1

/

of

9

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB/T 27690-2011 English PDF (GBT27690-2011)

GB/T 27690-2011 English PDF (GBT27690-2011)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.Newer version: (Replacing this standard) GB/T 27690-2023

Get QUOTATION in 1-minute: Click GB/T 27690-2011

Historical versions: GB/T 27690-2011

Preview True-PDF (Reload/Scroll if blank)

GB/T 27690-2011: Silica fume for cement mortar and concrete

GB/T 27690-2011

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 91.100.10

Q 12

Silica fume for cement mortar and concrete

ISSUED ON. NOVEMBER 21, 2011

IMPLEMENTED ON. AUGUST 01, 2012

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration Committee.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Classification and labels ... 5

5 Requirements ... 5

6 Test methods ... 6

7 Inspection rules ... 7

8 Packaging, marks, transport and storage ... 8

Annex A (normative) Inspection method for solid content of silica fume slurry

... 10

Annex B (normative) Test method for activity index ... 12

Annex C (normative) Test method for inhibition of alkali aggregate reaction.. 15

Silica fume for cement mortar and concrete

1 Scope

This Standard specifies the terms and definitions, classification and labels,

requirements, test methods, inspection rules, packaging, marks, transport and

storage of silica fume for cement mortar and concrete.

This Standard is applicable to silica fume for cement mortar and concrete.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 176, Method for Chemical Analysis of Cement

GB/T 2419, Test method for fluidity of cement mortar

GB 6566, Limit for Radionuclides in Building Materials

GB 8076-2008, Concrete Admixtures

GB/T 12573, Sampling method for cement

GB/T 19587, Determination of the specific surface area of solids by gas

absorption using the BET method

GB/T 1767-1999, Method for exterior exposure testes of paint films

GB/T 18736-2002, Mineral admixtures for high strength and high-

performance concrete

GB/T 50082-2009, Standard for test methods of long-term performance and

durability of ordinary concrete

JC/T 420, Method for chemical analysis of chloride for cement raw material

JC/T 681, Mixer for mixing mortars

Radioactivity Ira≤1.0 and Ir≤1.0

Inhibition of alkali aggregate reactivity 14d expansion rate’s reduction value ≥35%

Resistance to chloride ion permeability 28d electric flux ratio ≤40%

NOTE 1. Silica fume slurry is converted into solid content and tested according to this

table.

NOTE 2. The inhibition of alkali aggregate reactivity and chloride ion permeability

resistance is a selective test project, which is determined by both parties.

6 Test methods

6.1 SiO2 content

In accordance with Annex A of GB/T 18736-2002.

6.2 Chlorine content

In accordance with JC/T 420.

6.3 Water content, loss on ignition, total alkali content

In accordance with GB/T 176.

6.4 Solid content

In accordance with Annex A.

6.5 Water demand ratio

In accordance with Annex C of GB/T 18736-2002.

6.6 Specific surface area

In accordance with GB/T 19587.

6.7 Activity index

In accordance with Annex B.

6.8 Radioactivity

In accordance with GB 6566.

6.9 Inhibition of alkali aggregate reactivity

In accordance with Annex C.

6.10 Resistance to chloride ion permeability

Perform according to Clause 7 of GB/T 50082-2009. The resistance to chloride

ion permeation is expressed by the ratio of the tested concrete to the reference

concrete flux. Concrete mix ratio materials shall meet the requirements of GB

8076-2008. The reference concrete mix ratio of cement is 400 kg/m3 ± 5 kg/m3.

Sand rate is 36%~40%. Slump is controlled at 80mm ± 10mm. Incorporate 10%

silica ash into the tested concrete (accounting for the total proportion of

cementitious materials). Use naphthalene-series high-efficiency water-reducing

admixture that meets requirements for standard high-efficiency water-reducing

admixture in GB 8076-2008 to adjust the slump of testing concrete. The water

reducing rate of the water-reducing admixture is required to be greater than

18%.

NOTE. The method for preparing silica fume slurry is carried out according to the method

specified in Annex A.

7 Inspection rules

7.1 Batch number, sampling and sample retention

7.1.1 Batch number

Take 30t of the same type of silica fume/silica fume slurry as an inspection lot.

When it is less than 30t, it shall be regarded as an inspection batch.

7.1.2 Sampling

Sampling is according to GB/T 12573. The sampling shall be representative.

The sampling can be continuous. The same quantity of samples may be taken

from more than 10 different parts. The total shall be at least 5 kg. The silica

fume slurry shall be at least 15 kg. The sample shall be evenly mixed.

7.1.3 Sample retention

The same batch of silica fume samples of manufacturer shall be divided into

two equal portions. One is for product exit-factory inspection. The other is

sealed and stored for 6 months for re-inspection or arbitration.

7.2 Inspection

7.2.1 Exit-factory inspection

The exit-factory inspection items of each batch of silica fume include SiO2

content, water content (solid content), water demand ratio, and loss on ignition.

7.2.2 Type inspection

The type inspection items include all performance indexes in Clause 5 of this

Standard. Type inspection shall be performed in one of the following situations.

a) trial model identification for new product or old product produced in

transferred plant;

b) great changes in material, technique after official production which may

affect product performances;

c) at least once for every-year during normal production;

d) production resumed after log-term discontinued production;

e) great difference between exit-factory inspection results and previous type

inspection results;

f) required by national quality supervision organization.

7.3 Rules for determination

7.3.1 Exit-factory inspection

The inspection results of SiO2 content, water content (solid content), water

demand ratio and loss on ignition shall meet the requirements of Clause 5. If

one of the inspection results does not meet the requirements, it shall be

unqualified product and cannot be delivered.

7.3.2 Type inspection

If all the inspection items comply with the provisions of Clause 5, it shall be

accepted. Should one index fail to meet the requirements of this Standard, it

shall be rejected.

7.4 Re-inspection

During the product storage period, when the user disputes the product quality,

the re-inspection can be performed. Re-inspection can be carried out with the

same number of sealed samples. If the user requests on-site sampling, it shall

be specified in the supply contract in advance. The production plant shall, within

7 days of receiving the user's notice, sample together with the user and send it

to the quality supervision and inspection agency for inspection. If the production

plant shall not go to the site within the specified time, the user may take samples

with the quality inspection agency and the results are equally effective.

8 Packaging, marks, transport and storage

8.1 Packaging

Silica fume can be packed or bulk. Silica fume slurry is packaged in sealed

containers. Environmental considerations shall be considered. The net mass of

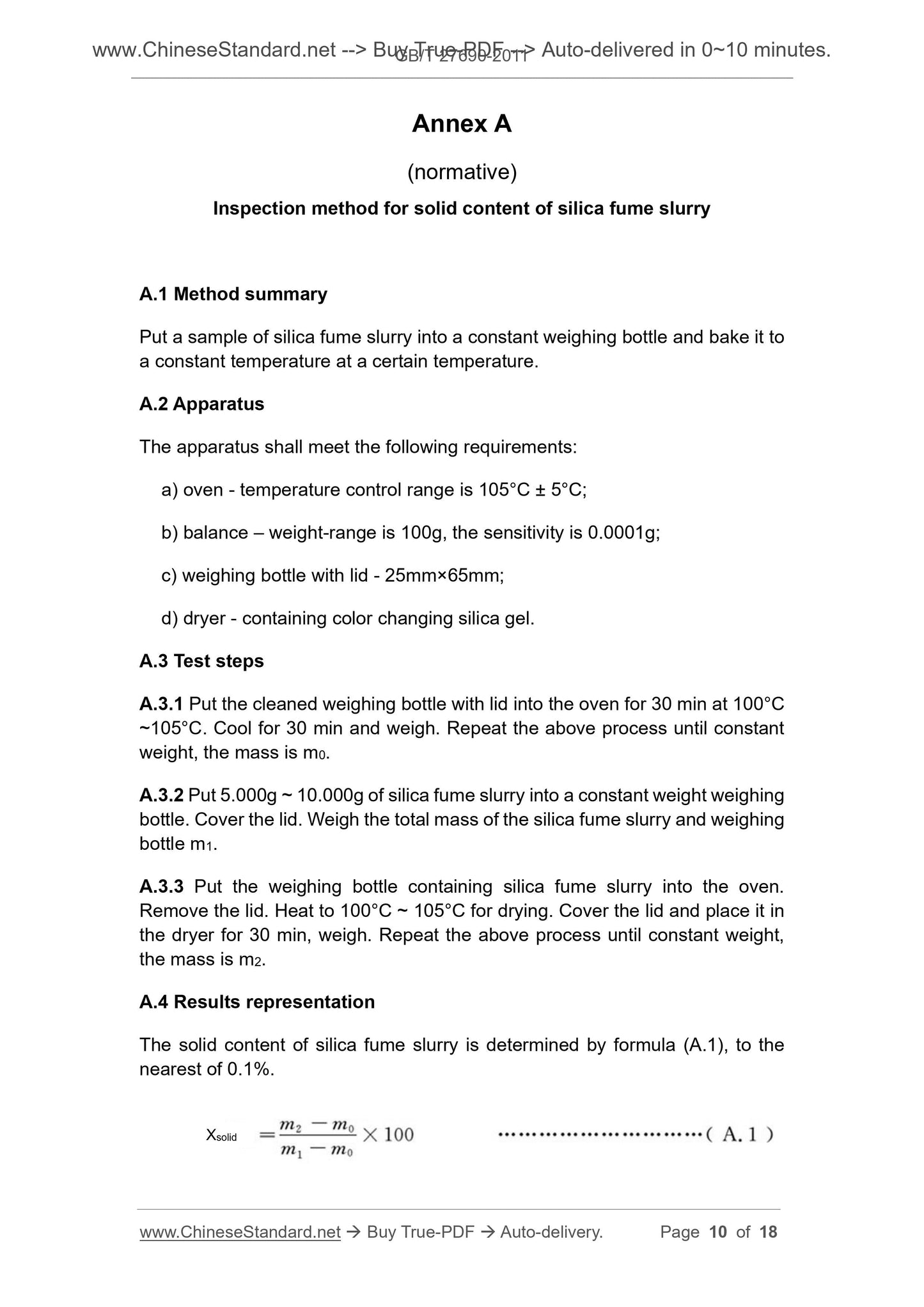

Annex A

(normative)

Inspection method for solid content of silica fume slurry

A.1 Method summary

Put a sample of silica fume slurry into a constant wei...

Get QUOTATION in 1-minute: Click GB/T 27690-2011

Historical versions: GB/T 27690-2011

Preview True-PDF (Reload/Scroll if blank)

GB/T 27690-2011: Silica fume for cement mortar and concrete

GB/T 27690-2011

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 91.100.10

Q 12

Silica fume for cement mortar and concrete

ISSUED ON. NOVEMBER 21, 2011

IMPLEMENTED ON. AUGUST 01, 2012

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration Committee.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Classification and labels ... 5

5 Requirements ... 5

6 Test methods ... 6

7 Inspection rules ... 7

8 Packaging, marks, transport and storage ... 8

Annex A (normative) Inspection method for solid content of silica fume slurry

... 10

Annex B (normative) Test method for activity index ... 12

Annex C (normative) Test method for inhibition of alkali aggregate reaction.. 15

Silica fume for cement mortar and concrete

1 Scope

This Standard specifies the terms and definitions, classification and labels,

requirements, test methods, inspection rules, packaging, marks, transport and

storage of silica fume for cement mortar and concrete.

This Standard is applicable to silica fume for cement mortar and concrete.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 176, Method for Chemical Analysis of Cement

GB/T 2419, Test method for fluidity of cement mortar

GB 6566, Limit for Radionuclides in Building Materials

GB 8076-2008, Concrete Admixtures

GB/T 12573, Sampling method for cement

GB/T 19587, Determination of the specific surface area of solids by gas

absorption using the BET method

GB/T 1767-1999, Method for exterior exposure testes of paint films

GB/T 18736-2002, Mineral admixtures for high strength and high-

performance concrete

GB/T 50082-2009, Standard for test methods of long-term performance and

durability of ordinary concrete

JC/T 420, Method for chemical analysis of chloride for cement raw material

JC/T 681, Mixer for mixing mortars

Radioactivity Ira≤1.0 and Ir≤1.0

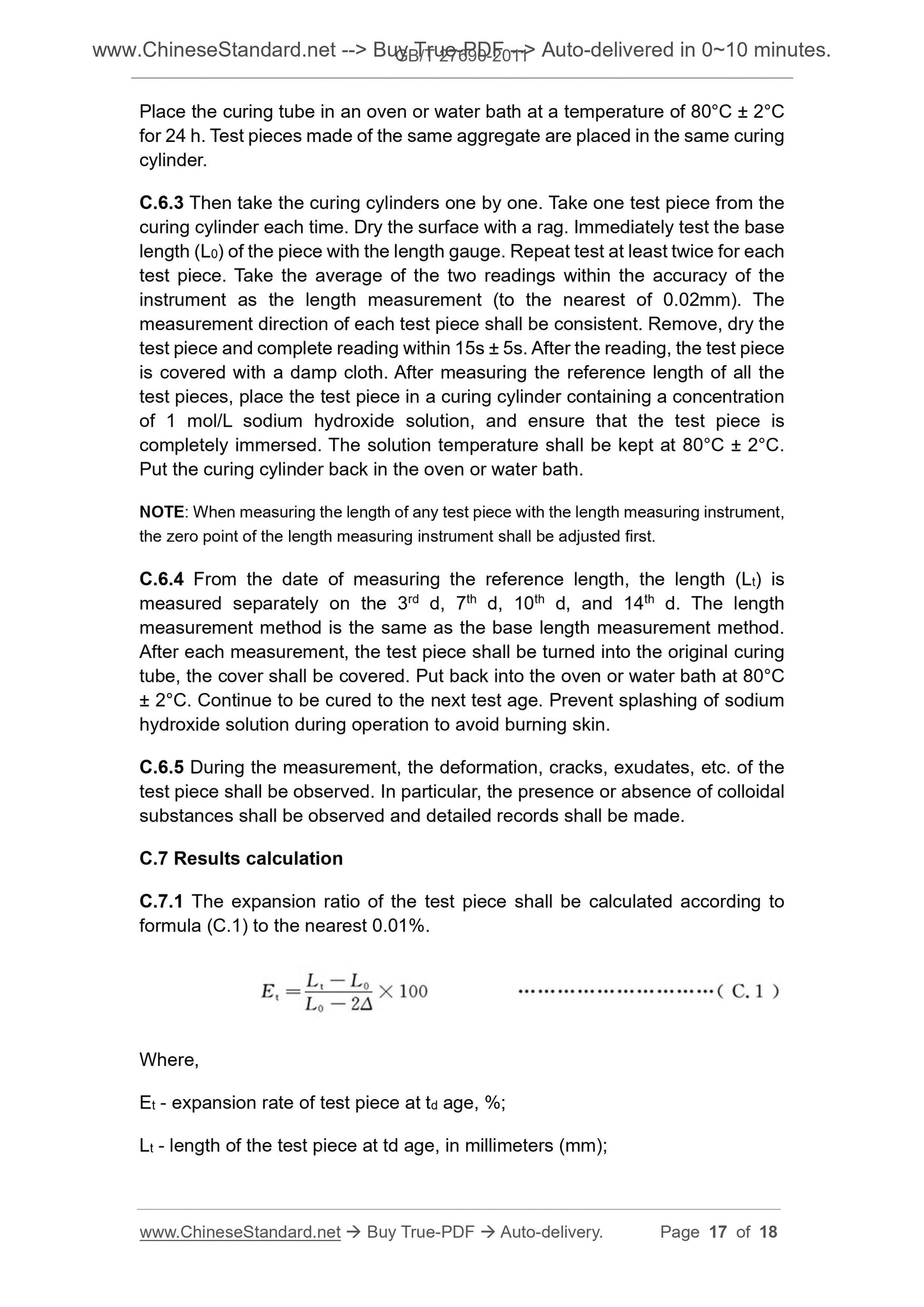

Inhibition of alkali aggregate reactivity 14d expansion rate’s reduction value ≥35%

Resistance to chloride ion permeability 28d electric flux ratio ≤40%

NOTE 1. Silica fume slurry is converted into solid content and tested according to this

table.

NOTE 2. The inhibition of alkali aggregate reactivity and chloride ion permeability

resistance is a selective test project, which is determined by both parties.

6 Test methods

6.1 SiO2 content

In accordance with Annex A of GB/T 18736-2002.

6.2 Chlorine content

In accordance with JC/T 420.

6.3 Water content, loss on ignition, total alkali content

In accordance with GB/T 176.

6.4 Solid content

In accordance with Annex A.

6.5 Water demand ratio

In accordance with Annex C of GB/T 18736-2002.

6.6 Specific surface area

In accordance with GB/T 19587.

6.7 Activity index

In accordance with Annex B.

6.8 Radioactivity

In accordance with GB 6566.

6.9 Inhibition of alkali aggregate reactivity

In accordance with Annex C.

6.10 Resistance to chloride ion permeability

Perform according to Clause 7 of GB/T 50082-2009. The resistance to chloride

ion permeation is expressed by the ratio of the tested concrete to the reference

concrete flux. Concrete mix ratio materials shall meet the requirements of GB

8076-2008. The reference concrete mix ratio of cement is 400 kg/m3 ± 5 kg/m3.

Sand rate is 36%~40%. Slump is controlled at 80mm ± 10mm. Incorporate 10%

silica ash into the tested concrete (accounting for the total proportion of

cementitious materials). Use naphthalene-series high-efficiency water-reducing

admixture that meets requirements for standard high-efficiency water-reducing

admixture in GB 8076-2008 to adjust the slump of testing concrete. The water

reducing rate of the water-reducing admixture is required to be greater than

18%.

NOTE. The method for preparing silica fume slurry is carried out according to the method

specified in Annex A.

7 Inspection rules

7.1 Batch number, sampling and sample retention

7.1.1 Batch number

Take 30t of the same type of silica fume/silica fume slurry as an inspection lot.

When it is less than 30t, it shall be regarded as an inspection batch.

7.1.2 Sampling

Sampling is according to GB/T 12573. The sampling shall be representative.

The sampling can be continuous. The same quantity of samples may be taken

from more than 10 different parts. The total shall be at least 5 kg. The silica

fume slurry shall be at least 15 kg. The sample shall be evenly mixed.

7.1.3 Sample retention

The same batch of silica fume samples of manufacturer shall be divided into

two equal portions. One is for product exit-factory inspection. The other is

sealed and stored for 6 months for re-inspection or arbitration.

7.2 Inspection

7.2.1 Exit-factory inspection

The exit-factory inspection items of each batch of silica fume include SiO2

content, water content (solid content), water demand ratio, and loss on ignition.

7.2.2 Type inspection

The type inspection items include all performance indexes in Clause 5 of this

Standard. Type inspection shall be performed in one of the following situations.

a) trial model identification for new product or old product produced in

transferred plant;

b) great changes in material, technique after official production which may

affect product performances;

c) at least once for every-year during normal production;

d) production resumed after log-term discontinued production;

e) great difference between exit-factory inspection results and previous type

inspection results;

f) required by national quality supervision organization.

7.3 Rules for determination

7.3.1 Exit-factory inspection

The inspection results of SiO2 content, water content (solid content), water

demand ratio and loss on ignition shall meet the requirements of Clause 5. If

one of the inspection results does not meet the requirements, it shall be

unqualified product and cannot be delivered.

7.3.2 Type inspection

If all the inspection items comply with the provisions of Clause 5, it shall be

accepted. Should one index fail to meet the requirements of this Standard, it

shall be rejected.

7.4 Re-inspection

During the product storage period, when the user disputes the product quality,

the re-inspection can be performed. Re-inspection can be carried out with the

same number of sealed samples. If the user requests on-site sampling, it shall

be specified in the supply contract in advance. The production plant shall, within

7 days of receiving the user's notice, sample together with the user and send it

to the quality supervision and inspection agency for inspection. If the production

plant shall not go to the site within the specified time, the user may take samples

with the quality inspection agency and the results are equally effective.

8 Packaging, marks, transport and storage

8.1 Packaging

Silica fume can be packed or bulk. Silica fume slurry is packaged in sealed

containers. Environmental considerations shall be considered. The net mass of

Annex A

(normative)

Inspection method for solid content of silica fume slurry

A.1 Method summary

Put a sample of silica fume slurry into a constant wei...

Share