1

/

of

8

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 223.26-2008 English PDF (GB/T223.26-2008)

GB/T 223.26-2008 English PDF (GB/T223.26-2008)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 223.26-2008

Historical versions: GB/T 223.26-2008

Preview True-PDF (Reload/Scroll if blank)

GB/T 223.26-2008: Iron, steel and alloy -- Determination of molybdenum content -- The thiocyanate spectrophotometric method

GB/T 223.26-2008

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.080.01

H 11

Replacing GB/T 223.26-1989, GB/T 223.27-1994

Iron, steel and alloy - Determination of molybdenum

content - The thiocyanate spectrophotometric method

ISSUED ON: MAY 13, 2008

IMPLEMENTED ON: NOVEMBER 01, 2008

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Method-1: Thiocyanate direct spectrophotometry ... 5

4 Method-2: Thiocyanate-butyl acetate extraction spectrophotometry ... 8

5 Test report ... 13

Appendix A (Informative) Raw data of common precision test ... 14

Iron, steel and alloy - Determination of molybdenum

content - The thiocyanate spectrophotometric method

Warning: Personnel who use this part shall have hands-on experience

with formal laboratory work. This part does not address all possible safety

issues. It is the responsibility of the user to take appropriate safety and

health measures and to ensure compliance with the conditions set by the

relevant national regulations.

1 Scope

This part of GB/T 223 specifies the determination of molybdenum by

thiocyanate direct spectrophotometry and thiocyanate-butyl acetate extraction

spectrophotometry.

The method-1 of this part is applicable to the determination of molybdenum

content of 0.10%~2.00% (mass fraction) in medium-and-low alloy steel, high-

temperature alloy steel, precision alloy. The method-2 of this part is applicable

to the determination of molybdenum content of 0.0025% ~ 0.20% (mass fraction)

in pig iron, carbon steel, alloy steel.

2 Normative references

The provisions in following documents become the provisions of this standard

through reference in this part of GB/T 223. For the dated references, the

subsequent amendments (excluding corrections) or revisions do not apply to

this part; however, parties who reach an agreement based on this standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 6379.1 Accuracy (trueness and precision) of measurement methods

and results - Part 1: General principles and definitions

GB/T 6379.2 Measurement methods and results - Accuracy (trueness and

precision) - Part 2: Determine the standard methods of measurement

repeatability and reproducibility of the basic method

GB/T 20066 Steel and iron - Sampling and preparation of samples for the

determination of chemical composition

3 Method-1: Thiocyanate direct spectrophotometry

3.1 Principle

In the sulfuric acid-perchloric acid medium, use stannous chloride to reduce

iron and molybdenum. Molybdenum reacts with sodium thiocyanate to produce

an orange-red complex. Measure the absorbance. In the color-developing

solution, there is no impact if the amount of copper is less than 0.2 mg, the

amount of vanadium is less than 0.05 mg, the amount of cobalt is less than 0.8

mg, the amount of antimony is less than 0.8 mg, the amount of chromium is

less than 2.4 mg.

3.2 Reagents and materials

Unless otherwise stated, only analytically pure reagents and distilled water or

water of comparable purity are used in the analysis.

3.2.1 Hydrochloric acid, ρ is about 1.19 g/mL.

3.2.2 Nitric acid, ρ is about 1.42 g/mL.

3.2.3 Sulfuric acid, ρ is about 1.84 g/mL, which is diluted to 1 + 1.

3.2.4 Sulfuric acid, ρ is about 1.84 g/mL, which is diluted to 5 + 95.

3.2.5 Mixed acid of sulfuric acid-phosphoric acid, in 700 mL of water, slowly add

150 mL of sulfuric acid (ρ is about 1.84 g/mL). After cooling it slightly, add 150

mL of phosphoric acid (ρ is about 1.70 g/mL). Mix it uniformly.

3.2.6 Perchloric acid, ρ is about 1.67 g/mL, which is diluted to 1 + 5.

3.2.7 Stannous chloride solution, 100 g/L. Weigh 10 g of stannous chloride

(SnCl2 • 2H2O). Place it in a 250 mL beaker. Add 10 mL of hydrochloric acid

(3.2.1). Heat to dissolve it and boil it. Cool it. Use water to dilute it to 100 mL.

Mix it uniformly. Prepare it before use.

3.2.8 Sodium thiocyanate solution, 100 g/L.

3.2.9 Iron solution, 20 g/L. Weigh 2.0 g of pure iron (the molybdenum content,

in mass fraction, must be less than 0.001%). Place it in a 250 mL beaker. Add

40 mL of mixed acid of sulfuric acid-phosphoric acid (3.2.5). Heat to dissolve it.

Add nitric acid (3.2.2) dropwise to oxidize it. Heat it until sulfuric acid smoke is

produced. Take it off and cool it slightly. Add 40 mL of water. Heat to dissolve

the salt. Cool it to room temperature. Transfer it to a 100 mL volumetric flask.

Use water to dilute it to the mark. Mix it uniformly. 1 mL of this solution contains

20 mg of iron.

min ~ 3 min. Remove to slightly cool it. Add 20 mL of water. Heat to dissolve

the salt. Cool it down. Transfer it into a 100 mL volumetric flask. Use water to

dilute it to the mark. Mix it uniformly.

3.5.3.3 Pipette two sets of 10.00 mL of test solution into two 50 mL volumetric

flasks, respectively [where the iron content is less than 30 mg, add iron solution

(3.2.9) to make up].

3.5.3.4 Add 4 mL of sulfuric acid (3.2.3) and 10 mL of perchloric acid (3.2.6) to

one set of solution. Mix it uniformly. Add 10 mL of sodium thiocyanate solution

(3.2.8). Mix it uniformly. Add 10 mL of stannous chloride solution (3.2.7) whilst

shaking it. Use sulfuric acid (3.2.4) to dilute it to the mark. Mix it uniformly. This

is the color-developing solution.

In the other test solution, except for adding the sodium thiocyanate solution

(3.2.8), the rest operations are same as that of the color-developing solution.

This is the reference solution.

3.5.3.5 Place it at room temperature for 10 min ~ 15 min. Transfer part of the

solution into a 1 cm ~ 2 cm absorption dish. Use the reference solution as a

reference. At the wavelength of 470 nm of the spectrophotometer, measure the

absorbance. Subtract the absorbance of the blank solution as made along with

the sample. From the calibration curve, check the corresponding mass of

molybdenum (μg) in the color-developing solution.

3.5.4 Drawing of calibration curve

Weigh 9 parts of 0.30 g of pure iron (molybdenum’s mass fraction is less than

0.001%). Place them in a 250 mL conical flask. Respectively pipette 0, 0.50 mL,

1.00 mL, 1.50 mL, 2.00 mL, 2.50 mL, 3.00 mL, 3.50 mL, 4.00 mL of

molybdenum standard solution (3.2.10). Add 40 mL of the mixed acid of sulfuric

acid-phosphoric acid (3.2.5). Heat to dissolve it. Follow the procedures of

3.5.3.2 ~ 3.5.3.5, until measuring the absorbance. Subtract the absorbance of

the compensation solution. Use the mass of molybdenum (μg) as the abscissa

and the absorbance as the ordinate, to draw the calibration curve.

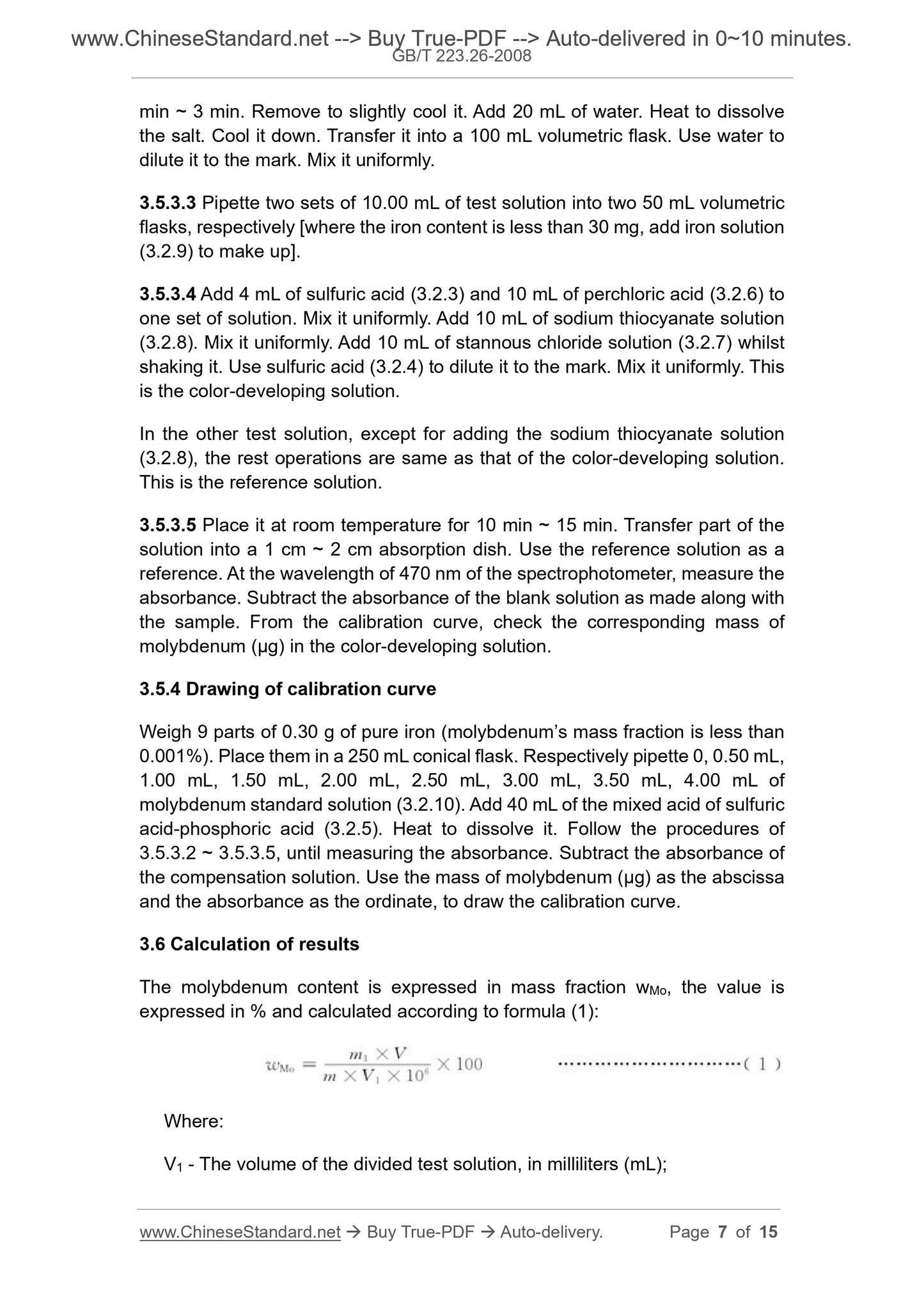

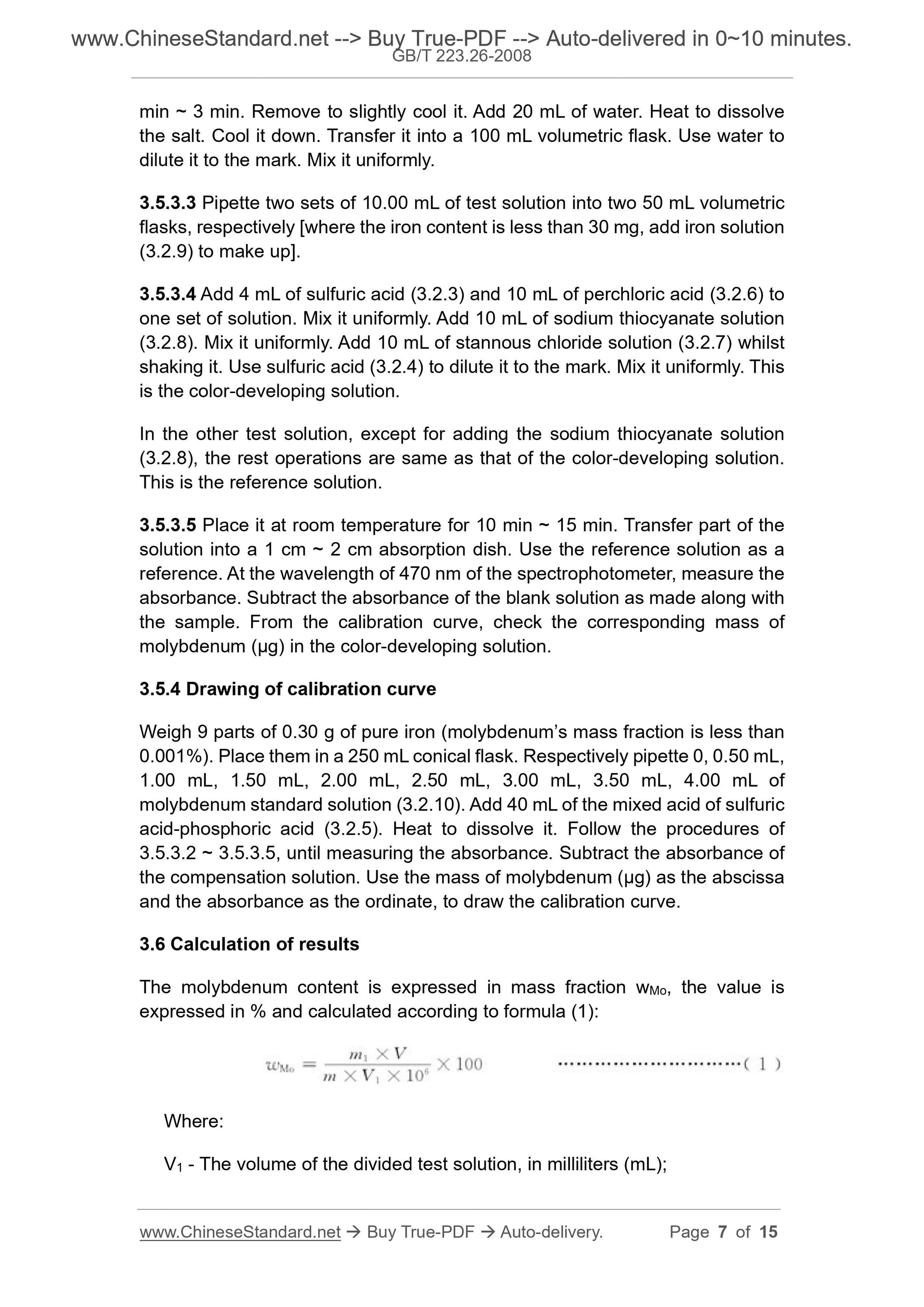

3.6 Calculation of results

The molybdenum content is expressed in mass fraction wMo, the value is

expressed in % and calculated according to formula (1):

Where:

V1 - The volume of the divided test solution, in milliliters (mL);

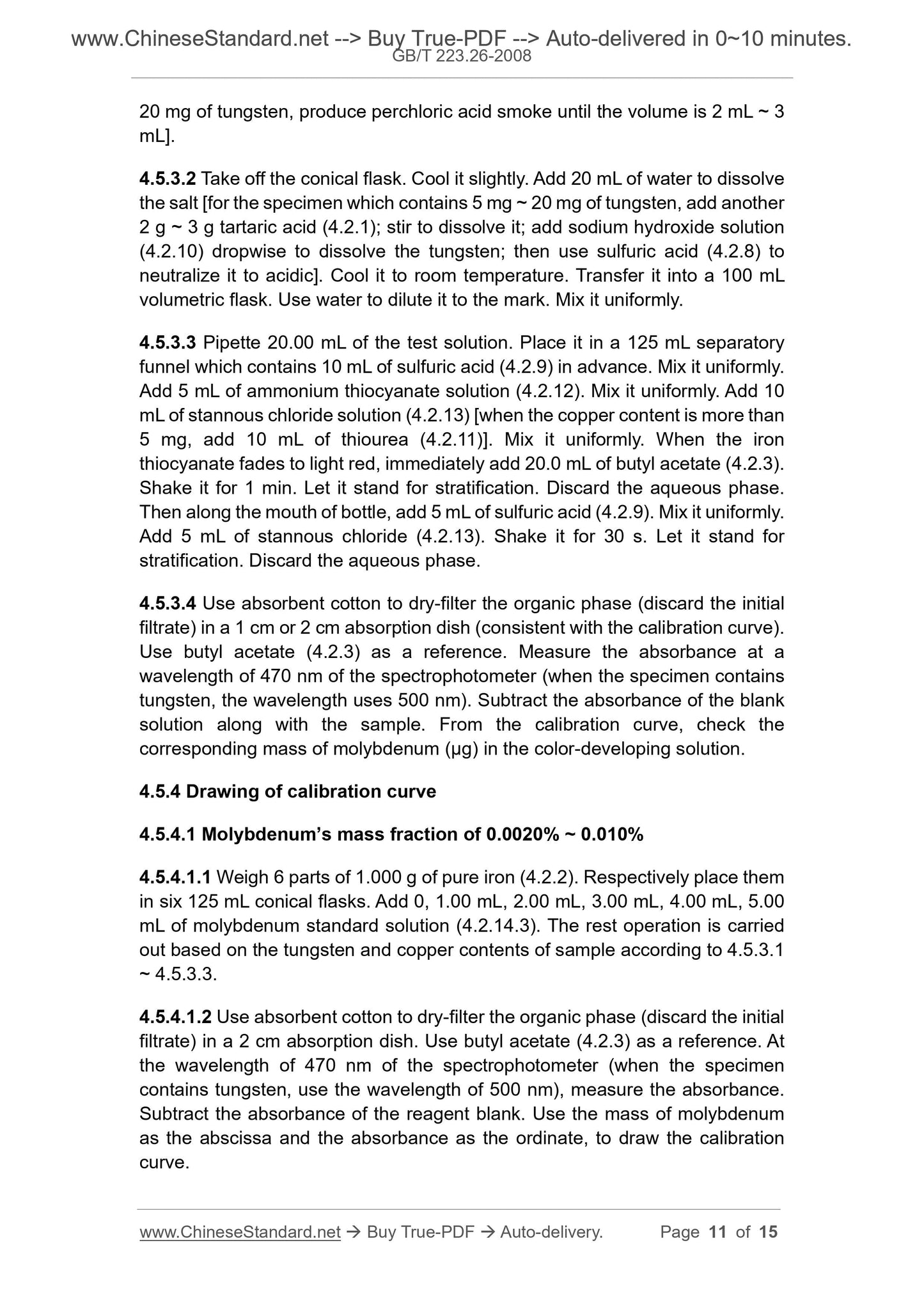

When the tungsten in the specimen is less than 5 mg, use phosphoric acid to

mask it. When the tungsten in the specimen is more than 5 mg ~ 20 mg, add 2

~ 3 g of tartaric acid to mask it. When the molybdenum is less than 0.010%, the

ratio of molybdenum to tungsten is not more than 1:80. In the pipetted solution,

when copper is more than 5 mg, add thiourea to mask it. When antimony is

more than 0.15 mg, it interferes with this method. ...

Get QUOTATION in 1-minute: Click GB/T 223.26-2008

Historical versions: GB/T 223.26-2008

Preview True-PDF (Reload/Scroll if blank)

GB/T 223.26-2008: Iron, steel and alloy -- Determination of molybdenum content -- The thiocyanate spectrophotometric method

GB/T 223.26-2008

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.080.01

H 11

Replacing GB/T 223.26-1989, GB/T 223.27-1994

Iron, steel and alloy - Determination of molybdenum

content - The thiocyanate spectrophotometric method

ISSUED ON: MAY 13, 2008

IMPLEMENTED ON: NOVEMBER 01, 2008

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Method-1: Thiocyanate direct spectrophotometry ... 5

4 Method-2: Thiocyanate-butyl acetate extraction spectrophotometry ... 8

5 Test report ... 13

Appendix A (Informative) Raw data of common precision test ... 14

Iron, steel and alloy - Determination of molybdenum

content - The thiocyanate spectrophotometric method

Warning: Personnel who use this part shall have hands-on experience

with formal laboratory work. This part does not address all possible safety

issues. It is the responsibility of the user to take appropriate safety and

health measures and to ensure compliance with the conditions set by the

relevant national regulations.

1 Scope

This part of GB/T 223 specifies the determination of molybdenum by

thiocyanate direct spectrophotometry and thiocyanate-butyl acetate extraction

spectrophotometry.

The method-1 of this part is applicable to the determination of molybdenum

content of 0.10%~2.00% (mass fraction) in medium-and-low alloy steel, high-

temperature alloy steel, precision alloy. The method-2 of this part is applicable

to the determination of molybdenum content of 0.0025% ~ 0.20% (mass fraction)

in pig iron, carbon steel, alloy steel.

2 Normative references

The provisions in following documents become the provisions of this standard

through reference in this part of GB/T 223. For the dated references, the

subsequent amendments (excluding corrections) or revisions do not apply to

this part; however, parties who reach an agreement based on this standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 6379.1 Accuracy (trueness and precision) of measurement methods

and results - Part 1: General principles and definitions

GB/T 6379.2 Measurement methods and results - Accuracy (trueness and

precision) - Part 2: Determine the standard methods of measurement

repeatability and reproducibility of the basic method

GB/T 20066 Steel and iron - Sampling and preparation of samples for the

determination of chemical composition

3 Method-1: Thiocyanate direct spectrophotometry

3.1 Principle

In the sulfuric acid-perchloric acid medium, use stannous chloride to reduce

iron and molybdenum. Molybdenum reacts with sodium thiocyanate to produce

an orange-red complex. Measure the absorbance. In the color-developing

solution, there is no impact if the amount of copper is less than 0.2 mg, the

amount of vanadium is less than 0.05 mg, the amount of cobalt is less than 0.8

mg, the amount of antimony is less than 0.8 mg, the amount of chromium is

less than 2.4 mg.

3.2 Reagents and materials

Unless otherwise stated, only analytically pure reagents and distilled water or

water of comparable purity are used in the analysis.

3.2.1 Hydrochloric acid, ρ is about 1.19 g/mL.

3.2.2 Nitric acid, ρ is about 1.42 g/mL.

3.2.3 Sulfuric acid, ρ is about 1.84 g/mL, which is diluted to 1 + 1.

3.2.4 Sulfuric acid, ρ is about 1.84 g/mL, which is diluted to 5 + 95.

3.2.5 Mixed acid of sulfuric acid-phosphoric acid, in 700 mL of water, slowly add

150 mL of sulfuric acid (ρ is about 1.84 g/mL). After cooling it slightly, add 150

mL of phosphoric acid (ρ is about 1.70 g/mL). Mix it uniformly.

3.2.6 Perchloric acid, ρ is about 1.67 g/mL, which is diluted to 1 + 5.

3.2.7 Stannous chloride solution, 100 g/L. Weigh 10 g of stannous chloride

(SnCl2 • 2H2O). Place it in a 250 mL beaker. Add 10 mL of hydrochloric acid

(3.2.1). Heat to dissolve it and boil it. Cool it. Use water to dilute it to 100 mL.

Mix it uniformly. Prepare it before use.

3.2.8 Sodium thiocyanate solution, 100 g/L.

3.2.9 Iron solution, 20 g/L. Weigh 2.0 g of pure iron (the molybdenum content,

in mass fraction, must be less than 0.001%). Place it in a 250 mL beaker. Add

40 mL of mixed acid of sulfuric acid-phosphoric acid (3.2.5). Heat to dissolve it.

Add nitric acid (3.2.2) dropwise to oxidize it. Heat it until sulfuric acid smoke is

produced. Take it off and cool it slightly. Add 40 mL of water. Heat to dissolve

the salt. Cool it to room temperature. Transfer it to a 100 mL volumetric flask.

Use water to dilute it to the mark. Mix it uniformly. 1 mL of this solution contains

20 mg of iron.

min ~ 3 min. Remove to slightly cool it. Add 20 mL of water. Heat to dissolve

the salt. Cool it down. Transfer it into a 100 mL volumetric flask. Use water to

dilute it to the mark. Mix it uniformly.

3.5.3.3 Pipette two sets of 10.00 mL of test solution into two 50 mL volumetric

flasks, respectively [where the iron content is less than 30 mg, add iron solution

(3.2.9) to make up].

3.5.3.4 Add 4 mL of sulfuric acid (3.2.3) and 10 mL of perchloric acid (3.2.6) to

one set of solution. Mix it uniformly. Add 10 mL of sodium thiocyanate solution

(3.2.8). Mix it uniformly. Add 10 mL of stannous chloride solution (3.2.7) whilst

shaking it. Use sulfuric acid (3.2.4) to dilute it to the mark. Mix it uniformly. This

is the color-developing solution.

In the other test solution, except for adding the sodium thiocyanate solution

(3.2.8), the rest operations are same as that of the color-developing solution.

This is the reference solution.

3.5.3.5 Place it at room temperature for 10 min ~ 15 min. Transfer part of the

solution into a 1 cm ~ 2 cm absorption dish. Use the reference solution as a

reference. At the wavelength of 470 nm of the spectrophotometer, measure the

absorbance. Subtract the absorbance of the blank solution as made along with

the sample. From the calibration curve, check the corresponding mass of

molybdenum (μg) in the color-developing solution.

3.5.4 Drawing of calibration curve

Weigh 9 parts of 0.30 g of pure iron (molybdenum’s mass fraction is less than

0.001%). Place them in a 250 mL conical flask. Respectively pipette 0, 0.50 mL,

1.00 mL, 1.50 mL, 2.00 mL, 2.50 mL, 3.00 mL, 3.50 mL, 4.00 mL of

molybdenum standard solution (3.2.10). Add 40 mL of the mixed acid of sulfuric

acid-phosphoric acid (3.2.5). Heat to dissolve it. Follow the procedures of

3.5.3.2 ~ 3.5.3.5, until measuring the absorbance. Subtract the absorbance of

the compensation solution. Use the mass of molybdenum (μg) as the abscissa

and the absorbance as the ordinate, to draw the calibration curve.

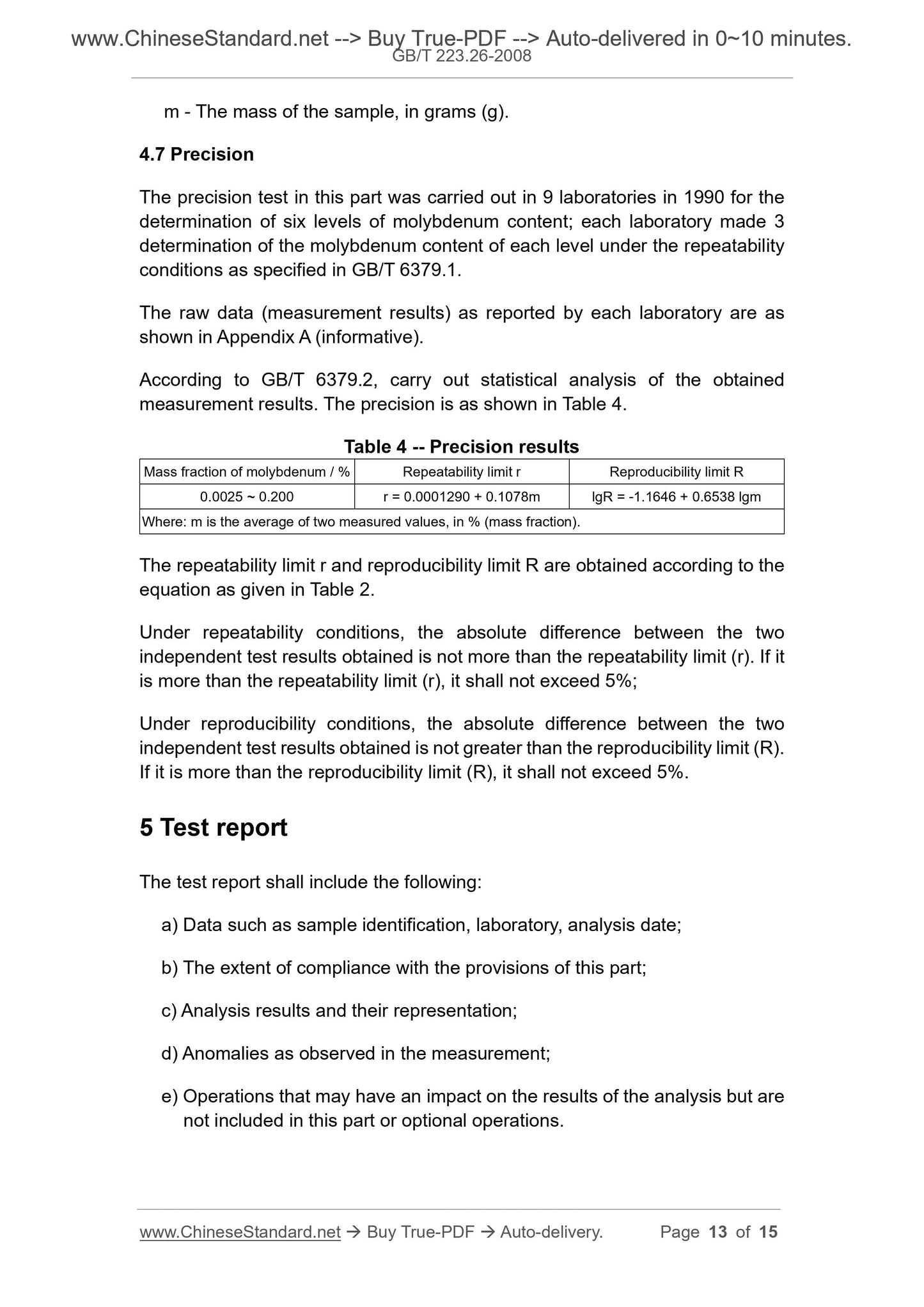

3.6 Calculation of results

The molybdenum content is expressed in mass fraction wMo, the value is

expressed in % and calculated according to formula (1):

Where:

V1 - The volume of the divided test solution, in milliliters (mL);

When the tungsten in the specimen is less than 5 mg, use phosphoric acid to

mask it. When the tungsten in the specimen is more than 5 mg ~ 20 mg, add 2

~ 3 g of tartaric acid to mask it. When the molybdenum is less than 0.010%, the

ratio of molybdenum to tungsten is not more than 1:80. In the pipetted solution,

when copper is more than 5 mg, add thiourea to mask it. When antimony is

more than 0.15 mg, it interferes with this method. ...

Share