1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 20878-2007 English PDF (GBT20878-2007)

GB/T 20878-2007 English PDF (GBT20878-2007)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.Newer version: (Replacing this standard) GB/T 20878-2024

Get QUOTATION in 1-minute: Click GB/T 20878-2007

Historical versions: GB/T 20878-2007

Preview True-PDF (Reload/Scroll if blank)

GB/T 20878-2007: Stainless and heat-resisting steels -- Designation and chemical composition

GB/T 20878-2007

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.20

H40

Replacing GB/T 4229-1984

Stainless and heat-resisting steels –

Designation and chemical composition

ISSUED ON. MARCH 9, 2007

IMPLEMENTED ON. OCTOBER 1, 2007

Issued by. General Administration of Quality Supervision, Inspection;

Quarantine of the People's Republic of China (GAQSIQ);

Standardization Administration of China (SAC).

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Terms and definitions ... 4

3 General rules for identifying chemical constitution limits ... 5

4 Chemical composition and application of stainless steel and heat resisting steel ... 7

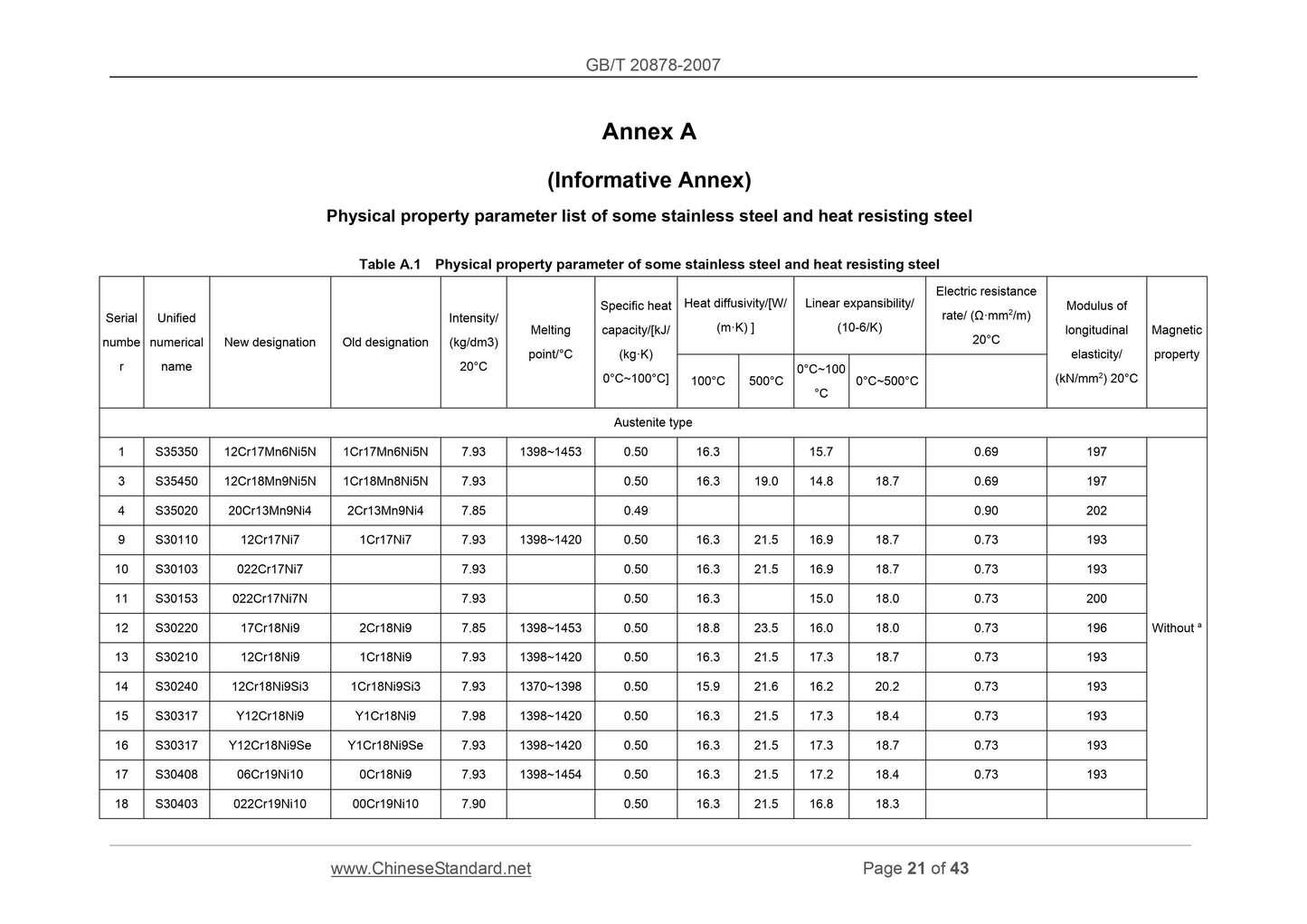

Annex A ... 21

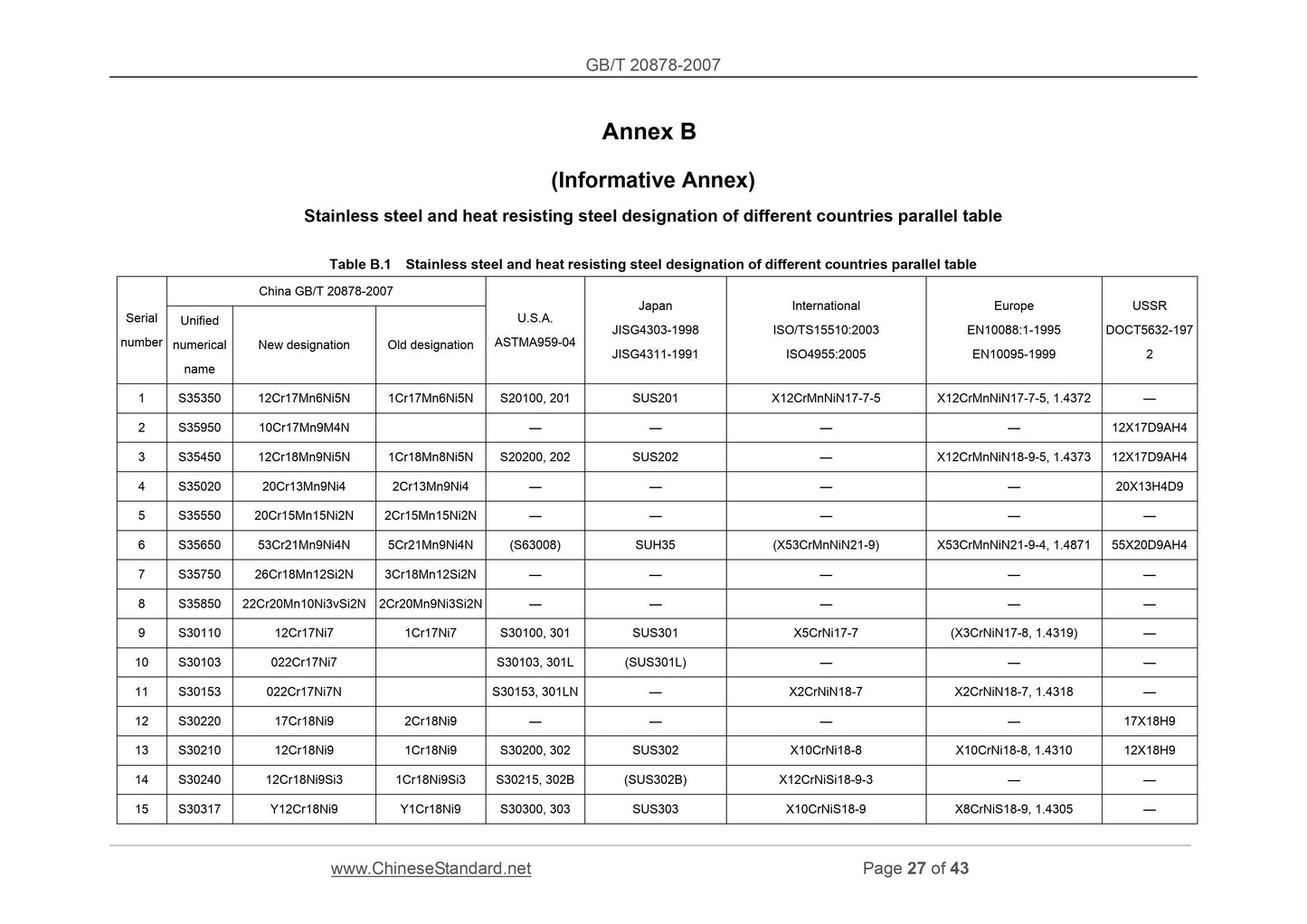

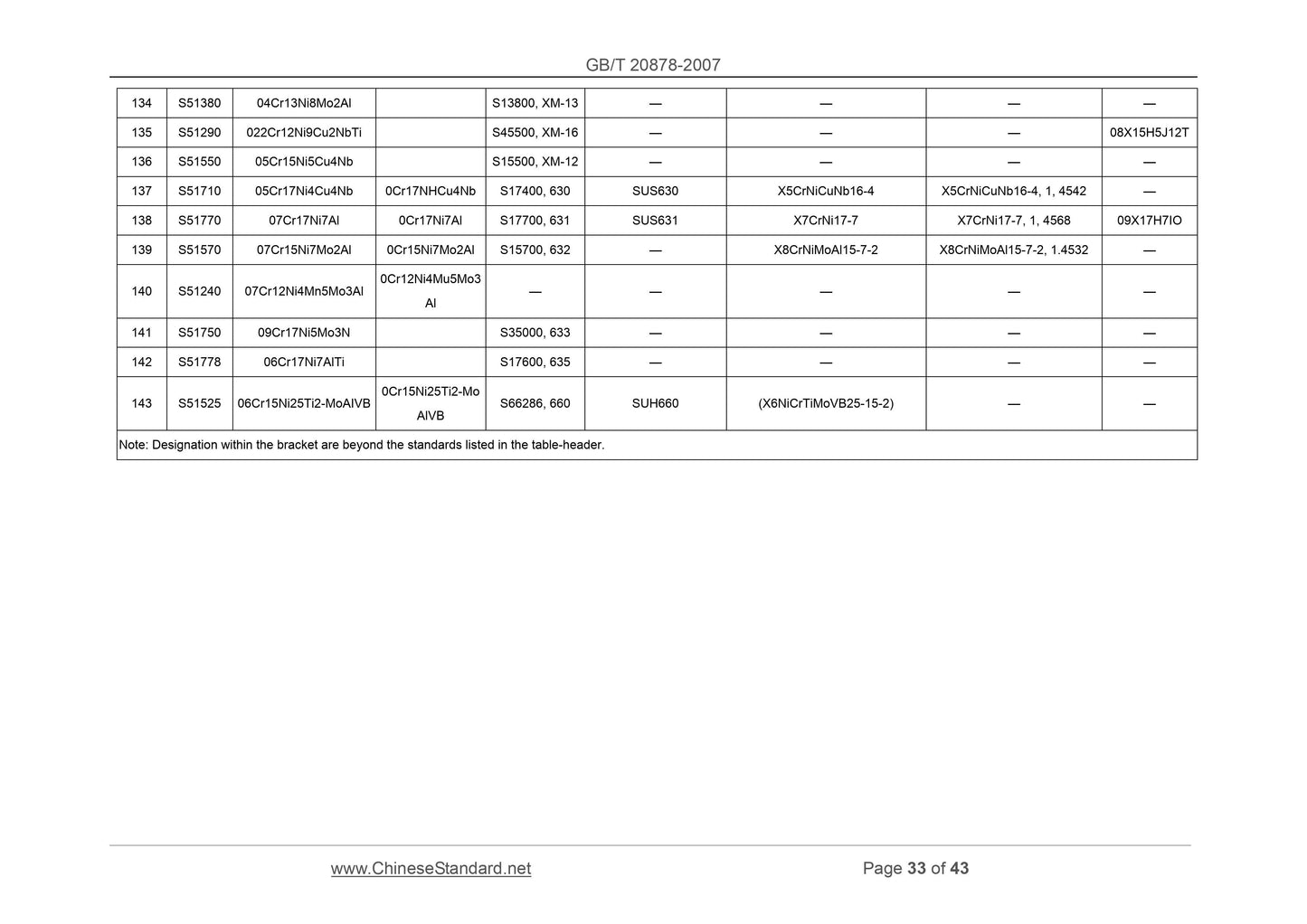

Annex B ... 27

Annex C ... 34

References ... 42

Foreword

Chemical constitution limit and designation time specified in this Standard is

applicable to formulate and revise product standard for stainless steel and refractory

steel (including steel ingot and half-finished product).

This Standard needs to be used with other technical standards; it can not be used for

ordering.

This Standard replaces GB/T 4229-1984 “Methods of weight calculation of stainless

steel plates and sheets" since the date of implementation.

Annex A, Annex B and Annex C of this Standard are informative.

This Standard was proposed by China Iron and Steel Association.

This Standard shall be under the jurisdiction of national steel standardization technical

committee.

Drafting organization of this Standard. China Metallurgical Information Standardization

Research Institute.

Main Drafters of this Standard. Luan Yan, Dai Qiang and Liu Baoshi.

Stainless and heat-resisting steels –

Designation and chemical composition

1 Scope

This Standard specifies the designation and its chemical constitution of stainless steel

and heat resisting steel (see Table 1 ~ Table 5). Physical parameter of some

designations, overseas standards designation or approximate designation parallel

table, stainless steel and heat resisting steel designation criterion of acceptability are

specified in the Informative Annex.

Chemical constitution limit and its designation time specified in this Standard are

applicable to formulating and revising the product standard for stainless steel and its

refractory steel (including steel ingot and its half-finished product).

2 Terms and definitions

The following terms and definitions are applicable to this Standard.

2.1

Stainless steel

Steel that does not rust and corrosion-resistant, of which the chromium content is at

least 10.5%, carbon content is at least 1.2%.

2.1.1

Austenitic grade stainless steel

Stainless steel of which the base is with face-centered cubic crystal austenite

structure (gamma phase), antimagnetic. This kind of stainless steel is intensified (may

cause magnetism) through cold-working.

2.1.2

Austenitic-ferritic (duplex) grade stainless steel

Stainless steel of which the base is with austenite and ferrite (one with less phrase is

more than 15%). The stainless steel is with magnetic property and can be intensified

through cold-working.

2.1.3

Ferritic grade stainless steel

Stainless steel of which the base is with space centered cubic lattice iron chain tissue

(alpha phase) and with magnetic property. It cannot be hardened through heat

treatment, but cold-working can lightly intensify it.

2.1.4

Martensitie grade stainless steel

Stainless steel of which the base is the magnetic martensitic structure. Through heat

treatment, mechanical property can be adjusted.

2.1.5

Precipitation hardening grade stainless steel

Stainless steel of which the base is austenite or martensitic structure. it can be

hardened through precipitation hardening (age hardening).

2.2

Heat-resisting steel

Steel with good chemical stability or higher strength at high temperature.

3 General rules for identifying chemical constitution

limits

3.1 Carbon

If carbon content is greater than or equal to 0.04%, it is recommended to take two

digits; if carbon content is not greater than 0.030%, it is recommended to take 3 digits.

3.2 Manganese

Apart from Cr-Ni-Mn, it is recommended to use 2.00% and 1.00% (maximum value),

but it does not include automatic steel containing high sulphur or selenium or steel

that need to raise nitrogen solid solubility.

3.3 Phosphor

Unless related producer recommend using lower limit due to technical reasons, it is

recommended to be with at minimum 0.045% phosphor for austenitic steel. Phosphor

content for other kind of steel shall not be greater than 0.040%, but is does not include

automatic steel.

3.4 Sulfur

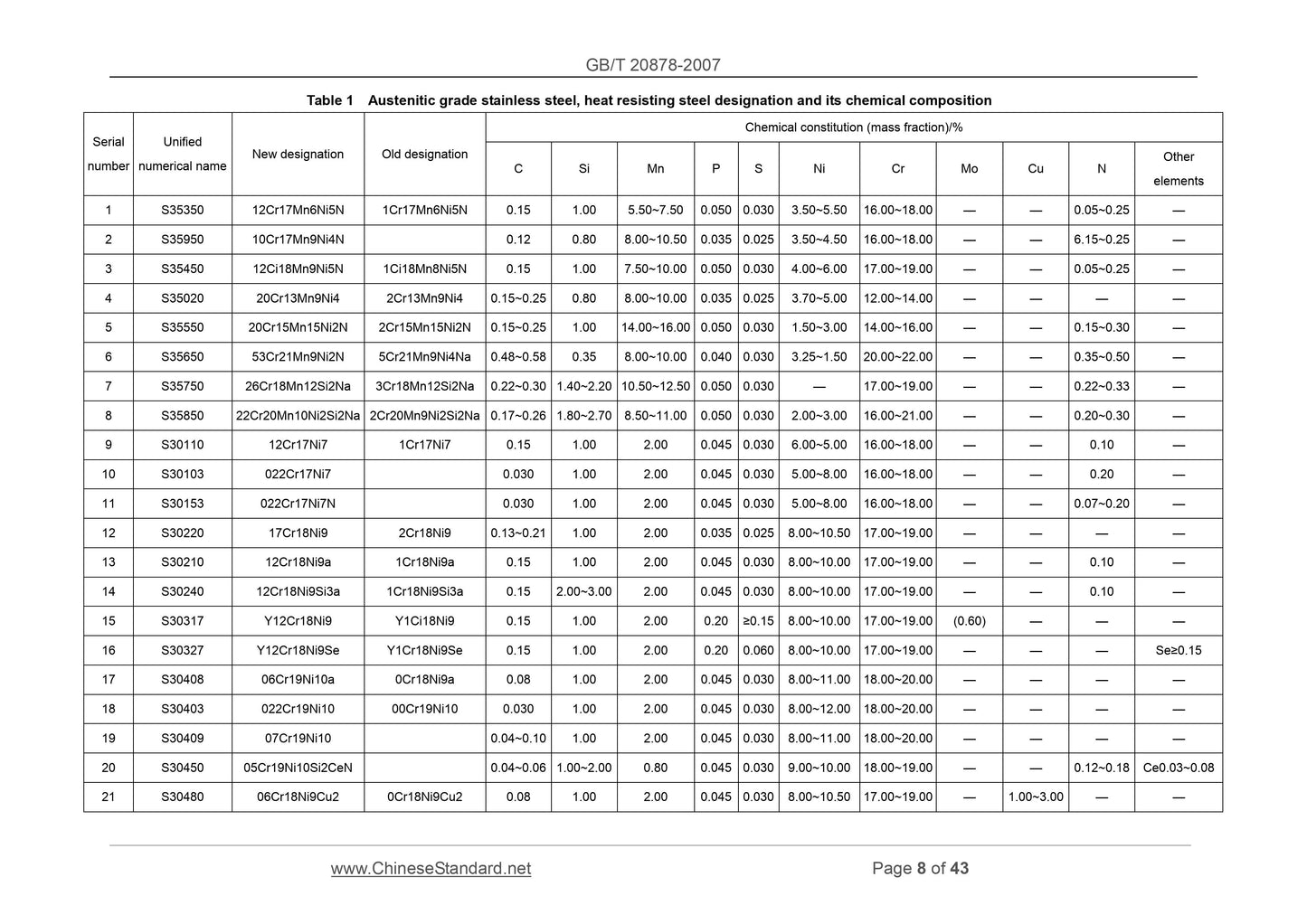

Table 1 Austenitic grade stainless steel, heat resisting steel designation and its chemical composition

Serial

number

Unified

numerical name New designation Old designation

Chemical constitution (mass fraction)/%

C Si Mn P S Ni Cr Mo Cu N Other elements

1 S35350 12Cr17Mn6Ni5N 1Cr17Mn6Ni5N 0.15 1.00 5.50~7.50 0.050 0.030 3.50~5.50 16.00~18.00 — — 0.05~0.25 —

2 S35950 10Cr17Mn9Ni4N 0.12 0.80 8.00~10.50 0.035 0.025 3.50~4.50 16.00~18.00 — — 6.15~0.25 —

3 S35450 12Ci18Mn9Ni5N 1Ci18Mn8Ni5N 0.15 1.00 7.50~10.00 0.050 0.030 4.00~6.00 17.00~19.00 — — 0.05~0.25 —

4 S35020 20Cr13Mn9Ni4 2Cr13Mn9Ni4 0.15~0.25 0.80 8.00~10.00 0.035 0.025 3.70~5.00 12.00~14.00 — — — —

5 S35550 20Cr15Mn15Ni2N 2Cr15Mn15Ni2N 0.15~0.25 1.00 14.00~16.00 0.050 0.030 1.50~3.00 14.00~16.00 — — 0.15~0.30 —

6 S35650 53Cr21Mn9Ni2N 5Cr21Mn9Ni4Na 0.48~0.58 0.35 8.00~10.00 0.040 0.030 3.25~1.50 20.00~22.00 — — 0.35~0.50 —

7 S35750 26Cr18Mn12Si2Na 3Cr18Mn12Si2Na 0.22~0.30 1.40~2.20 10.50~12.50 0.050 0.030 — 17.00~19.00 — — 0.22~0.33 —

8 S35850 22Cr20Mn10Ni2Si2Na 2Cr20Mn9Ni2Si2Na 0.17~0.26 1.80~2.70 8.50~11.00 0.050 0.030 2.00~3.00 16.00~21.00 — — 0.20~0.30 —

9 S30110 12Cr17Ni7 1Cr17Ni7 0.15 1.00 2.00 0.045 0.030 6.00~5.00 16.00~18.00 — — 0.10 —

10 S30103 022Cr17Ni7 0.030 1.00 2.00 0.045 0.030 5.00~8.00 16.00~18.00 — — 0.20 —

11 S30153 022Cr17Ni7N 0.030 1.00 2.00 0.045 0.030 5.00~8.00 16.00~18.00 — — 0.07~0.20 —

12 S30220 17Cr18Ni9 2Cr18Ni9 0.13~0.21 1.00 2.00 0.035 0.025 8.00~10.50 17.00~19.00 — — — —

13 S30210 12Cr18Ni9a 1Cr18Ni9a 0.15 1.00 2.00 0.045 0.030 8.00~10.00 17.00~19.00 — — 0.10 —

14 S30240 12Cr18Ni9Si3a 1Cr18Ni9Si3a 0.15 2.00~3.00 2.00 0.045 0.030 8.00~10.00 17.00~19.00 — — 0.10 —

15 S30317 Y12Cr18Ni9 Y1Ci18Ni9 0.15 1.00 2.00 0.20 ≥0.15 8.00~10.00 17.00~19.00 (0.60) — — —

16 S30327 Y12Cr18Ni9Se Y1Cr18Ni9Se 0.15 1.00 2.00 0.20 0.060 8.00~10.00 17.00~19.00 — — — Se≥0.15

17 S30408 06Cr19Ni10a 0Cr18Ni9a 0.08 1.00 2.00 0.045 0.030 8.00~11.00 18.00~20.00 — — — —

18 S30403 022Cr19Ni10 00Cr19Ni10 0.030 1.00 2.00 0.045 0.030 8.00~12.00 18.00~20.00 — — — —

19 S30409 07Cr19Ni10 0.04~0.10 1.00 2.00 0.045 0.030 8.00~11.00 18.00~20.00 — — — —

20 S30450 05Cr19Ni10Si2CeN 0.04~0.06 1.00~2.00 0.80 0.045 0.030 9.00~10.00 18.00~19.00 — — 0.12~0.18 Ce0.03~0.08

21 S30480 06Cr18Ni9Cu2 0Cr18Ni9Cu2 0.08 1.00 2.00 0.045 0.030 8.00~10.50 17.00~19.00 — 1.00~3.00 — —

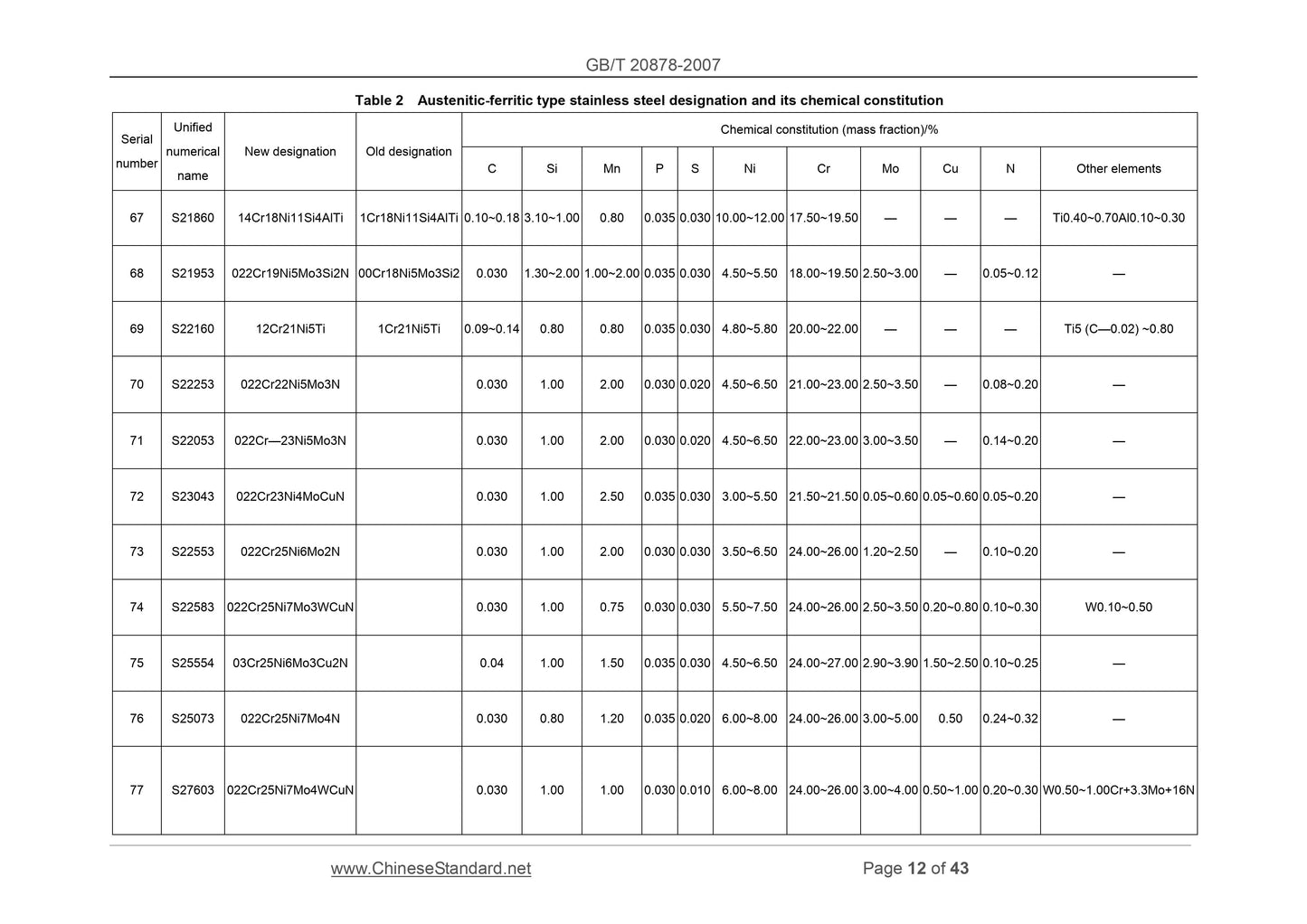

Table 2 Austenitic-ferritic type stainless steel designation and its chemical constitution

Serial

number

Unified

numerical

name

New designation Old designation

Chemical constitution (mass fraction)/%

C Si Mn P S Ni Cr Mo Cu N Other elements

67 S21860 14Cr18Ni11Si4AlTi 1Cr18Ni11Si4AlTi 0.10~0.18 3.10~1.00 0.80 0.035 0.030 10.00~12.00 17.50~19.50 — — — Ti0.40~0.70Al0.10~0.30

68 S21953 022Cr19Ni5Mo3Si2N 00Cr18Ni5Mo3Si2 0.030 1.30~2.00 1.00~2.00 0.03...

Get QUOTATION in 1-minute: Click GB/T 20878-2007

Historical versions: GB/T 20878-2007

Preview True-PDF (Reload/Scroll if blank)

GB/T 20878-2007: Stainless and heat-resisting steels -- Designation and chemical composition

GB/T 20878-2007

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.20

H40

Replacing GB/T 4229-1984

Stainless and heat-resisting steels –

Designation and chemical composition

ISSUED ON. MARCH 9, 2007

IMPLEMENTED ON. OCTOBER 1, 2007

Issued by. General Administration of Quality Supervision, Inspection;

Quarantine of the People's Republic of China (GAQSIQ);

Standardization Administration of China (SAC).

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Terms and definitions ... 4

3 General rules for identifying chemical constitution limits ... 5

4 Chemical composition and application of stainless steel and heat resisting steel ... 7

Annex A ... 21

Annex B ... 27

Annex C ... 34

References ... 42

Foreword

Chemical constitution limit and designation time specified in this Standard is

applicable to formulate and revise product standard for stainless steel and refractory

steel (including steel ingot and half-finished product).

This Standard needs to be used with other technical standards; it can not be used for

ordering.

This Standard replaces GB/T 4229-1984 “Methods of weight calculation of stainless

steel plates and sheets" since the date of implementation.

Annex A, Annex B and Annex C of this Standard are informative.

This Standard was proposed by China Iron and Steel Association.

This Standard shall be under the jurisdiction of national steel standardization technical

committee.

Drafting organization of this Standard. China Metallurgical Information Standardization

Research Institute.

Main Drafters of this Standard. Luan Yan, Dai Qiang and Liu Baoshi.

Stainless and heat-resisting steels –

Designation and chemical composition

1 Scope

This Standard specifies the designation and its chemical constitution of stainless steel

and heat resisting steel (see Table 1 ~ Table 5). Physical parameter of some

designations, overseas standards designation or approximate designation parallel

table, stainless steel and heat resisting steel designation criterion of acceptability are

specified in the Informative Annex.

Chemical constitution limit and its designation time specified in this Standard are

applicable to formulating and revising the product standard for stainless steel and its

refractory steel (including steel ingot and its half-finished product).

2 Terms and definitions

The following terms and definitions are applicable to this Standard.

2.1

Stainless steel

Steel that does not rust and corrosion-resistant, of which the chromium content is at

least 10.5%, carbon content is at least 1.2%.

2.1.1

Austenitic grade stainless steel

Stainless steel of which the base is with face-centered cubic crystal austenite

structure (gamma phase), antimagnetic. This kind of stainless steel is intensified (may

cause magnetism) through cold-working.

2.1.2

Austenitic-ferritic (duplex) grade stainless steel

Stainless steel of which the base is with austenite and ferrite (one with less phrase is

more than 15%). The stainless steel is with magnetic property and can be intensified

through cold-working.

2.1.3

Ferritic grade stainless steel

Stainless steel of which the base is with space centered cubic lattice iron chain tissue

(alpha phase) and with magnetic property. It cannot be hardened through heat

treatment, but cold-working can lightly intensify it.

2.1.4

Martensitie grade stainless steel

Stainless steel of which the base is the magnetic martensitic structure. Through heat

treatment, mechanical property can be adjusted.

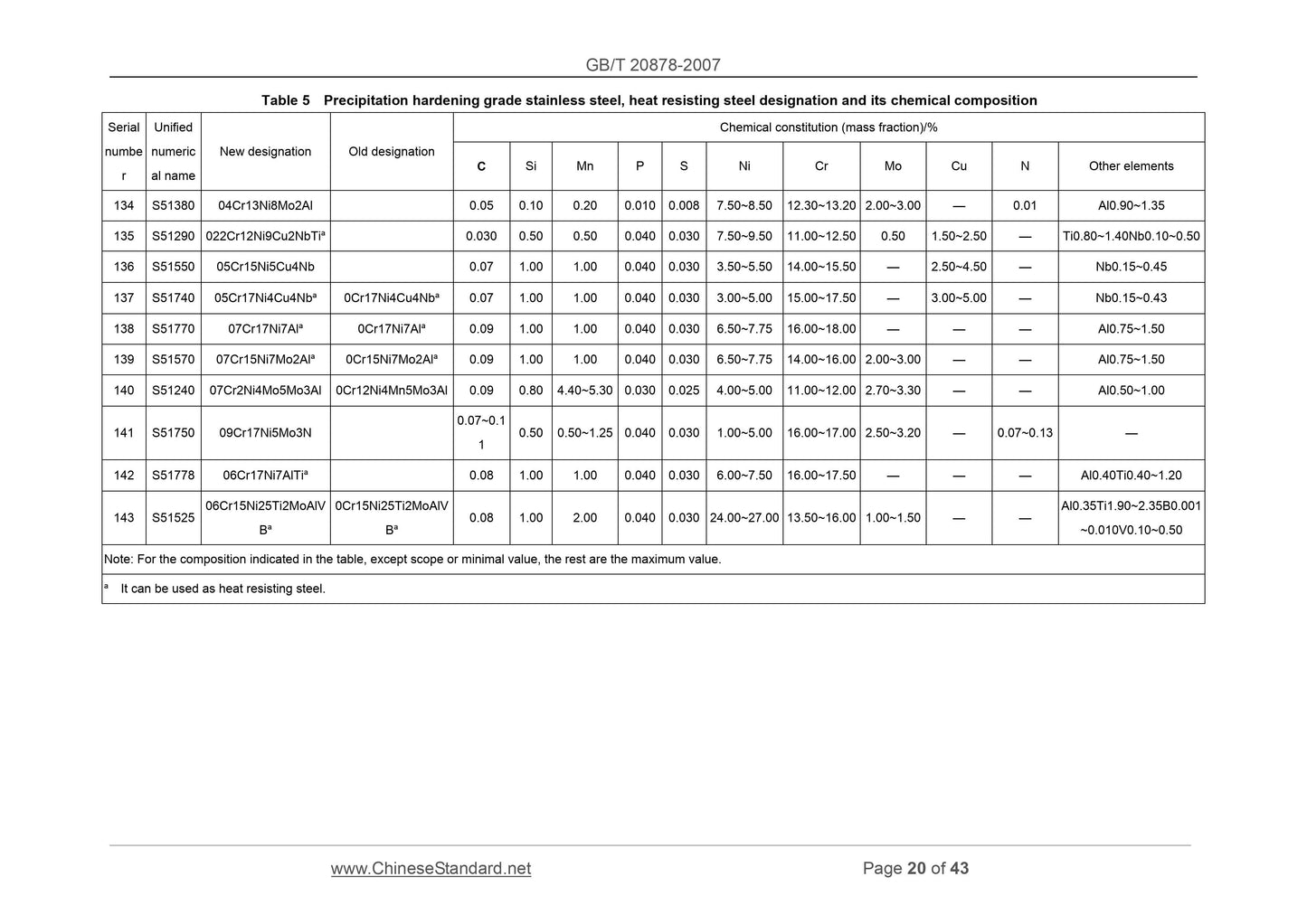

2.1.5

Precipitation hardening grade stainless steel

Stainless steel of which the base is austenite or martensitic structure. it can be

hardened through precipitation hardening (age hardening).

2.2

Heat-resisting steel

Steel with good chemical stability or higher strength at high temperature.

3 General rules for identifying chemical constitution

limits

3.1 Carbon

If carbon content is greater than or equal to 0.04%, it is recommended to take two

digits; if carbon content is not greater than 0.030%, it is recommended to take 3 digits.

3.2 Manganese

Apart from Cr-Ni-Mn, it is recommended to use 2.00% and 1.00% (maximum value),

but it does not include automatic steel containing high sulphur or selenium or steel

that need to raise nitrogen solid solubility.

3.3 Phosphor

Unless related producer recommend using lower limit due to technical reasons, it is

recommended to be with at minimum 0.045% phosphor for austenitic steel. Phosphor

content for other kind of steel shall not be greater than 0.040%, but is does not include

automatic steel.

3.4 Sulfur

Table 1 Austenitic grade stainless steel, heat resisting steel designation and its chemical composition

Serial

number

Unified

numerical name New designation Old designation

Chemical constitution (mass fraction)/%

C Si Mn P S Ni Cr Mo Cu N Other elements

1 S35350 12Cr17Mn6Ni5N 1Cr17Mn6Ni5N 0.15 1.00 5.50~7.50 0.050 0.030 3.50~5.50 16.00~18.00 — — 0.05~0.25 —

2 S35950 10Cr17Mn9Ni4N 0.12 0.80 8.00~10.50 0.035 0.025 3.50~4.50 16.00~18.00 — — 6.15~0.25 —

3 S35450 12Ci18Mn9Ni5N 1Ci18Mn8Ni5N 0.15 1.00 7.50~10.00 0.050 0.030 4.00~6.00 17.00~19.00 — — 0.05~0.25 —

4 S35020 20Cr13Mn9Ni4 2Cr13Mn9Ni4 0.15~0.25 0.80 8.00~10.00 0.035 0.025 3.70~5.00 12.00~14.00 — — — —

5 S35550 20Cr15Mn15Ni2N 2Cr15Mn15Ni2N 0.15~0.25 1.00 14.00~16.00 0.050 0.030 1.50~3.00 14.00~16.00 — — 0.15~0.30 —

6 S35650 53Cr21Mn9Ni2N 5Cr21Mn9Ni4Na 0.48~0.58 0.35 8.00~10.00 0.040 0.030 3.25~1.50 20.00~22.00 — — 0.35~0.50 —

7 S35750 26Cr18Mn12Si2Na 3Cr18Mn12Si2Na 0.22~0.30 1.40~2.20 10.50~12.50 0.050 0.030 — 17.00~19.00 — — 0.22~0.33 —

8 S35850 22Cr20Mn10Ni2Si2Na 2Cr20Mn9Ni2Si2Na 0.17~0.26 1.80~2.70 8.50~11.00 0.050 0.030 2.00~3.00 16.00~21.00 — — 0.20~0.30 —

9 S30110 12Cr17Ni7 1Cr17Ni7 0.15 1.00 2.00 0.045 0.030 6.00~5.00 16.00~18.00 — — 0.10 —

10 S30103 022Cr17Ni7 0.030 1.00 2.00 0.045 0.030 5.00~8.00 16.00~18.00 — — 0.20 —

11 S30153 022Cr17Ni7N 0.030 1.00 2.00 0.045 0.030 5.00~8.00 16.00~18.00 — — 0.07~0.20 —

12 S30220 17Cr18Ni9 2Cr18Ni9 0.13~0.21 1.00 2.00 0.035 0.025 8.00~10.50 17.00~19.00 — — — —

13 S30210 12Cr18Ni9a 1Cr18Ni9a 0.15 1.00 2.00 0.045 0.030 8.00~10.00 17.00~19.00 — — 0.10 —

14 S30240 12Cr18Ni9Si3a 1Cr18Ni9Si3a 0.15 2.00~3.00 2.00 0.045 0.030 8.00~10.00 17.00~19.00 — — 0.10 —

15 S30317 Y12Cr18Ni9 Y1Ci18Ni9 0.15 1.00 2.00 0.20 ≥0.15 8.00~10.00 17.00~19.00 (0.60) — — —

16 S30327 Y12Cr18Ni9Se Y1Cr18Ni9Se 0.15 1.00 2.00 0.20 0.060 8.00~10.00 17.00~19.00 — — — Se≥0.15

17 S30408 06Cr19Ni10a 0Cr18Ni9a 0.08 1.00 2.00 0.045 0.030 8.00~11.00 18.00~20.00 — — — —

18 S30403 022Cr19Ni10 00Cr19Ni10 0.030 1.00 2.00 0.045 0.030 8.00~12.00 18.00~20.00 — — — —

19 S30409 07Cr19Ni10 0.04~0.10 1.00 2.00 0.045 0.030 8.00~11.00 18.00~20.00 — — — —

20 S30450 05Cr19Ni10Si2CeN 0.04~0.06 1.00~2.00 0.80 0.045 0.030 9.00~10.00 18.00~19.00 — — 0.12~0.18 Ce0.03~0.08

21 S30480 06Cr18Ni9Cu2 0Cr18Ni9Cu2 0.08 1.00 2.00 0.045 0.030 8.00~10.50 17.00~19.00 — 1.00~3.00 — —

Table 2 Austenitic-ferritic type stainless steel designation and its chemical constitution

Serial

number

Unified

numerical

name

New designation Old designation

Chemical constitution (mass fraction)/%

C Si Mn P S Ni Cr Mo Cu N Other elements

67 S21860 14Cr18Ni11Si4AlTi 1Cr18Ni11Si4AlTi 0.10~0.18 3.10~1.00 0.80 0.035 0.030 10.00~12.00 17.50~19.50 — — — Ti0.40~0.70Al0.10~0.30

68 S21953 022Cr19Ni5Mo3Si2N 00Cr18Ni5Mo3Si2 0.030 1.30~2.00 1.00~2.00 0.03...

Share