1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 22799-2019 English PDF (GBT22799-2019)

GB/T 22799-2019 English PDF (GBT22799-2019)

Regular price

$130.00 USD

Regular price

Sale price

$130.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 22799-2019

Historical versions: GB/T 22799-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 22799-2019: Test method for absorption of towel products

GB/T 22799-2019

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 97.160

W 55

Replacing GB/T 22799-2009

Test method for absorption of towel products

ISSUED ON: DECEMBER 31, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Principle ... 4

4 Test conditions ... 4

5 Reagents or materials ... 5

6 Apparatus ... 5

7 Sample ... 6

8 Test procedures ... 7

9 Test data processing ... 9

10 Test report ... 9

Appendix A (Informative) Installation drawing of test apparatus for method B 11

Test method for absorption of towel products

1 Scope

This Standard specifies the test method for absorption of towel products.

This Standard applies to all kinds of towel products using textile fibers as raw

materials.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 6529 Textiles - Standard atmospheres for conditioning and testing

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 8629-2017 Textiles - Domestic washing and drying procedures for

textile testing

3 Principle

3.1 Method A - Sedimentation method: After the sample is washed, dried and

conditioned, under a standard state, measure the time required for the sample

from contact with the water surface to completely wetted and begin to sink, to

determine the absorption of the sample.

3.2 Method B - Absorption method: After the sample is washed, dried and

conditioned, under a standard state, a certain amount of water flows through

the sample within a specified time. Determine the percentage of the amount of

water absorbed by the sample to the amount of original water as the water

absorption rate of towel.

4 Test conditions

4.1 The environmental conditions for conditioning shall meet the requirements

of standard atmospheres of GB/T 6529.

4.2 If pre-conditioning is required, it shall be carried out under atmospheric

conditions with a relative humidity of 10%~25% and a temperature not

exceeding 50 °C.

5 Reagents or materials

5.1 Accompanying laundry: USE type III (100% polyester fiber accompanying

laundry) specified in GB/T 8629-2017.

5.2 Detergent: USE standard detergent 3 (ECE standard detergent 98)

specified in GB/T 8629-2017.

6 Apparatus

6.1 Fully-automatic washing machine: Type A standard washing machine (see

5.1.1 in GB/T 8629-2017); front door charging; horizontal rolling type.

Note: Other apparatus, which have been proven to give the same test results, can also be

used.

6.2 Rotary tumble dryer: Tumble dryer used with type A standard washing

machine (see 5.2 in GB/T 8629-2017).

Note: Other dryers, which have been proven to give the same test results, can also be

used.

6.3 Water flow tester: Funnels, valves, devices, pipelines and measuring

cylinders installed on the water flow tester shall not obstruct the flowing out of

water. The time difference from opening the valve to the water flowing out shall

be less than 8.0 s.

The composition of the water flow tester is shown in Figure 1, including the

following components:

a) Waterproof base: See Appendix A for dimensions and specifications;

b) Waterproof circular retainer ring: The inner ring outer diameter is

(150±2)mm;

c) Measuring cylinder: Organic glass material; 50 mL; see E in Figure 1;

d) Funnel: Polypropylene material; the inner diameter of the neck is

(9.0±2.0)mm.

6.4 Beaker: Capacity is 1000 mL.

ADD (20±1)g of standard detergent (5.2); WASH according to the procedures

specified in Clause 9 of GB/T 8629-2017.

7.3 After washing, immediately put the sample and the accompanying laundry

into the dryer; SET the drying temperature to (66±5)°C and dry the sample.

7.4 After the sample is dried, take it out immediately; SHAKE it gently to remove

the lint; PICK up the lint and thread residue entangled on the towel. Expose the

sample to the standard atmosphere for textile conditioning (see 4.2), until it

reaches a constant weight (weigh continuously at 2 h intervals; when the mass

change is not greater than 0.25%, it is considered to have reached a constant

weight).

8 Test procedures

8.1 Method A - Sedimentation method

8.1.1 Along the diagonal direction of the sample (see Clause 7), respectively

cut out test specimens with a size of 5 cm×5 cm; 1 group on the front and back

respectively; each group shall include at least 3 test specimens. When sampling,

it shall avoid decorative parts such as satin or embroidery.

8.1.2 USE a measuring cylinder (6.7) to take 800 mL of grade 3 water or

deionized water. The water temperature is (20±2)°C. The water level is not less

than 5 cm.

8.1.3 PLACE the test surface of the test specimen on the water surface in

parallel and lightly without external force; START timing at the same time. When

the sample is completely wetted and begins to sink, stop the timing and record

the required time t, accurate to 0.1 s. If the sample is not completely wetted for

more than 90 s, the test is terminated; the time required is recorded as greater

than 90 s.

8.1.4 REPEAT the test according to 8.1.3. TEST 3 test specimens for the front

and back respectively.

8.1.5 Calculate the measured average value of the front and back test

specimens. According to GB/T 8170, round to one decimal place.

8.1.6 If 1 of the 6 test specimens exceeds 90 s, add 1 test specimen for this

test surface. If the added test specimen does not exceed 90 s, calculate the

average value of the 6 test specimens that do not exceed 90 s; and, indicate

that 1 test specimen is greater than 90 s. If the added test specimen exceeds

90 s, the test is ended; the result is recorded as greater than 90 s.

8.2.7 REPEAT the steps 8.2.2~8.2.6 for the remaining 5 test specimens.

9 Test data processing

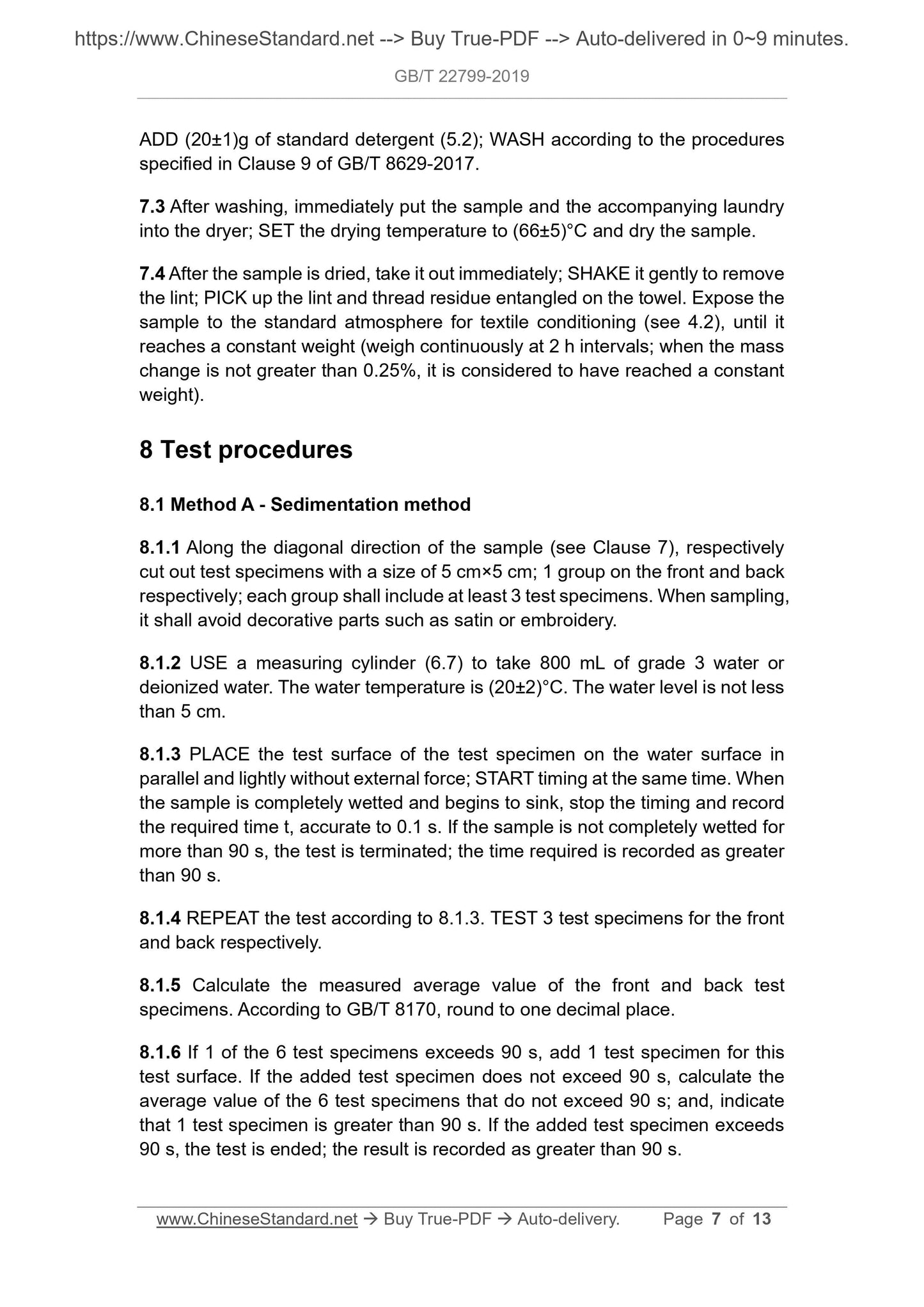

9.1 Method A - Sedimentation method

According to formula (1), calculate the average value of the water absorption

time of sample; ROUND to one decimal place according to GB/T 8170.

Where:

𝑡̅ - The average water absorption time of sample, in seconds (s);

ti - The water absorption time of each test specimen, in seconds (s);

i - The number of test specimens, in pieces.

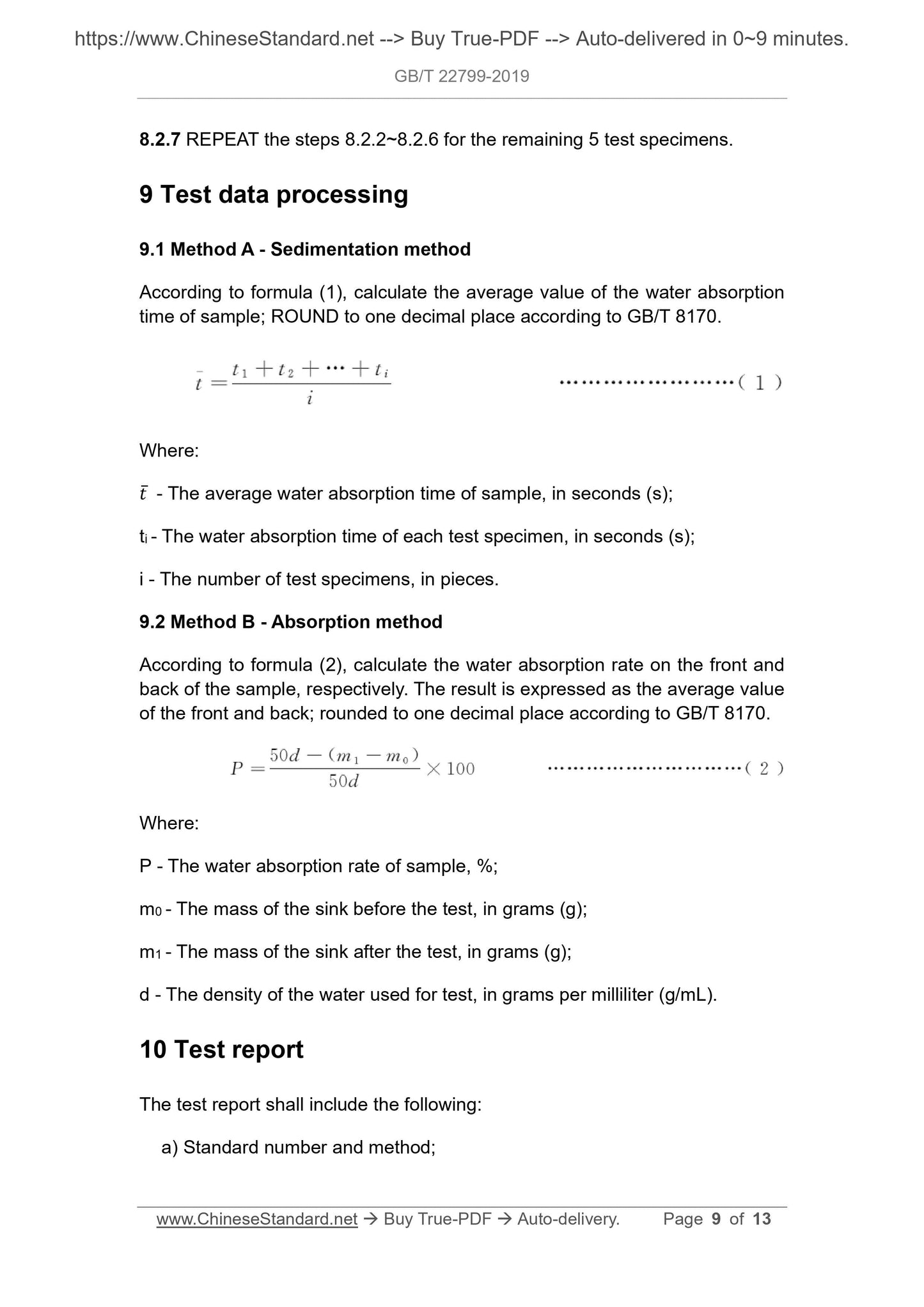

9.2 Method B - Absorption method

According to formula (2), calculate the water absorption rate on the front and

back of the sample, respectively. The result is expressed as the average value

of the front and back; rounded to one decimal place according to GB/T 8170.

Where:

P - The water absorption rate of sample, %;

m0 - The mass of the sink before the test, in grams (g);

m1 - The mass of the sink after the test, in grams (g);

d - The density of the water used for test, in grams per milliliter (g/mL).

10 Test report

The test report shall include the following:

a) Standard number and method;

Get QUOTATION in 1-minute: Click GB/T 22799-2019

Historical versions: GB/T 22799-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 22799-2019: Test method for absorption of towel products

GB/T 22799-2019

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 97.160

W 55

Replacing GB/T 22799-2009

Test method for absorption of towel products

ISSUED ON: DECEMBER 31, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Principle ... 4

4 Test conditions ... 4

5 Reagents or materials ... 5

6 Apparatus ... 5

7 Sample ... 6

8 Test procedures ... 7

9 Test data processing ... 9

10 Test report ... 9

Appendix A (Informative) Installation drawing of test apparatus for method B 11

Test method for absorption of towel products

1 Scope

This Standard specifies the test method for absorption of towel products.

This Standard applies to all kinds of towel products using textile fibers as raw

materials.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 6529 Textiles - Standard atmospheres for conditioning and testing

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 8629-2017 Textiles - Domestic washing and drying procedures for

textile testing

3 Principle

3.1 Method A - Sedimentation method: After the sample is washed, dried and

conditioned, under a standard state, measure the time required for the sample

from contact with the water surface to completely wetted and begin to sink, to

determine the absorption of the sample.

3.2 Method B - Absorption method: After the sample is washed, dried and

conditioned, under a standard state, a certain amount of water flows through

the sample within a specified time. Determine the percentage of the amount of

water absorbed by the sample to the amount of original water as the water

absorption rate of towel.

4 Test conditions

4.1 The environmental conditions for conditioning shall meet the requirements

of standard atmospheres of GB/T 6529.

4.2 If pre-conditioning is required, it shall be carried out under atmospheric

conditions with a relative humidity of 10%~25% and a temperature not

exceeding 50 °C.

5 Reagents or materials

5.1 Accompanying laundry: USE type III (100% polyester fiber accompanying

laundry) specified in GB/T 8629-2017.

5.2 Detergent: USE standard detergent 3 (ECE standard detergent 98)

specified in GB/T 8629-2017.

6 Apparatus

6.1 Fully-automatic washing machine: Type A standard washing machine (see

5.1.1 in GB/T 8629-2017); front door charging; horizontal rolling type.

Note: Other apparatus, which have been proven to give the same test results, can also be

used.

6.2 Rotary tumble dryer: Tumble dryer used with type A standard washing

machine (see 5.2 in GB/T 8629-2017).

Note: Other dryers, which have been proven to give the same test results, can also be

used.

6.3 Water flow tester: Funnels, valves, devices, pipelines and measuring

cylinders installed on the water flow tester shall not obstruct the flowing out of

water. The time difference from opening the valve to the water flowing out shall

be less than 8.0 s.

The composition of the water flow tester is shown in Figure 1, including the

following components:

a) Waterproof base: See Appendix A for dimensions and specifications;

b) Waterproof circular retainer ring: The inner ring outer diameter is

(150±2)mm;

c) Measuring cylinder: Organic glass material; 50 mL; see E in Figure 1;

d) Funnel: Polypropylene material; the inner diameter of the neck is

(9.0±2.0)mm.

6.4 Beaker: Capacity is 1000 mL.

ADD (20±1)g of standard detergent (5.2); WASH according to the procedures

specified in Clause 9 of GB/T 8629-2017.

7.3 After washing, immediately put the sample and the accompanying laundry

into the dryer; SET the drying temperature to (66±5)°C and dry the sample.

7.4 After the sample is dried, take it out immediately; SHAKE it gently to remove

the lint; PICK up the lint and thread residue entangled on the towel. Expose the

sample to the standard atmosphere for textile conditioning (see 4.2), until it

reaches a constant weight (weigh continuously at 2 h intervals; when the mass

change is not greater than 0.25%, it is considered to have reached a constant

weight).

8 Test procedures

8.1 Method A - Sedimentation method

8.1.1 Along the diagonal direction of the sample (see Clause 7), respectively

cut out test specimens with a size of 5 cm×5 cm; 1 group on the front and back

respectively; each group shall include at least 3 test specimens. When sampling,

it shall avoid decorative parts such as satin or embroidery.

8.1.2 USE a measuring cylinder (6.7) to take 800 mL of grade 3 water or

deionized water. The water temperature is (20±2)°C. The water level is not less

than 5 cm.

8.1.3 PLACE the test surface of the test specimen on the water surface in

parallel and lightly without external force; START timing at the same time. When

the sample is completely wetted and begins to sink, stop the timing and record

the required time t, accurate to 0.1 s. If the sample is not completely wetted for

more than 90 s, the test is terminated; the time required is recorded as greater

than 90 s.

8.1.4 REPEAT the test according to 8.1.3. TEST 3 test specimens for the front

and back respectively.

8.1.5 Calculate the measured average value of the front and back test

specimens. According to GB/T 8170, round to one decimal place.

8.1.6 If 1 of the 6 test specimens exceeds 90 s, add 1 test specimen for this

test surface. If the added test specimen does not exceed 90 s, calculate the

average value of the 6 test specimens that do not exceed 90 s; and, indicate

that 1 test specimen is greater than 90 s. If the added test specimen exceeds

90 s, the test is ended; the result is recorded as greater than 90 s.

8.2.7 REPEAT the steps 8.2.2~8.2.6 for the remaining 5 test specimens.

9 Test data processing

9.1 Method A - Sedimentation method

According to formula (1), calculate the average value of the water absorption

time of sample; ROUND to one decimal place according to GB/T 8170.

Where:

𝑡̅ - The average water absorption time of sample, in seconds (s);

ti - The water absorption time of each test specimen, in seconds (s);

i - The number of test specimens, in pieces.

9.2 Method B - Absorption method

According to formula (2), calculate the water absorption rate on the front and

back of the sample, respectively. The result is expressed as the average value

of the front and back; rounded to one decimal place according to GB/T 8170.

Where:

P - The water absorption rate of sample, %;

m0 - The mass of the sink before the test, in grams (g);

m1 - The mass of the sink after the test, in grams (g);

d - The density of the water used for test, in grams per milliliter (g/mL).

10 Test report

The test report shall include the following:

a) Standard number and method;

Share