1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 25988-2010 English PDF (GBT25988-2010)

GB/T 25988-2010 English PDF (GBT25988-2010)

Regular price

$170.00 USD

Regular price

Sale price

$170.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 25988-2010

Historical versions: GB/T 25988-2010

Preview True-PDF (Reload/Scroll if blank)

GB/T 25988-2010: Road vehicles -- Towing vehicle coupling device to tow caravans or light trailers -- Mechanical strength test

GB/T 25988-2010

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.080.10

T 72

GB/T 25988-2010 / ISO 3853:1994

Road vehicles - Towing vehicles coupling device to tow

caravans or light trailers - Mechanical strength test

(ISO 3853:1994, IDT)

ISSUED ON: JANUARY 10, 2011

IMPLEMENTED ON: MAY 01, 2011

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions... 4

4 Symbols ... 5

5 General conditions ... 6

6 Strength test of coupling device ... 8

7 Different test conditions for different types of coupling devices ... 9

8 Evaluation criteria of strength ... 10

9 Welding of coupling device ... 10

10 Marks ... 10

Road vehicles - Towing vehicles coupling device to tow

caravans or light trailers - Mechanical strength test

1 Scope

This standard specifies the test methods for the mechanical strength of coupling devices.

This standard applies to the coupling device, which is installed on the towing vehicle,

for towing the category O1 and O2 caravans or light trailer (excluding semi-trailer).

2 Normative references

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For the dated references, the subsequent amendments

(excluding corrections) or revisions do not apply to this Standard; however, parties who

reach an agreement based on this Standard are encouraged to study if the latest versions

of these documents are applicable. For undated references, the latest edition of the

referenced document applies.

GB/T 3730.2 Road vehicle - Masses - Vocabulary and codes (GB/T 3730.2-1996,

idt ISO 1176:1990)

GB/T 22552 Caravans - Masses and dimensions - Vocabulary (GB/T 22552-2008,

ISO 7237:1993, IDT)

GB/T 25980 Road vehicles - Coupling balls for caravans and light trailers -

Dimensions (GB/T 25980-2010, ISO 1103:2007, IDT)

3 Terms and definitions

The terms and definitions, as established in GB/T 22552, as well as the following terms

and definitions, apply to this standard.

3.1

Coupling device

A device, which is equipped with towing bracket and coupling ball.

Note: Its common terms are as shown in Figure 1.

Fres - Test resultant force, in Newton (N);

α - Test angle, which is composed of the test resultant Fres and the reference line,

indicating the degree of the angle;

Fstat - The maximum allowable static load of the trailer, on the coupling point of the

towing vehicle, which is determined by the towing vehicle manufacturer;

h - The vertical distance, between the center of the coupling ball and the center of

the support;

l - The horizontal distance, between the center of the coupling ball and the

connection point of the ball support OR between the connection point of the ball

attachment.

5 General conditions

5.1 The size of the coupling device shall comply with the provisions of GB/T 25980.

It shall provide the detailed design information of the coupling device, including

information the data that may affect the strength of its components or assemblies (such

as electrical connector socket plates, markings, etc.).

5.2 The test range is from the coupling ball to the fixed point or assembly point. The

geometrical position of the coupling ball and the fixed point of the connection device,

as corresponding to the reference line, shall be marked by the manufacturer AND

quoted in the test report.

5.3 The strength test in Chapter 6 is a dynamic test, which is performed on a test rig

(e.g., a vibration pulse test rig).

5.4 The test load does not take into account the lateral loads, which are generated by

the front and rear axles of the trailer and their supporting devices.

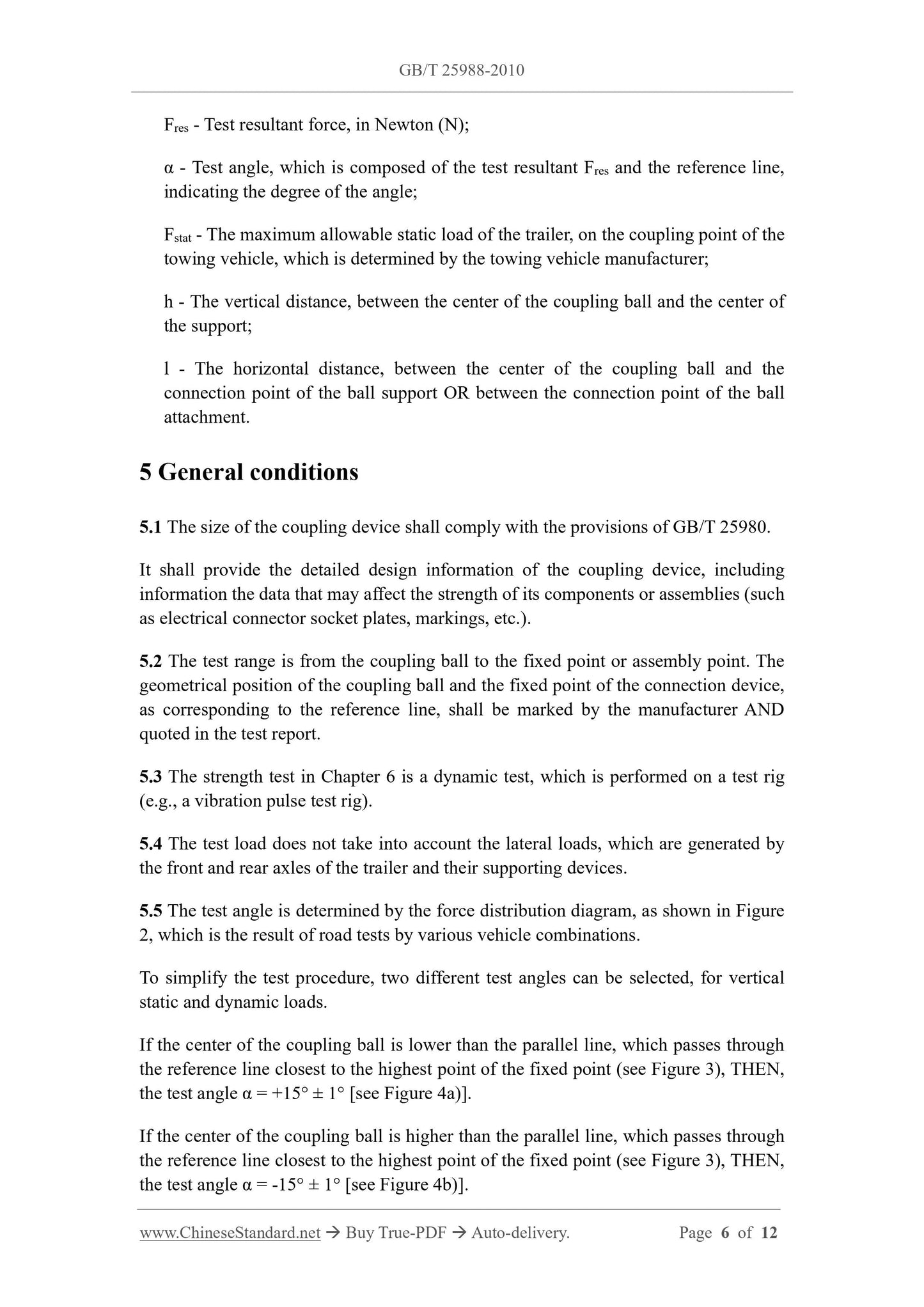

5.5 The test angle is determined by the force distribution diagram, as shown in Figure

2, which is the result of road tests by various vehicle combinations.

To simplify the test procedure, two different test angles can be selected, for vertical

static and dynamic loads.

If the center of the coupling ball is lower than the parallel line, which passes through

the reference line closest to the highest point of the fixed point (see Figure 3), THEN,

the test angle α = +15° ± 1° [see Figure 4a)].

If the center of the coupling ball is higher than the parallel line, which passes through

the reference line closest to the highest point of the fixed point (see Figure 3), THEN,

the test angle α = -15° ± 1° [see Figure 4b)].

it shall determine whether the test is appropriate or whether other tests are required, as

necessary.

6 Strength test of coupling device

6.1 Installation on the test bench

The towing bracket shall be connected to the rigid test bench. Its fixed position on the

test bench is the same as the installation position on the towing vehicle, OR has the

same characteristics.

6.2 Fixed points and reference lines

For the installation of the coupling device on the test bench, it shall keep the position

of all fixed points, as relative to the reference line, be consistent with the position of the

fixed point, as relative to the reference line, which is provided by the towing vehicle

manufacturer to the coupling device manufacturer.

If the towing vehicle manufacturer does not provide a fixed point or reference line, the

coupling device manufacturer may choose its own fixed point and reference line, BUT

shall bear the consequences, which are caused by its selected fixed point and reference

line, especially be responsible for the maximum allowable towing mass. In order to

make the position of the coupling ball correct, the towing vehicle manufacturer shall

generally specify the maximum towing mass of the towing vehicle (see code M16 of

GB/T 3730.2).

6.3 Test method

Under the conditions of complying with the requirements of 6.1 and 6.2, the coupling

device, which is installed on the test bench, will be tested, using an alternating load

tensile testing machine. When securing components and applying forces on the test

bench, it shall be ensured that additional movements 1) or other forces 2) are as small

as possible.

The test load shall be applied, at a selected frequency, in an approximate sinusoidal

manner; the frequency shall not exceed 35 Hz and avoid the resonance frequency of the

test device, including the towing device.

The amplitude of the test resultant force Fres is 0.6D ± 3%; the number of cycles is 2 ×

106.

Note: The test device, that connects the force sensor with the ball of the towing device, shall

have a larger mass. The measurement force includes the inertial force, that accelerates the mass.

The applied inertial force can be adjusted, by measuring the acceleration of the coupling ball.

1 For example, it can be realized by relying on the double connection points, which have a spacing of ≥ 300 mm.

2 For example, the force which is generated by large acceleration.

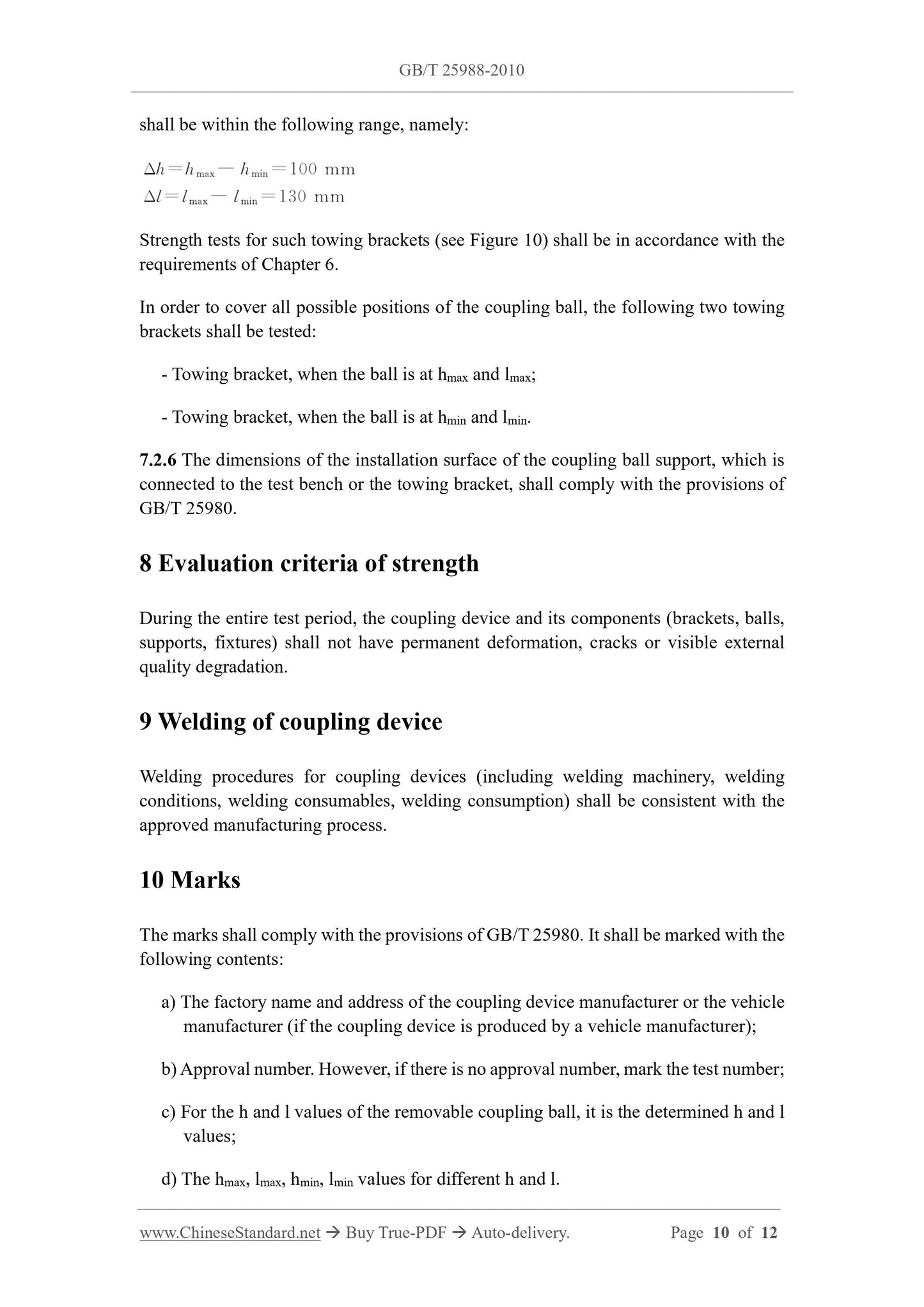

shall be within the following range, namely:

Strength tests for such towing brackets (see Figure 10) shall be in accordance with the

requirements of Chapter 6.

In order to cover all possible positions of the coupling ball, the following two towing

brackets shall be tested:

- Towing bracket, when the ball is at hmax and lmax;

- Towing bracket, when the ball is at hmin and lmin.

7.2.6 The dimensions of the installation surface of the coupling ball support, which is

connected to...

Get QUOTATION in 1-minute: Click GB/T 25988-2010

Historical versions: GB/T 25988-2010

Preview True-PDF (Reload/Scroll if blank)

GB/T 25988-2010: Road vehicles -- Towing vehicle coupling device to tow caravans or light trailers -- Mechanical strength test

GB/T 25988-2010

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.080.10

T 72

GB/T 25988-2010 / ISO 3853:1994

Road vehicles - Towing vehicles coupling device to tow

caravans or light trailers - Mechanical strength test

(ISO 3853:1994, IDT)

ISSUED ON: JANUARY 10, 2011

IMPLEMENTED ON: MAY 01, 2011

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions... 4

4 Symbols ... 5

5 General conditions ... 6

6 Strength test of coupling device ... 8

7 Different test conditions for different types of coupling devices ... 9

8 Evaluation criteria of strength ... 10

9 Welding of coupling device ... 10

10 Marks ... 10

Road vehicles - Towing vehicles coupling device to tow

caravans or light trailers - Mechanical strength test

1 Scope

This standard specifies the test methods for the mechanical strength of coupling devices.

This standard applies to the coupling device, which is installed on the towing vehicle,

for towing the category O1 and O2 caravans or light trailer (excluding semi-trailer).

2 Normative references

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For the dated references, the subsequent amendments

(excluding corrections) or revisions do not apply to this Standard; however, parties who

reach an agreement based on this Standard are encouraged to study if the latest versions

of these documents are applicable. For undated references, the latest edition of the

referenced document applies.

GB/T 3730.2 Road vehicle - Masses - Vocabulary and codes (GB/T 3730.2-1996,

idt ISO 1176:1990)

GB/T 22552 Caravans - Masses and dimensions - Vocabulary (GB/T 22552-2008,

ISO 7237:1993, IDT)

GB/T 25980 Road vehicles - Coupling balls for caravans and light trailers -

Dimensions (GB/T 25980-2010, ISO 1103:2007, IDT)

3 Terms and definitions

The terms and definitions, as established in GB/T 22552, as well as the following terms

and definitions, apply to this standard.

3.1

Coupling device

A device, which is equipped with towing bracket and coupling ball.

Note: Its common terms are as shown in Figure 1.

Fres - Test resultant force, in Newton (N);

α - Test angle, which is composed of the test resultant Fres and the reference line,

indicating the degree of the angle;

Fstat - The maximum allowable static load of the trailer, on the coupling point of the

towing vehicle, which is determined by the towing vehicle manufacturer;

h - The vertical distance, between the center of the coupling ball and the center of

the support;

l - The horizontal distance, between the center of the coupling ball and the

connection point of the ball support OR between the connection point of the ball

attachment.

5 General conditions

5.1 The size of the coupling device shall comply with the provisions of GB/T 25980.

It shall provide the detailed design information of the coupling device, including

information the data that may affect the strength of its components or assemblies (such

as electrical connector socket plates, markings, etc.).

5.2 The test range is from the coupling ball to the fixed point or assembly point. The

geometrical position of the coupling ball and the fixed point of the connection device,

as corresponding to the reference line, shall be marked by the manufacturer AND

quoted in the test report.

5.3 The strength test in Chapter 6 is a dynamic test, which is performed on a test rig

(e.g., a vibration pulse test rig).

5.4 The test load does not take into account the lateral loads, which are generated by

the front and rear axles of the trailer and their supporting devices.

5.5 The test angle is determined by the force distribution diagram, as shown in Figure

2, which is the result of road tests by various vehicle combinations.

To simplify the test procedure, two different test angles can be selected, for vertical

static and dynamic loads.

If the center of the coupling ball is lower than the parallel line, which passes through

the reference line closest to the highest point of the fixed point (see Figure 3), THEN,

the test angle α = +15° ± 1° [see Figure 4a)].

If the center of the coupling ball is higher than the parallel line, which passes through

the reference line closest to the highest point of the fixed point (see Figure 3), THEN,

the test angle α = -15° ± 1° [see Figure 4b)].

it shall determine whether the test is appropriate or whether other tests are required, as

necessary.

6 Strength test of coupling device

6.1 Installation on the test bench

The towing bracket shall be connected to the rigid test bench. Its fixed position on the

test bench is the same as the installation position on the towing vehicle, OR has the

same characteristics.

6.2 Fixed points and reference lines

For the installation of the coupling device on the test bench, it shall keep the position

of all fixed points, as relative to the reference line, be consistent with the position of the

fixed point, as relative to the reference line, which is provided by the towing vehicle

manufacturer to the coupling device manufacturer.

If the towing vehicle manufacturer does not provide a fixed point or reference line, the

coupling device manufacturer may choose its own fixed point and reference line, BUT

shall bear the consequences, which are caused by its selected fixed point and reference

line, especially be responsible for the maximum allowable towing mass. In order to

make the position of the coupling ball correct, the towing vehicle manufacturer shall

generally specify the maximum towing mass of the towing vehicle (see code M16 of

GB/T 3730.2).

6.3 Test method

Under the conditions of complying with the requirements of 6.1 and 6.2, the coupling

device, which is installed on the test bench, will be tested, using an alternating load

tensile testing machine. When securing components and applying forces on the test

bench, it shall be ensured that additional movements 1) or other forces 2) are as small

as possible.

The test load shall be applied, at a selected frequency, in an approximate sinusoidal

manner; the frequency shall not exceed 35 Hz and avoid the resonance frequency of the

test device, including the towing device.

The amplitude of the test resultant force Fres is 0.6D ± 3%; the number of cycles is 2 ×

106.

Note: The test device, that connects the force sensor with the ball of the towing device, shall

have a larger mass. The measurement force includes the inertial force, that accelerates the mass.

The applied inertial force can be adjusted, by measuring the acceleration of the coupling ball.

1 For example, it can be realized by relying on the double connection points, which have a spacing of ≥ 300 mm.

2 For example, the force which is generated by large acceleration.

shall be within the following range, namely:

Strength tests for such towing brackets (see Figure 10) shall be in accordance with the

requirements of Chapter 6.

In order to cover all possible positions of the coupling ball, the following two towing

brackets shall be tested:

- Towing bracket, when the ball is at hmax and lmax;

- Towing bracket, when the ball is at hmin and lmin.

7.2.6 The dimensions of the installation surface of the coupling ball support, which is

connected to...

Share