation of Engineering Materials and Carestream

Asia-Pacific Investment Management (Shanghai) Co., Ltd.

Non-destructive Testing – Industrial Radiographic

Film – Part 1. Classification of Film Systems for

Industrial Radiography

1 Application Scope

The purpose of this Part of GB/T 19348 is to establish the performance of film systems.

This Part is applicable for the classification of film systems in combination with

specified lead screens for industrial radiography (non-destructive testing). This Part is

intended to ensure that the image quality of radiographs – as far as this is influenced

by the film system – is in conformity with the requirements of other standards such as

ISO 5579, ISO 17636 and EN 12681.

This Part does not apply to the classification of films used with fluorescent intensifying

screens. The measurement of film systems in this Part is restricted to a selected

radiation quality to simplify the procedure. The properties of films will change with

radiation energy, but not the ranking of film system quality.

Additional methods for evaluating the photographic process are described in GB/T

19348.2, by which the performance of film systems can be controlled under the

conditions given in industry.

2 Normative References

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 19348.2, Non-destructive Testing – Industrial Radiographic Films – Part 2.

Control of Film Processing by Means of Reference Values (GB/T 19348.2-2003,

ISO 11699-2.1998, IDT)

GB/T 27025, General requirements for the competence of testing and calibration

laboratories (GB/T 27028-2008, ISO/IEC 17025.2005, IDT)

3 Terms and Definitions

For the purpose of this document, the following terms and definitions apply.

layers.

The granularity value shall be determined in terms of diffuse density.

If the optical density is measured as specular density, it shall be converted into diffuse

optical density, using the plot of the curve of diffuse density versus specular density at

the mean density value of the granularity film specimen. The diffuse density of each

step shall be measured with the calibrated densitometer.

Determine this curve using a film having a stepped series of densities, which is

prepared using the same type of film, exposure, and processing techniques as used

for the granularity film specimen. The specimen film shall be scanned using identical

microdensitometer settings. A limited range of densities can typically be measured for

a given microdensitometer gain setting. The stepped series of densities shall lie within

that range.

The calibration shall be made from the diffuse versus specular density plot with at least

5 values between diffuse density 1.5 and 2.8 (including fog and base). The conversion

can be performed on basis of a linear regression analysis of the log (diffuse density)

versus log (specular density) plot. The determined coefficients shall be used for the

conversion of the specular density into diffuse density values.

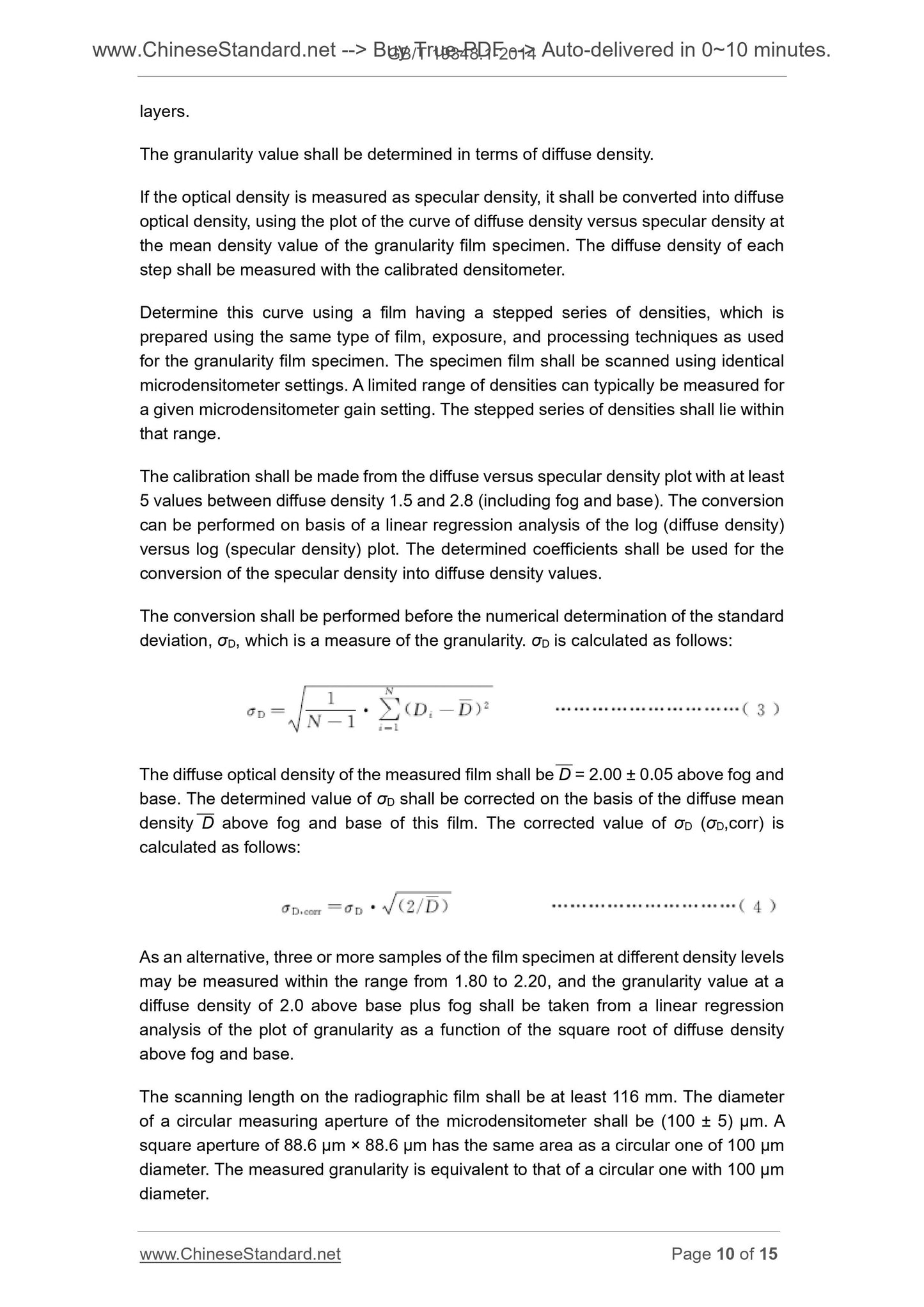

The conversion shall be performed before the numerical determination of the standard

deviation, σD, which is a measure of the granularity. σD is calculated as follows.

The diffuse optical density of the measured film shall be D = 2.00 ± 0.05 above fog and

base. The determined value of σD shall be corrected on the basis of the diffuse mean

density D above fog and base of this film. The corrected value of σD (σD,corr) is

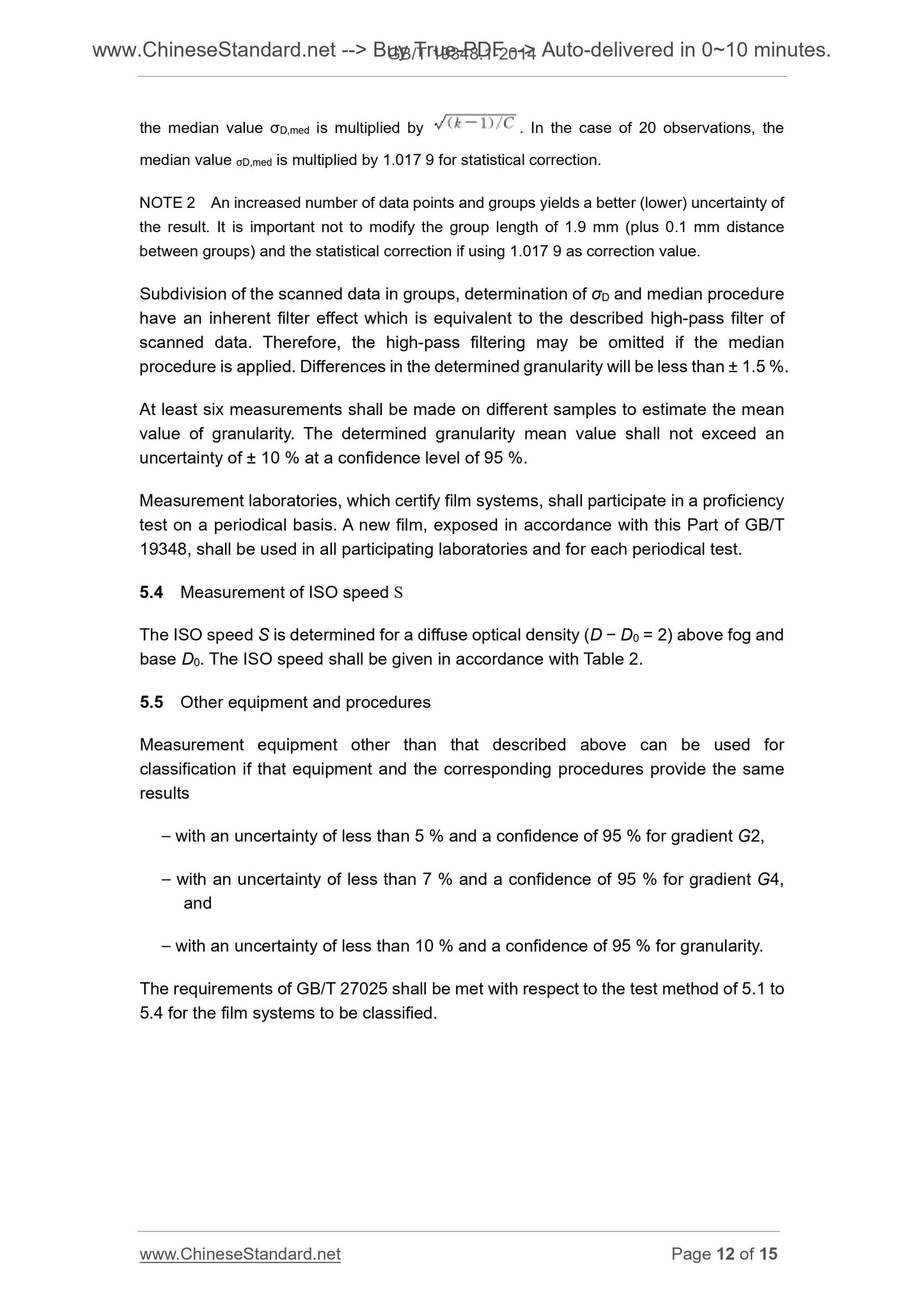

calculated as follows.

As an alternative, three or more samples of the film specimen at different density levels

may be measured within the range from 1.80 to 2.20, and the granularity value at a

diffuse density of 2.0 above base plus fog shall be taken from a linear regression

analysis of the plot of granularity as a function of the square root of diffuse density

above fog and base.

The scanning length on the radiographic film shall be at least 116 mm. The diameter

of a circular measuring aperture of the microdensitometer shall be (100 ± 5) μm. A

square aperture of 88.6 μm × 88.6 μm has the same area as a circular one of 100 μm

diameter. The measured granularity is equivalent to that of a circular one with 100 μm

diameter.

the median value σD,med is multiplied by . In the case of 20 observations, the

median value σD,med is multiplied by 1.017 9 for statistical correction.

NOTE 2 An increased number of data points and groups yields a better (lower) uncertainty of

the result. It is important not to modify the group length of 1.9 mm (plus 0.1 mm distance

between groups) and the statistical correction if using 1.017 9 as correction value.

Subdivision of the scanned data in groups, determination of σD and median procedure

have an inherent filter effect which is equivalent to the described high-pass filter of

scanned data. Therefore, the high-pass filtering may be omitted if the median

procedure is applied. Differences in the determined granularity will be less than ± 1.5 %.

At least six measurements shall be made on different samples to estimate the mean

value of granularity. The determined granularity mean value shall not exceed an

uncertainty of ± 10 % at a confidence level of 95 %.

Measurement laboratories, which certify film systems, shall participate in a proficiency

test on a periodical basis. A new film, exposed in accordance with this Part of GB/T

19348, shall be used in all participating laboratories and for each periodical test.

5.4 Measurement of ISO speed S

The ISO speed S is determined for a diffuse optical density (D − D0 = 2) above fog and

base D0. The ISO speed shall be given in accordance with Table 2.

5.5 Other equipment and procedures

Measurement equipment other than that described above can be used for

classification if that equipment and the corresponding procedures provide the same

results

ۛ with an uncertainty of less than 5 % and a confidence of 95 % for gradient G2,

ۛ with an uncertainty of less than 7 % and a confidence of 95 % for gradient G4,

and

ۛ with an uncertainty of less than 10 % and a confidence of 95 % for granularity.

The requirements of GB/T 27025 shall be met with respect to the test method of 5.1 t...

GB/T 19348.1-2014

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 37.040.25; 19.100

J 04

Replacing GB/T 19348.1-2003

Non-destructive Testing – Industrial Radiographic

Film – Part 1. Classification of Film Systems for

Industrial Radiography

(ISO 11699-1. 2008, MOD)

ISSUED ON. JUNE 24, 2014

IMPLEMENTED ON. DECEMBER 31, 2014

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Application Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 5

4 Sampling and Storage ... 7

5 Test Method ... 8

6 Limiting Values for Classification ... 13

Bibliography ... 15

Foreword

GB/T 19348, Non-destructive Testing – Industrial Radiographic Film, is divided into two

parts.

-- Part 1. Classification of Film Systems for Industrial Radiography

-- Part 2. Control of Film Processing by Means of Reference Values

This Part is the 1st part of GB/T 19348.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 19348.1, Non-destructive Testing – Industrial Radiographic

Film - Part 1. Classification of Film Systems for Industrial Radiography. Compared with

GB/T 19348.1-2003, the main technical changes of this Part, except editorial changes,

are as follows.

-- adds normative references (see Article 2);

-- modifies part of test methods (see Article 5; Article 4 of Edition 2003); and

-- modifies limiting values for classification.

This Part was redrafted by modifying and adopting ISO 11699-1.2008, Non-destructive

Testing – Industrial Radiographic Film – Part 1. Classification of Film Systems for

Industrial Radiography.

The main technical differences and their reasons between this Part and ISO 11699-

1.2008 are as follows.

-- for normative references, some adjustments with technical differences are made

in this Part, in order to suit the technical conditions of China. The details of

adjustments are mainly reflected in Article 2 “Normative References”, including.

uses Chinese standard GB/T 19348.2 to replace ISO 11699-2 (Article 1 and

5.2); and

uses Chinese standard GB/T 27025 to replace ISO/IEC 17025 (see 5.5).

This Part was proposed by and shall be under the jurisdiction of the National Technical

Committee 56 on Non-destructive Testing of Standardization Administration of China

(SAC/TC 56).

The drafting organizations of this Part. Shanghai Taisi Testing Technology Co., Ltd.,

Shanghai Electric Nuclear Power Group Co., Ltd., Shanghai Research Institute of

Materials, COMAC Shanghai Aircraft Design and Research Institute, Shanghai Key

Laboratory for Application and Evaluation of Engineering Materials and Carestream

Asia-Pacific Investment Management (Shanghai) Co., Ltd.

Non-destructive Testing – Industrial Radiographic

Film – Part 1. Classification of Film Systems for

Industrial Radiography

1 Application Scope

The purpose of this Part of GB/T 19348 is to establish the performance of film systems.

This Part is applicable for the classification of film systems in combination with

specified lead screens for industrial radiography (non-destructive testing). This Part is

intended to ensure that the image quality of radiographs – as far as this is influenced

by the film system – is in conformity with the requirements of other standards such as

ISO 5579, ISO 17636 and EN 12681.

This Part does not apply to the classification of films used with fluorescent intensifying

screens. The measurement of film systems in this Part is restricted to a selected

radiation quality to simplify the procedure. The properties of films will change with

radiation energy, but not the ranking of film system quality.

Additional methods for evaluating the photographic process are described in GB/T

19348.2, by which the performance of film systems can be controlled under the

conditions given in industry.

2 Normative References

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 19348.2, Non-destructive Testing – Industrial Radiographic Films – Part 2.

Control of Film Processing by Means of Reference Values (GB/T 19348.2-2003,

ISO 11699-2.1998, IDT)

GB/T 27025, General requirements for the competence of testing and calibration

laboratories (GB/T 27028-2008, ISO/IEC 17025.2005, IDT)

3 Terms and Definitions

For the purpose of this document, the following terms and definitions apply.

layers.

The granularity value shall be determined in terms of diffuse density.

If the optical density is measured as specular density, it shall be converted into diffuse

optica...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 19348.1-2014 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 19348.1-2014

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 19348.1-2014

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 37.040.25; 19.100

J 04

Replacing GB/T 19348.1-2003

Non-destructive Testing – Industrial Radiographic

Film – Part 1. Classification of Film Systems for

Industrial Radiography

(ISO 11699-1. 2008, MOD)

ISSUED ON. JUNE 24, 2014

IMPLEMENTED ON. DECEMBER 31, 2014

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Application Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 5

4 Sampling and Storage ... 7

5 Test Method ... 8

6 Limiting Values for Classification ... 13

Bibliography ... 15

Foreword

GB/T 19348, Non-destructive Testing – Industrial Radiographic Film, is divided into two

parts.

-- Part 1. Classification of Film Systems for Industrial Radiography

-- Part 2. Control of Film Processing by Means of Reference Values

This Part is the 1st part of GB/T 19348.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 19348.1, Non-destructive Testing – Industrial Radiographic

Film - Part 1. Classification of Film Systems for Industrial Radiography. Compared with

GB/T 19348.1-2003, the main technical changes of this Part, except editorial changes,

are as follows.

-- adds normative references (see Article 2);

-- modifies part of test methods (see Article 5; Article 4 of Edition 2003); and

-- modifies limiting values for classification.

This Part was redrafted by modifying and adopting ISO 11699-1.2008, Non-destructive

Testing – Industrial Radiographic Film – Part 1. Classification of Film Systems for

Industrial Radiography.

The main technical differences and their reasons between this Part and ISO 11699-

1.2008 are as follows.

-- for normative references, some adjustments with technical differences are made

in this Part, in order to suit the technical conditions of China. The details of

adjustments are mainly reflected in Article 2 “Normative References”, including.

uses Chinese standard GB/T 19348.2 to replace ISO 11699-2 (Article 1 and

5.2); and

uses Chinese standard GB/T 27025 to replace ISO/IEC 17025 (see 5.5).

This Part was proposed by and shall be under the jurisdiction of the National Technical

Committee 56 on Non-destructive Testing of Standardization Administration of China

(SAC/TC 56).

The drafting organizations of this Part. Shanghai Taisi Testing Technology Co., Ltd.,

Shanghai Electric Nuclear Power Group Co., Ltd., Shanghai Research Institute of

Materials, COMAC Shanghai Aircraft Design and Research Institute, Shanghai Key

Laboratory for Application and Evaluation of Engineering Materials and Carestream

Asia-Pacific Investment Management (Shanghai) Co., Ltd.

Non-destructive Testing – Industrial Radiographic

Film – Part 1. Classification of Film Systems for

Industrial Radiography

1 Application Scope

The purpose of this Part of GB/T 19348 is to establish the performance of film systems.

This Part is applicable for the classification of film systems in combination with

specified lead screens for industrial radiography (non-destructive testing). This Part is

intended to ensure that the image quality of radiographs – as far as this is influenced

by the film system – is in conformity with the requirements of other standards such as

ISO 5579, ISO 17636 and EN 12681.

This Part does not apply to the classification of films used with fluorescent intensifying

screens. The measurement of film systems in this Part is restricted to a selected

radiation quality to simplify the procedure. The properties of films will change with

radiation energy, but not the ranking of film system quality.

Additional methods for evaluating the photographic process are described in GB/T

19348.2, by which the performance of film systems can be controlled under the

conditions given in industry.

2 Normative References

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 19348.2, Non-destructive Testing – Industrial Radiographic Films – Part 2.

Control of Film Processing by Means of Reference Values (GB/T 19348.2-2003,

ISO 11699-2.1998, IDT)

GB/T 27025, General requirements for the competence of testing and calibration

laboratories (GB/T 27028-2008, ISO/IEC 17025.2005, IDT)

3 Terms and Definitions

For the purpose of this document, the following terms and definitions apply.

layers.

The granularity value shall be determined in terms of diffuse density.

If the optical density is measured as specular density, it shall be converted into diffuse

optical density, using the plot of the curve of diffuse density versus specular density at

the mean density value of the granularity film specimen. The diffuse density of each

step shall be measured with the calibrated densitometer.

Determine this curve using a film having a stepped series of densities, which is

prepared using the same type of film, exposure, and processing techniques as used

for the granularity film specimen. The specimen film shall be scanned using identical

microdensitometer settings. A limited range of densities can typically be measured for

a given microdensitometer gain setting. The stepped series of densities shall lie within

that range.

The calibration shall be made from the diffuse versus specular density plot with at least

5 values between diffuse density 1.5 and 2.8 (including fog and base). The conversion

can be performed on basis of a linear regression analysis of the log (diffuse density)

versus log (specular density) plot. The determined coefficients shall be used for the

conversion of the specular density into diffuse density values.

The conversion shall be performed before the numerical determination of the standard

deviation, σD, which is a measure of the granularity. σD is calculated as follows.

The diffuse optical density of the measured film shall be D = 2.00 ± 0.05 above fog and

base. The determined value of σD shall be corrected on the basis of the diffuse mean

density D above fog and base of this film. The corrected value of σD (σD,corr) is

calculated as follows.

As an alternative, three or more samples of the film specimen at different density levels

may be measured within the range from 1.80 to 2.20, and the granularity value at a

diffuse density of 2.0 above base plus fog shall be taken from a linear regression

analysis of the plot of granularity as a function of the square root of diffuse density

above fog and base.

The scanning length on the radiographic film shall be at least 116 mm. The diameter

of a circular measuring aperture of the microdensitometer shall be (100 ± 5) μm. A

square aperture of 88.6 μm × 88.6 μm has the same area as a circular one of 100 μm

diameter. The measured granularity is equivalent to that of a circular one with 100 μm

diameter.

the median value σD,med is multiplied by . In the case of 20 observations, the

median value σD,med is multiplied by 1.017 9 for statistical correction.

NOTE 2 An increased number of data points and groups yields a better (lower) uncertainty of

the result. It is important not to modify the group length of 1.9 mm (plus 0.1 mm distance

between groups) and the statistical correction if using 1.017 9 as correction value.

Subdivision of the scanned data in groups, determination of σD and median procedure

have an inherent filter effect which is equivalent to the described high-pass filter of

scanned data. Therefore, the high-pass filtering may be omitted if the median

procedure is applied. Differences in the determined granularity will be less than ± 1.5 %.

At least six measurements shall be made on different samples to estimate the mean

value of granularity. The determined granularity mean value shall not exceed an

uncertainty of ± 10 % at a confidence level of 95 %.

Measurement laboratories, which certify film systems, shall participate in a proficiency

test on a periodical basis. A new film, exposed in accordance with this Part of GB/T

19348, shall be used in all participating laboratories and for each periodical test.

5.4 Measurement of ISO speed S

The ISO speed S is determined for a diffuse optical density (D − D0 = 2) above fog and

base D0. The ISO speed shall be given in accordance with Table 2.

5.5 Other equipment and procedures

Measurement equipment other than that described above can be used for

classification if that equipment and the corresponding procedures provide the same

results

ۛ with an uncertainty of less than 5 % and a confidence of 95 % for gradient G2,

ۛ with an uncertainty of less than 7 % and a confidence of 95 % for gradient G4,

and

ۛ with an uncertainty of less than 10 % and a confidence of 95 % for granularity.

The requirements of GB/T 27025 shall be met with respect to the test method of 5.1 t...

GB/T 19348.1-2014

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 37.040.25; 19.100

J 04

Replacing GB/T 19348.1-2003

Non-destructive Testing – Industrial Radiographic

Film – Part 1. Classification of Film Systems for

Industrial Radiography

(ISO 11699-1. 2008, MOD)

ISSUED ON. JUNE 24, 2014

IMPLEMENTED ON. DECEMBER 31, 2014

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Application Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 5

4 Sampling and Storage ... 7

5 Test Method ... 8

6 Limiting Values for Classification ... 13

Bibliography ... 15

Foreword

GB/T 19348, Non-destructive Testing – Industrial Radiographic Film, is divided into two

parts.

-- Part 1. Classification of Film Systems for Industrial Radiography

-- Part 2. Control of Film Processing by Means of Reference Values

This Part is the 1st part of GB/T 19348.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 19348.1, Non-destructive Testing – Industrial Radiographic

Film - Part 1. Classification of Film Systems for Industrial Radiography. Compared with

GB/T 19348.1-2003, the main technical changes of this Part, except editorial changes,

are as follows.

-- adds normative references (see Article 2);

-- modifies part of test methods (see Article 5; Article 4 of Edition 2003); and

-- modifies limiting values for classification.

This Part was redrafted by modifying and adopting ISO 11699-1.2008, Non-destructive

Testing – Industrial Radiographic Film – Part 1. Classification of Film Systems for

Industrial Radiography.

The main technical differences and their reasons between this Part and ISO 11699-

1.2008 are as follows.

-- for normative references, some adjustments with technical differences are made

in this Part, in order to suit the technical conditions of China. The details of

adjustments are mainly reflected in Article 2 “Normative References”, including.

uses Chinese standard GB/T 19348.2 to replace ISO 11699-2 (Article 1 and

5.2); and

uses Chinese standard GB/T 27025 to replace ISO/IEC 17025 (see 5.5).

This Part was proposed by and shall be under the jurisdiction of the National Technical

Committee 56 on Non-destructive Testing of Standardization Administration of China

(SAC/TC 56).

The drafting organizations of this Part. Shanghai Taisi Testing Technology Co., Ltd.,

Shanghai Electric Nuclear Power Group Co., Ltd., Shanghai Research Institute of

Materials, COMAC Shanghai Aircraft Design and Research Institute, Shanghai Key

Laboratory for Application and Evaluation of Engineering Materials and Carestream

Asia-Pacific Investment Management (Shanghai) Co., Ltd.

Non-destructive Testing – Industrial Radiographic

Film – Part 1. Classification of Film Systems for

Industrial Radiography

1 Application Scope

The purpose of this Part of GB/T 19348 is to establish the performance of film systems.

This Part is applicable for the classification of film systems in combination with

specified lead screens for industrial radiography (non-destructive testing). This Part is

intended to ensure that the image quality of radiographs – as far as this is influenced

by the film system – is in conformity with the requirements of other standards such as

ISO 5579, ISO 17636 and EN 12681.

This Part does not apply to the classification of films used with fluorescent intensifying

screens. The measurement of film systems in this Part is restricted to a selected

radiation quality to simplify the procedure. The properties of films will change with

radiation energy, but not the ranking of film system quality.

Additional methods for evaluating the photographic process are described in GB/T

19348.2, by which the performance of film systems can be controlled under the

conditions given in industry.

2 Normative References

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 19348.2, Non-destructive Testing – Industrial Radiographic Films – Part 2.

Control of Film Processing by Means of Reference Values (GB/T 19348.2-2003,

ISO 11699-2.1998, IDT)

GB/T 27025, General requirements for the competence of testing and calibration

laboratories (GB/T 27028-2008, ISO/IEC 17025.2005, IDT)

3 Terms and Definitions

For the purpose of this document, the following terms and definitions apply.

layers.

The granularity value shall be determined in terms of diffuse density.

If the optical density is measured as specular density, it shall be converted into diffuse

optica...

Share