1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB/T 20975.28-2019 English PDF (GB/T20975.28-2019)

GB/T 20975.28-2019 English PDF (GB/T20975.28-2019)

Regular price

$90.00 USD

Regular price

Sale price

$90.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 20975.28-2019

Historical versions: GB/T 20975.28-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 20975.28-2019: Methods for chemical analysis of aluminium and aluminium alloys -- Part 28: Determination of cobalt content -- Flame atomic absorption spectrometry

GB/T 20975.28-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.120.10

H 12

Methods for chemical analysis of aluminium and

aluminium alloys - Part 28: Determination of cobalt

content - Flame atomic absorption spectrometry

ISSUED ON: JUNE 04, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Method summary ... 6

4 Reagents ... 7

5 Apparatus ... 7

6 Sample ... 8

7 Analysis steps ... 8

8 Calculation of analysis result ... 10

9 Precision ... 10

10 Quality assurance and control ... 11

11 Test report ... 11

Methods for chemical analysis of aluminium and

aluminium alloys - Part 28: Determination of cobalt

content - Flame atomic absorption spectrometry

WARNING - The personnel using this Part shall have practical experience

in formal laboratory work. This Part does not address all possible security

issues. It is the responsibility of the user to take appropriate safety and

health measures and to ensure compliance with the relevant national

regulations.

1 Scope

This Part of GB/T 20975 specifies the method of flame atomic absorption

spectrometry to determine cobalt content in aluminium and aluminium alloys.

This Part is applicable to determination of cobalt content in aluminum and

aluminum alloy, aluminum-cobalt intermediate alloy. Determination range:

0.005%~12.0%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 6682, Water for analytical laboratory use - Specification and test

methods

GB/T 8170-2008, Rules of rounding off for numerical values and expression

and judgement of limiting values

3 Method summary

Use hydrochloric acid, nitric acid to dissolve test material. In dilute acid medium,

at the wavelength of 240.7nm of atomic absorption spectrometer, in air-

acetylene flame, measure absorbance of cobalt so as to determine cobalt

content.

standard deviation shall not exceed 0.5% of average absorbance of

highest-concentration standard solution.

- Working curve linear: Divide working curve into five segments according to

concentration. The ratio of difference between absorbance of the highest

segment and absorbance of the lowest segment shall be not less than

0.80.

6 Sample

Process sample into chips of no more than 1mm.

7 Analysis steps

7.1 Test material

Weigh a sample of which mass (m) is 0.20g (see Clause 6), to the nearest of

0.0001g.

7.2 Number of determination

Perform two determinations independently. Take the average value.

7.3 Blank test

Weigh 0.20g of aluminum (4.1) to replace test material (7.1). Carry out blank

test with test material.

7.4 Determination

7.4.1 Place test material (7.1) into a 100mL beaker. Add into 10mL of

hydrochloric acid (4.5). After violent reaction stops, heat until test material is

dissolved. Add few drops of nitric acid (4.6). Boil to remove nitrogen oxide. Cool.

Move into a 100mL volumetric flask. Use water to dilute to scale. Set volume

(V). Mix well.

NOTE: If there is insoluble matter, filtrate and wash. Place residue together with filter paper

in a platinum crucible. Perform ashing (do not let filter paper burn). Burn at about 550°C.

Cool. Add 5mL of hydrofluoric acid (4.4). And add into hydrochloric acid (4.5) drop by drop

till solution is clear. Heat to evaporate to dry. Burn at 700°C for several minutes. Cool. Use

hydrochloric acid (4.5) as little as possible to dissolve residue. Combine this filtrate in stock

solution.

7.4.2 According to Table 1, distribute test solution in a suitable volumetric flask.

Add into hydrochloric acid (4.5). Use water to dilute to scale. Mix well for testing.

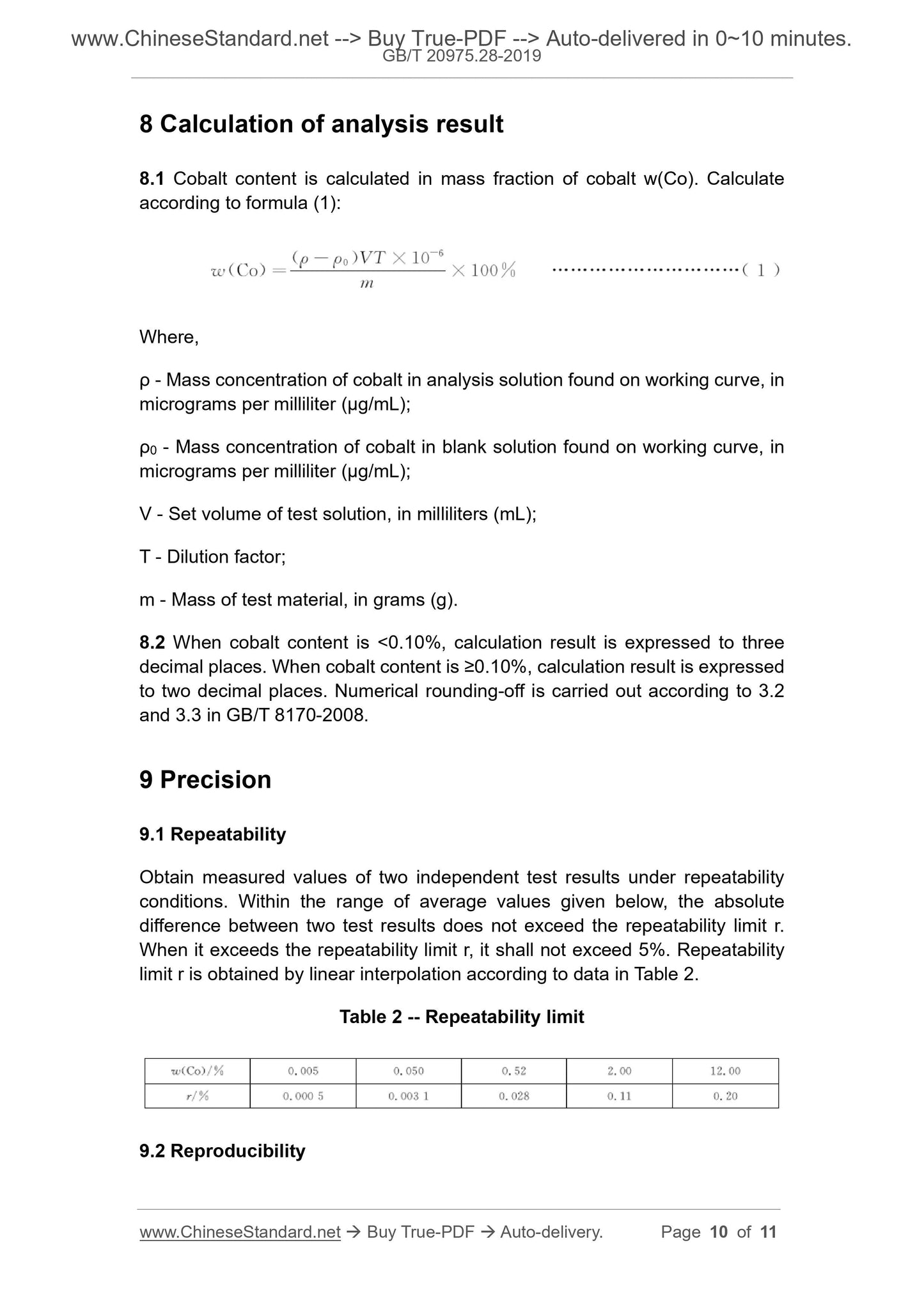

8 Calculation of analysis result

8.1 Cobalt content is calculated in mass fraction of cobalt w(Co). Calculate

according to formula (1):

Where,

ρ - Mass concentration of cobalt in analysis solution found on working curve, in

micrograms per milliliter (μg/mL);

ρ0 - Mass concentration of cobalt in blank solution found on working curve, in

micrograms per milliliter (μg/mL);

V - Set volume of test solution, in milliliters (mL);

T - Dilution factor;

m - Mass of test material, in grams (g).

8.2 When cobalt content is < 0.10%, calculation result is expressed to three

decimal places. When cobalt content is ≥0.10%, calculation result is expressed

to two decimal places. Numerical rounding-off is carried out according to 3.2

and 3.3 in GB/T 8170-2008.

9 Precision

9.1 Repeatability

Obtain measured values of two independent test results under repeatability

conditions. Within the range of average values given below, the absolute

difference between two test results does not exceed the repeatability limit r.

When it exceeds the repeatability limit r, it shall not exceed 5%. Repeatability

limit r is obtained by linear interpolation according to data in Table 2.

Table 2 -- Repeatability limit

9.2 Reproducibility

Get QUOTATION in 1-minute: Click GB/T 20975.28-2019

Historical versions: GB/T 20975.28-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 20975.28-2019: Methods for chemical analysis of aluminium and aluminium alloys -- Part 28: Determination of cobalt content -- Flame atomic absorption spectrometry

GB/T 20975.28-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.120.10

H 12

Methods for chemical analysis of aluminium and

aluminium alloys - Part 28: Determination of cobalt

content - Flame atomic absorption spectrometry

ISSUED ON: JUNE 04, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Method summary ... 6

4 Reagents ... 7

5 Apparatus ... 7

6 Sample ... 8

7 Analysis steps ... 8

8 Calculation of analysis result ... 10

9 Precision ... 10

10 Quality assurance and control ... 11

11 Test report ... 11

Methods for chemical analysis of aluminium and

aluminium alloys - Part 28: Determination of cobalt

content - Flame atomic absorption spectrometry

WARNING - The personnel using this Part shall have practical experience

in formal laboratory work. This Part does not address all possible security

issues. It is the responsibility of the user to take appropriate safety and

health measures and to ensure compliance with the relevant national

regulations.

1 Scope

This Part of GB/T 20975 specifies the method of flame atomic absorption

spectrometry to determine cobalt content in aluminium and aluminium alloys.

This Part is applicable to determination of cobalt content in aluminum and

aluminum alloy, aluminum-cobalt intermediate alloy. Determination range:

0.005%~12.0%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 6682, Water for analytical laboratory use - Specification and test

methods

GB/T 8170-2008, Rules of rounding off for numerical values and expression

and judgement of limiting values

3 Method summary

Use hydrochloric acid, nitric acid to dissolve test material. In dilute acid medium,

at the wavelength of 240.7nm of atomic absorption spectrometer, in air-

acetylene flame, measure absorbance of cobalt so as to determine cobalt

content.

standard deviation shall not exceed 0.5% of average absorbance of

highest-concentration standard solution.

- Working curve linear: Divide working curve into five segments according to

concentration. The ratio of difference between absorbance of the highest

segment and absorbance of the lowest segment shall be not less than

0.80.

6 Sample

Process sample into chips of no more than 1mm.

7 Analysis steps

7.1 Test material

Weigh a sample of which mass (m) is 0.20g (see Clause 6), to the nearest of

0.0001g.

7.2 Number of determination

Perform two determinations independently. Take the average value.

7.3 Blank test

Weigh 0.20g of aluminum (4.1) to replace test material (7.1). Carry out blank

test with test material.

7.4 Determination

7.4.1 Place test material (7.1) into a 100mL beaker. Add into 10mL of

hydrochloric acid (4.5). After violent reaction stops, heat until test material is

dissolved. Add few drops of nitric acid (4.6). Boil to remove nitrogen oxide. Cool.

Move into a 100mL volumetric flask. Use water to dilute to scale. Set volume

(V). Mix well.

NOTE: If there is insoluble matter, filtrate and wash. Place residue together with filter paper

in a platinum crucible. Perform ashing (do not let filter paper burn). Burn at about 550°C.

Cool. Add 5mL of hydrofluoric acid (4.4). And add into hydrochloric acid (4.5) drop by drop

till solution is clear. Heat to evaporate to dry. Burn at 700°C for several minutes. Cool. Use

hydrochloric acid (4.5) as little as possible to dissolve residue. Combine this filtrate in stock

solution.

7.4.2 According to Table 1, distribute test solution in a suitable volumetric flask.

Add into hydrochloric acid (4.5). Use water to dilute to scale. Mix well for testing.

8 Calculation of analysis result

8.1 Cobalt content is calculated in mass fraction of cobalt w(Co). Calculate

according to formula (1):

Where,

ρ - Mass concentration of cobalt in analysis solution found on working curve, in

micrograms per milliliter (μg/mL);

ρ0 - Mass concentration of cobalt in blank solution found on working curve, in

micrograms per milliliter (μg/mL);

V - Set volume of test solution, in milliliters (mL);

T - Dilution factor;

m - Mass of test material, in grams (g).

8.2 When cobalt content is < 0.10%, calculation result is expressed to three

decimal places. When cobalt content is ≥0.10%, calculation result is expressed

to two decimal places. Numerical rounding-off is carried out according to 3.2

and 3.3 in GB/T 8170-2008.

9 Precision

9.1 Repeatability

Obtain measured values of two independent test results under repeatability

conditions. Within the range of average values given below, the absolute

difference between two test results does not exceed the repeatability limit r.

When it exceeds the repeatability limit r, it shall not exceed 5%. Repeatability

limit r is obtained by linear interpolation according to data in Table 2.

Table 2 -- Repeatability limit

9.2 Reproducibility

Share