1

/

of

8

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 20882.2-2021 English PDF (GBT20882.2-2021)

GB/T 20882.2-2021 English PDF (GBT20882.2-2021)

Regular price

$230.00 USD

Regular price

Sale price

$230.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 20882.2-2021

Historical versions: GB/T 20882.2-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 20882.2-2021: Quality requirements for starch sugar -- Part 2: Glucose syrup and glucose syrup powder

GB/T 20882.2-2021

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 67.180.20

CCS X 31

Replacing GB/T 20885-2007

Quality requirements for starch sugar - Part 2: Glucose

syrup and glucose syrup powder

ISSUED ON: DECEMBER 31, 2021

IMPLEMENTED ON: JULY 01, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions... 6

4 Product classification ... 7

5 Requirements ... 7

6 Test methods ... 8

7 Inspection rules ... 14

8 Marking, packaging, transportation and storage ... 16

Appendix A (Informative) Determination of sugar boiling temperature ... 18

Quality requirements for starch sugar - Part 2: Glucose

syrup and glucose syrup powder

1 Scope

This document specifies the quality requirements for glucose syrup and glucose syrup

powder, including terms and definitions, product classification, requirements, test

methods, inspection rules, marking, packaging, transportation and storage.

This document applies to the production, inspection and sales of glucose syrup and

glucose syrup powder.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this

document and are indispensable for its application. For dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 191, Packaging - Pictorial marking for handling of goods

GB/T 601, Chemical reagent - Preparations of reference titration solutions

GB/T 602, Chemical reagent - Preparations of standard solutions for impurity

GB/T 603, Chemical reagent - Preparations of reagent solutions for use in test

methods

GB 5009.3-2016, National Food Safety Standard - Determination of Moisture

Content in Foods

GB/T 6682, Water for analytical laboratory use - Specification and test methods

3 Terms and definitions

The following terms and definitions are applicable to this document.

3.1

glucose syrup

Weigh 1.5 g (accurate to 0.000 1 g) of standard or high-purity (99.5% pure) anhydrous

dextrose which has been dried to constant weight at 105 °C ± 2 °C; dissolve in water,

and dilute to 250 mL; shake well and set aside. This solution shall be prepared on the

day of use.

6.3.1.3 Fehling's reagent

6.3.1.3.1 Fehling’s solution I: Weigh 34.7 g of copper sulfate pentahydrate

(CuSO4·5H2O); add water to dissolve and dilute to 500 mL; shake well.

6.3.1.3.2 Fehling's solution II: Weigh 173.0 g of potassium sodium tartrate tetrahydrate

(C4H4KNaO6·4H2O) and 50.0 g of sodium hydroxide (NaOH); add water to dissolve

and dilute to 500 mL; shake well.

6.3.1.3.3 Mixed Fehling's solution: Pour 100 mL Fehling's solution I and 100 mL

Fehling's solution II into a dry reagent bottle; mix them evenly.

Note: This solution is prepared for immediate use.

6.3.1.3.4 Calibration: During pre-titration, pipette 25 mL of mixed Fehling’s solution

into a conical flask; add 10 mL of water; add three glass beads; use a 25 mL burette to

add 18 mL of glucose standard solution in advance; shake well; place it on an electric

furnace that is covered with asbestos mesh to heat; control the liquid in the bottle to

boil within 120 s ± 15 s and keep it slightly boiled for 2 min; add two drops of methylene

blue indicator solution; add standard glucose solution drop by drop from the burette

(one drop for about 2 s is appropriate) until the blue color just fades as the end point.

The entire titration operation shall be completed within 1 min. In the formal titration,

add standard glucose solution which is 0.5 mL less than the pre-titration in advance,

where the operation is the same as the pre-titration. Add the standard glucose solution

drop by drop until the blue color just disappears. The entire titration operation shall be

completed within 1 min. At the same time, perform a parallel experiment, and record

the total volume of consumed glucose solution (whichever is the arithmetic mean).

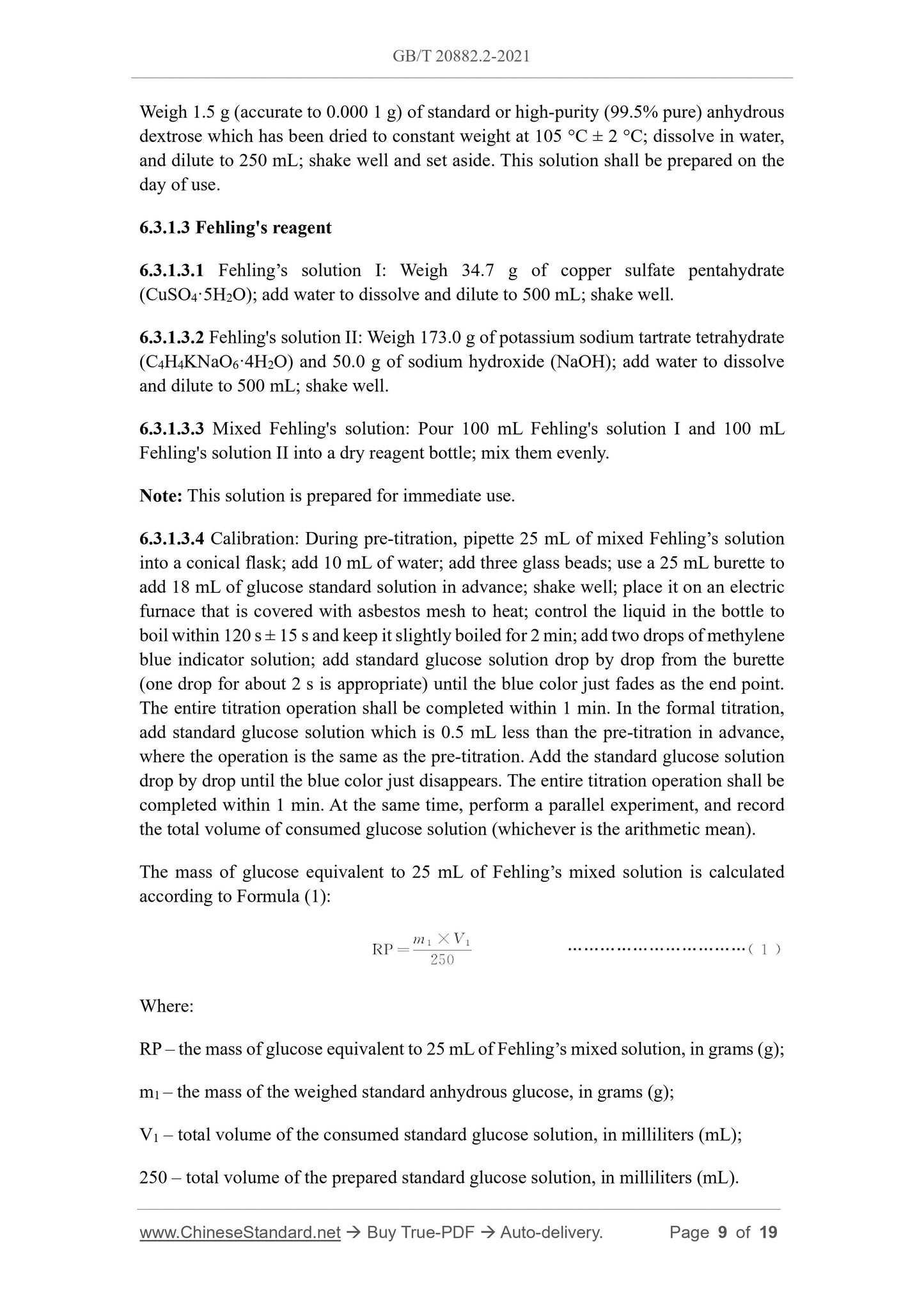

The mass of glucose equivalent to 25 mL of Fehling’s mixed solution is calculated

according to Formula (1):

Where:

RP – the mass of glucose equivalent to 25 mL of Fehling’s mixed solution, in grams (g);

m1 – the mass of the weighed standard anhydrous glucose, in grams (g);

V1 – total volume of the consumed standard glucose solution, in milliliters (mL);

250 – total volume of the prepared standard glucose solution, in milliliters (mL).

The absolute difference between two independent determination results which are

obtained under repeatability conditions shall not exceed 1% of its arithmetic mean.

6.5 Moisture

Measure according to Method I of GB 5009.3-2016, "Direct drying method", in which

the drying temperature is set to 105 °C ± 2 °C.

6.6 pH

6.6.1 Instruments and apparatuses

Acidity meter: The accuracy is 0.01 pH; it is equipped with glass electrode and calomel

electrode (or composite electrode).

6.6.2 Analysis steps

6.6.2.1 Determination method

Adjust and calibrate the pH meter according to the instrument instruction manual.

Weigh an appropriate amount of sample; use freshly boiled and cooled (carbon dioxide

removed) water whose pH is 5.0 ~ 7.0 to prepare a glucose syrup with a dry matter of

30%. Then, use water to rinse the electrode probe; use a filter paper to dry it gently;

insert the electrode into the sample solution to be tested; turn on the electromagnetic

stirrer; adjust the temperature regulator so that the indicated temperature of the

instrument is the same as the solution temperature; read after it is stable.

6.6.2.2 Result expression

Express the calculation result to one decimal place.

6.6.3 Precision

The absolute difference between two independent determination results which are

obtained under repeatability conditions shall not exceed 3% of its arithmetic mean.

6.7 Light transmittance

6.7.1 Instruments and apparatuses

Spectrophotometry.

6.7.2 Analysis steps

6.7.2.1 Determination method

According to the instrument manual, adjust the zero point and light transmittance of the

instrument at a wavelength of 440 nm. Weigh an appropriate amount of sample; use

carbon dioxide removed water whose pH is 5.0 ~ 7.0 to prepare a glucose syrup with a

dry matter of 30%. Then, inject the to-be-tested solution into a 1 cm cuvette; use a

spectrophotometer, at a wavelength of 440 nm, to measure the light transmittance of the

sample solution with the same batch of water as a reference.

6.7.2.2 Result expression

Express the calculation result to one decimal place.

6.7.3 Precision

The absolute difference between two independent determination results which are

obtained under repeatability conditions shall not exceed 1% of its arithmetic mean.

6.8 Sulfated ash

6.8.1 Reagents

6.8.1.1 Hydrochloric acid.

6.8.1.2 Concentrated sulfuric acid.

6.8.2 Instruments and apparatuses

6.8.2.1 Porcelain crucible: 50 mL.

6.8.2.2 High-temperature furnace: The temperature control range is 525 °C ± 25 °C.

6.8.2.3 Dryer: Use silica gel as desiccant.

6.8.2.4 Analytical balance: The accuracy is 0.01 mg.

6.8.3 Analysis steps

6.8.3.1 First, use hydrochloric acid to heat and boil the crucible; then, use running water

to wash it; then, use distilled water to clean it. Place the cleaned crucible in a high- ...

Get QUOTATION in 1-minute: Click GB/T 20882.2-2021

Historical versions: GB/T 20882.2-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 20882.2-2021: Quality requirements for starch sugar -- Part 2: Glucose syrup and glucose syrup powder

GB/T 20882.2-2021

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 67.180.20

CCS X 31

Replacing GB/T 20885-2007

Quality requirements for starch sugar - Part 2: Glucose

syrup and glucose syrup powder

ISSUED ON: DECEMBER 31, 2021

IMPLEMENTED ON: JULY 01, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions... 6

4 Product classification ... 7

5 Requirements ... 7

6 Test methods ... 8

7 Inspection rules ... 14

8 Marking, packaging, transportation and storage ... 16

Appendix A (Informative) Determination of sugar boiling temperature ... 18

Quality requirements for starch sugar - Part 2: Glucose

syrup and glucose syrup powder

1 Scope

This document specifies the quality requirements for glucose syrup and glucose syrup

powder, including terms and definitions, product classification, requirements, test

methods, inspection rules, marking, packaging, transportation and storage.

This document applies to the production, inspection and sales of glucose syrup and

glucose syrup powder.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this

document and are indispensable for its application. For dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 191, Packaging - Pictorial marking for handling of goods

GB/T 601, Chemical reagent - Preparations of reference titration solutions

GB/T 602, Chemical reagent - Preparations of standard solutions for impurity

GB/T 603, Chemical reagent - Preparations of reagent solutions for use in test

methods

GB 5009.3-2016, National Food Safety Standard - Determination of Moisture

Content in Foods

GB/T 6682, Water for analytical laboratory use - Specification and test methods

3 Terms and definitions

The following terms and definitions are applicable to this document.

3.1

glucose syrup

Weigh 1.5 g (accurate to 0.000 1 g) of standard or high-purity (99.5% pure) anhydrous

dextrose which has been dried to constant weight at 105 °C ± 2 °C; dissolve in water,

and dilute to 250 mL; shake well and set aside. This solution shall be prepared on the

day of use.

6.3.1.3 Fehling's reagent

6.3.1.3.1 Fehling’s solution I: Weigh 34.7 g of copper sulfate pentahydrate

(CuSO4·5H2O); add water to dissolve and dilute to 500 mL; shake well.

6.3.1.3.2 Fehling's solution II: Weigh 173.0 g of potassium sodium tartrate tetrahydrate

(C4H4KNaO6·4H2O) and 50.0 g of sodium hydroxide (NaOH); add water to dissolve

and dilute to 500 mL; shake well.

6.3.1.3.3 Mixed Fehling's solution: Pour 100 mL Fehling's solution I and 100 mL

Fehling's solution II into a dry reagent bottle; mix them evenly.

Note: This solution is prepared for immediate use.

6.3.1.3.4 Calibration: During pre-titration, pipette 25 mL of mixed Fehling’s solution

into a conical flask; add 10 mL of water; add three glass beads; use a 25 mL burette to

add 18 mL of glucose standard solution in advance; shake well; place it on an electric

furnace that is covered with asbestos mesh to heat; control the liquid in the bottle to

boil within 120 s ± 15 s and keep it slightly boiled for 2 min; add two drops of methylene

blue indicator solution; add standard glucose solution drop by drop from the burette

(one drop for about 2 s is appropriate) until the blue color just fades as the end point.

The entire titration operation shall be completed within 1 min. In the formal titration,

add standard glucose solution which is 0.5 mL less than the pre-titration in advance,

where the operation is the same as the pre-titration. Add the standard glucose solution

drop by drop until the blue color just disappears. The entire titration operation shall be

completed within 1 min. At the same time, perform a parallel experiment, and record

the total volume of consumed glucose solution (whichever is the arithmetic mean).

The mass of glucose equivalent to 25 mL of Fehling’s mixed solution is calculated

according to Formula (1):

Where:

RP – the mass of glucose equivalent to 25 mL of Fehling’s mixed solution, in grams (g);

m1 – the mass of the weighed standard anhydrous glucose, in grams (g);

V1 – total volume of the consumed standard glucose solution, in milliliters (mL);

250 – total volume of the prepared standard glucose solution, in milliliters (mL).

The absolute difference between two independent determination results which are

obtained under repeatability conditions shall not exceed 1% of its arithmetic mean.

6.5 Moisture

Measure according to Method I of GB 5009.3-2016, "Direct drying method", in which

the drying temperature is set to 105 °C ± 2 °C.

6.6 pH

6.6.1 Instruments and apparatuses

Acidity meter: The accuracy is 0.01 pH; it is equipped with glass electrode and calomel

electrode (or composite electrode).

6.6.2 Analysis steps

6.6.2.1 Determination method

Adjust and calibrate the pH meter according to the instrument instruction manual.

Weigh an appropriate amount of sample; use freshly boiled and cooled (carbon dioxide

removed) water whose pH is 5.0 ~ 7.0 to prepare a glucose syrup with a dry matter of

30%. Then, use water to rinse the electrode probe; use a filter paper to dry it gently;

insert the electrode into the sample solution to be tested; turn on the electromagnetic

stirrer; adjust the temperature regulator so that the indicated temperature of the

instrument is the same as the solution temperature; read after it is stable.

6.6.2.2 Result expression

Express the calculation result to one decimal place.

6.6.3 Precision

The absolute difference between two independent determination results which are

obtained under repeatability conditions shall not exceed 3% of its arithmetic mean.

6.7 Light transmittance

6.7.1 Instruments and apparatuses

Spectrophotometry.

6.7.2 Analysis steps

6.7.2.1 Determination method

According to the instrument manual, adjust the zero point and light transmittance of the

instrument at a wavelength of 440 nm. Weigh an appropriate amount of sample; use

carbon dioxide removed water whose pH is 5.0 ~ 7.0 to prepare a glucose syrup with a

dry matter of 30%. Then, inject the to-be-tested solution into a 1 cm cuvette; use a

spectrophotometer, at a wavelength of 440 nm, to measure the light transmittance of the

sample solution with the same batch of water as a reference.

6.7.2.2 Result expression

Express the calculation result to one decimal place.

6.7.3 Precision

The absolute difference between two independent determination results which are

obtained under repeatability conditions shall not exceed 1% of its arithmetic mean.

6.8 Sulfated ash

6.8.1 Reagents

6.8.1.1 Hydrochloric acid.

6.8.1.2 Concentrated sulfuric acid.

6.8.2 Instruments and apparatuses

6.8.2.1 Porcelain crucible: 50 mL.

6.8.2.2 High-temperature furnace: The temperature control range is 525 °C ± 25 °C.

6.8.2.3 Dryer: Use silica gel as desiccant.

6.8.2.4 Analytical balance: The accuracy is 0.01 mg.

6.8.3 Analysis steps

6.8.3.1 First, use hydrochloric acid to heat and boil the crucible; then, use running water

to wash it; then, use distilled water to clean it. Place the cleaned crucible in a high- ...

Share