1

/

of

7

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB/T 223.63-2022 English PDF (GB/T223.63-2022)

GB/T 223.63-2022 English PDF (GB/T223.63-2022)

Regular price

$230.00 USD

Regular price

Sale price

$230.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 223.63-2022

Historical versions: GB/T 223.63-2022

Preview True-PDF (Reload/Scroll if blank)

GB/T 223.63-2022: Iron, steel and alloy - Determination of manganese content - Sodium (potassium) periodate spectrophotometric method

GB/T 223.63-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.080.01

CCS H 11

Replacing GB/T 223.63-1988

Iron, Steel and Alloy - Determination of Manganese Content

- Sodium (potassium) Periodate Spectrophotometric Method

(ISO 629:1982, Steel and Cast Iron - Determination of Manganese Content -

Spectrophotometric Method, NEQ)

ISSUED ON: JULY 11, 2022

IMPLEMENTED ON: FEBRUARY 1, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative References ... 6

3 Terms and Definitions ... 7

4 Principle ... 7

5 Reagents or Materials ... 7

6 Instruments and Equipment ... 9

7 Sample ... 9

8 Test Procedures ... 9

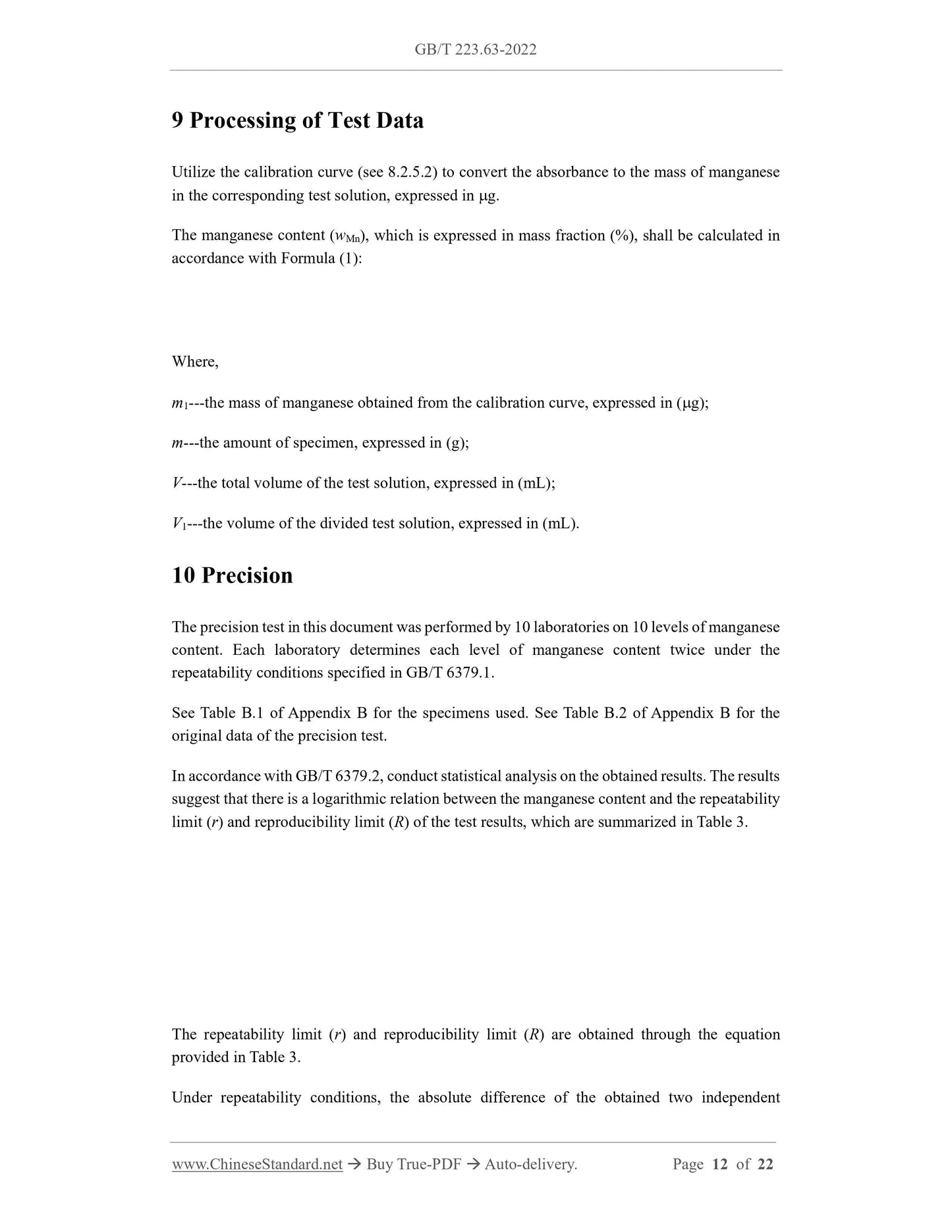

9 Processing of Test Data ... 12

10 Precision ... 12

11 Test Report ... 13

Appendix A (informative) Constituent Documents of GB/T 223 ... 14

Appendix B (informative) Relevant Information of Precision Test ... 20

Iron, Steel and Alloy - Determination of Manganese Content

- Sodium (potassium) Periodate Spectrophotometric Method

WARNING---the personnel using this document shall have practical experience in formal

laboratory work. This document does not point out all possible safety issues. It is the user’s

responsibility to take appropriate safety and health measures and ensure the compliance

with the conditions stipulated in the relevant national laws and regulations.

1 Scope

This document specifies the method for the determination of manganese content in iron, steel

and alloy by the sodium (potassium) periodate spectrophotometric method.

This document is applicable to the determination of manganese content in iron, steel, high-

temperature alloy and precision alloy. The range of determination is: 0.001% ~ 4.00%.

2 Normative References

The contents of the following documents constitute indispensable clauses of this document

through the normative references in the text. In terms of references with a specified date, only

versions with a specified date are applicable to this document. In terms of references without a

specified date, the latest version (including all the modifications) is applicable to this document.

GB/T 6379.1 Accuracy (trueness and precision) of Measurement Methods and Results - Part 1:

General Principles and Definitions

GB/T 6379.2 Accuracy (trueness and precision) of Measurement Methods and Results - Part 2:

Basic Method for the Determination of Repeatability and Reproducibility of a Standard

Measurement Method

GB/T 7729 Chemical Analysis of Metallurgical Products - General Rule for Spectrophotometric

Methods

GB/T 12805 Laboratory Glassware - Burettes

GB/T 12806 Laboratory Glassware - One-mark Volumetric Flasks

GB/T 12808 Laboratory Glassware - One-mark Pipettes

GB/T 20066 Sample and Iron - Sampling and Preparation of Samples for the Determination of

Chemical Composition

3 Terms and Definitions

This document does not have terms or definitions that need to be defined.

4 Principle

After the specimen is dissolved in acid, in sulfuric acid and phosphoric acid medium, use

sodium (potassium) periodate to oxidize manganese to heptavalent; at a wavelength of 530 nm,

use a spectrophotometer to measure the absorbance.

5 Reagents or Materials

Unless it is otherwise specified, only reagents confirmed to be analytically pure, as well as

distilled water or deionized water (or water of equivalent purity) are used in the analysis.

5.1 Hydrofluoric Acid

ρ is about 1.15 g/mL.

5.2 Hydrochloric Acid

ρ is about 1.19 g/mL.

5.3 Nitric Acid

ρ is about 1.42 g/mL.

5.4 Nitric Acid, 1 + 4

Dilute with nitric acid (5.3).

5.5 Sulfuric Acid, 1 + 1

Dilute with sulfuric acid with ρ about 1.84 g/mL.

5.6 Perchloric Acid, 1 + 499

Dilute with perchloric acid with ρ about 1.67 g/mL.

5.7 Phosphoric Acid - Perchloric Acid Mixed Acid

Mix three portions of phosphoric acid (ρ about 1.69 g/mL) and one portion of perchloric acid

(ρ about 1.67 g/mL).

5.8 Sodium (potassium) Periodate Solution, 50 g/L

Weigh-take 5 g of sodium periodate or potassium periodate and place in a 250 mL beaker; add

60 mL of water and 20 mL of nitric acid (see 5.3), warm to dissolve it, then, cool it. Use water

to dilute to 100 mL and mix it well.

5.9 Sodium Nitrite Solution, 10 g/L

Weigh-take 1 g of sodium nitrite, place in a 250 mL beaker, add 60 mL of water to dissolve it,

then, use water to dilute to 100 mL and mix it well.

5.10 Manganese Standard Solution

5.10.1 Manganese standard solution, 500 g/mL

Weigh-take 1.4383 g of potassium permanganate (mass fraction not less than 99.9%) and place

in a 600 mL beaker; add 300 mL of water to dissolve it, add 10 mL of sulfuric acid (see 5.5)

and dropwise add hydrogen peroxide (ρ about 1.10 g/mL), until the red color just disappears;

heat to boil for 5 min ~ 10 min, then, cool it. Transfer it to a 1,000 mL volumetric flask; use

water to dilute to the mark and mix it well.

Alternatively, weigh-take 0.5000 g of electrolytic manganese (mass fraction not less than 99.9%)

[electrolytic manganese needs to be cleaned in sulfuric acid (5 + 95) in advance, and after

manganese oxide on the surface is cleaned, take it out, immediately use distilled water to

repeatedly wash it, then, wash it in absolute ethanol for 4 ~ 5 times, take it out and dry it in a

desiccator before use] and place in a 250 mL beaker; add 20 mL of nitric acid (1 + 3), heat to

dissolve it and boil to drive out nitrogen oxides; remove and cool it to room temperature. Then,

transfer to a 1,000 mL volumetric flask, use water to dilute to the mark and mix it well.

1 mL of this standard solution contains 500 g of manganese.

5.10.2 Manganese standard solution, 100 g/mL

Weigh-take 20.0 mL of manganese standard solution (see 5.10.1) and place in a 100 mL

volumetric flask; use water to dilute to the mark and mix it well.

1 mL of this standard solution contains 100 g of manganese.

5.10.3 Manganese standard solution, 20 g/mL

Weigh-take 20.0 mL of manganese standard solution (see 5.10.2) and place in a 100 mL

volumetric flask; use water to dilute to the mark and mix it well.

1 mL of this standard solution contains 20 g of manganese.

5.11 Water without Reducing Substances

Heat distilled water or deionized water to boil, use 10 mL of sulfuric acid (1 + 3) to acidify each

liter; add a few granules of sodium (potassium) periodate and continue to boil for 1 min ~ 2

min, cool it before use.

reaction stops. Add 1 mL ~ 2 mL of hydrochloric acid (see 5.2), and continue heating,

until it is completely decomposed.

---For high-nickel-chromium specimens, add 10 mL of (3 + 1), (6 + 1) or (10 + 1) mixed

acid of hydrochloric acid (see 5.2) and nitric acid (see 5.3), heat at low temperature to

dissolve it.

NOTE: when the amount of specimen is 2 g, depending on the situation, the amount of acid can be

increased, so that the specimen can be completely dissolved.

Add 10 mL of phosphoric acid - perchloric acid mixed acid (see 5.7) [when the amount of

specimen is 2.0 g, add 15 mL of phosphoric acid - perchloric acid mixed acid (see 5.7); when

using 15 mL of phosphoric acid - perchloric acid mixed acid (see 5.7) to dissolve high-tungsten

specimens, it is not necessary to add], heat and evaporate it, until perchloric acid fumes are

emitted for 2 min ~ 5 min (for specimens with high chromium content, the chromium needs to

be oxidized); slightly c...

Get QUOTATION in 1-minute: Click GB/T 223.63-2022

Historical versions: GB/T 223.63-2022

Preview True-PDF (Reload/Scroll if blank)

GB/T 223.63-2022: Iron, steel and alloy - Determination of manganese content - Sodium (potassium) periodate spectrophotometric method

GB/T 223.63-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.080.01

CCS H 11

Replacing GB/T 223.63-1988

Iron, Steel and Alloy - Determination of Manganese Content

- Sodium (potassium) Periodate Spectrophotometric Method

(ISO 629:1982, Steel and Cast Iron - Determination of Manganese Content -

Spectrophotometric Method, NEQ)

ISSUED ON: JULY 11, 2022

IMPLEMENTED ON: FEBRUARY 1, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative References ... 6

3 Terms and Definitions ... 7

4 Principle ... 7

5 Reagents or Materials ... 7

6 Instruments and Equipment ... 9

7 Sample ... 9

8 Test Procedures ... 9

9 Processing of Test Data ... 12

10 Precision ... 12

11 Test Report ... 13

Appendix A (informative) Constituent Documents of GB/T 223 ... 14

Appendix B (informative) Relevant Information of Precision Test ... 20

Iron, Steel and Alloy - Determination of Manganese Content

- Sodium (potassium) Periodate Spectrophotometric Method

WARNING---the personnel using this document shall have practical experience in formal

laboratory work. This document does not point out all possible safety issues. It is the user’s

responsibility to take appropriate safety and health measures and ensure the compliance

with the conditions stipulated in the relevant national laws and regulations.

1 Scope

This document specifies the method for the determination of manganese content in iron, steel

and alloy by the sodium (potassium) periodate spectrophotometric method.

This document is applicable to the determination of manganese content in iron, steel, high-

temperature alloy and precision alloy. The range of determination is: 0.001% ~ 4.00%.

2 Normative References

The contents of the following documents constitute indispensable clauses of this document

through the normative references in the text. In terms of references with a specified date, only

versions with a specified date are applicable to this document. In terms of references without a

specified date, the latest version (including all the modifications) is applicable to this document.

GB/T 6379.1 Accuracy (trueness and precision) of Measurement Methods and Results - Part 1:

General Principles and Definitions

GB/T 6379.2 Accuracy (trueness and precision) of Measurement Methods and Results - Part 2:

Basic Method for the Determination of Repeatability and Reproducibility of a Standard

Measurement Method

GB/T 7729 Chemical Analysis of Metallurgical Products - General Rule for Spectrophotometric

Methods

GB/T 12805 Laboratory Glassware - Burettes

GB/T 12806 Laboratory Glassware - One-mark Volumetric Flasks

GB/T 12808 Laboratory Glassware - One-mark Pipettes

GB/T 20066 Sample and Iron - Sampling and Preparation of Samples for the Determination of

Chemical Composition

3 Terms and Definitions

This document does not have terms or definitions that need to be defined.

4 Principle

After the specimen is dissolved in acid, in sulfuric acid and phosphoric acid medium, use

sodium (potassium) periodate to oxidize manganese to heptavalent; at a wavelength of 530 nm,

use a spectrophotometer to measure the absorbance.

5 Reagents or Materials

Unless it is otherwise specified, only reagents confirmed to be analytically pure, as well as

distilled water or deionized water (or water of equivalent purity) are used in the analysis.

5.1 Hydrofluoric Acid

ρ is about 1.15 g/mL.

5.2 Hydrochloric Acid

ρ is about 1.19 g/mL.

5.3 Nitric Acid

ρ is about 1.42 g/mL.

5.4 Nitric Acid, 1 + 4

Dilute with nitric acid (5.3).

5.5 Sulfuric Acid, 1 + 1

Dilute with sulfuric acid with ρ about 1.84 g/mL.

5.6 Perchloric Acid, 1 + 499

Dilute with perchloric acid with ρ about 1.67 g/mL.

5.7 Phosphoric Acid - Perchloric Acid Mixed Acid

Mix three portions of phosphoric acid (ρ about 1.69 g/mL) and one portion of perchloric acid

(ρ about 1.67 g/mL).

5.8 Sodium (potassium) Periodate Solution, 50 g/L

Weigh-take 5 g of sodium periodate or potassium periodate and place in a 250 mL beaker; add

60 mL of water and 20 mL of nitric acid (see 5.3), warm to dissolve it, then, cool it. Use water

to dilute to 100 mL and mix it well.

5.9 Sodium Nitrite Solution, 10 g/L

Weigh-take 1 g of sodium nitrite, place in a 250 mL beaker, add 60 mL of water to dissolve it,

then, use water to dilute to 100 mL and mix it well.

5.10 Manganese Standard Solution

5.10.1 Manganese standard solution, 500 g/mL

Weigh-take 1.4383 g of potassium permanganate (mass fraction not less than 99.9%) and place

in a 600 mL beaker; add 300 mL of water to dissolve it, add 10 mL of sulfuric acid (see 5.5)

and dropwise add hydrogen peroxide (ρ about 1.10 g/mL), until the red color just disappears;

heat to boil for 5 min ~ 10 min, then, cool it. Transfer it to a 1,000 mL volumetric flask; use

water to dilute to the mark and mix it well.

Alternatively, weigh-take 0.5000 g of electrolytic manganese (mass fraction not less than 99.9%)

[electrolytic manganese needs to be cleaned in sulfuric acid (5 + 95) in advance, and after

manganese oxide on the surface is cleaned, take it out, immediately use distilled water to

repeatedly wash it, then, wash it in absolute ethanol for 4 ~ 5 times, take it out and dry it in a

desiccator before use] and place in a 250 mL beaker; add 20 mL of nitric acid (1 + 3), heat to

dissolve it and boil to drive out nitrogen oxides; remove and cool it to room temperature. Then,

transfer to a 1,000 mL volumetric flask, use water to dilute to the mark and mix it well.

1 mL of this standard solution contains 500 g of manganese.

5.10.2 Manganese standard solution, 100 g/mL

Weigh-take 20.0 mL of manganese standard solution (see 5.10.1) and place in a 100 mL

volumetric flask; use water to dilute to the mark and mix it well.

1 mL of this standard solution contains 100 g of manganese.

5.10.3 Manganese standard solution, 20 g/mL

Weigh-take 20.0 mL of manganese standard solution (see 5.10.2) and place in a 100 mL

volumetric flask; use water to dilute to the mark and mix it well.

1 mL of this standard solution contains 20 g of manganese.

5.11 Water without Reducing Substances

Heat distilled water or deionized water to boil, use 10 mL of sulfuric acid (1 + 3) to acidify each

liter; add a few granules of sodium (potassium) periodate and continue to boil for 1 min ~ 2

min, cool it before use.

reaction stops. Add 1 mL ~ 2 mL of hydrochloric acid (see 5.2), and continue heating,

until it is completely decomposed.

---For high-nickel-chromium specimens, add 10 mL of (3 + 1), (6 + 1) or (10 + 1) mixed

acid of hydrochloric acid (see 5.2) and nitric acid (see 5.3), heat at low temperature to

dissolve it.

NOTE: when the amount of specimen is 2 g, depending on the situation, the amount of acid can be

increased, so that the specimen can be completely dissolved.

Add 10 mL of phosphoric acid - perchloric acid mixed acid (see 5.7) [when the amount of

specimen is 2.0 g, add 15 mL of phosphoric acid - perchloric acid mixed acid (see 5.7); when

using 15 mL of phosphoric acid - perchloric acid mixed acid (see 5.7) to dissolve high-tungsten

specimens, it is not necessary to add], heat and evaporate it, until perchloric acid fumes are

emitted for 2 min ~ 5 min (for specimens with high chromium content, the chromium needs to

be oxidized); slightly c...

Share