1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 2529-2012 English PDF (GB/T2529-2012)

GB/T 2529-2012 English PDF (GB/T2529-2012)

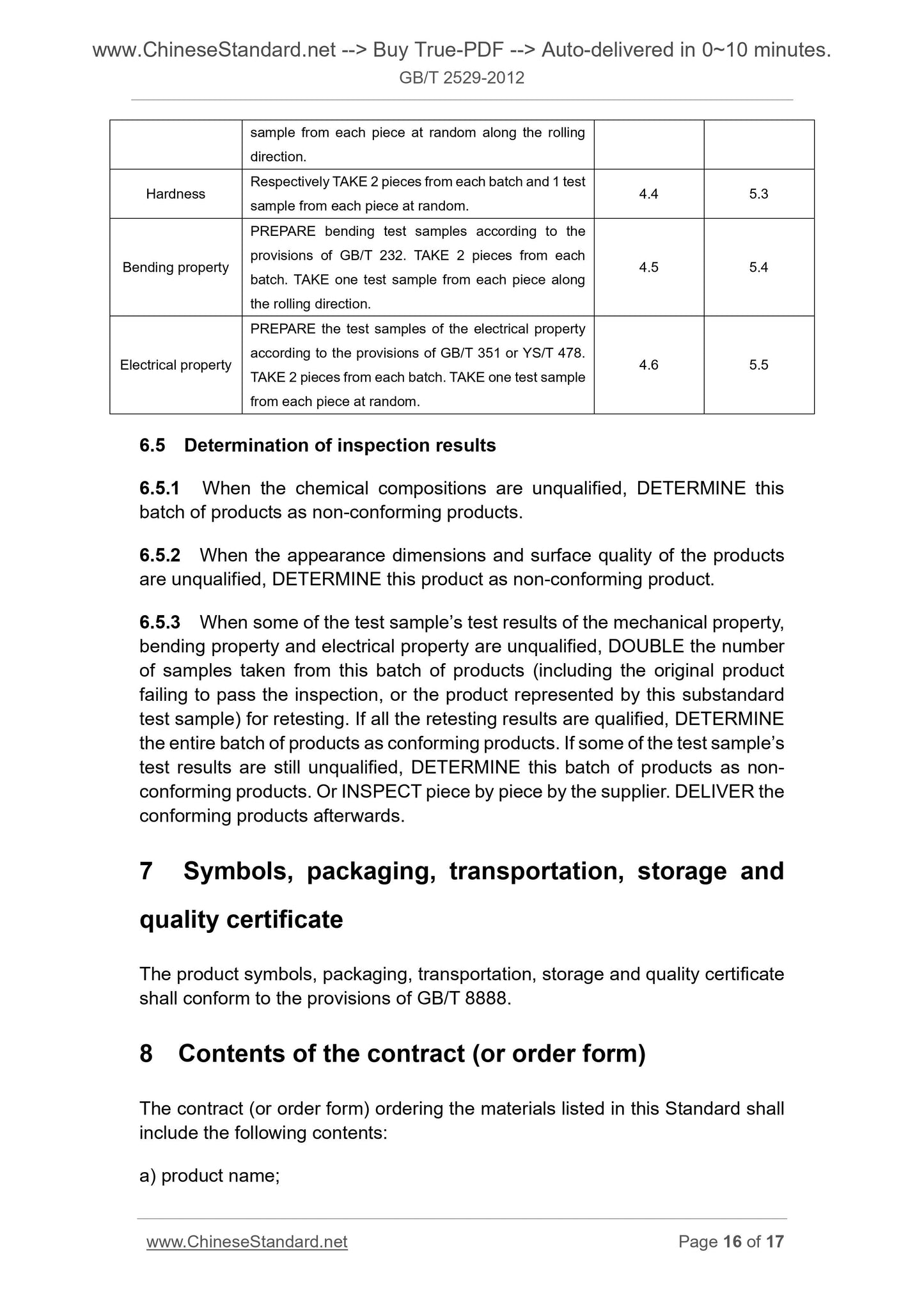

Regular price

$125.00 USD

Regular price

Sale price

$125.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 2529-2012

Historical versions: GB/T 2529-2012

Preview True-PDF (Reload/Scroll if blank)

GB/T 2529-2012: Copper sheets and bars for electrical conduction purpose

GB/T 2529-2012

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.30

H 62

Replacing GB/T 2529-2005

Copper sheets and bars for

electrical conduction purpose

ISSUED ON. DECEMBER 31, 2012

IMPLEMENTED ON. OCTOBER 1, 2013

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Term and definition ... 6

4 Requirements ... 6

5 Test methods ... 14

6 Inspection rules ... 14

7 Symbols, packaging, transportation, storage and quality certificate ... 16

8 Contents of the contract (or order form) ... 16

Foreword

This Standard is drafted according to the rules given in GB/T 1.1-2009.

The major technical specifications of the bars in this Standard reference to and

adopt the contents of the bars in ASTM B 187M-2006 Copper bars, rods and

shapes for bus bars.

This Standard replaces GB/T 2529-2005 Copper sheets and bars for electrical

conduction purpose.

Compared with GB/T 2529-2005, the major changes in this Standard are as

follows.

— ADD “TU2” and “TU3” to the alloy designations of the products.

— USE the new edition of Temper designations for copper and copper alloys

to represent the product state.

— ADD GB/T 26303.3 Measuring methods for dimensions and shapes of

wrought copper and copper alloys - Part 3. Sheets and strips, YS/T 478

The method for electrical conductivity measurement of copper and

copper alloys by use of eddy current, and YS/T 482 Methods for analysis

of copper and copper alloys - The atomic emission spectrometry to

normative references.

— DELETE “1/8 hard” from the state of the sheets and bars.

— INCREASE the maximum length of the sheets and bars from “8,000mm”

to “12,000mm”.

— DIVIDE the straightness of longitudinal edge according to the state as

required.

— ADD the requirements for rounding off to the contents of the edge

appearance.

— For the percentage elongation after fracture in the mechanical properties

of the sheets and bars, MODIFY the “long specimen A11.3” to “short

specimen A”.

— ADD the property indicators of the resistivity to the electrical property of

the sheets and bars.

— ADD the following contents. For the electrical property, USE the test

methods in YS/T 478 The method for electrical conductivity measurement

Copper sheets and bars for electrical

conduction purpose

1 Scope

This Standard specifies the requirements, test methods, inspection rules,

symbols, packaging, transportation, storage, and contents of the quality

certificate and contract (or order form) of the copper sheets and bars for

electrical conduction purpose.

This Standard is applicable to the copper sheets and bars for electrical

conduction purpose used in industrial sectors, such as smelting sector, electric

power sector, chemical sector, plating sector, etc.

2 Normative references

The following documents are essential to the application of this document. For

dated references, only the editions with the dates indicated are applicable to

this document. For undated references, only the latest editions (including all the

amendments) are applicable to this document.

GB/T 228.1-2010 Metallic materials - Tensile testing - Part 1. Method of test

at room temperature (ISO 6892-1.2009, MOD)

GB/T 230.1 Metallic materials - Rockwell hardness test - Part 1. Test method

GB/T 232 Metallic materials - Bend test

GB/T 351 Metallic materials - Resistivity measurement method

GB/T 4340.1 Metallic materials - Vickers hardness test - Part 1. Test method

(ISO 6507-1.2005, MOD)

GB/T 5121 (all Parts) Methods for chemical analysis of copper and copper

alloys

GB/T 5231 Wrought copper and copper alloys chemical composition limits

and forms of wrought products

GB/T 8888 Wrought heavy non-ferrous metal products - Packing, marking,

transporting and storing

GB/T 26303.3 Measuring methods for dimensions and shapes of wrought

copper and copper alloys - Part 3. Sheets and strips

YS/T 478 The method for electrical conductivity measurement of copper and

copper alloys by use of eddy current

YS/T 482 Methods for analysis of copper and copper alloys - The atomic

emission spectrometry

3 Term and definition

The following term and definition are applicable to this document.

3.1 Straightness of longitudinal edge

It refers to the deviation of the absolute straightness of any longitudinal surface

or edge, including side curvature and flatness.

4 Requirements

4.1 Product classification

4.1.1 Designations, state and specifications

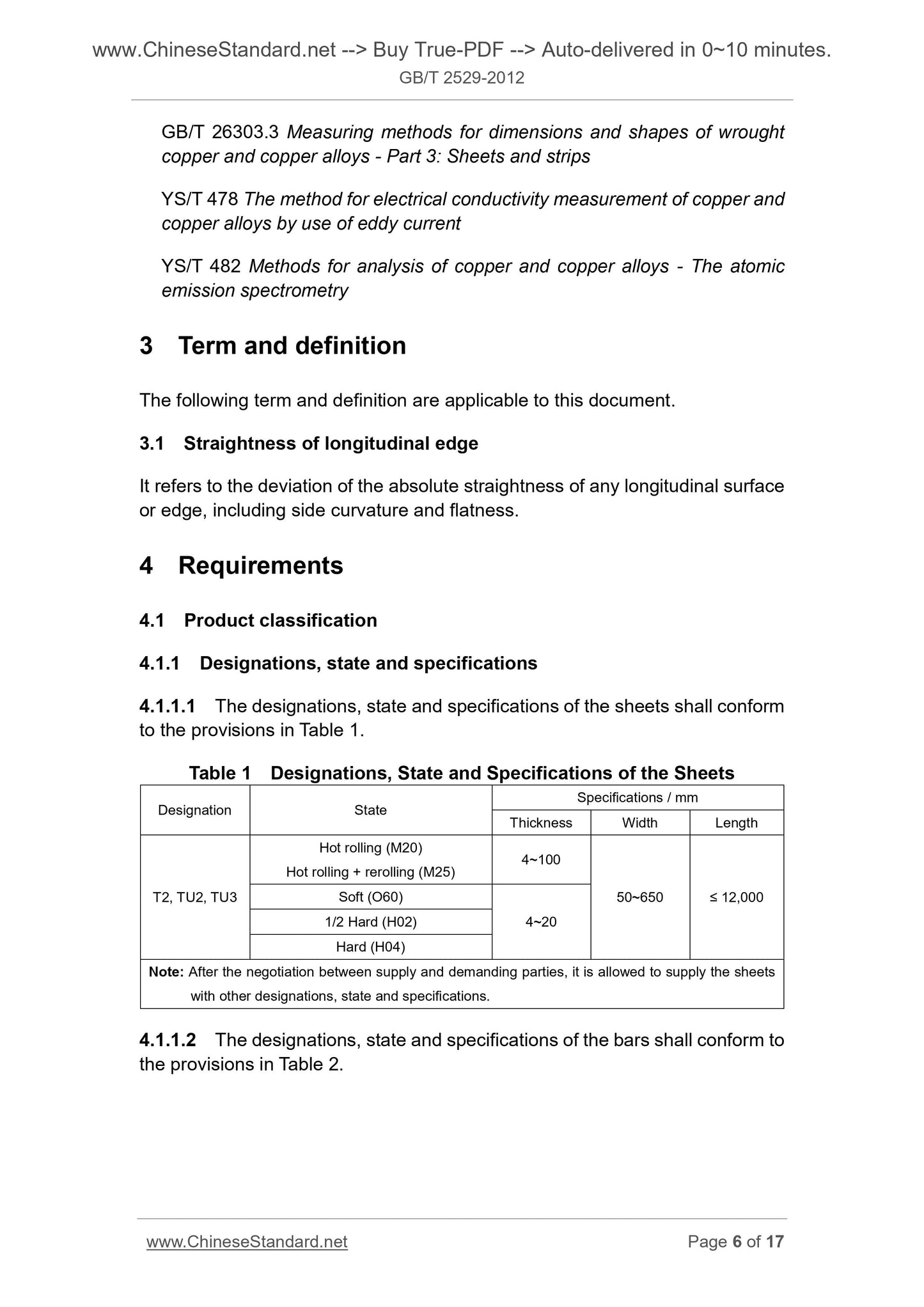

4.1.1.1 The designations, state and specifications of the sheets shall conform

to the provisions in Table 1.

Table 1 Designations, State and Specifications of the Sheets

Designation State

Specifications / mm

Thickness Width Length

T2, TU2, TU3

Hot rolling (M20)

Hot rolling + rerolling (M25)

4~100

50~650 ≤ 12,000 Soft (O60)

4~20 1/2 Hard (H02)

Hard (H04)

Note. After the negotiation between supply and demanding parties, it is allowed to supply the sheets

with other designations, state and specifications.

4.1.1.2 The designations, state and specifications of the bars shall conform to

the provisions in Table 2.

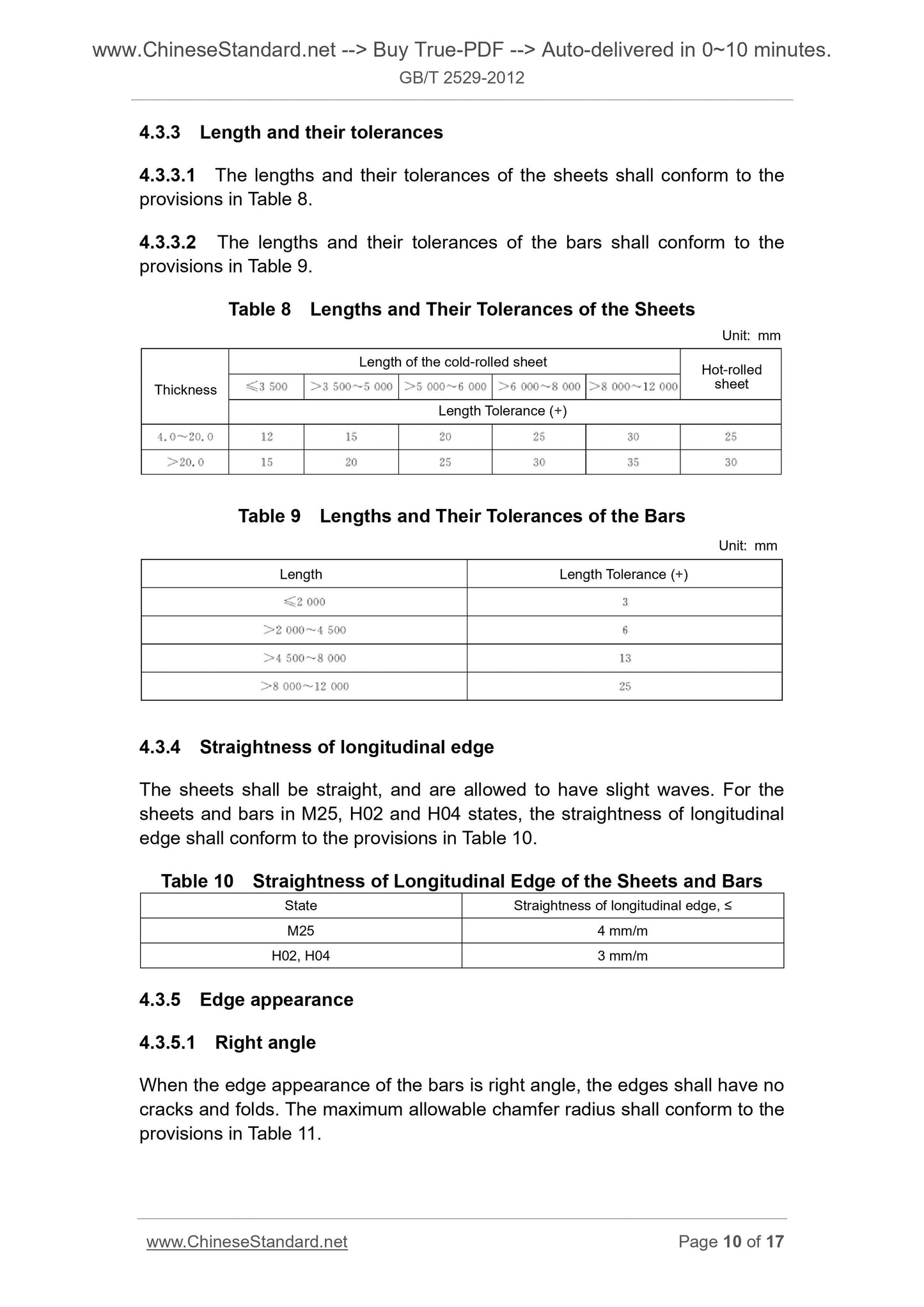

4.3.3 Length and their tolerances

4.3.3.1 The lengths and their tolerances of the sheets shall conform to the

provisions in Table 8.

4.3.3.2 The lengths and their tolerances of the bars shall conform to the

provisions in Table 9.

Table 8 Lengths and Their Tolerances of the Sheets

Table 9 Lengths and Their Tolerances of the Bars

4.3.4 Straightness of longitudinal edge

The sheets shall be straight, and are allowed to have slight waves. For the

sheets and bars in M25, H02 and H04 states, the straightness of longitudinal

edge shall conform to the provisions in Table 10.

Table 10 Straightness of Longitudinal Edge of the Sheets and Bars

State Straightness of longitudinal edge, ≤

M25 4 mm/m

H02, H04 3 mm/m

4.3.5 Edge appearance

4.3.5.1 Right angle

When the edge appearance of the bars is right angle, the edges shall have no

cracks and folds. The maximum allowable chamfer radius shall conform to the

provisions in Table 11.

Unit. mm

Length of the cold-rolled sheet

Thickness

Length Tolerance (+)

Hot-rolled

sheet

Length Tolerance (+) Length

Unit. mm

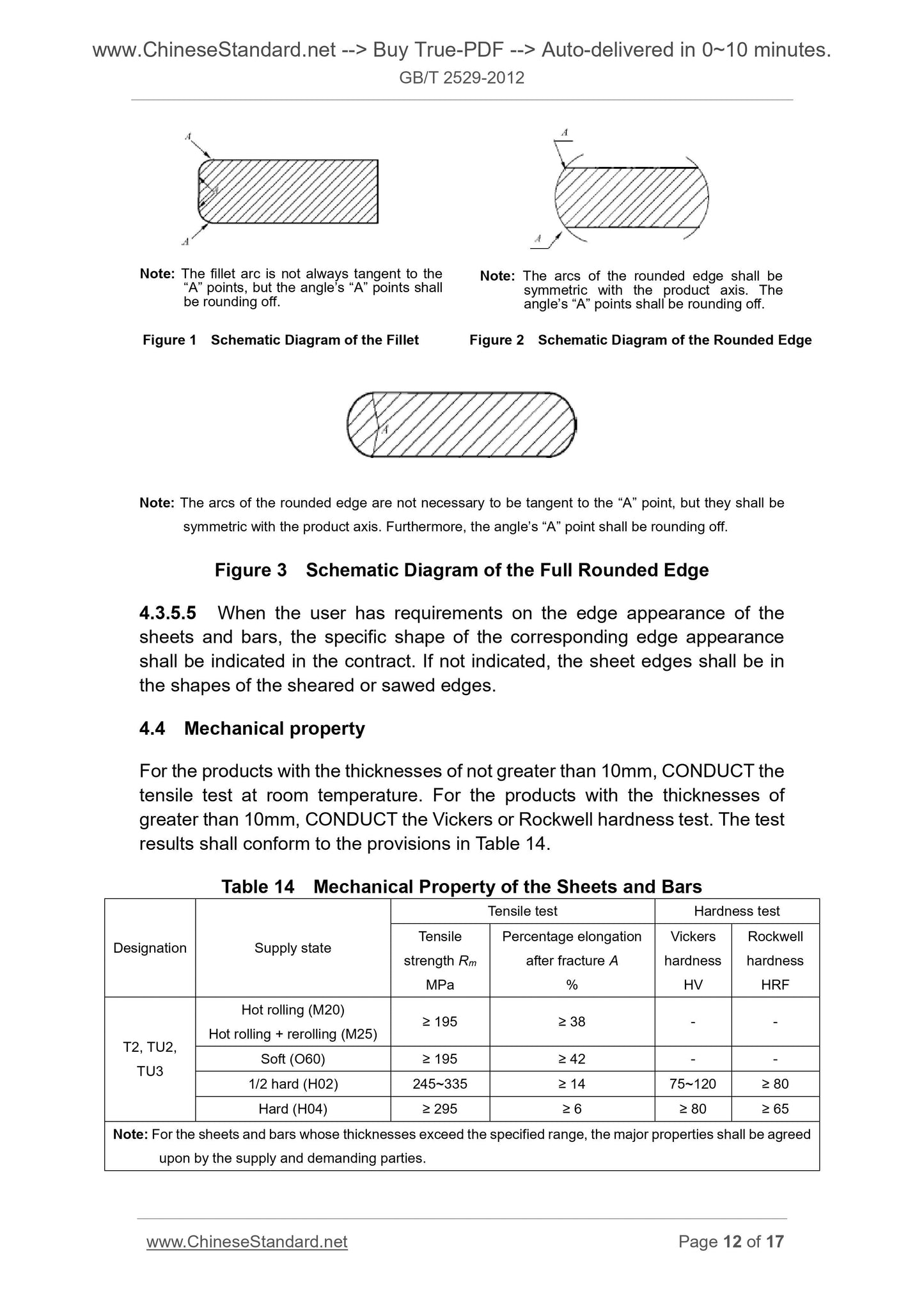

Note. The arcs of the rounded edge are not necessary to be tangent to the “A” point, but they shall be

symmetric with the product axis. Furthermore, the angle’s “A” point shall be rounding off.

Figure 3 Schematic Diagram of the Full Rounded Edge

4.3.5.5 When the user has requirements on the edge appearance of the

sheets and bars, the specific shape of the corresponding edge appearance

shall be indicated in the contract. If not indicated, the sheet edges shall be in

the shapes of the sheared or sawed edges.

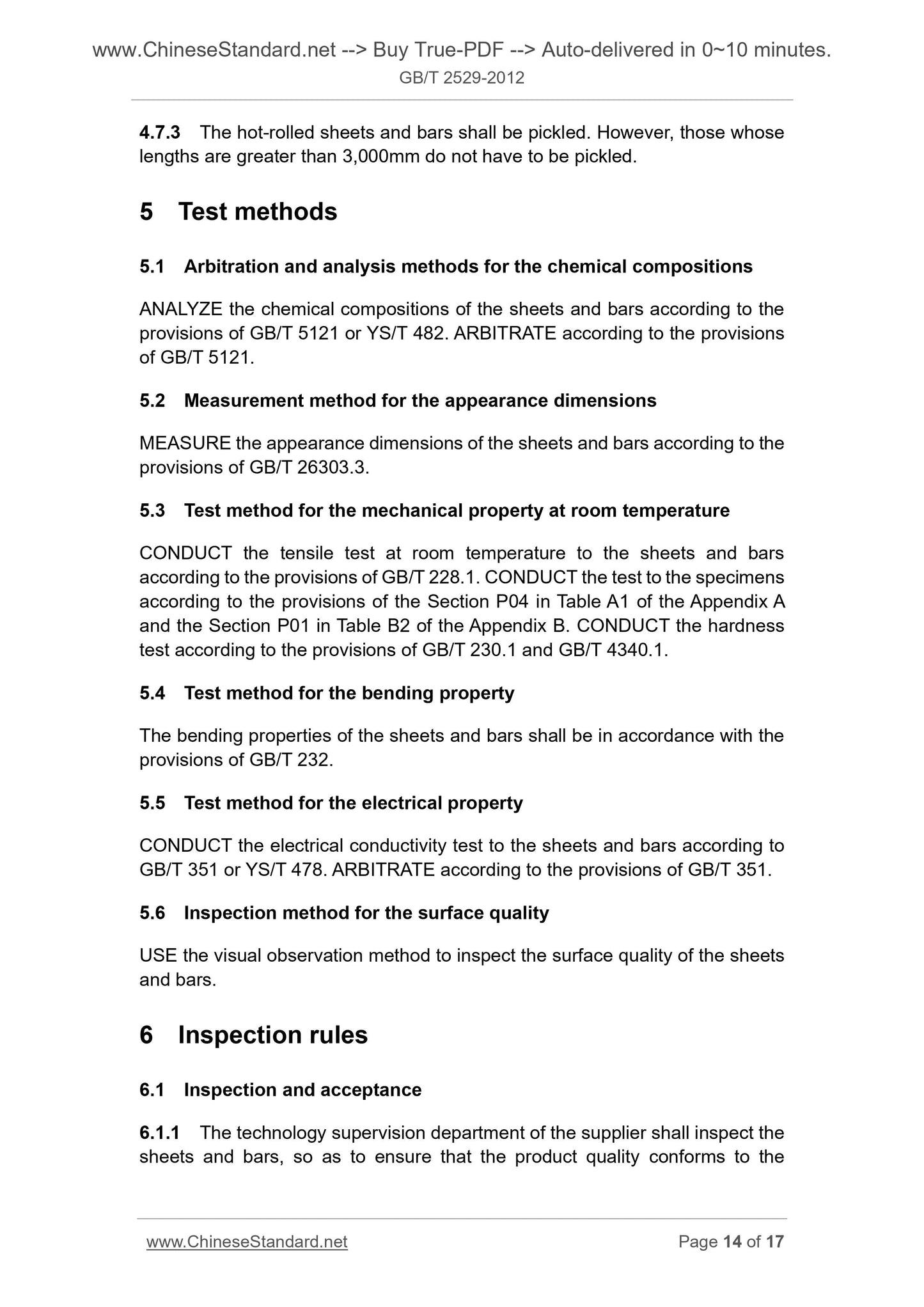

4.4 Mechanical property

For the products with the thicknesses of not greater than 10mm, CONDUCT the

tensile test at room temperature. For the products with the thicknesses of

greater than 10mm, CONDUCT the Vickers or Rockwell hardness test. The test

results shall conform to the provisions in Table 14.

Table 14 Mechanical Property of the Sheets and Bars

Designation Supply state

Tensile test Hardness test

Tensile

strength Rm

MPa

Percentage ...

Get QUOTATION in 1-minute: Click GB/T 2529-2012

Historical versions: GB/T 2529-2012

Preview True-PDF (Reload/Scroll if blank)

GB/T 2529-2012: Copper sheets and bars for electrical conduction purpose

GB/T 2529-2012

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.30

H 62

Replacing GB/T 2529-2005

Copper sheets and bars for

electrical conduction purpose

ISSUED ON. DECEMBER 31, 2012

IMPLEMENTED ON. OCTOBER 1, 2013

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Term and definition ... 6

4 Requirements ... 6

5 Test methods ... 14

6 Inspection rules ... 14

7 Symbols, packaging, transportation, storage and quality certificate ... 16

8 Contents of the contract (or order form) ... 16

Foreword

This Standard is drafted according to the rules given in GB/T 1.1-2009.

The major technical specifications of the bars in this Standard reference to and

adopt the contents of the bars in ASTM B 187M-2006 Copper bars, rods and

shapes for bus bars.

This Standard replaces GB/T 2529-2005 Copper sheets and bars for electrical

conduction purpose.

Compared with GB/T 2529-2005, the major changes in this Standard are as

follows.

— ADD “TU2” and “TU3” to the alloy designations of the products.

— USE the new edition of Temper designations for copper and copper alloys

to represent the product state.

— ADD GB/T 26303.3 Measuring methods for dimensions and shapes of

wrought copper and copper alloys - Part 3. Sheets and strips, YS/T 478

The method for electrical conductivity measurement of copper and

copper alloys by use of eddy current, and YS/T 482 Methods for analysis

of copper and copper alloys - The atomic emission spectrometry to

normative references.

— DELETE “1/8 hard” from the state of the sheets and bars.

— INCREASE the maximum length of the sheets and bars from “8,000mm”

to “12,000mm”.

— DIVIDE the straightness of longitudinal edge according to the state as

required.

— ADD the requirements for rounding off to the contents of the edge

appearance.

— For the percentage elongation after fracture in the mechanical properties

of the sheets and bars, MODIFY the “long specimen A11.3” to “short

specimen A”.

— ADD the property indicators of the resistivity to the electrical property of

the sheets and bars.

— ADD the following contents. For the electrical property, USE the test

methods in YS/T 478 The method for electrical conductivity measurement

Copper sheets and bars for electrical

conduction purpose

1 Scope

This Standard specifies the requirements, test methods, inspection rules,

symbols, packaging, transportation, storage, and contents of the quality

certificate and contract (or order form) of the copper sheets and bars for

electrical conduction purpose.

This Standard is applicable to the copper sheets and bars for electrical

conduction purpose used in industrial sectors, such as smelting sector, electric

power sector, chemical sector, plating sector, etc.

2 Normative references

The following documents are essential to the application of this document. For

dated references, only the editions with the dates indicated are applicable to

this document. For undated references, only the latest editions (including all the

amendments) are applicable to this document.

GB/T 228.1-2010 Metallic materials - Tensile testing - Part 1. Method of test

at room temperature (ISO 6892-1.2009, MOD)

GB/T 230.1 Metallic materials - Rockwell hardness test - Part 1. Test method

GB/T 232 Metallic materials - Bend test

GB/T 351 Metallic materials - Resistivity measurement method

GB/T 4340.1 Metallic materials - Vickers hardness test - Part 1. Test method

(ISO 6507-1.2005, MOD)

GB/T 5121 (all Parts) Methods for chemical analysis of copper and copper

alloys

GB/T 5231 Wrought copper and copper alloys chemical composition limits

and forms of wrought products

GB/T 8888 Wrought heavy non-ferrous metal products - Packing, marking,

transporting and storing

GB/T 26303.3 Measuring methods for dimensions and shapes of wrought

copper and copper alloys - Part 3. Sheets and strips

YS/T 478 The method for electrical conductivity measurement of copper and

copper alloys by use of eddy current

YS/T 482 Methods for analysis of copper and copper alloys - The atomic

emission spectrometry

3 Term and definition

The following term and definition are applicable to this document.

3.1 Straightness of longitudinal edge

It refers to the deviation of the absolute straightness of any longitudinal surface

or edge, including side curvature and flatness.

4 Requirements

4.1 Product classification

4.1.1 Designations, state and specifications

4.1.1.1 The designations, state and specifications of the sheets shall conform

to the provisions in Table 1.

Table 1 Designations, State and Specifications of the Sheets

Designation State

Specifications / mm

Thickness Width Length

T2, TU2, TU3

Hot rolling (M20)

Hot rolling + rerolling (M25)

4~100

50~650 ≤ 12,000 Soft (O60)

4~20 1/2 Hard (H02)

Hard (H04)

Note. After the negotiation between supply and demanding parties, it is allowed to supply the sheets

with other designations, state and specifications.

4.1.1.2 The designations, state and specifications of the bars shall conform to

the provisions in Table 2.

4.3.3 Length and their tolerances

4.3.3.1 The lengths and their tolerances of the sheets shall conform to the

provisions in Table 8.

4.3.3.2 The lengths and their tolerances of the bars shall conform to the

provisions in Table 9.

Table 8 Lengths and Their Tolerances of the Sheets

Table 9 Lengths and Their Tolerances of the Bars

4.3.4 Straightness of longitudinal edge

The sheets shall be straight, and are allowed to have slight waves. For the

sheets and bars in M25, H02 and H04 states, the straightness of longitudinal

edge shall conform to the provisions in Table 10.

Table 10 Straightness of Longitudinal Edge of the Sheets and Bars

State Straightness of longitudinal edge, ≤

M25 4 mm/m

H02, H04 3 mm/m

4.3.5 Edge appearance

4.3.5.1 Right angle

When the edge appearance of the bars is right angle, the edges shall have no

cracks and folds. The maximum allowable chamfer radius shall conform to the

provisions in Table 11.

Unit. mm

Length of the cold-rolled sheet

Thickness

Length Tolerance (+)

Hot-rolled

sheet

Length Tolerance (+) Length

Unit. mm

Note. The arcs of the rounded edge are not necessary to be tangent to the “A” point, but they shall be

symmetric with the product axis. Furthermore, the angle’s “A” point shall be rounding off.

Figure 3 Schematic Diagram of the Full Rounded Edge

4.3.5.5 When the user has requirements on the edge appearance of the

sheets and bars, the specific shape of the corresponding edge appearance

shall be indicated in the contract. If not indicated, the sheet edges shall be in

the shapes of the sheared or sawed edges.

4.4 Mechanical property

For the products with the thicknesses of not greater than 10mm, CONDUCT the

tensile test at room temperature. For the products with the thicknesses of

greater than 10mm, CONDUCT the Vickers or Rockwell hardness test. The test

results shall conform to the provisions in Table 14.

Table 14 Mechanical Property of the Sheets and Bars

Designation Supply state

Tensile test Hardness test

Tensile

strength Rm

MPa

Percentage ...

Share