1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 20042.6-2024 English PDF (GB/T20042.6-2024)

GB/T 20042.6-2024 English PDF (GB/T20042.6-2024)

Regular price

$550.00

Regular price

Sale price

$550.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 20042.6-2024: Proton exchange membrane fuel cell - Part 6: Test method of bipolar plate properties

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 20042.6-2024 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 20042.6-2024

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 20042.6-2024

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 27.070

CCS K 82

Replacing GB/T 20042.6-2011

Proton Exchange Membrane Fuel Cell – Part 6.Test Method

of Bipolar Plate Properties

ISSUED ON. MARCH 15, 2024

IMPLEMENTED ON. OCTOBER 1, 2024

Issued by. State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword... 3

Introduction... 6

1 Scope... 7

2 Normative References... 7

3 Terms and Definitions... 8

4 Flexural Strength Test of Bipolar Plate Materials... 9

5 Density Test of Bipolar Plate Materials... 11

6 Resistance Test of Bipolar Plate Material... 12

7 Corrosion Current Density Test of Bipolar Plate Materials... 16

8 Area Utilization Rate Test of Bipolar Plate Component... 20

9 Thickness Uniformity Test of Bipolar Plate Component... 21

10 Groove Depth Uniformity Test of Bipolar Plate Component... 24

11 Flatness Test of Bipolar Plate Components... 26

12 Relative Flatness Test of Bipolar Plate Component... 27

13 Contact Resistance Test of Bipolar Plate Component... 29

14 Air Tightness Test of Bipolar Plate Component... 29

15 Water Contact Angle Test of Bipolar Plate Component... 33

16 Coating Thickness Test of Bipolar Plate Component... 34

17 Coating Bonding Strength Test of Bipolar Plate Component... 35

18 Corrosion Current Density Test of Bipolar Plate Component... 36

19 Specific Heat Capacity Test of Bipolar Plate Component... 37

20 Thermal Conductivity Test of Bipolar Plate Component... 38

21 Precipitation Ion Composition and Concentration Test for Bipolar Plate Component

... 39

22 Applicability of Test Indicators, Test Preparation and Test Report... 41

Appendix A (Normative) Applicability of Test Indicators... 42

Appendix B (Informative) Test Preparation... 43

Appendix C (Informative) Test Report... 44

Bibliography... 47

Proton Exchange Membrane Fuel Cell – Part 6.Test Method

of Bipolar Plate Properties

1 Scope

This Document specifies the test methods for the flexural strength, density, resistance and

corrosion current density, etc. of bipolar plate materials for proton exchange membrane fuel

cells; and the test methods for the area utilization, thickness uniformity, groove depth uniformity,

flatness, relative flatness, contact resistance, air tightness, etc. of bipolar plate components.

This Document is applicable to various types of bipolar plate materials and components for

proton exchange membrane fuel cells.

NOTE. The definitions of bipolar plate materials and bipolar plate components are as follows.

a) Bipolar plate material. Plate material in the same state as the finished bipolar plate material;

b) Bipolar plate component. Finished bipolar plate in the same state as the used state.

2 Normative References

The provisions in following documents become the essential provisions of this Document

through reference in this Document. For the dated documents, only the versions with the dates

indicated are applicable to this Document; for the undated documents, only the latest version

(including all the amendments) is applicable to this Document.

GB/T 230.2 Metallic materials – Rockwell hardness test – Part 2.Verification and

calibration of testing machines and indenters

GB/T 1958 Geometrical product Specifications (GPS) - Geometrical tolerance -

Verification prescription

GB/T 4472-2011 Determination of density and relative density for chemical products

GB/T 13465.2 Test method of impermeable graphite materials - Part 2.Flexure strength

GB/T 19466.4-2016 Plastics - Differential scanning calorimetry (DSC) - Part 4.

Determination of specific heat capacity

GB/T 20042.1-2017 Proton exchange membrane fuel cell - Part 1.Terminology

Take 3 valid samples as a group; calculate the average value as the test result, and retain two

digits after the decimal point.

6 Resistance Test of Bipolar Plate Material

6.1 Test instrument

The test instrument includes the following equipment and tools.

--- Four-probe low resistance measuring instrument. accuracy is 0.1mΩ·cm;

--- Thickness gauge. accuracy is 1μm, used to measure the thickness of the sample;

--- Low resistance measuring instrument. DC mode, accuracy is 0.01mΩ; the pressure

device accuracy meets the requirements of Level-0.5.

6.2 Preparation of sample

6.2.1 The sample shape is square (5cm×5cm) and the area is 25cm2; the sample shape and size

can also be negotiated by the test parties.

6.2.2 The number of samples is 5 (ensure 3 valid values to be obtained); and there shall be no

wrinkles, scratches or damage.

6.2.3 For samples from different batches, they should be sampled separately.

6.3 Test methods

6.3.1 In-plane resistivity test

6.3.1.1 The zero point of the tester shall be calibrated before each test. The influence of sample

deformation, dust on the sample surface and other factors shall be avoided during the test.

6.3.1.2 Use a four-probe low-resistance meter to test at least 5 locations near the edge and center

of the sample; and record the in-plane resistivity values of different locations.

6.3.2 Through-plane resistivity test

6.3.2.1 Use a low-resistance meter to test the resistance value; and the test electrode is a gold-

plated copper electrode. The connection method between the gold-plated copper electrode and

the wire is determined by negotiation between the two test parties to minimize the influence of

the low-resistance meter on the test results.

6.3.2.2 Use a thickness gauge to measure the sample thickness; and the measurement positions

shall be no less than 3.

6.3.2.3 Install the sample on the test device as shown in Figure 1.During the test, place

5cm×5cm carbon paper on both sides of the sample as a support to further improve the contact

condition. During the test, record a resistance value for every 0.1MPa increase in pressure until

the change rate of the current resistance test value relative to the previous resistance test value

is ≤5%, then it is considered that the minimum resistance value has been reached and the test

is stopped. The resistance value under different pressures is recorded as Rm.

6.3.2.4 Use new carbon paper of the same specification for each test, and the carbon paper

manufacturer and model shall be indicated in the test report.

NOTE. The test current density is 40mA/cm2 or determined by negotiation between the two test parties.

The test pressure range is generally 0.1MPa~2.0MPa; and the resistance value at a pressure of 1.5MPa

is selected, or it is determined by negotiation between the two test parties.

6.3.3 Contact resistance test

6.3.3.1 Use a low resistance meter to test the resistance value; and the test electrode is a gold-

plated copper electrode. The connection method between the gold-plated copper electrode and

the wire is determined by negotiation between the two test parties to minimize the impact of

the low resistance meter on the test results.

6.3.3.2 Install the sample on the test device as shown in Figure 1.During the test, place

5cm×5cm carbon paper on both sides of the sample as a support to further improve the contact

condition. During the test, record a resistance value for each 0.1MPa increase in pressure until

the change rate of the current resistance test value relative to the previous resistance test value

is ≤5%; then it is considered that the minimum resistance value is reached and the test is stopped.

The resistance value under different pressures is recorded as R1.

6.3.3.3 In the same way, place a 5cm×5cm carbon paper between the two gold-plated copper

electrodes; test according to the method described in 6.3.3.2; and record the resistance value R2

under different pressures.

6.3.3.4 Use new carbon paper of the same specification for each test; and the carbon paper

manufacturer and model shall be indicated in the test report.

NOTE. The test current density is 40mA/cm2, or determined by negotiation between the two test parties.

The test pressure range is generally 0.1 MPa~2.0 MPa; and the resistance value at a pressure of 1.5MPa

is selected, or determined by negotiation between the two test parties.

NOTE. The thickness of the samples for the two tests satisfies. ̅1=(1.5~2.0)̅2, or is determined by

negotiation between the two test parties.

6.4.3 The contact resistance of the sample is calculated according to Formula (5).

Where.

R – the contact resistance between sample and carbon paper, in mΩ·cm2;

R1 - the sum of the body resistance of the sample, the body resistance of the two carbon papers,

the contact resistance between the two samples and the carbon papers, the body resistance of

the two copper electrodes and the contact resistance between the two carbon papers and the

copper electrodes, in mΩ;

R2 - the sum of the body resistance of the two copper electrodes, the body resistance of the

carbon paper and the contact resistance between the carbon paper and the two copper electrodes,

in mΩ;

RBP - the through-plane resistance of the sample, in mΩ;

RCP - the through-plane resistance of the carbon paper, in mΩ;

S - the contact area between the sample and the carbon paper, in cm2.

NOTE. The through-plane resistance of the sample and the through-plane resistance of the carbon paper

are relatively small compared with R1, so they are ignored.

Take 3 valid samples as a group; calculate the average value as the test result, and retain two

digits after the decimal point.

7 Corrosion Current Density Test of Bipolar Plate Materials

7.1 Test instrument

The test instrument includes the following equipment and tools.

--- Electrochemical constant potential tester;

--- Electrochemical test cell. The test cell has a capacity of at least 300mL and is used to

hold electrolyte solution. The material is corrosion-resistant materials such as glass or

plastic.

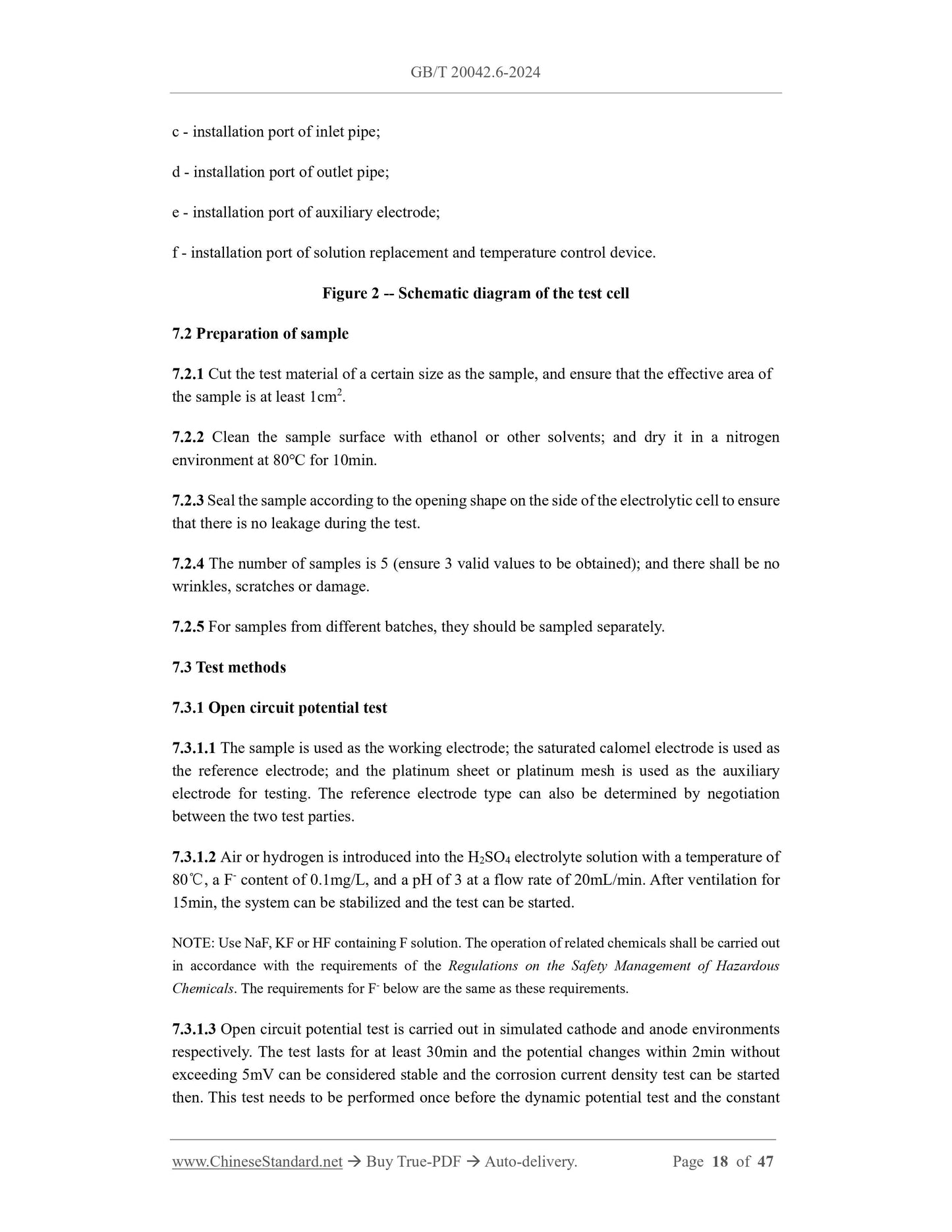

NOTE. The test cell is shown in Figure 2.The capacity of the electrolyte solution is two-thirds of the

capacity of the test cell. An opening a is left on the side of the test cell. During the test, the sample is

c - installation port of inlet pipe;

d - installation port of outlet pipe;

e - installation port of auxiliary electrode;

f - installation port of solution replacement and temperature control device.

Figure 2 -- Schematic diagram of the test cell

7.2 Preparation of sample

7.2.1 Cut the test material of a certain size as the sample, and ensure that the effective area of

the sample is at least 1cm2.

7.2.2 Clean the sample surface with ethanol or other solvents; and dry it in a nitrogen

environment at 80℃ for 10min.

7.2.3 Seal the sample according to the opening shape on the side of the electrolytic cell to ensure

that there is no leakage during the test.

7.2.4 The number of samples is 5 (ensure 3 valid values to be obtained); and there shall be no

wrinkles, scratches or damage.

7.2.5 For samples from different batches, they should be sampled separately.

7.3 Test methods

7.3.1 Open circuit potential test

7.3.1.1 The sample is used as the working electrode; the saturated calomel electrode is used as

the reference electrode; and the platinum sheet or platinum mesh is used as the auxiliary

electrode for testing. The reference electrode type can also be determined by negotiation

between the two test parties.

7.3.1.2 Air or hydrogen is introduced into the H2SO4 electrolyte solution with a temperature of

80℃, a F- content of 0.1mg/L, and a pH of 3 at a flow rate of 20mL/min. After ventilation for

15min, the system can be stabilized and the test can be started.

NOTE. Use NaF, KF or HF containing F solution. The operation of related chemicals shall be carried out

in accordance with the requirements of the Regulations on the Safety Management of Hazardous

Chemicals. The requirements for F- below are the same as these requirements.

7.3.1.3 Open circuit potential test is carried out in simulated cathode and anode environments

respectively. The test lasts for at least 30min and the potential changes within 2min without

exceeding 5mV can be considered stable and the corrosion current density test can be started

then. This test needs to be performed once before the dynamic potential test and the constant

potential test.

7.3.2 Dynamic potential test

7.3.2.1 Test with the sample as the working electrode, the saturated calomel electrode as the

reference electrode, and the platinum sheet or platinum mesh as the auxiliary electrode. The

reference electrode type can also be determined by negotiation between the two test parties;

and the linear potential scanning range is converted accordingly according to the used reference

electrode type.

7.3.2.2 Air or hydrogen is introduced into the H2SO4 electrolyte solution with a temperature of

80℃, a F- content of 0.1mg/L, and a pH of 3 at a flow rate of 20mL/min to simulate the cathode

or anode environment of the fuel cell. After ventilation for 15 min, the system is stable and the

test can be started.

7.3.2.3 The sample is subjected to a linear potential scan at a scan rate of 2mV/s and a potential

scan range of -0.5V~1.4V (vs. SCE). The test data are recorded separately under different gas

environments.

7.3.2.4 Perform Tafel fitting on the measured linear potential scanning curve. The current

corresponding to the intersection of the Tafel straight line is the corrosion current of the sample.

7.3.3 Constant potential test

7.3.3.1 Test with the sample as the working electrode, the saturated calomel electrode as the

reference electrode, and the platinum sheet or platinum mesh as the auxiliary electrode. The

reference electrode type can also be determined by negotiation between the two test parties;

and the test potential is converted accordingly according to the used reference electrode type.

7.3.3.2 Air or hydrogen is introduced into the H2SO4 electrolyte solution with a temperature of

80℃, a F- content of 0.1mg/L, and a pH of 3 at a flow rate of 20mL/min to simulate the cathode

or anode environment of the fuel cell.

7.3.3.3 Apply 0.6V (vs. SCE) and -0.1V (vs. SCE) potentials to the samples in the simulated

cathode a...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 20042.6-2024 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 20042.6-2024

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 20042.6-2024

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 27.070

CCS K 82

Replacing GB/T 20042.6-2011

Proton Exchange Membrane Fuel Cell – Part 6.Test Method

of Bipolar Plate Properties

ISSUED ON. MARCH 15, 2024

IMPLEMENTED ON. OCTOBER 1, 2024

Issued by. State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword... 3

Introduction... 6

1 Scope... 7

2 Normative References... 7

3 Terms and Definitions... 8

4 Flexural Strength Test of Bipolar Plate Materials... 9

5 Density Test of Bipolar Plate Materials... 11

6 Resistance Test of Bipolar Plate Material... 12

7 Corrosion Current Density Test of Bipolar Plate Materials... 16

8 Area Utilization Rate Test of Bipolar Plate Component... 20

9 Thickness Uniformity Test of Bipolar Plate Component... 21

10 Groove Depth Uniformity Test of Bipolar Plate Component... 24

11 Flatness Test of Bipolar Plate Components... 26

12 Relative Flatness Test of Bipolar Plate Component... 27

13 Contact Resistance Test of Bipolar Plate Component... 29

14 Air Tightness Test of Bipolar Plate Component... 29

15 Water Contact Angle Test of Bipolar Plate Component... 33

16 Coating Thickness Test of Bipolar Plate Component... 34

17 Coating Bonding Strength Test of Bipolar Plate Component... 35

18 Corrosion Current Density Test of Bipolar Plate Component... 36

19 Specific Heat Capacity Test of Bipolar Plate Component... 37

20 Thermal Conductivity Test of Bipolar Plate Component... 38

21 Precipitation Ion Composition and Concentration Test for Bipolar Plate Component

... 39

22 Applicability of Test Indicators, Test Preparation and Test Report... 41

Appendix A (Normative) Applicability of Test Indicators... 42

Appendix B (Informative) Test Preparation... 43

Appendix C (Informative) Test Report... 44

Bibliography... 47

Proton Exchange Membrane Fuel Cell – Part 6.Test Method

of Bipolar Plate Properties

1 Scope

This Document specifies the test methods for the flexural strength, density, resistance and

corrosion current density, etc. of bipolar plate materials for proton exchange membrane fuel

cells; and the test methods for the area utilization, thickness uniformity, groove depth uniformity,

flatness, relative flatness, contact resistance, air tightness, etc. of bipolar plate components.

This Document is applicable to various types of bipolar plate materials and components for

proton exchange membrane fuel cells.

NOTE. The definitions of bipolar plate materials and bipolar plate components are as follows.

a) Bipolar plate material. Plate material in the same state as the finished bipolar plate material;

b) Bipolar plate component. Finished bipolar plate in the same state as the used state.

2 Normative References

The provisions in following documents become the essential provisions of this Document

through reference in this Document. For the dated documents, only the versions with the dates

indicated are applicable to this Document; for the undated documents, only the latest version

(including all the amendments) is applicable to this Document.

GB/T 230.2 Metallic materials – Rockwell hardness test – Part 2.Verification and

calibration of testing machines and indenters

GB/T 1958 Geometrical product Specifications (GPS) - Geometrical tolerance -

Verification prescription

GB/T 4472-2011 Determination of density and relative density for chemical products

GB/T 13465.2 Test method of impermeable graphite materials - Part 2.Flexure strength

GB/T 19466.4-2016 Plastics - Differential scanning calorimetry (DSC) - Part 4.

Determination of specific heat capacity

GB/T 20042.1-2017 Proton exchange membrane fuel cell - Part 1.Terminology

Take 3 valid samples as a group; calculate the average value as the test result, and retain two

digits after the decimal point.

6 Resistance Test of Bipolar Plate Material

6.1 Test instrument

The test instrument includes the following equipment and tools.

--- Four-probe low resistance measuring instrument. accuracy is 0.1mΩ·cm;

--- Thickness gauge. accuracy is 1μm, used to measure the thickness of the sample;

--- Low resistance measuring instrument. DC mode, accuracy is 0.01mΩ; the pressure

device accuracy meets the requirements of Level-0.5.

6.2 Preparation of sample

6.2.1 The sample shape is square (5cm×5cm) and the area is 25cm2; the sample shape and size

can also be negotiated by the test parties.

6.2.2 The number of samples is 5 (ensure 3 valid values to be obtained); and there shall be no

wrinkles, scratches or damage.

6.2.3 For samples from different batches, they should be sampled separately.

6.3 Test methods

6.3.1 In-plane resistivity test

6.3.1.1 The zero point of the tester shall be calibrated before each test. The influence of sample

deformation, dust on the sample surface and other factors shall be avoided during the test.

6.3.1.2 Use a four-probe low-resistance meter to test at least 5 locations near the edge and center

of the sample; and record the in-plane resistivity values of different locations.

6.3.2 Through-plane resistivity test

6.3.2.1 Use a low-resistance meter to test the resistance value; and the test electrode is a gold-

plated copper electrode. The connection method between the gold-plated copper electrode and

the wire is determined by negotiation between the two test parties to minimize the influence of

the low-resistance meter on the test results.

6.3.2.2 Use a thickness gauge to measure the sample thickness; and the measurement positions

shall be no less than 3.

6.3.2.3 Install the sample on the test device as shown in Figure 1.During the test, place

5cm×5cm carbon paper on both sides of the sample as a support to further improve the contact

condition. During the test, record a resistance value for every 0.1MPa increase in pressure until

the change rate of the current resistance test value relative to the previous resistance test value

is ≤5%, then it is considered that the minimum resistance value has been reached and the test

is stopped. The resistance value under different pressures is recorded as Rm.

6.3.2.4 Use new carbon paper of the same specification for each test, and the carbon paper

manufacturer and model shall be indicated in the test report.

NOTE. The test current density is 40mA/cm2 or determined by negotiation between the two test parties.

The test pressure range is generally 0.1MPa~2.0MPa; and the resistance value at a pressure of 1.5MPa

is selected, or it is determined by negotiation between the two test parties.

6.3.3 Contact resistance test

6.3.3.1 Use a low resistance meter to test the resistance value; and the test electrode is a gold-

plated copper electrode. The connection method between the gold-plated copper electrode and

the wire is determined by negotiation between the two test parties to minimize the impact of

the low resistance meter on the test results.

6.3.3.2 Install the sample on the test device as shown in Figure 1.During the test, place

5cm×5cm carbon paper on both sides of the sample as a support to further improve the contact

condition. During the test, record a resistance value for each 0.1MPa increase in pressure until

the change rate of the current resistance test value relative to the previous resistance test value

is ≤5%; then it is considered that the minimum resistance value is reached and the test is stopped.

The resistance value under different pressures is recorded as R1.

6.3.3.3 In the same way, place a 5cm×5cm carbon paper between the two gold-plated copper

electrodes; test according to the method described in 6.3.3.2; and record the resistance value R2

under different pressures.

6.3.3.4 Use new carbon paper of the same specification for each test; and the carbon paper

manufacturer and model shall be indicated in the test report.

NOTE. The test current density is 40mA/cm2, or determined by negotiation between the two test parties.

The test pressure range is generally 0.1 MPa~2.0 MPa; and the resistance value at a pressure of 1.5MPa

is selected, or determined by negotiation between the two test parties.

NOTE. The thickness of the samples for the two tests satisfies. ̅1=(1.5~2.0)̅2, or is determined by

negotiation between the two test parties.

6.4.3 The contact resistance of the sample is calculated according to Formula (5).

Where.

R – the contact resistance between sample and carbon paper, in mΩ·cm2;

R1 - the sum of the body resistance of the sample, the body resistance of the two carbon papers,

the contact resistance between the two samples and the carbon papers, the body resistance of

the two copper electrodes and the contact resistance between the two carbon papers and the

copper electrodes, in mΩ;

R2 - the sum of the body resistance of the two copper electrodes, the body resistance of the

carbon paper and the contact resistance between the carbon paper and the two copper electrodes,

in mΩ;

RBP - the through-plane resistance of the sample, in mΩ;

RCP - the through-plane resistance of the carbon paper, in mΩ;

S - the contact area between the sample and the carbon paper, in cm2.

NOTE. The through-plane resistance of the sample and the through-plane resistance of the carbon paper

are relatively small compared with R1, so they are ignored.

Take 3 valid samples as a group; calculate the average value as the test result, and retain two

digits after the decimal point.

7 Corrosion Current Density Test of Bipolar Plate Materials

7.1 Test instrument

The test instrument includes the following equipment and tools.

--- Electrochemical constant potential tester;

--- Electrochemical test cell. The test cell has a capacity of at least 300mL and is used to

hold electrolyte solution. The material is corrosion-resistant materials such as glass or

plastic.

NOTE. The test cell is shown in Figure 2.The capacity of the electrolyte solution is two-thirds of the

capacity of the test cell. An opening a is left on the side of the test cell. During the test, the sample is

c - installation port of inlet pipe;

d - installation port of outlet pipe;

e - installation port of auxiliary electrode;

f - installation port of solution replacement and temperature control device.

Figure 2 -- Schematic diagram of the test cell

7.2 Preparation of sample

7.2.1 Cut the test material of a certain size as the sample, and ensure that the effective area of

the sample is at least 1cm2.

7.2.2 Clean the sample surface with ethanol or other solvents; and dry it in a nitrogen

environment at 80℃ for 10min.

7.2.3 Seal the sample according to the opening shape on the side of the electrolytic cell to ensure

that there is no leakage during the test.

7.2.4 The number of samples is 5 (ensure 3 valid values to be obtained); and there shall be no

wrinkles, scratches or damage.

7.2.5 For samples from different batches, they should be sampled separately.

7.3 Test methods

7.3.1 Open circuit potential test

7.3.1.1 The sample is used as the working electrode; the saturated calomel electrode is used as

the reference electrode; and the platinum sheet or platinum mesh is used as the auxiliary

electrode for testing. The reference electrode type can also be determined by negotiation

between the two test parties.

7.3.1.2 Air or hydrogen is introduced into the H2SO4 electrolyte solution with a temperature of

80℃, a F- content of 0.1mg/L, and a pH of 3 at a flow rate of 20mL/min. After ventilation for

15min, the system can be stabilized and the test can be started.

NOTE. Use NaF, KF or HF containing F solution. The operation of related chemicals shall be carried out

in accordance with the requirements of the Regulations on the Safety Management of Hazardous

Chemicals. The requirements for F- below are the same as these requirements.

7.3.1.3 Open circuit potential test is carried out in simulated cathode and anode environments

respectively. The test lasts for at least 30min and the potential changes within 2min without

exceeding 5mV can be considered stable and the corrosion current density test can be started

then. This test needs to be performed once before the dynamic potential test and the constant

potential test.

7.3.2 Dynamic potential test

7.3.2.1 Test with the sample as the working electrode, the saturated calomel electrode as the

reference electrode, and the platinum sheet or platinum mesh as the auxiliary electrode. The

reference electrode type can also be determined by negotiation between the two test parties;

and the linear potential scanning range is converted accordingly according to the used reference

electrode type.

7.3.2.2 Air or hydrogen is introduced into the H2SO4 electrolyte solution with a temperature of

80℃, a F- content of 0.1mg/L, and a pH of 3 at a flow rate of 20mL/min to simulate the cathode

or anode environment of the fuel cell. After ventilation for 15 min, the system is stable and the

test can be started.

7.3.2.3 The sample is subjected to a linear potential scan at a scan rate of 2mV/s and a potential

scan range of -0.5V~1.4V (vs. SCE). The test data are recorded separately under different gas

environments.

7.3.2.4 Perform Tafel fitting on the measured linear potential scanning curve. The current

corresponding to the intersection of the Tafel straight line is the corrosion current of the sample.

7.3.3 Constant potential test

7.3.3.1 Test with the sample as the working electrode, the saturated calomel electrode as the

reference electrode, and the platinum sheet or platinum mesh as the auxiliary electrode. The

reference electrode type can also be determined by negotiation between the two test parties;

and the test potential is converted accordingly according to the used reference electrode type.

7.3.3.2 Air or hydrogen is introduced into the H2SO4 electrolyte solution with a temperature of

80℃, a F- content of 0.1mg/L, and a pH of 3 at a flow rate of 20mL/min to simulate the cathode

or anode environment of the fuel cell.

7.3.3.3 Apply 0.6V (vs. SCE) and -0.1V (vs. SCE) potentials to the samples in the simulated

cathode a...

Share