1

/

of

11

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 20948-2007 English PDF (GB/T20948-2007)

GB/T 20948-2007 English PDF (GB/T20948-2007)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 20948-2007: Rear-view mirrors requirements for agricultural and forestry tractors

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 20948-2007 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 20948-2007

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 20948-2007

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 65.060.10

T 68

Rear-view mirrors requirements for

agricultural and forestry tractors

ISSUED ON: JUNE 25, 2007

IMPLEMENTED ON: NOVEMBER 1, 2007

Issued by: General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms ... 4

4 Performance requirements ... 7

5 Installation requirements ... 11

6 Measurement and devices and test methods ... 12

7 Inspection rules ... 24

8 Marking, packaging, transportation and storage ... 26

Appendix A (Normative) Spectral tristimulus values of the CIE standard

colorimetric observer ... 28

Rear-view mirrors requirements for

agricultural and forestry tractors

1 Scope

This Standard specifies the definitions, performance requirements,

installation requirements, test methods, inspection rules and marking,

packaging, transportation and storage of rear-view mirrors for agricultural and

forestry wheeled and crawler tractors.

This Standard applies to the agricultural and forestry wheeled and crawler

tractors.

2 Normative references

The provisions in the following documents become the provisions of this

Standard through reference in this Standard. For dated references, the

subsequent amendments (excluding corrections) or revisions do not apply to

this Standard. However, parties who reach an agreement based on this

Standard are encouraged to study if the latest editions of these documents

are applicable. For undated references, the latest editions apply to this

Standard.

QC/T 625-1999 Metallic coatings and conversion coatings for automobile

QC/T 484-1999 Automobile paint coatings

ISO 5353:1995 Earth-moving machinery, and tractors and machinery for

agriculture and forestry - Seat index point

3 Terms

The following terms and definitions are applicable to this Standard.

3.1 Rear-view mirror

A device that is able to see the rear and side images of the tractor within the

vision specified in 3.10.

3.2 Interior rear-view mirror

A device that meets the vision defined in 3.1 and is mounted in the tractor

cab.

3.3 Exterior rear-view mirror

A device that meets the vision defined in 3.1 and is mounted on the outer

surface of the tractor.

3.4 Class of rear-view mirror

Various rear-view mirrors with one or more common features or functions.

Class I is an interior rear-view mirror; and Class II is an exterior rear-view

mirror.

3.5 Center of the mirror

The center of mass of the visible area on the reflecting surface.

3.6 Principal radius of curvature at one point obtained on the

reflecting surface (ri, ri’)

The radius of curvature measured by the instrument specified in 6.3.1 through

the center of the reflecting surface, parallel to the line segment b of the mirror

and perpendicular to the direction of the line. See 4.3.1.2 for the

determination of line segment b.

3.7 Radius of curvature at one point on the reflecting surface (rpi)

Refer to the arithmetic mean value of the principal radius of curvature:

Where:

rpi - Radius of curvature at the ith point, in millimeters (mm);

ri, ri’ - Principal radius of curvature measured in two mutually perpendicular

directions at the ith point, in millimeters (mm).

3.8 Radius of curvature of the constituent parts of the rear-view mirror

(C)

C refers to the radius of the arc of the curved shape of the components such

as protective frame, support frame, and connecting member of the rear-view

mirror.

3.9 Driver’s ocular points

4.1.5 For the edge of the fixed hole or recess with a diameter or a maximum

diagonal of less than 12mm on the rear-view mirror, if it has been rounded,

the requirements for radius of curvature in 4.1.4 are not necessarily met.

4.1.6 The connection of the rear-view mirror to the tractor is designed to

ensure that the rear-view mirror is offset from the axis of rotation or the center

of rotation in the direction of impact, or either of them, to form a cylinder with a

radius of 50mm. The cylinder shall be cut at least to the surface portion to

which the connector is attached.

4.1.7 For exterior rear-view mirrors, if the parts involved in 4.1.3, 4.1.4, and

4.1.5 are made of materials not greater than Shore hardness of A60, it is not

necessary to meet the above requirements.

4.1.8 For interior rear-view mirrors, if the parts on the rear-view mirrors are

made of materials less than Shore hardness of A50 and mounted on a steel

support, the tests of 4.1.3 and 4.1.4 apply only to this support.

4.2 Appearance requirements

4.2.1 Under the illumination condition of 500 lx, when the mirror surface is

viewed from the 45° direction at 500mm from the naked eye, there shall be no

defects such as deformation, blur, streaks, bubbles, scratches, cracks and

inclusions on the rear-view mirror surface.

4.2.2 Rubber parts shall not have obvious defects such as damages and

cracks.

4.2.3 Plastic parts shall not have obvious defects such as fading, cracks,

scratches and deformation.

4.3 Performance requirements

4.3.1 Size requirements

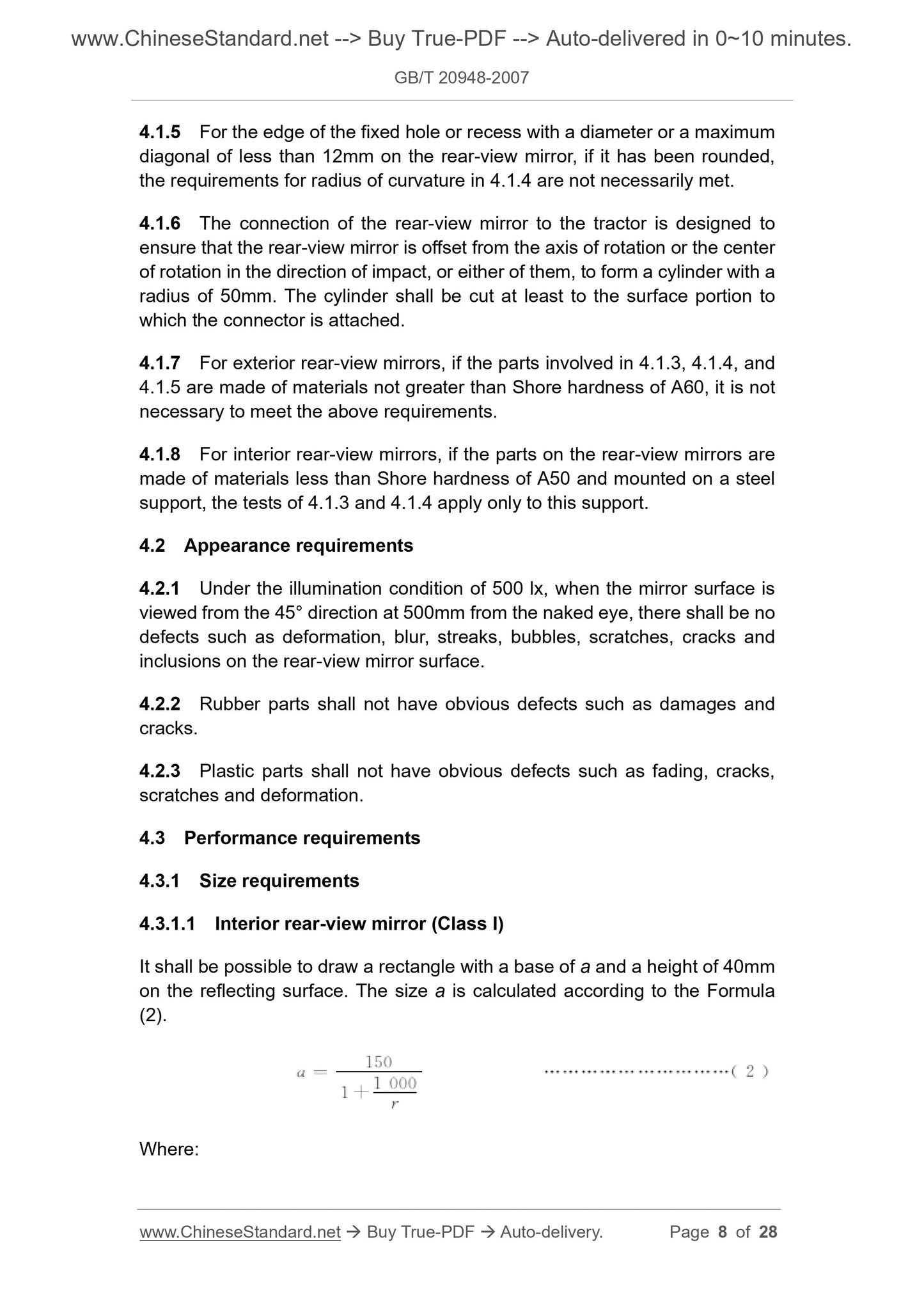

4.3.1.1 Interior rear-view mirror (Class I)

It shall be possible to draw a rectangle with a base of a and a height of 40mm

on the reflecting surface. The size a is calculated according to the Formula

(2).

Where:

4.4.3.2 The difference between rpi (rp1, rp2 and rp3) value and r value of the

radius of curvature at any point shall be no more than 0.15r.

4.5 Reflectance

4.5.1 The reflectance value determined according to the method specified in

6.4 shall be not less than 40%. If the rear-view mirror has two working

positions (daytime and nighttime), the color signal of road traffic shall be

correctly recognized when it is in the daytime position, and the reflectance

value at nighttime position shall be no less than 4%.

4.5.2 Except for long-term rear-view mirrors under extremely harsh weather

conditions, the reflectance shall meet the reflectance values specified in 4.5.1

during normal use.

4.6 Impact resistance and bending resistance

4.6.1 The rear-view mirrors shall be subjected to an anti-impact test in

accordance with 6.5 and subjected to an anti-bending test in accordance with

6.6.

4.6.2 When the rear-view mirror performs the anti-impact test specified in

6.5 and the anti-bending test specified in 6.6, the reflecting surface shall not

be broken, but the following two conditions may be considered as meeting the

requirements:

4.6.2.1 The shards of glass remain attached to the protective casing or to

objects that are firmly attached to the protective casing. The glass is allowed

to partially detach from the above portion, but the length of any side of the

rupture shall not exceed 2.5mm. At the point of impact, small shards are

allowed to detach from the above portion.

4.6.2.2 The reflecting surface is made of safety glass.

4.6.3 For the rear-view mirror attached to the windshield glass, if the

support member of the rear-view mirror is damaged during the impact test,

the residual part of the protruding base shall be no more than 10mm, and the

shape shall still meet the requirements of 4.1.4 and 4.6.2.

4.7 Vibration resistance

When the vibration resistance of the rear-view mirror is tested in accordance

with the provisions of 6.7, each component shall be free from deformation,

damage, or detachment, which may affect its function. The mirror direction

shall be kept in the original normal operation position.

4.8 Moisture resistance

5.2 Position

5.2.1 The position of the exterior rear-view mirror shall be such that the

driver can clearly see the vision defined in 5.4 when sitting in the seat while

driving normally.

5.2.2 The rear-view mirror shall be visible from the part of the windshield

wiper that is not operating, or from the side window of the tractor (if installed).

5.2.3 In the case of the maximum operation mass of the tractor, if the

bottom edge of the rear-view mirror is less than 2m from the ground, the

installation protrusion of the rear-view mirror shall be no more than 0.20m of

the total width of the tractor.

5.3 Adjustment

5.3.1 The interior rear-view mirror shall enable the driver to make

adjustments at the driving position.

5.3.2 The exterior rear-view mirror shall enable the driver’s arm to make

adjustments by extending out of the tractor or outside the window.

5.4 Vision

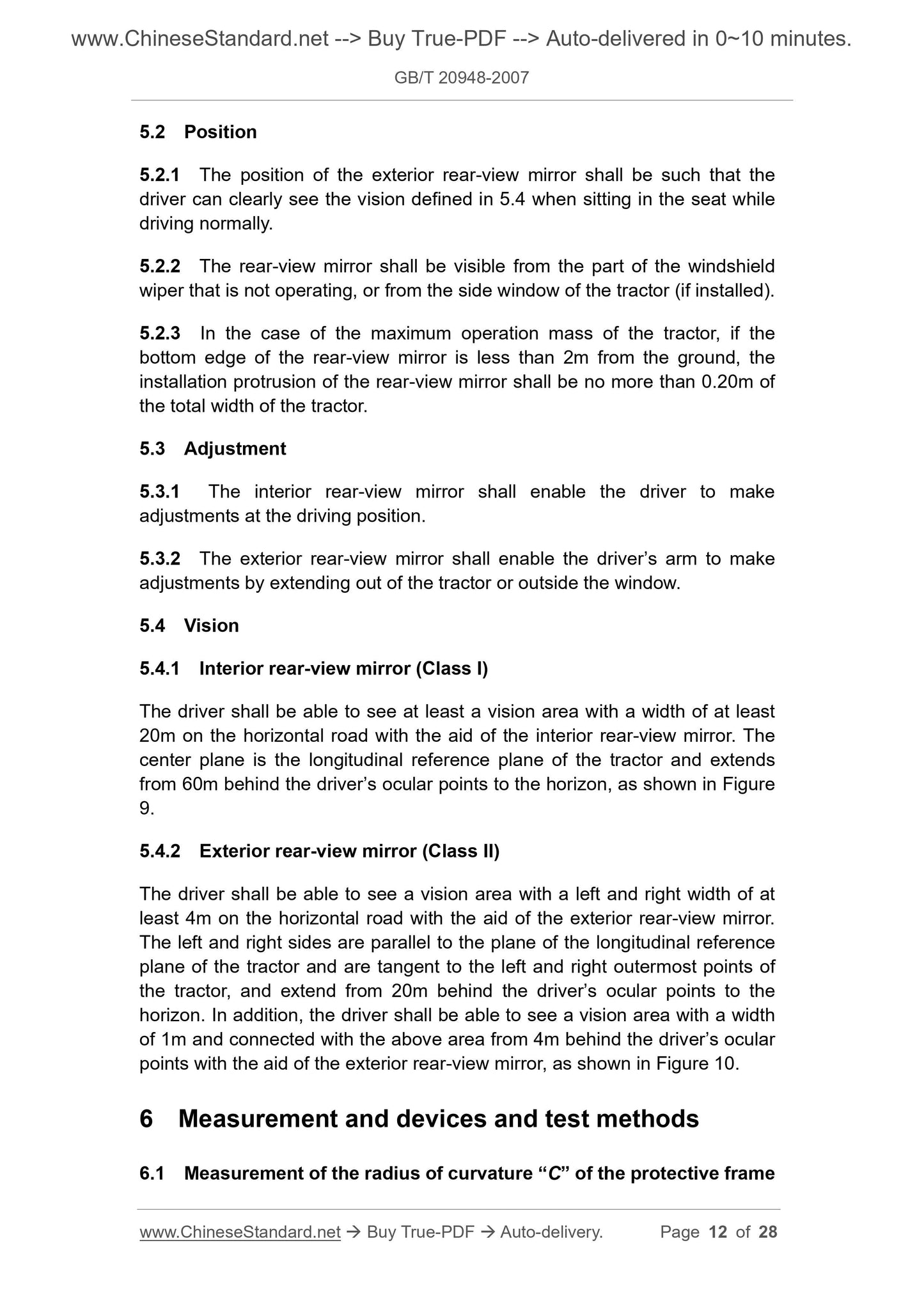

5.4.1 Interior rear-view mirror (Class I)

The driver shall be able to see at least a vision area with a width of at least

20m on the horizontal road with the aid of the interior rear-view mirror. The

center plane is the longitudinal reference plane of the tractor and extends

from 60m behind the driver’s ocular points to the horizon, as shown in Figure

9.

5.4.2 Exterior rear-view mirror (Class II)

The driver shall be able to see a vision area with a left and right width of at

least 4m on the horizontal road with the aid of the exterior rear-view mirror.

The left and right sides are parallel to the plane of the longitudinal reference

plane of the tractor and are tangent to the left and right outermost points of

the tractor, and extend from 20m behind the driver’s ocular points to the

horizon. In addition, the driver shall be able to see a vision area with a width

of 1m and connected with the above area from 4m behind the driver’s ocular

points with the aid of the exterior rear-view mirror, as shown in Figure 10.

6 Measurement and devices and test methods

6.1 Measurement of the radius of curvature “C” of the protective frame

the sum of the regular reflectance and the diffuse reflectance.

6.4.1.3 Spectral characteristics of light sources and photodetectors

a) The light source consists of a CIE standard light source A and a lens that

enables the light from the light source to be a parallel beam. In order to

keep the light source voltage stable while the instrument is operating, a

regulated power supply shall be used.

b) The spectral response of the photodetector carried by the receiving unit is

proportional to the appropriate brightness function of the CIE (1931)

standard colorimetric observer (SEE Appendix A). Other combinations of

illuminator-filter-receiver that produce effects that are fully equivalent to

CIE standard illuminator A and daylight vision may also be used. When an

optical integrating sphere is used in the receiving unit, the inner surface of

the sphere shall be coated with a matt (diffusely reflective), non-spectral

selective, white paint.

6.4.1.4 Geometric conditions

a) The incident beam angle (θ) is preferably 0.44 rad ± 0.09 rad (25° ± 5°)

from the perpendicular line perpendicular to the surface of the rear-view

mirror, and shall not exceed the upper limit (0.53 rad or 30°). The angle (θ)

of the receiver axis to the perpendicular line shall be equal to the incident

beam angle (as shown in Figure 5). The diameter of the incident beam on

the test surface shall be not less than 19mm. The area of the reflected

beam covering the photodetector shall be less than the photosensitive

area, but shall be no less than 50% of the photosensitive area, and as

close as possible to the coverage area of the instrument during

calibration.

b) When the optical integrating sphere is used for the receiving unit, the

diameter of the sphere shall be no less than 127mm. On the sphere, the

aperture of the incident beam of the rear-view mirror and the ball wall

shall pass all of the incident beam and the reflected beam. The

photodetector shall be placed in a position that is not exposed to incident

and reflected beams.

6.4.1.5 Electrical characteristic of the photodetector, i.e., indicating

meter device

On the indicating meter, the reading output by the photodetector is a linear

function of the brightness on the photosensitive area. In order to facilitate

zeroing and calibration, light, electricity or a combination of light and

electricity may be used, but the method shall not affect the linearity and

spectral characteristics of the instrument. The accuracy of the receiver, i.e.,

indicating system shall be within ±2% of full scale or within ±10% of the

reading, whichever is less.

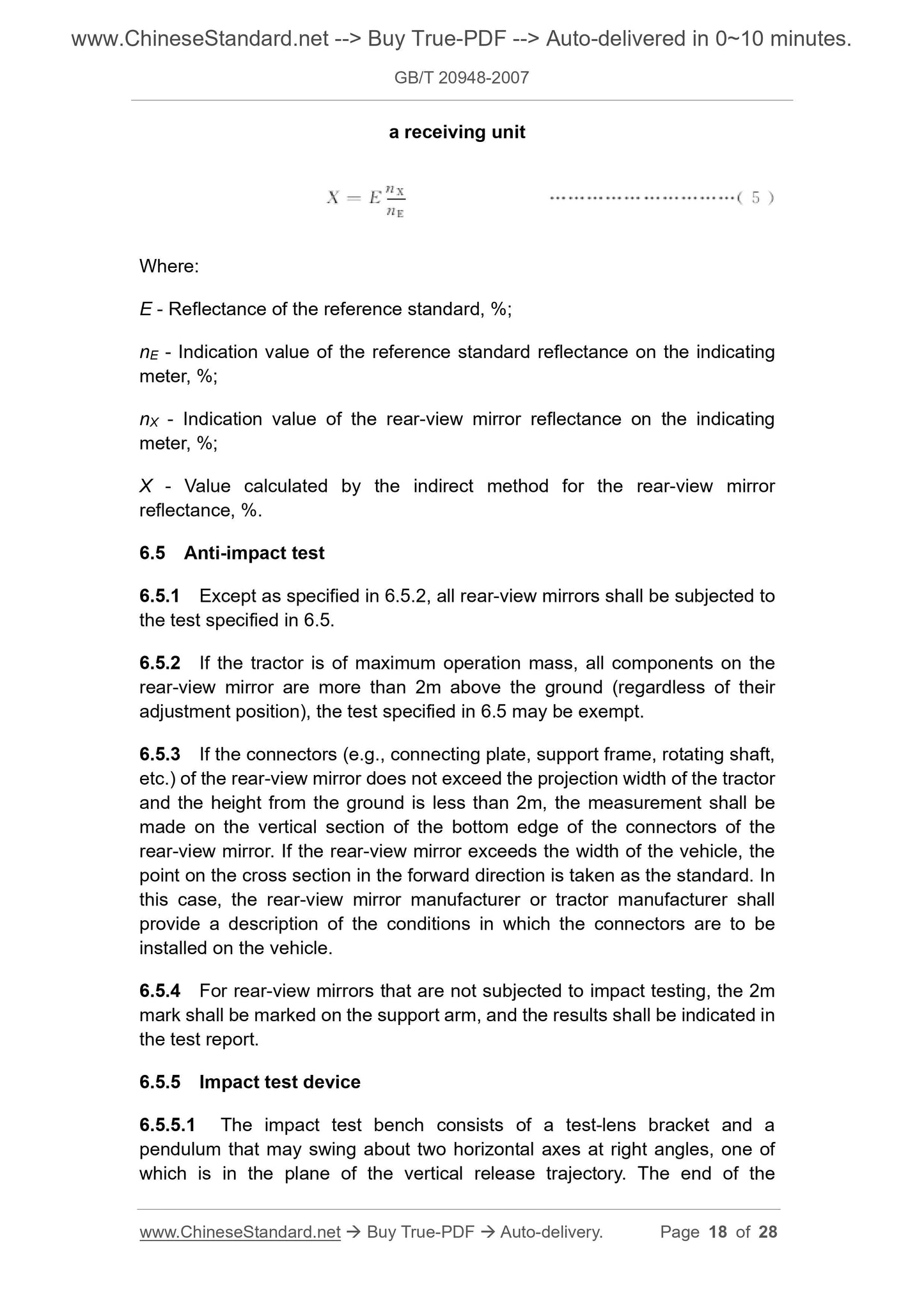

a receiving unit

Where:

E - Reflectance of the reference standard, %;

nE - Indication value of the reference standard reflectance on the indicating

meter, %;

nX - Indication value of the rear-view mirror reflectance on the indicating

meter, %;

X - Value calculated by the indirect method for the rear-view mirror

reflectance, %.

6.5 Anti-impact test

6.5.1 Except as specified in 6.5.2, all rear-view mirrors shall be subjected to

the test specified in 6.5.

6.5.2 If the tractor is of maximum operation mass, all components on the

rear-view mirror are more than 2m above the ground (regardless of their

adjustment position), the test specified in 6.5 may be exempt.

6.5.3 If the connectors (e.g., connecting plate, support frame, rotating shaft,

etc.) of the rear-view mirror does not exceed the projection width of the tractor

and the height from the ground is less than 2m, the measurement shall be

made on the vertical section of the bottom edge of the connectors of the

rear-view mirror. If the rear-view mirror exceeds the width of the vehicle, the

point on the cross section in the forward direction is taken as the standard. In

this case, the rear-view mirror manufacturer or tractor manufacturer shall

provide a description of the conditions in which the connectors are to be

installed on the vehicle.

6.5.4 For rear-view mirrors that are not subjected to impact testing, the 2m

mark shall be marked on the support arm, and the results shall be indicated in

the test report.

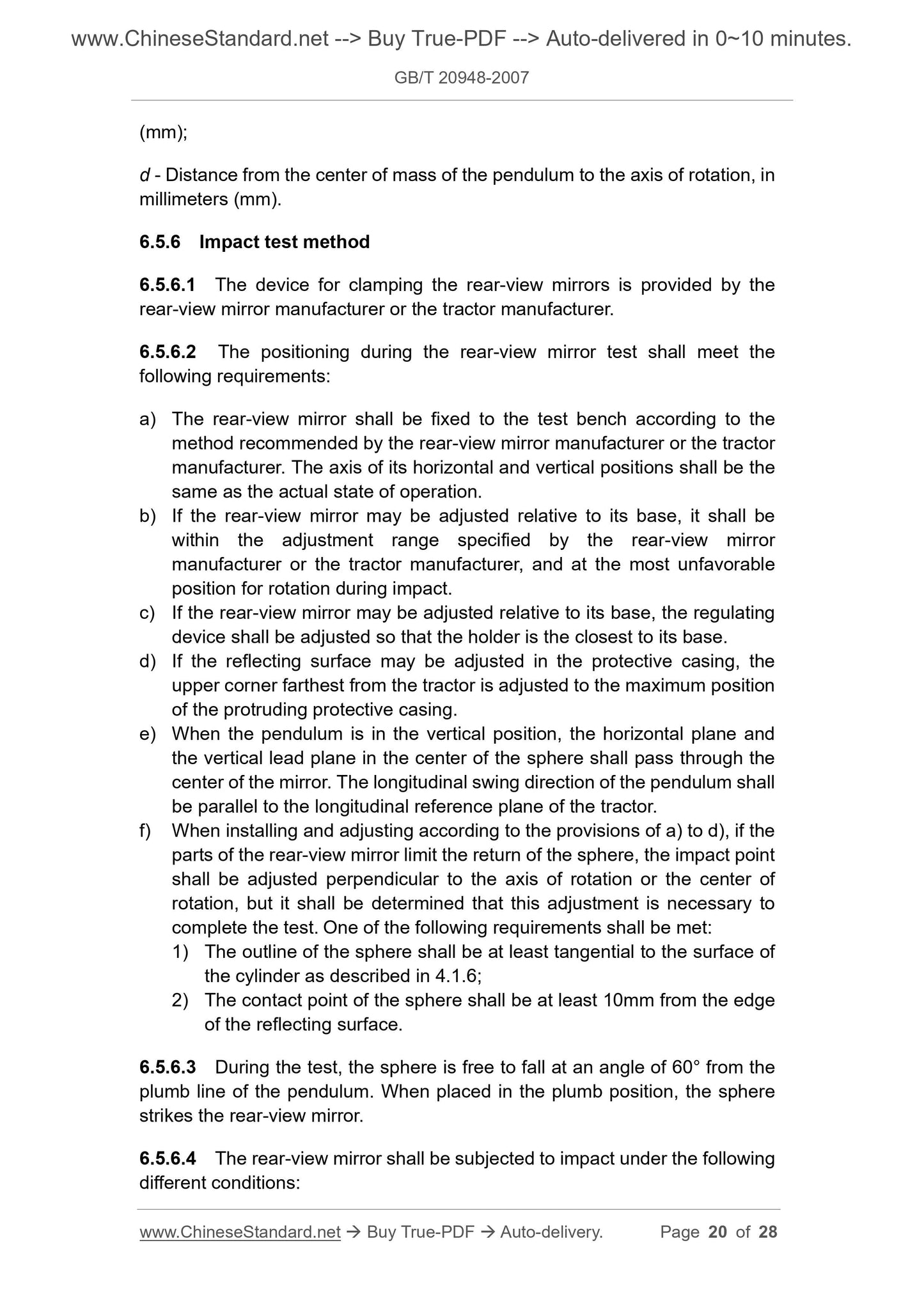

6.5.5 Impact test device

6.5.5.1 The impact test bench consists of a test-lens bracket and a

pendulum that may swing about two horizontal axes at right angles, one of

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 20948-2007 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 20948-2007

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 20948-2007

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 65.060.10

T 68

Rear-view mirrors requirements for

agricultural and forestry tractors

ISSUED ON: JUNE 25, 2007

IMPLEMENTED ON: NOVEMBER 1, 2007

Issued by: General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms ... 4

4 Performance requirements ... 7

5 Installation requirements ... 11

6 Measurement and devices and test methods ... 12

7 Inspection rules ... 24

8 Marking, packaging, transportation and storage ... 26

Appendix A (Normative) Spectral tristimulus values of the CIE standard

colorimetric observer ... 28

Rear-view mirrors requirements for

agricultural and forestry tractors

1 Scope

This Standard specifies the definitions, performance requirements,

installation requirements, test methods, inspection rules and marking,

packaging, transportation and storage of rear-view mirrors for agricultural and

forestry wheeled and crawler tractors.

This Standard applies to the agricultural and forestry wheeled and crawler

tractors.

2 Normative references

The provisions in the following documents become the provisions of this

Standard through reference in this Standard. For dated references, the

subsequent amendments (excluding corrections) or revisions do not apply to

this Standard. However, parties who reach an agreement based on this

Standard are encouraged to study if the latest editions of these documents

are applicable. For undated references, the latest editions apply to this

Standard.

QC/T 625-1999 Metallic coatings and conversion coatings for automobile

QC/T 484-1999 Automobile paint coatings

ISO 5353:1995 Earth-moving machinery, and tractors and machinery for

agriculture and forestry - Seat index point

3 Terms

The following terms and definitions are applicable to this Standard.

3.1 Rear-view mirror

A device that is able to see the rear and side images of the tractor within the

vision specified in 3.10.

3.2 Interior rear-view mirror

A device that meets the vision defined in 3.1 and is mounted in the tractor

cab.

3.3 Exterior rear-view mirror

A device that meets the vision defined in 3.1 and is mounted on the outer

surface of the tractor.

3.4 Class of rear-view mirror

Various rear-view mirrors with one or more common features or functions.

Class I is an interior rear-view mirror; and Class II is an exterior rear-view

mirror.

3.5 Center of the mirror

The center of mass of the visible area on the reflecting surface.

3.6 Principal radius of curvature at one point obtained on the

reflecting surface (ri, ri’)

The radius of curvature measured by the instrument specified in 6.3.1 through

the center of the reflecting surface, parallel to the line segment b of the mirror

and perpendicular to the direction of the line. See 4.3.1.2 for the

determination of line segment b.

3.7 Radius of curvature at one point on the reflecting surface (rpi)

Refer to the arithmetic mean value of the principal radius of curvature:

Where:

rpi - Radius of curvature at the ith point, in millimeters (mm);

ri, ri’ - Principal radius of curvature measured in two mutually perpendicular

directions at the ith point, in millimeters (mm).

3.8 Radius of curvature of the constituent parts of the rear-view mirror

(C)

C refers to the radius of the arc of the curved shape of the components such

as protective frame, support frame, and connecting member of the rear-view

mirror.

3.9 Driver’s ocular points

4.1.5 For the edge of the fixed hole or recess with a diameter or a maximum

diagonal of less than 12mm on the rear-view mirror, if it has been rounded,

the requirements for radius of curvature in 4.1.4 are not necessarily met.

4.1.6 The connection of the rear-view mirror to the tractor is designed to

ensure that the rear-view mirror is offset from the axis of rotation or the center

of rotation in the direction of impact, or either of them, to form a cylinder with a

radius of 50mm. The cylinder shall be cut at least to the surface portion to

which the connector is attached.

4.1.7 For exterior rear-view mirrors, if the parts involved in 4.1.3, 4.1.4, and

4.1.5 are made of materials not greater than Shore hardness of A60, it is not

necessary to meet the above requirements.

4.1.8 For interior rear-view mirrors, if the parts on the rear-view mirrors are

made of materials less than Shore hardness of A50 and mounted on a steel

support, the tests of 4.1.3 and 4.1.4 apply only to this support.

4.2 Appearance requirements

4.2.1 Under the illumination condition of 500 lx, when the mirror surface is

viewed from the 45° direction at 500mm from the naked eye, there shall be no

defects such as deformation, blur, streaks, bubbles, scratches, cracks and

inclusions on the rear-view mirror surface.

4.2.2 Rubber parts shall not have obvious defects such as damages and

cracks.

4.2.3 Plastic parts shall not have obvious defects such as fading, cracks,

scratches and deformation.

4.3 Performance requirements

4.3.1 Size requirements

4.3.1.1 Interior rear-view mirror (Class I)

It shall be possible to draw a rectangle with a base of a and a height of 40mm

on the reflecting surface. The size a is calculated according to the Formula

(2).

Where:

4.4.3.2 The difference between rpi (rp1, rp2 and rp3) value and r value of the

radius of curvature at any point shall be no more than 0.15r.

4.5 Reflectance

4.5.1 The reflectance value determined according to the method specified in

6.4 shall be not less than 40%. If the rear-view mirror has two working

positions (daytime and nighttime), the color signal of road traffic shall be

correctly recognized when it is in the daytime position, and the reflectance

value at nighttime position shall be no less than 4%.

4.5.2 Except for long-term rear-view mirrors under extremely harsh weather

conditions, the reflectance shall meet the reflectance values specified in 4.5.1

during normal use.

4.6 Impact resistance and bending resistance

4.6.1 The rear-view mirrors shall be subjected to an anti-impact test in

accordance with 6.5 and subjected to an anti-bending test in accordance with

6.6.

4.6.2 When the rear-view mirror performs the anti-impact test specified in

6.5 and the anti-bending test specified in 6.6, the reflecting surface shall not

be broken, but the following two conditions may be considered as meeting the

requirements:

4.6.2.1 The shards of glass remain attached to the protective casing or to

objects that are firmly attached to the protective casing. The glass is allowed

to partially detach from the above portion, but the length of any side of the

rupture shall not exceed 2.5mm. At the point of impact, small shards are

allowed to detach from the above portion.

4.6.2.2 The reflecting surface is made of safety glass.

4.6.3 For the rear-view mirror attached to the windshield glass, if the

support member of the rear-view mirror is damaged during the impact test,

the residual part of the protruding base shall be no more than 10mm, and the

shape shall still meet the requirements of 4.1.4 and 4.6.2.

4.7 Vibration resistance

When the vibration resistance of the rear-view mirror is tested in accordance

with the provisions of 6.7, each component shall be free from deformation,

damage, or detachment, which may affect its function. The mirror direction

shall be kept in the original normal operation position.

4.8 Moisture resistance

5.2 Position

5.2.1 The position of the exterior rear-view mirror shall be such that the

driver can clearly see the vision defined in 5.4 when sitting in the seat while

driving normally.

5.2.2 The rear-view mirror shall be visible from the part of the windshield

wiper that is not operating, or from the side window of the tractor (if installed).

5.2.3 In the case of the maximum operation mass of the tractor, if the

bottom edge of the rear-view mirror is less than 2m from the ground, the

installation protrusion of the rear-view mirror shall be no more than 0.20m of

the total width of the tractor.

5.3 Adjustment

5.3.1 The interior rear-view mirror shall enable the driver to make

adjustments at the driving position.

5.3.2 The exterior rear-view mirror shall enable the driver’s arm to make

adjustments by extending out of the tractor or outside the window.

5.4 Vision

5.4.1 Interior rear-view mirror (Class I)

The driver shall be able to see at least a vision area with a width of at least

20m on the horizontal road with the aid of the interior rear-view mirror. The

center plane is the longitudinal reference plane of the tractor and extends

from 60m behind the driver’s ocular points to the horizon, as shown in Figure

9.

5.4.2 Exterior rear-view mirror (Class II)

The driver shall be able to see a vision area with a left and right width of at

least 4m on the horizontal road with the aid of the exterior rear-view mirror.

The left and right sides are parallel to the plane of the longitudinal reference

plane of the tractor and are tangent to the left and right outermost points of

the tractor, and extend from 20m behind the driver’s ocular points to the

horizon. In addition, the driver shall be able to see a vision area with a width

of 1m and connected with the above area from 4m behind the driver’s ocular

points with the aid of the exterior rear-view mirror, as shown in Figure 10.

6 Measurement and devices and test methods

6.1 Measurement of the radius of curvature “C” of the protective frame

the sum of the regular reflectance and the diffuse reflectance.

6.4.1.3 Spectral characteristics of light sources and photodetectors

a) The light source consists of a CIE standard light source A and a lens that

enables the light from the light source to be a parallel beam. In order to

keep the light source voltage stable while the instrument is operating, a

regulated power supply shall be used.

b) The spectral response of the photodetector carried by the receiving unit is

proportional to the appropriate brightness function of the CIE (1931)

standard colorimetric observer (SEE Appendix A). Other combinations of

illuminator-filter-receiver that produce effects that are fully equivalent to

CIE standard illuminator A and daylight vision may also be used. When an

optical integrating sphere is used in the receiving unit, the inner surface of

the sphere shall be coated with a matt (diffusely reflective), non-spectral

selective, white paint.

6.4.1.4 Geometric conditions

a) The incident beam angle (θ) is preferably 0.44 rad ± 0.09 rad (25° ± 5°)

from the perpendicular line perpendicular to the surface of the rear-view

mirror, and shall not exceed the upper limit (0.53 rad or 30°). The angle (θ)

of the receiver axis to the perpendicular line shall be equal to the incident

beam angle (as shown in Figure 5). The diameter of the incident beam on

the test surface shall be not less than 19mm. The area of the reflected

beam covering the photodetector shall be less than the photosensitive

area, but shall be no less than 50% of the photosensitive area, and as

close as possible to the coverage area of the instrument during

calibration.

b) When the optical integrating sphere is used for the receiving unit, the

diameter of the sphere shall be no less than 127mm. On the sphere, the

aperture of the incident beam of the rear-view mirror and the ball wall

shall pass all of the incident beam and the reflected beam. The

photodetector shall be placed in a position that is not exposed to incident

and reflected beams.

6.4.1.5 Electrical characteristic of the photodetector, i.e., indicating

meter device

On the indicating meter, the reading output by the photodetector is a linear

function of the brightness on the photosensitive area. In order to facilitate

zeroing and calibration, light, electricity or a combination of light and

electricity may be used, but the method shall not affect the linearity and

spectral characteristics of the instrument. The accuracy of the receiver, i.e.,

indicating system shall be within ±2% of full scale or within ±10% of the

reading, whichever is less.

a receiving unit

Where:

E - Reflectance of the reference standard, %;

nE - Indication value of the reference standard reflectance on the indicating

meter, %;

nX - Indication value of the rear-view mirror reflectance on the indicating

meter, %;

X - Value calculated by the indirect method for the rear-view mirror

reflectance, %.

6.5 Anti-impact test

6.5.1 Except as specified in 6.5.2, all rear-view mirrors shall be subjected to

the test specified in 6.5.

6.5.2 If the tractor is of maximum operation mass, all components on the

rear-view mirror are more than 2m above the ground (regardless of their

adjustment position), the test specified in 6.5 may be exempt.

6.5.3 If the connectors (e.g., connecting plate, support frame, rotating shaft,

etc.) of the rear-view mirror does not exceed the projection width of the tractor

and the height from the ground is less than 2m, the measurement shall be

made on the vertical section of the bottom edge of the connectors of the

rear-view mirror. If the rear-view mirror exceeds the width of the vehicle, the

point on the cross section in the forward direction is taken as the standard. In

this case, the rear-view mirror manufacturer or tractor manufacturer shall

provide a description of the conditions in which the connectors are to be

installed on the vehicle.

6.5.4 For rear-view mirrors that are not subjected to impact testing, the 2m

mark shall be marked on the support arm, and the results shall be indicated in

the test report.

6.5.5 Impact test device

6.5.5.1 The impact test bench consists of a test-lens bracket and a

pendulum that may swing about two horizontal axes at right angles, one of

Share