1

/

of

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 23986-2009 English PDF (GBT23986-2009)

GB/T 23986-2009 English PDF (GBT23986-2009)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click GB/T 23986-2009 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 23986-2009

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 23986-2009: Paints and varnishes -- Determination of volatile organic compound (VOC) content -- Gas-chromatographic method

GB/T 23986-2009

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 87.040

G 58

GB/T 23986-2009 / ISO 11890-2.2006

Paints and Varnishes - Determination of Volatile

Organic Compound (VOC) Content - Gas-

chromatographic Method

色漆和清漆 挥发性有机化合物(VOC)含量的测定

气相色谱法

(ISO 1890-2.2006, Paints and varnishes - Determination of volatile organic compound

(VOC) content - Part 2. Gas-chromatographic method, IDT)

ISSUED ON. JUNE 02, 2009

IMPLEMENTED ON. FEB 1, 2010

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Principle ... 6

5 Required supplementary information ... 6

6 Apparatus ... 6

7 Reagents ... 9

8 Sampling ... 10

9 Procedure ... 10

10 Calculation ... 13

11 Expression of results... 14

12 Precision ... 14

13 Test report ... 15

Annex A (Normative) Required supplementary information ... 17

Annex B (Informative) Examples of gas-chromatographic conditions ... 18

Bibliography ... 21

Foreword

This Standard is identical with the international standard ISO 11890-2.2006 “Paints

and Varnishes - Determination of Volatile Organic Compound (VOC) - Part 2. Gas

chromatographic” (English Version).

This Standard is equivalent to translate ISO 11890-2.2006.

For ease of use, the editorial modified contents of this Standard are as follows.

--- Use “this Standard” to replace “this international standard”;

--- Delete the foreword of the international standard;

--- For the international standards that are quoted by ISO 11890-2.2006, if those

have been equivalently adopted by the corresponding Chinese standards, then

use the corresponding Chinese standards to replace; if those are not equivalently

adopted by Chinese standards, then directly quote those international standards;

--- Delete the Part 2 of the international standard;

--- Because, currently in domestic market, the majority of determination of water

content in paint adopts gas chromatography, therefore, ADD content note 3 in

9.2.

In this Standard, Appendix A is normative, Appendix B is informative.

This Standard was proposed by China Petroleum and Chemical Industry Association.

This Standard shall be under the jurisdiction of National Standardization Technical

Committee of Paint and Color Industry.

Drafting organizations of this Standard. CNOOC Changzhou Painting Chemical

Research Institute, Kunshan Shiming Technology Development Co., Ltd.

Chief drafting staffs of this Standard. Ji Junhong, Huang Ning, Du Changsen.

Paints and Varnishes - Determination of Volatile

Organic Compound (VOC) Content - Gas-

chromatographic Method

1 Scope

This Standard is one of a series of standards dealing with the sampling and testing of

paints, varnishes and related products.

It specifies a method for the determination of the volatile organic compound (VOC)

content of paints, varnishes and their raw materials. It is preferred if the expected VOC

content is greater than 0.1% (mass fraction) and less than about 15% (mass fraction).

When the VOC content is greater than about 15% by mass, the less complicated

method given in GB/T 23985 may be used.

This method assumes that the volatile matter is either water or organic. However, other

volatile inorganic compounds can be present and might need to be quantified by

another suitable method and allowed for in the calculations.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 3186 Paint, Varnishes and raw materials for paint and varnish - Sampling

(GB/T 3186-2006, ISO 15528.2000, IDT)

GB/T 6283 Determination of water content of industrial products - Karl Fischer

method (General method) [GB/T 6283-1986, eqv ISO 760.1978, Determination of

water - Karl Fischer Method (General Method)]

GB/T 6750 Paints and varnish - Density determination - Pycnometer method

(GB/T 6750-2007, ISO 2811-1, 1997, Paints and varnishes - Determination of

density - Part 1. Pycnometer method, IDT)

GB/T 20777 Paints and varnishes - Examination and preparation of samples for

testing (GB/T 20777-2006, ISO 1513.1992, IDT)

GB/T 21862.2 Paints and varnishes - Determination of density - Part 2. Immersed

body (plummet) method (GB/T 21862. 2-2008. ISO 2811- 2.1997, IDT)

GB/T 21862.3 Paints and varnishes - Determination of density - Part 3. Oscillation

method (GB/T 21862.3-2008, ISO 2811-3.1977, IDT)

GB/T 21862.4 Paints and varnishes - Determination of density - Part 4. Pressure

cup method (GB/T 21862.4-008, ISO 2811-4.1997, IDT)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Volatile organic compound (VOC)

Any organic liquid and/or solid that evaporates spontaneously at the prevailing

temperature and pressure of the atmosphere with which it is in contact.

NOTE 1. As to current usage of the term VOC in the field of coating materials, see

volatile organic compound content (VOC content).

NOTE 2. Under U.S. government legislation, the term VOC is restricted solely to

those compounds that are photochemically active in the atmosphere (see ASTM D

3960). Any other compound is then defined as being an exempt compound.

[ISO 4618.2006]

NOTE 3. Under European legislation, EU Directive 2004/42/EC, the term VOC refers

to volatile organic compounds with boiling points up to 250°C, measured at a standard

pressure of 101.3 kPa.

3.2 Volatile organic compound content (VOC content)

Mass of the volatile organic compounds present in a coating material, as determined

under specified conditions.

NOTE 1. The properties and the amounts of the compounds to be taken into account

will depend on the field of application of the coating material. For each field of

application, the limiting values and the methods of determination or calculation are

stipulated by regulations or by agreement.

[ISO 4618.2006]

NOTE 2. If the term VOC refers to compounds with a defined maximum boiling point

(see Note 3 to 3.1), the compounds considered to be part of the VOC content are those

with boiling points below that limit and compounds with higher boiling points are

considered to be non-volatile organic compounds.

The instrument shall have a variable-temperature injection block with a sample splitter.

The injection temperature shall be capable of being set to an accuracy of 1 °C. The

split ratio shall be adjustable and capable of being monitored. The sample splitter insert

shall contain silanized glass wool to retain non-volatile constituents, and shall be

cleaned and provided with new glass wool packing or replaced as required to rule out

errors due to residues of binder or pigment (i.e. adsorption of compounds). The

occurrence of adsorption is revealed by peak tailing, in particular with components of

low volatility.

6.2.3 Cold-injection system with sample splitter

The cold-injection system shall be provided with temperature programming for heating

from ambient to 300°C and shall have a sample splitter inlet which is made of an inert

material such as glass. The sample splitter shall be provided with silanized glass wool

packing and shall be maintained as specified in 6.2.2. The split ratio shall be adjustable

and capable of being monitored.

Method precision will be increased if the injection system, especially the hot-injection

system, is coupled to an auto-injector. The manufacturer's instructions shall be

followed when an auto-injector is used.

6.2.4 Selection of sample injection system

The choice between hot-injection and cold-injection will depend on the type of product

under test. It will be necessary to use the cold-injection system for products which at

high temperature release substances which interfere with the determination.

Indications of cleavage or decomposition reactions may be obtained by looking for

changes in the chromatogram (for example the occurrence of foreign peaks or an

increase or decrease in peak size) at various sample injector temperatures.

The hot-injection system covers all of the volatile constituents, compounds and

cleavage products of the binders and additives. Cleavage products of the binders or

additives which are identical to a constituent of the product can be separated by a cold-

injection system, since they elute later as a result of the programmed increase in

injection block temperature.

6.3 Oven

The oven shall be capable of being heated between 40°C ~ 300°C both isothermally

and under programmed temperature control. It shall be possible to set the oven

temperature to within 1°C. The final temperature of the temperature programme shall

not exceed the maximum operating temperature of the column (see 6.5).

6.4 Detector

Any of the following three detectors may be used, as well as other detectors suitable

observe contaminants and possible interference peaks, especially in trace analysis.

NOTE. Solvents such as methanol and tetrahydrofuran have been found suitable.

7.4 Marker compound

If the term VOC is being used for compounds whose boiling points are below a defined

maximum limit (see Note 3 to 3.1), a marker compound of known purity and with a

boiling point within ± 3°C of the defined maximum limit shall be used.

EXAMPLE. If the defined maximum boiling point is 250°C, tetradecane, with a boiling

point of 252.6 °C, could be used as the marker compound for non-polar systems and

diethyl adipate, with a boiling point of 251°C, as the marker compound for polar

systems.

8 Sampling

Take a representative sample of the product to be tested (or of each product in the

case of a multi-coat system), as specified in GB/T 3186.

Examine and prepare each sample for testing as specified in GB/T 20777, preparing

the final sample for testing in the ‘ready for use’ state.

9 Procedure

9.1 Density

If required by the calculation (see 10.3 ~ 10.5), determine the density of the sample

using the part of GB/T 6750, GB/T 21862, GB/T 21862.3 and GB/T 21862, in which

will give the best precision for the type of sample concerned. Determine the density at

23 °C.

9.2 Water content

If required by the calculation (see 10.4 and 10.5), determine the water content, as a

percentage by mass, by the method given in GB/T 6283, selecting the reagents so that

there will be no interference from the compounds contained in the sample. If the

compounds are not known, then determine them qualitatively (see 9.4).

NOTE 1. Typical compounds likely to cause interference are ketones and aldehydes.

Reagent manufacturers normally publish literature for guidance on correct reagent

selection.

NOTE 2. If the product to be tested is well characterized and known not to contain

water, it may not be necessary to determine the water content, which can be assumed

capability, then the total area will have to be summed manually. The equation above

can then be used to determine the amount of solvent in the test sample.

9.7.4 Repeat the procedure.

10 Calculation

10.1 General

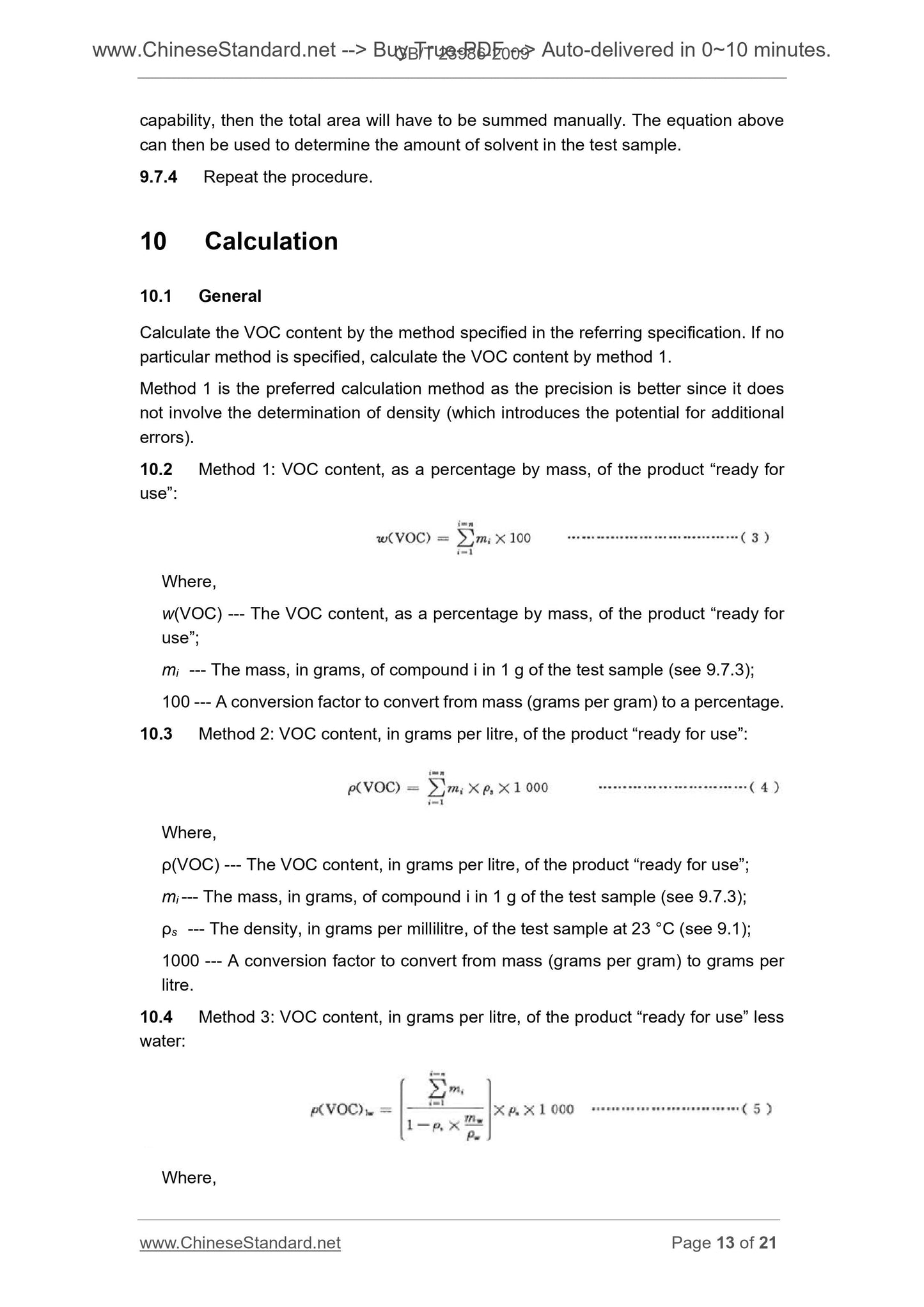

Calculate the VOC content by the method specified in the referring specification. If no

particular method is specified, calculate the VOC content by method 1.

Method 1 is the preferred calculation method as the precision is better since it does

not involve the determination of density (which introduces the potential for additional

errors).

10.2 Method 1. VOC content, as a percentage by mass, of the product “ready for

use”.

Where,

w(VOC) --- The VOC content, as a percentage by mass, of the product “ready for

use”;

mi --- The mass, in grams, of compound i in 1 g of the test sample (see 9.7.3);

100 --- A conversion factor to convert from mass (grams per gram) to a percentage.

10.3 Method 2. VOC content, in grams per litre, of the product “ready for use”.

Where,

ρ(VOC) --- The VOC content, in grams per litre, of the product “ready for use”;

mi --- The mass, in grams, of compound i in 1 g of the test sample (see 9.7.3);

ρs --- The density, in grams per millilitre, of the test sample at 23 °C (see 9.1);

1000 --- A conversion factor to convert from mass (grams per gram) to grams per

litre.

10.4 Method 3. VOC content, in grams per litre, of the product “ready for use” less

water.

Where,

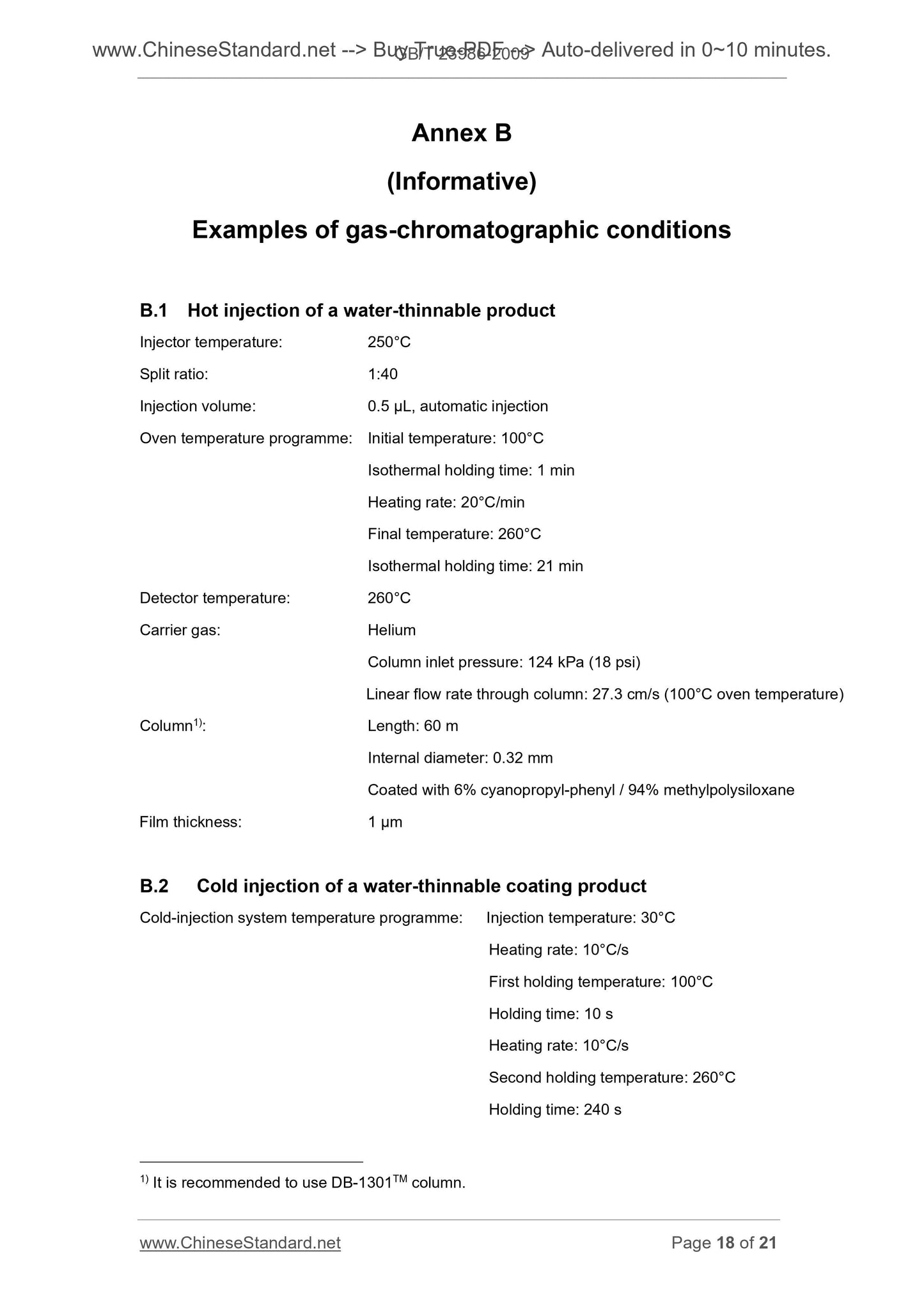

Annex B

(Informative)

Examples of gas-chromatographic conditions

B.1 Hot injection of a water-thinnable product

Injector temperature. 250°C

Split ratio. 1.40

Injection volume. 0.5 μL, automatic injection

Oven temperature programme. Initial temperature. 100°C

Isothermal holding time. 1 min

Heating rate. 20°C/min

Final temperature. 260°C

Isothermal holding time. 21 min

Detector temperature. 260°C

Carrier gas. Helium

Column inlet pressure. 124 kPa (18 psi)

Linear flow rate through column. 27.3 cm/s (100°C oven temperature)

Column1). Length. 60 m

Internal diameter. 0.32 mm

Coated with 6% cyanopropyl-phenyl / 94% methylpolysiloxane

Film thickness. 1 μm

B.2 Cold injection of a water-thinnable coating product

Cold-injection system temperature programme. Injection temperature. 30°C

Heating rate. 10°C/s

First holding temperature. 100°C

Holding time. 10 s

Heating rate. 10°C/s

Second holding temperature. 260°C

Holding time. 240 s

1) It is recommended to use DB-1301TM column.

Bibliography

[1] GB/T 23985 Paints and varnishes - Determination of v...

Get Quotation: Click GB/T 23986-2009 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 23986-2009

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 23986-2009: Paints and varnishes -- Determination of volatile organic compound (VOC) content -- Gas-chromatographic method

GB/T 23986-2009

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 87.040

G 58

GB/T 23986-2009 / ISO 11890-2.2006

Paints and Varnishes - Determination of Volatile

Organic Compound (VOC) Content - Gas-

chromatographic Method

色漆和清漆 挥发性有机化合物(VOC)含量的测定

气相色谱法

(ISO 1890-2.2006, Paints and varnishes - Determination of volatile organic compound

(VOC) content - Part 2. Gas-chromatographic method, IDT)

ISSUED ON. JUNE 02, 2009

IMPLEMENTED ON. FEB 1, 2010

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Principle ... 6

5 Required supplementary information ... 6

6 Apparatus ... 6

7 Reagents ... 9

8 Sampling ... 10

9 Procedure ... 10

10 Calculation ... 13

11 Expression of results... 14

12 Precision ... 14

13 Test report ... 15

Annex A (Normative) Required supplementary information ... 17

Annex B (Informative) Examples of gas-chromatographic conditions ... 18

Bibliography ... 21

Foreword

This Standard is identical with the international standard ISO 11890-2.2006 “Paints

and Varnishes - Determination of Volatile Organic Compound (VOC) - Part 2. Gas

chromatographic” (English Version).

This Standard is equivalent to translate ISO 11890-2.2006.

For ease of use, the editorial modified contents of this Standard are as follows.

--- Use “this Standard” to replace “this international standard”;

--- Delete the foreword of the international standard;

--- For the international standards that are quoted by ISO 11890-2.2006, if those

have been equivalently adopted by the corresponding Chinese standards, then

use the corresponding Chinese standards to replace; if those are not equivalently

adopted by Chinese standards, then directly quote those international standards;

--- Delete the Part 2 of the international standard;

--- Because, currently in domestic market, the majority of determination of water

content in paint adopts gas chromatography, therefore, ADD content note 3 in

9.2.

In this Standard, Appendix A is normative, Appendix B is informative.

This Standard was proposed by China Petroleum and Chemical Industry Association.

This Standard shall be under the jurisdiction of National Standardization Technical

Committee of Paint and Color Industry.

Drafting organizations of this Standard. CNOOC Changzhou Painting Chemical

Research Institute, Kunshan Shiming Technology Development Co., Ltd.

Chief drafting staffs of this Standard. Ji Junhong, Huang Ning, Du Changsen.

Paints and Varnishes - Determination of Volatile

Organic Compound (VOC) Content - Gas-

chromatographic Method

1 Scope

This Standard is one of a series of standards dealing with the sampling and testing of

paints, varnishes and related products.

It specifies a method for the determination of the volatile organic compound (VOC)

content of paints, varnishes and their raw materials. It is preferred if the expected VOC

content is greater than 0.1% (mass fraction) and less than about 15% (mass fraction).

When the VOC content is greater than about 15% by mass, the less complicated

method given in GB/T 23985 may be used.

This method assumes that the volatile matter is either water or organic. However, other

volatile inorganic compounds can be present and might need to be quantified by

another suitable method and allowed for in the calculations.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 3186 Paint, Varnishes and raw materials for paint and varnish - Sampling

(GB/T 3186-2006, ISO 15528.2000, IDT)

GB/T 6283 Determination of water content of industrial products - Karl Fischer

method (General method) [GB/T 6283-1986, eqv ISO 760.1978, Determination of

water - Karl Fischer Method (General Method)]

GB/T 6750 Paints and varnish - Density determination - Pycnometer method

(GB/T 6750-2007, ISO 2811-1, 1997, Paints and varnishes - Determination of

density - Part 1. Pycnometer method, IDT)

GB/T 20777 Paints and varnishes - Examination and preparation of samples for

testing (GB/T 20777-2006, ISO 1513.1992, IDT)

GB/T 21862.2 Paints and varnishes - Determination of density - Part 2. Immersed

body (plummet) method (GB/T 21862. 2-2008. ISO 2811- 2.1997, IDT)

GB/T 21862.3 Paints and varnishes - Determination of density - Part 3. Oscillation

method (GB/T 21862.3-2008, ISO 2811-3.1977, IDT)

GB/T 21862.4 Paints and varnishes - Determination of density - Part 4. Pressure

cup method (GB/T 21862.4-008, ISO 2811-4.1997, IDT)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Volatile organic compound (VOC)

Any organic liquid and/or solid that evaporates spontaneously at the prevailing

temperature and pressure of the atmosphere with which it is in contact.

NOTE 1. As to current usage of the term VOC in the field of coating materials, see

volatile organic compound content (VOC content).

NOTE 2. Under U.S. government legislation, the term VOC is restricted solely to

those compounds that are photochemically active in the atmosphere (see ASTM D

3960). Any other compound is then defined as being an exempt compound.

[ISO 4618.2006]

NOTE 3. Under European legislation, EU Directive 2004/42/EC, the term VOC refers

to volatile organic compounds with boiling points up to 250°C, measured at a standard

pressure of 101.3 kPa.

3.2 Volatile organic compound content (VOC content)

Mass of the volatile organic compounds present in a coating material, as determined

under specified conditions.

NOTE 1. The properties and the amounts of the compounds to be taken into account

will depend on the field of application of the coating material. For each field of

application, the limiting values and the methods of determination or calculation are

stipulated by regulations or by agreement.

[ISO 4618.2006]

NOTE 2. If the term VOC refers to compounds with a defined maximum boiling point

(see Note 3 to 3.1), the compounds considered to be part of the VOC content are those

with boiling points below that limit and compounds with higher boiling points are

considered to be non-volatile organic compounds.

The instrument shall have a variable-temperature injection block with a sample splitter.

The injection temperature shall be capable of being set to an accuracy of 1 °C. The

split ratio shall be adjustable and capable of being monitored. The sample splitter insert

shall contain silanized glass wool to retain non-volatile constituents, and shall be

cleaned and provided with new glass wool packing or replaced as required to rule out

errors due to residues of binder or pigment (i.e. adsorption of compounds). The

occurrence of adsorption is revealed by peak tailing, in particular with components of

low volatility.

6.2.3 Cold-injection system with sample splitter

The cold-injection system shall be provided with temperature programming for heating

from ambient to 300°C and shall have a sample splitter inlet which is made of an inert

material such as glass. The sample splitter shall be provided with silanized glass wool

packing and shall be maintained as specified in 6.2.2. The split ratio shall be adjustable

and capable of being monitored.

Method precision will be increased if the injection system, especially the hot-injection

system, is coupled to an auto-injector. The manufacturer's instructions shall be

followed when an auto-injector is used.

6.2.4 Selection of sample injection system

The choice between hot-injection and cold-injection will depend on the type of product

under test. It will be necessary to use the cold-injection system for products which at

high temperature release substances which interfere with the determination.

Indications of cleavage or decomposition reactions may be obtained by looking for

changes in the chromatogram (for example the occurrence of foreign peaks or an

increase or decrease in peak size) at various sample injector temperatures.

The hot-injection system covers all of the volatile constituents, compounds and

cleavage products of the binders and additives. Cleavage products of the binders or

additives which are identical to a constituent of the product can be separated by a cold-

injection system, since they elute later as a result of the programmed increase in

injection block temperature.

6.3 Oven

The oven shall be capable of being heated between 40°C ~ 300°C both isothermally

and under programmed temperature control. It shall be possible to set the oven

temperature to within 1°C. The final temperature of the temperature programme shall

not exceed the maximum operating temperature of the column (see 6.5).

6.4 Detector

Any of the following three detectors may be used, as well as other detectors suitable

observe contaminants and possible interference peaks, especially in trace analysis.

NOTE. Solvents such as methanol and tetrahydrofuran have been found suitable.

7.4 Marker compound

If the term VOC is being used for compounds whose boiling points are below a defined

maximum limit (see Note 3 to 3.1), a marker compound of known purity and with a

boiling point within ± 3°C of the defined maximum limit shall be used.

EXAMPLE. If the defined maximum boiling point is 250°C, tetradecane, with a boiling

point of 252.6 °C, could be used as the marker compound for non-polar systems and

diethyl adipate, with a boiling point of 251°C, as the marker compound for polar

systems.

8 Sampling

Take a representative sample of the product to be tested (or of each product in the

case of a multi-coat system), as specified in GB/T 3186.

Examine and prepare each sample for testing as specified in GB/T 20777, preparing

the final sample for testing in the ‘ready for use’ state.

9 Procedure

9.1 Density

If required by the calculation (see 10.3 ~ 10.5), determine the density of the sample

using the part of GB/T 6750, GB/T 21862, GB/T 21862.3 and GB/T 21862, in which

will give the best precision for the type of sample concerned. Determine the density at

23 °C.

9.2 Water content

If required by the calculation (see 10.4 and 10.5), determine the water content, as a

percentage by mass, by the method given in GB/T 6283, selecting the reagents so that

there will be no interference from the compounds contained in the sample. If the

compounds are not known, then determine them qualitatively (see 9.4).

NOTE 1. Typical compounds likely to cause interference are ketones and aldehydes.

Reagent manufacturers normally publish literature for guidance on correct reagent

selection.

NOTE 2. If the product to be tested is well characterized and known not to contain

water, it may not be necessary to determine the water content, which can be assumed

capability, then the total area will have to be summed manually. The equation above

can then be used to determine the amount of solvent in the test sample.

9.7.4 Repeat the procedure.

10 Calculation

10.1 General

Calculate the VOC content by the method specified in the referring specification. If no

particular method is specified, calculate the VOC content by method 1.

Method 1 is the preferred calculation method as the precision is better since it does

not involve the determination of density (which introduces the potential for additional

errors).

10.2 Method 1. VOC content, as a percentage by mass, of the product “ready for

use”.

Where,

w(VOC) --- The VOC content, as a percentage by mass, of the product “ready for

use”;

mi --- The mass, in grams, of compound i in 1 g of the test sample (see 9.7.3);

100 --- A conversion factor to convert from mass (grams per gram) to a percentage.

10.3 Method 2. VOC content, in grams per litre, of the product “ready for use”.

Where,

ρ(VOC) --- The VOC content, in grams per litre, of the product “ready for use”;

mi --- The mass, in grams, of compound i in 1 g of the test sample (see 9.7.3);

ρs --- The density, in grams per millilitre, of the test sample at 23 °C (see 9.1);

1000 --- A conversion factor to convert from mass (grams per gram) to grams per

litre.

10.4 Method 3. VOC content, in grams per litre, of the product “ready for use” less

water.

Where,

Annex B

(Informative)

Examples of gas-chromatographic conditions

B.1 Hot injection of a water-thinnable product

Injector temperature. 250°C

Split ratio. 1.40

Injection volume. 0.5 μL, automatic injection

Oven temperature programme. Initial temperature. 100°C

Isothermal holding time. 1 min

Heating rate. 20°C/min

Final temperature. 260°C

Isothermal holding time. 21 min

Detector temperature. 260°C

Carrier gas. Helium

Column inlet pressure. 124 kPa (18 psi)

Linear flow rate through column. 27.3 cm/s (100°C oven temperature)

Column1). Length. 60 m

Internal diameter. 0.32 mm

Coated with 6% cyanopropyl-phenyl / 94% methylpolysiloxane

Film thickness. 1 μm

B.2 Cold injection of a water-thinnable coating product

Cold-injection system temperature programme. Injection temperature. 30°C

Heating rate. 10°C/s

First holding temperature. 100°C

Holding time. 10 s

Heating rate. 10°C/s

Second holding temperature. 260°C

Holding time. 240 s

1) It is recommended to use DB-1301TM column.

Bibliography

[1] GB/T 23985 Paints and varnishes - Determination of v...

Share